化工学报 ›› 2021, Vol. 72 ›› Issue (8): 4346-4353.DOI: 10.11949/0438-1157.20201672

收稿日期:2020-11-19

修回日期:2021-02-17

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

蒋崇文

作者简介:谢乐(1989—),男,博士,讲师,基金资助:Received:2020-11-19

Revised:2021-02-17

Online:2021-08-05

Published:2021-08-05

Contact:

Chongwen JIANG

摘要:

以生物滴滤塔(BTF)去除高浓度H2S废气为研究对象,建立了一维轴向扩散反应器模型和双基质生物降解反应动力学模型,通过比较单基质模型和双基质模型在不同H2S入口浓度条件下的模拟结果和实验结果,验证了双基质模型的有效性和可行性,研究了生物膜中H2S的动态去除过程,考察了BTF在不同液相H2S浓度和空床停留时间条件下的除臭性能。研究表明,当生物膜表面H2S浓度为7589.3 mg/m3 时,生物膜中传质-生物降解过程需要0.75 s才能达到稳态;较厚的生物膜使得内扩散阻力增大,生物降解反应速率分布的不均匀性增大,O2浓度对生物降解速率的影响将越来越显著;进气速度和喷淋浓度可显著影响BTF中H2S的去除率。

中图分类号:

谢乐, 蒋崇文. 生物滴滤塔去除高浓度H2S废气的模拟研究[J]. 化工学报, 2021, 72(8): 4346-4353.

Le XIE, Chongwen JIANG. Simulation study on the removal of high concentration H2S waste gas by biotrickling filter[J]. CIESC Journal, 2021, 72(8): 4346-4353.

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 气相中H2S扩散系数( | 1.8×10-5 m2/s | 气相中O2扩散系数(Dog) | 1.775×10-5 m2/s |

| 生物膜中H2S扩散系数( | 1.28×10-9 m2/s | 生物膜中O2扩散系数(Dos) | 2.86×10-9 m2/s |

| H2S半饱和常数 (Kh) | 0.039 g/m3 | O2半饱和常数 (Ko) | 0.26 g/m3 |

| 最大比生长速率 (μmax) | 3.61 d-1 | O2亨利系数 (mo) | 34.13 |

| H2S亨利系数 (mh) | 0.47 | 生物膜密度(Xb) | 28 kg/m3 |

| 产率(Yh) | 0.03 | 产率(Yo) | 0.3436 |

表1 扩散系数和生物降解反应动力学参数

Table 1 Diffusion coefficients and kinetic parameters of biodegradation

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 气相中H2S扩散系数( | 1.8×10-5 m2/s | 气相中O2扩散系数(Dog) | 1.775×10-5 m2/s |

| 生物膜中H2S扩散系数( | 1.28×10-9 m2/s | 生物膜中O2扩散系数(Dos) | 2.86×10-9 m2/s |

| H2S半饱和常数 (Kh) | 0.039 g/m3 | O2半饱和常数 (Ko) | 0.26 g/m3 |

| 最大比生长速率 (μmax) | 3.61 d-1 | O2亨利系数 (mo) | 34.13 |

| H2S亨利系数 (mh) | 0.47 | 生物膜密度(Xb) | 28 kg/m3 |

| 产率(Yh) | 0.03 | 产率(Yo) | 0.3436 |

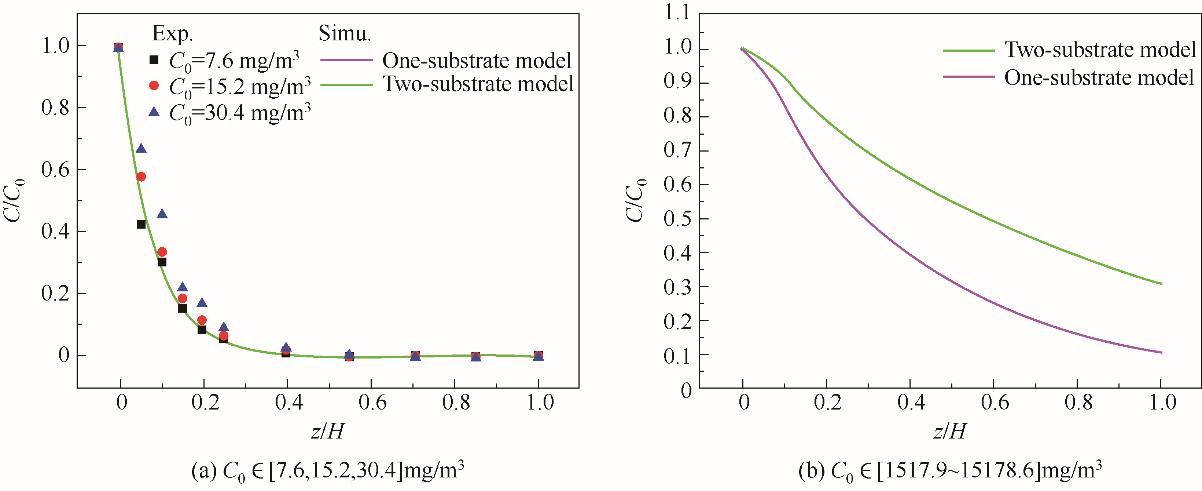

图2 不同H2S进气浓度下单基质模型和双基质模型预测得到的H2S轴向浓度分布对比分析(EBRT=10.9 s;δ=20 μm)

Fig.2 The obtained axial H2S concentration distribution using the one-substrate and two-substrate models were compared with each other at different H2S inlet concentrations (EBRT is 10.9 s and biofilm thick is 20 μm)

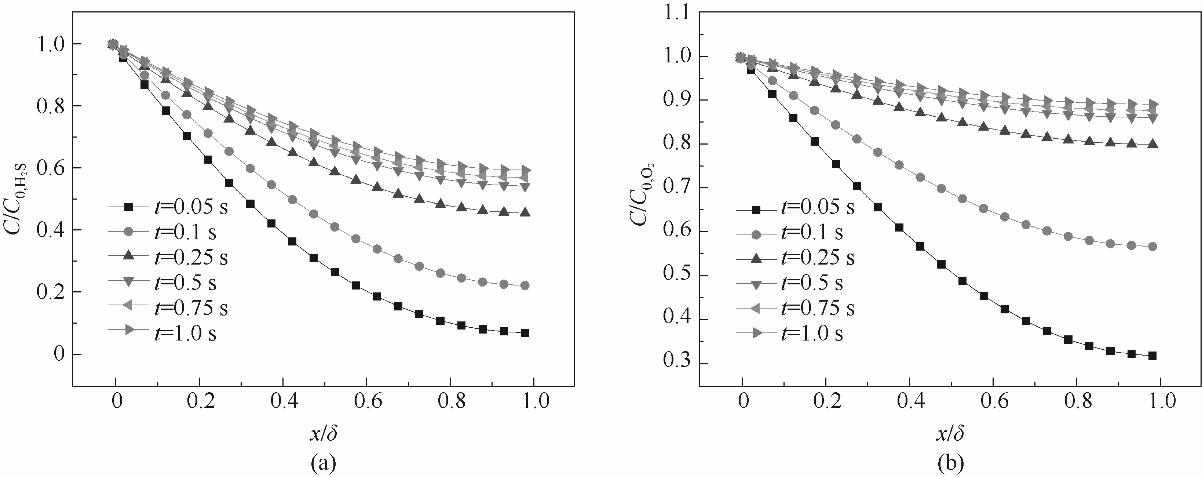

图3 生物膜中无量纲H2S和O2浓度的动态分布趋势图(H2S界面浓度为7589.3 mg/m3,生物膜厚度为20 μm)

Fig.3 The dynamic changes of the dimensionless H2S and O2 concentration in the biofilm when the H2S interfacial concentration is 7589.3 mg/m3 and the biofilm thickness is 20 μm

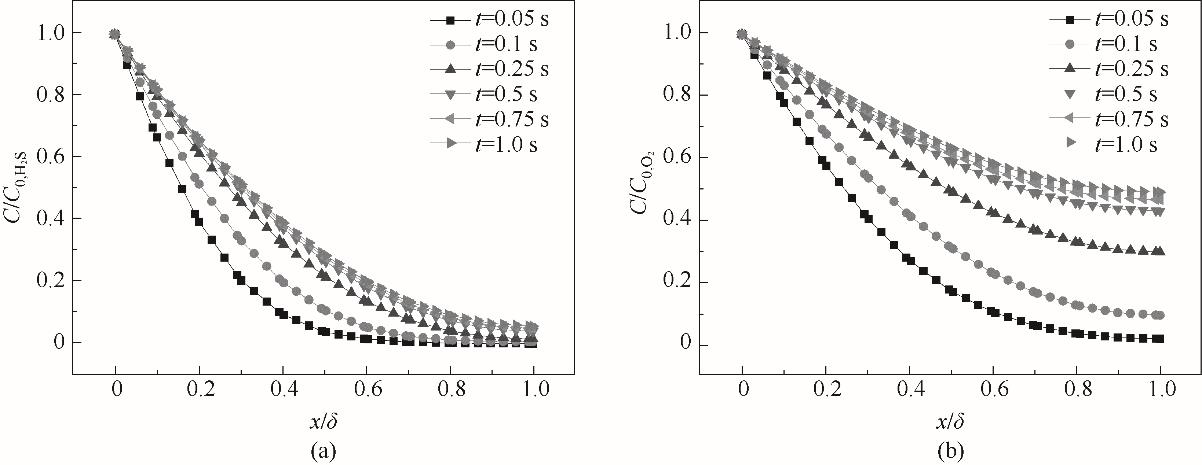

图4 生物膜中无量纲H2S和O2浓度的动态分布趋势图(H2S界面浓度为7589.3 mg/m3,生物膜厚度为40 μm)

Fig.4 The dynamic changes of the dimensionless H2S and O2 concentration in the biofilm when the H2S interfacial concentration is 7589.3 mg/m3 and the biofilm thickness is 40 μm

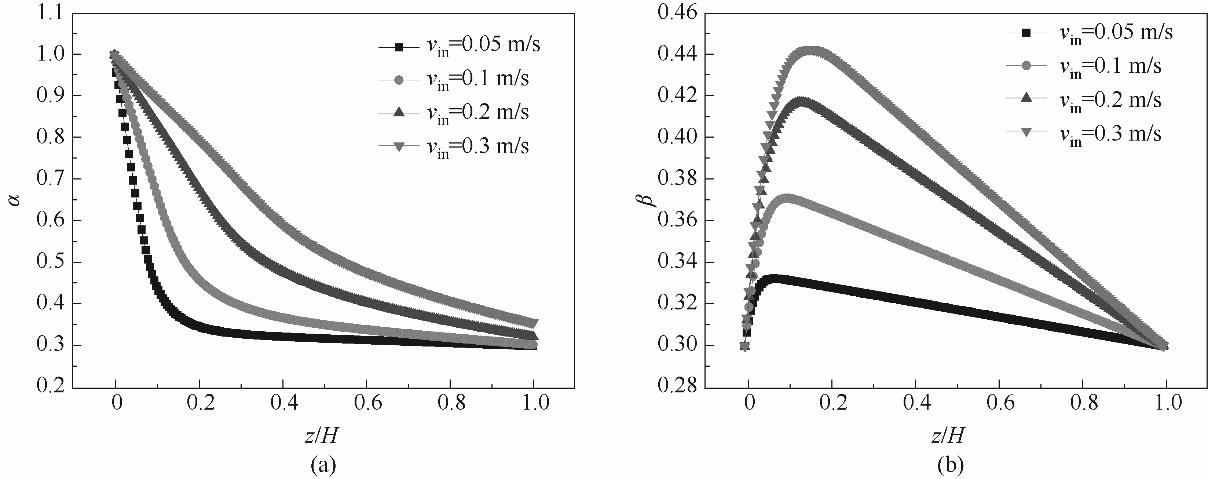

图5 不同进气速度条件下气相和液相中的无量纲H2S浓度沿塔轴向分布趋势

Fig.5 Dimensionless H2S concentration in gas phase and liquid phase along the axial direction of the BTF at different inlet velocities

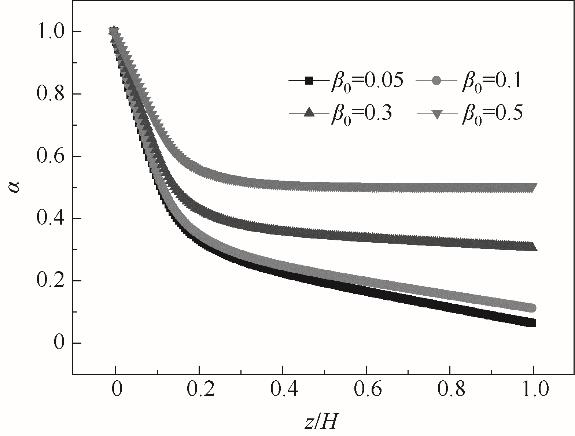

图6 不同循环喷淋液相H2S浓度条件下气相中的无量纲H2S浓度沿塔轴向分布趋势

Fig.6 Dimensionless H2S concentration in gas phase along the axial direction of the BTF at different H2S concentrations in the recirculated liquid phase

| 1 | Bonilla-Blancas W, Mora M, Revah S, et al. Application of a novel respirometric methodology to characterize mass transfer and activity of H2S-oxidizing biofilms in biotrickling filter beds[J]. Biochem. Eng. J., 2015, 99: 24-34. |

| 2 | Jia T, Sun S, Chen K, et al. Simultaneous methanethiol and dimethyl sulfide removal in a single-stage biotrickling filter packed with polyurethane foam: performance, parameters and microbial community analysis[J]. Chemosphere, 2020, 244: 125460. |

| 3 | Rybarczyk P, Szulczyński B, Gębicki J, et al. Treatment of malodorous air in biotrickling filters: a review[J]. Biochem. Eng. J., 2019, 141: 146-162. |

| 4 | 钱东升, 房俊逸, 陈东之, 等. 板式生物滴滤塔高效净化硫化氢废气的研究[J]. 环境科学, 2011, 32(9): 2786-2793. |

| Qian D S, Fang J Y, Chen D Z, et al. Removal of hydrogen sulfide by plate type-biotrickling filter[J]. Environmental Science, 2011, 32(9): 2786-2793. | |

| 5 | 廖强, 田鑫, 朱恂, 等. 陶瓷球填料生物滴滤塔降解甲苯废气[J]. 化工学报, 2003, 54(12): 1774-1778. |

| Liao Q, Tian X, Zhu X, et al. Purifying waste gas containing low concentration toluene in trickling biofilter with ceramic spheres[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(12): 1774-1778. | |

| 6 | 廖强, 田鑫, 朱恂. 生物膜滴滤床内温度及其分布特性对废气净化性能的影响[J]. 化工学报, 2006, 57(7): 1643-1648. |

| Liao Q, Tian X, Zhu X. Effects of temperature and its profile on purification performance of biotrickling bed for waste gas treatment[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(7): 1643-1648. | |

| 7 | Dupnock T L, Deshusses M A. Biological co-treatment of H2S and reduction of CO2 to methane in an anoxic biological trickling filter upgrading biogas[J]. Chemosphere, 2020, 256: 127078. |

| 8 | Zhang Y, Liu J, Xing H, et al. Performance and fungal diversity of bio-trickling filters packed with composite media of polydimethylsiloxane and foam ceramics for hydrophobic VOC removal[J]. Chemosphere, 2020, 256: 127093. |

| 9 | Zhang Y, Oshita K, Kusakabe T, et al. Simultaneous removal of siloxanes and H2S from biogas using an aerobic biotrickling filter[J]. J. Hazard. Mater., 2020, 391: 122187. |

| 10 | Estrada J M, Dudek A, Muñoz R, et al. Fundamental study on gas-liquid mass transfer in a biotrickling filter packed with polyurethane foam[J]. J. Chem. Technol. Biotechnol., 2014, 89: 1419-1424. |

| 11 | Fernandez M, Ramírez M, Perez R M, et al. Hydrogen sulphide removal from biogas by an anoxic biotrickling filter packed with pall rings[J]. Chem. Eng. J., 2013, 225: 456-463. |

| 12 | San-Valero P, Penya-Roja J M, Álvarez-Hornos F J, et al. Modelling mass transfer properties in a biotrickling filter for the removal of isopropanol[J]. Chem. Eng. Sci., 2014, 108: 47-56. |

| 13 | Liu D, Andreasen R R, Poulsen T G, et al. A comparative study of mass transfer coefficients of reduced volatile sulfur compounds for biotrickling filter packing materials[J]. Chem. Eng. J., 2015, 260: 209-221. |

| 14 | Gonzalez-Sanchez A, Arellano-García L, Bonilla-Blancas W, et al. Kinetic characterization by respirometry of volatile organic compound-degrading biofilms from gas-phase biological filters[J]. Ind. Eng. Chem. Res., 2014, 53: 19405-19415. |

| 15 | Wang X, Wang Q, Li S, et al. Degradation pathway and kinetic analysis for p-xylene removal by a novel Pandoraea sp. strain WL1 and its application in a biotrickling filter[J]. J. Hazard. Mater., 2015, 288: 17-24. |

| 16 | Mathur A K, Sundaramurthy J, Balomajumder C. Kinetics of the removal of mono-chlorobenzene vapour from waste gases using a trickle bed air biofilter[J]. J. Hazard. Mater., 2006, 137: 1560-1568. |

| 17 | Malhautier L, Quijano G, Avezac M, et al. Kinetic characterization of toluene biodegradation by Rhodococcus erythropolis: towards a rationale for microflora enhancement in bioreactors devoted to air treatment[J]. Chem. Eng. J., 2014, 247: 199-204. |

| 18 | Giri B S, Goswami M, Pandey R A, et al. Kinetics and biofiltration of dimethyl sulfide emitted from P&P industry[J]. Biochem. Eng. J., 2015, 102: 108-114. |

| 19 | van Krevelen D W, Hoftijzer P J. Kinetics of simultaneous absorption and chemical reaction[J]. Chem. Eng. Pro., 1948, 44: 529-536. |

| 20 | Shulman H L, Ullrich C F, Proulx A Z, et al. Performance of packed columns(Ⅱ): Wetted and effective-interfacial areas, gas- and liquid-phase mass transfer rates[J]. AIChE J., 1955, 1: 253-258. |

| 21 | Billet R, Schultes M. Prediction of mass transfer columns with dumped and arranged packings: updated summary of the calculation method of billet and schultes[J]. Chem. Eng. Res. Des. ,1999, 77: 498-504. |

| 22 | Onda K, Takeuchi H, Okumoto Y. Mass transfer coefficients between gas and liquid phases in packed columns[J]. J. Chem. Eng. Jap., 1968, 1: 56-62. |

| 23 | Kim S, Deshusses M A. Determination of mass transfer coefficients for packing materials used in biofilters and biotrickling filters for air pollution control(2): Development of mass transfer coefficients correlations[J]. Chem. Eng. Sci., 2008, 63: 856-861. |

| 24 | Kim S, Deshusses M A. Determination of mass transfer coefficients for packing materials used in biofilters and biotrickling filters for air pollution control (1): Experimental results[J]. Chem. Eng. Sci., 2008, 63: 841-855. |

| 25 | Cox H H J, Deshusses M A. Co-treatment of H2S and toluene in a biotrickling filter[J]. Chem. Eng. J., 2002, 87: 101-110. |

| 26 | Jin Y, Veiga M C, Kennes C. Co-treatment of hydrogen sulfide and methanol in a single-stage biotrickling filter under acidic conditions[J]. Chemosphere, 2007, 68: 1186-1193. |

| 27 | Montebello A M, Fernández M, Almenglo F, et al. Simultaneous methylmercaptan and hydrogen sulfide removal in the desulfurization of biogas in aerobic and anoxic biotrickling filters[J]. Chem. Eng. J., 2012, 200/201/202: 237-246. |

| 28 | López L R, Luis R, Bezerra T, et al. Influence of trickling liquid velocity and flow pattern in the improvement of oxygen transport in aerobic biotrickling filters for biogas desulfurization[J]. J. Chem. Technol. Biotechnol., 2016, 91: 1031-1039. |

| 29 | Gaszczak A, Bartelmus G, Burghardt A, et al. Experiments and modelling of a biotrickling filter (BTF) for removal of styrene from airstreams[J]. J. Chem. Technol. Biotechnol., 2018, 93: 2659-2670. |

| 30 | Xie L, Zhu J, Hu J, et al. Study of the mass transfer-biodegradation kinetics in a pilot-scale biotrickling filter for the removal of H2S[J]. Indus. Eng. Chem. Res., 2020, 59: 8383-8392. |

| 31 | Chen Y, Xie L, Cai W, et al. Pilot-scale study using biotrickling filter to remove H2S from sewage lift station: experiment and CFD simulation[J]. Biochem. Eng. J., 2019, 144: 177-184. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [3] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [4] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [5] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [6] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [7] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [8] | 于旭东, 李琪, 陈念粗, 杜理, 任思颖, 曾英. 三元体系KCl + CaCl2 + H2O 298.2、323.2及348.2 K相平衡研究及计算[J]. 化工学报, 2023, 74(8): 3256-3265. |

| [9] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [10] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [11] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [12] | 郭雨莹, 敬加强, 黄婉妮, 张平, 孙杰, 朱宇, 冯君炫, 陆洪江. 稠油管道水润滑减阻及压降预测模型修正[J]. 化工学报, 2023, 74(7): 2898-2907. |

| [13] | 刘春雨, 周桓宇, 马跃, 岳长涛. CaO调质含油污泥干燥特性及数学模型[J]. 化工学报, 2023, 74(7): 3018-3027. |

| [14] | 李艳辉, 丁邵明, 白周央, 张一楠, 于智红, 邢利梅, 高鹏飞, 王永贞. 非常规服役超临界锅炉的微纳尺度腐蚀动力学模型建立及应用[J]. 化工学报, 2023, 74(6): 2436-2446. |

| [15] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号