化工学报 ›› 2021, Vol. 72 ›› Issue (3): 1751-1760.DOI: 10.11949/0438-1157.20200632

岳航勃( ),郑萍璇,郑煜如,邝柳尹,张银,李梁君,郭建维(

),郑萍璇,郑煜如,邝柳尹,张银,李梁君,郭建维( )

)

收稿日期:2020-05-22

修回日期:2020-10-16

出版日期:2021-03-05

发布日期:2021-03-05

通讯作者:

郭建维

作者简介:岳航勃(1985—),男,博士,副教授,基金资助:

YUE Hangbo( ),ZHENG Pingxuan,ZHENG Yuru,KUANG Liuyin,ZHANG Yin,LI Liangjun,GUO Jianwei(

),ZHENG Pingxuan,ZHENG Yuru,KUANG Liuyin,ZHANG Yin,LI Liangjun,GUO Jianwei( )

)

Received:2020-05-22

Revised:2020-10-16

Online:2021-03-05

Published:2021-03-05

Contact:

GUO Jianwei

摘要:

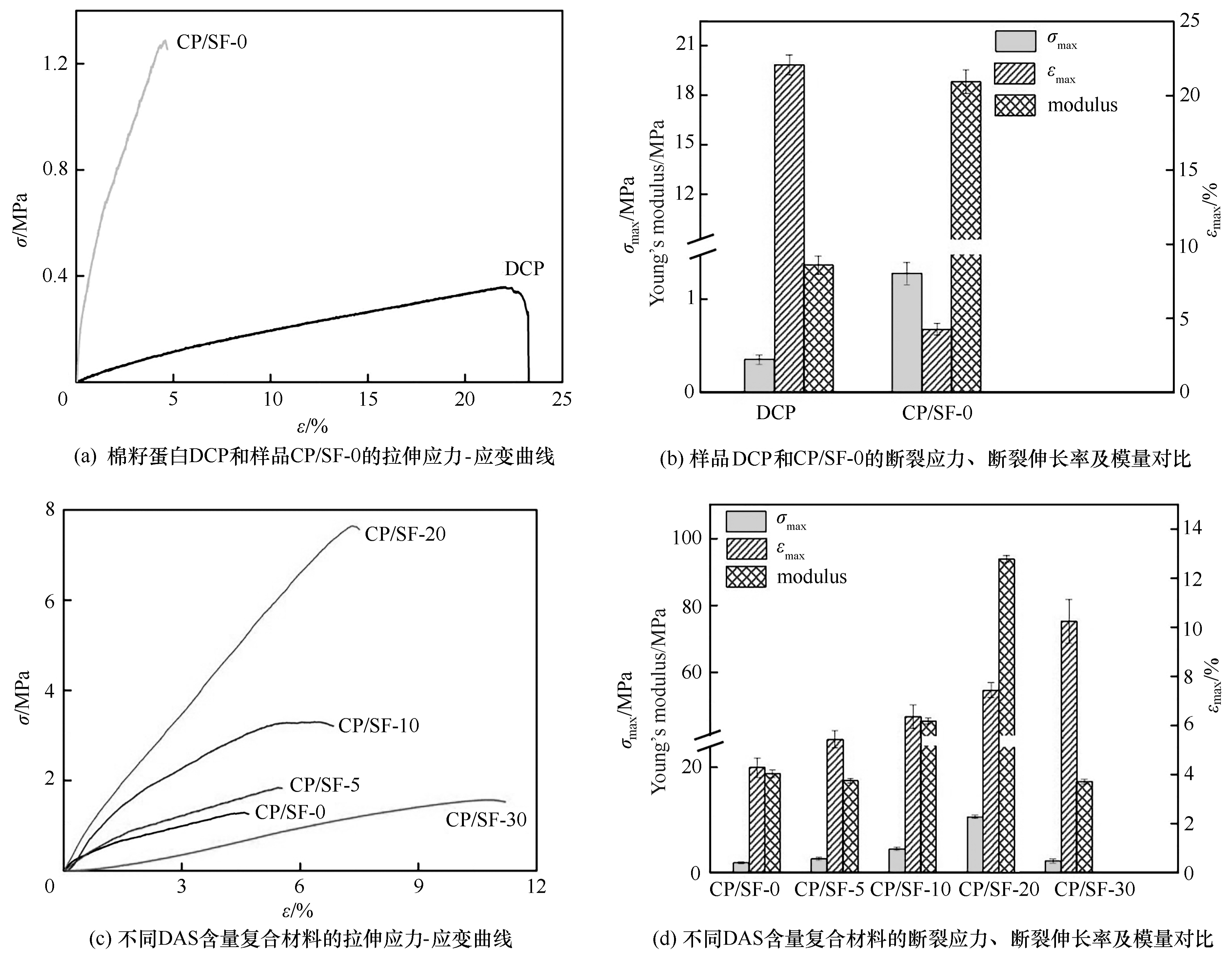

为了提高植物蛋白基绿色高分子材料的力学性能和热稳定性能,以棉籽蛋白(CP)为原料,在尿素变性、甘油增塑、双醛淀粉(DAS)交联的基础上,将其与取向排列的天然剑麻长纤维(SF)复合,经热压硫化加工制备得到具有优异性能的棉籽蛋白/剑麻纤维全绿色复合材料。微观结构形貌和性能分析测试表明,复合材料获得改善性能主要归功于:CP基体与SF增强相间形成的紧密界面结合、对剑麻长纤维的预浸渍处理、CP与SF生物大分子间的强氢键作用。考察了不同DAS含量对复合材料力学性能和热稳定性能的影响。拉伸、热重和差示量热分析表明,经20%(质量) DAS交联的复合材料具有最优的拉伸强度(断裂应力7.5 MPa)、模量(杨氏模量93 MPa)、热稳定性(最大分解温度328℃)和玻璃化转变温度(102℃)。

中图分类号:

岳航勃, 郑萍璇, 郑煜如, 邝柳尹, 张银, 李梁君, 郭建维. 棉籽蛋白/剑麻纤维复合材料加工、界面与性能[J]. 化工学报, 2021, 72(3): 1751-1760.

YUE Hangbo, ZHENG Pingxuan, ZHENG Yuru, KUANG Liuyin, ZHANG Yin, LI Liangjun, GUO Jianwei. Processing, interfaces and properties of cottonseed protein/sisal fiber green composites[J]. CIESC Journal, 2021, 72(3): 1751-1760.

| Element | Spot 1 (SF) | Spot 2 (CP) | Spot 3 (CP/SF-20) | Spot 4 (CP/SF-20) |

|---|---|---|---|---|

| C | 63.2% | 57.3% | 51.5% | 48.5% |

| O | 36.7% | 23.4% | 22.6% | 21.8% |

| N | — | 19.2% | 15.4% | 17.6% |

| Na | — | — | 10.3% | 11.9% |

表1 X射线能谱检测样品所含元素的原子百分比

Table 1 Atomic percentage of elements in samples detected by SEM-EDS

| Element | Spot 1 (SF) | Spot 2 (CP) | Spot 3 (CP/SF-20) | Spot 4 (CP/SF-20) |

|---|---|---|---|---|

| C | 63.2% | 57.3% | 51.5% | 48.5% |

| O | 36.7% | 23.4% | 22.6% | 21.8% |

| N | — | 19.2% | 15.4% | 17.6% |

| Na | — | — | 10.3% | 11.9% |

图6 CP/SF复合材料的应力(σ)-应变(ε)曲线及其力学性能对比

Fig.6 Tensile stress (σ)-strain (ε) curves of CP/SF composites and the comparison on their mechanical properties (fracture stress, elongation at break, and Young’s modulus)

| 样品 | Tg/℃ | Td/℃ | 残留量/% |

|---|---|---|---|

| DCP | 94 | 313 | 27 |

| CP/SF-0 | 83 | 325 | 25 |

| CP/SF-5 | 91 | 328 | 27 |

| CP/SF-10 | 99 | 328 | 28 |

| CP/SF-20 | 102 | 328 | 30 |

| CP/SF-30 | 96 | 316 | 26 |

表2 CP/SF复合材料的热分析结果

Table 2 Results on thermal analysis of CP/SF composites

| 样品 | Tg/℃ | Td/℃ | 残留量/% |

|---|---|---|---|

| DCP | 94 | 313 | 27 |

| CP/SF-0 | 83 | 325 | 25 |

| CP/SF-5 | 91 | 328 | 27 |

| CP/SF-10 | 99 | 328 | 28 |

| CP/SF-20 | 102 | 328 | 30 |

| CP/SF-30 | 96 | 316 | 26 |

| 1 | Iwata T. Biodegradable and bio-based polymers: future prospects of eco-friendly plastics[J]. Angewandte Chemie International Edition, 2015, 54(11): 3210-3215. |

| 2 | Luck P J, Vardhanabhuti B, Yong Y H, et al. Comparison of functional properties of 34% and 80% whey protein and milk serum protein concentrates[J]. Journal of Dairy Science, 2013, 96(9): 5522-5531. |

| 3 | Zubair M, Ullah A. Recent advances in protein derived bionanocomposites for food packaging applications[J]. Critical Reviews in Food Science and Nutrition, 2020, 60(3): 406-434. |

| 4 | Reddy N, Chen L, Yang Y. Thermoplastic films from peanut proteins extracted from peanut meal[J]. Industrial Crops and Products, 2013, 43: 159-164. |

| 5 | Kazmi A, Shuttleworth P. The Economic Utilisation of Food Co-Products[M]. Cambridge: Royal Society of Chemistry, 2013. |

| 6 | 岳航勃. 无腺棉籽蛋白可降解塑料的合成与性能研究[D]. 西安: 西北工业大学, 2016. |

| Yue H B. Study on the prepapration and properties of degradable plastics derived from glandless cottonseed protein[D]. Xi'an: Northwestern Polytechnical University, 2016. | |

| 7 | Yue H B, Cui Y D, Shuttleworth P S, et al. Preparation and characterisation of bioplastics made from cottonseed protein[J]. Green Chemistry, 2012, 14(7): 2009-2016. |

| 8 | Grevellec J, Marquié C, Ferry L, et al. Processability of cottonseed proteins into biodegradable materials[J]. Biomacromolecules, 2001, 2(4): 1104-1109. |

| 9 | Marquie C, Aymard C, Cuq J L, et al. Biodegradable packaging made from cottonseed flour: formation and improvement by chemical treatments with gossypol, formaldehyde, and glutaraldehyde[J]. Journal of Agricultural & Food Chemistry, 1995, 43(10): 2762-2767. |

| 10 | Dou Y, Zhang B, He M, et al. Keratin/polyvinyl alcohol blend films cross-linked by dialdehyde starch and their potential application for drug release[J]. Polymers, 2015, 7: 580-591. |

| 11 | Zuo Y, Liu W, Xiao J, et al. Preparation and characterization of dialdehyde starch by one-step acid hydrolysis and oxidation[J]. International Journal of Biological Macromolecules, 2017, 103: 1257-1264. |

| 12 | Fiedorowicz M, Para A. Structural and molecular properties of dialdehyde starch[J]. Carbohydrate Polymers, 2006, 63(3): 360-366. |

| 13 | Dou Y, Huang X, Zhang B, et al. Preparation and characterization of a dialdehyde starch crosslinked feather keratin film for food packaging application[J]. RSC Advances, 2015, 5(34): 27168-27174. |

| 14 | Skopinska-Wisniewska J, Wegrzynowska-Drzymalska K, Bajek A, et al. Is dialdehyde starch a valuable cross-linking agent for collagen/elastin based materials?[J]. Journal of Materials Science Materials in Medicine, 2016, 27(4): 67-77. |

| 15 | Ciannamea E M, Federica Sagüés M, Saumell C, et al. Soybean protein films. Characterization and potential as novel delivery devices of Duddingtonia flagrans chlamydospores[J]. Biological Control, 2013, 66(2): 92-101. |

| 16 | 岳航勃, 窦瑶, 何明, 等. 提高蛋白质生物塑料力学性能的研究进展[J]. 化工进展, 2013, 32(7): 1591-1597. |

| Yue H B, Dou Y, He M, et al. Improvement of mechanical properties of protein-based bioplastics[J]. Chemical Industry and Engineering Progress, 2013, 32(7): 1591-1597. | |

| 17 | de Oliveira Filho J G, Rodrigues J M, Valadares A C F, et al. Active food packaging: alginate films with cottonseed protein hydrolysates[J]. Food Hydrocolloids, 2019, 92(7): 267-275. |

| 18 | Lodha P, Netravali A N. Characterization of interfacial and mechanical properties of “green” composites with soy protein isolate and ramie fiber[J]. Journal of Materials Science, 2002, 37(17): 3657-3665. |

| 19 | Chabba S, Matthews G F, Netravali A N. 'Green' composites using cross-linked soy flour and flax yarns[J]. Green Chemistry, 2005, 7(8): 576-581. |

| 20 | 陈福泉, 赵永青, 冯彦洪, 等. 木质素/热塑性塑料复合材料界面增容的研究进展[J]. 化工学报, 2014, 65(3): 777-784. |

| Chen F Q, Zhao Y Q, Feng Y H, et al. Progress of interfacial compatibilization methods of lignin/thermoplast composites[J]. CIESC Journal, 2014, 65(3): 777-784. | |

| 21 | Ratna Prasad A V, Mohana Rao K M. Mechanical properties of natural fibre reinforced polyester composites: jowar, sisal and bamboo[J]. Materials & Design, 2011, 32: 4658-4663. |

| 22 | Tansaz S, Boccaccini A R. Biomedical applications of soy protein: a brief overview[J]. Journal of Biomedical Materials Research Part A, 2016, 104(2): 553-569. |

| 23 | Yang S, Madbouly S A, Schrader J A, et al. Characterization and biodegradation behavior of bio-based poly(lactic acid) and soy protein blends for sustainable horticultural applications[J]. Green Chemistry, 2015, 17(1): 380-393. |

| 24 | Yu J, Chang P R, Ma X. The preparation and properties of dialdehyde starch and thermoplastic dialdehyde starch[J]. Carbohydrate Polymers, 2010, 79(2): 296-300. |

| 25 | Guilbert S, Marquie C. Formation and properties of cottonseed protein films and coatines[M]//Gennadios A. Protein-based Films and Coatings. Florida: CRC Press, 2002. |

| 26 | Chen W, Ding J, Yan X, et al. Plasticization of cottonseed protein/polyvinyl alcohol blend films[J]. Polymers, 2019, 11(12): 2096-2112. |

| 27 | Gu W, Liu X, Li F, et al. Tough, strong, and biodegradable composite film with excellent UV barrier performance comprising soy protein isolate, hyperbranched polyester, and cardanol derivative[J]. Green Chemistry, 2019, 21(13): 3651-3665. |

| 28 | Parveen S, Chaudhury S, Dasgupta S. Tuning the mechanical and physicochemical properties of cross-linked protein films[J]. Biopolymers, 2019, 110(10): 23321-23334. |

| 29 | Yue H, Fernández-Blázquez J, Shuttleworth P, et al. Thermomechanical relaxation and different water states in cottonseed protein derived bioplastics[J]. RSC Advances, 2014, 4(61): 32320-32326. |

| 30 | Chen P, Zhang L, Cao F. Effects of moisture on glass transition and microstructure of glycerol-plasticized soy protein[J]. Macromolecular Bioscience, 2005, 5(9): 872-880. |

| 31 | Mokhothu T H, John M J. Review on hygroscopic aging of cellulose fibres and their biocomposites[J]. Carbohydrate Polymers, 2015, 131: 337-354. |

| 32 | Schmidt V, Giacomelli C, Soldi V. Thermal stability of films formed by soy protein isolate–sodium dodecyl sulfate[J]. Polymer Degradation and Stability, 2005, 87(1): 25-31. |

| [1] | 周晓庆, 李春煜, 杨光, 蔡爱峰, 吴静怡. 液滴撞击不同曲率过冷波纹面结冰动力学行为及机理研究[J]. 化工学报, 2023, 74(S1): 141-153. |

| [2] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [3] | 陆俊凤, 孙怀宇, 王艳磊, 何宏艳. 离子液体界面极化及其调控氢键性质的分子机理[J]. 化工学报, 2023, 74(9): 3665-3680. |

| [4] | 林典, 江国梅, 徐秀彬, 赵波, 刘冬梅, 吴旭. 硅基类液防原油黏附涂层的研制及其减阻性能研究[J]. 化工学报, 2023, 74(8): 3438-3445. |

| [5] | 徐文杰, 贾献峰, 王际童, 乔文明, 凌立成, 王任平, 余子舰, 张寅旭. 有机硅/酚醛杂化气凝胶的制备和性能研究[J]. 化工学报, 2023, 74(8): 3572-3583. |

| [6] | 傅予, 刘兴翀, 王瀚雨, 李海敏, 倪亚飞, 邹文静, 雷月, 彭永姗. F3EACl修饰层对钙钛矿太阳能电池性能提升的研究[J]. 化工学报, 2023, 74(8): 3554-3563. |

| [7] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [8] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [9] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| [10] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [11] | 刘杰, 吴立盛, 李锦锦, 罗正鸿, 周寅宁. 含乙烯基胺酯键聚醚类可逆交联聚合物的制备及性能研究[J]. 化工学报, 2023, 74(7): 3051-3057. |

| [12] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [13] | 崔张宁, 胡紫璇, 吴雷, 周军, 叶干, 刘田田, 张秋利, 宋永辉. 可降解纤维素基材料的耐水性能研究进展[J]. 化工学报, 2023, 74(6): 2296-2307. |

| [14] | 杨琴, 秦传鉴, 李明梓, 杨文晶, 赵卫杰, 刘虎. 用于柔性传感的双形状记忆MXene基水凝胶的制备及性能研究[J]. 化工学报, 2023, 74(6): 2699-2707. |

| [15] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号