化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5053-5063.DOI: 10.11949/0438-1157.20210322

收稿日期:2021-03-04

修回日期:2021-05-07

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

贾胜坤,袁希钢

作者简介:肖凡(1994—),男,硕士研究生,基金资助:

Fan XIAO1( ),Shengkun JIA1(

),Shengkun JIA1( ),Yiqing LUO1,Xigang YUAN1,2(

),Yiqing LUO1,Xigang YUAN1,2( )

)

Received:2021-03-04

Revised:2021-05-07

Online:2021-10-05

Published:2021-10-05

Contact:

Shengkun JIA,Xigang YUAN

摘要:

太阳能裂解甲烷具有产物纯度高且环保的优点。对湍流条件下的甲烷高温裂解太阳能管式反应器进行计算流体力学(CFD)模拟,为提高太阳能甲烷裂解反应器的转化率,通过调节反应器结构对流场进行优化。为了更加准确计算太阳能辐射的加热效应,在湍流反应扩散模型中引入碳颗粒的生成和聚集模型,并采用离散坐标(DO)模型进行辐射模型求解。然后,在太阳能管式反应器中引入射流及挡板进行流场调节,并对挡板高度、射流流速及角度进行优化,达到强化反应过程的目的。优化后的反应器中,甲烷转化率可以提高约8%。以反应转化率和代表强化成本的黏性耗散为指标,筛选出不同离散条件下的Pareto最优解,并用支持向量机回归(SVR)算法对离散的Pareto最优解进行插值,得到操作曲线和与之相对应的最优射流角度及流速。

中图分类号:

肖凡,贾胜坤,罗祎青,袁希钢. 基于CFD模拟的甲烷裂解太阳能管式反应器结构优化[J]. 化工学报, 2021, 72(10): 5053-5063.

Fan XIAO,Shengkun JIA,Yiqing LUO,Xigang YUAN. Structural optimization of methane cracking solar tube reactor based on CFD simulation[J]. CIESC Journal, 2021, 72(10): 5053-5063.

| 温度/K | 转化率/% | |

|---|---|---|

| 实验值 | 模拟值 | |

| 1608 | 72 | 71.45 |

| 1693 | 95 | 95.03 |

| 1778 | 99 | 100 |

| 1793 | 99 | 100 |

| 1928 | 100 | 100 |

表1 模型验证数据

Table 1 Model validation data

| 温度/K | 转化率/% | |

|---|---|---|

| 实验值 | 模拟值 | |

| 1608 | 72 | 71.45 |

| 1693 | 95 | 95.03 |

| 1778 | 99 | 100 |

| 1793 | 99 | 100 |

| 1928 | 100 | 100 |

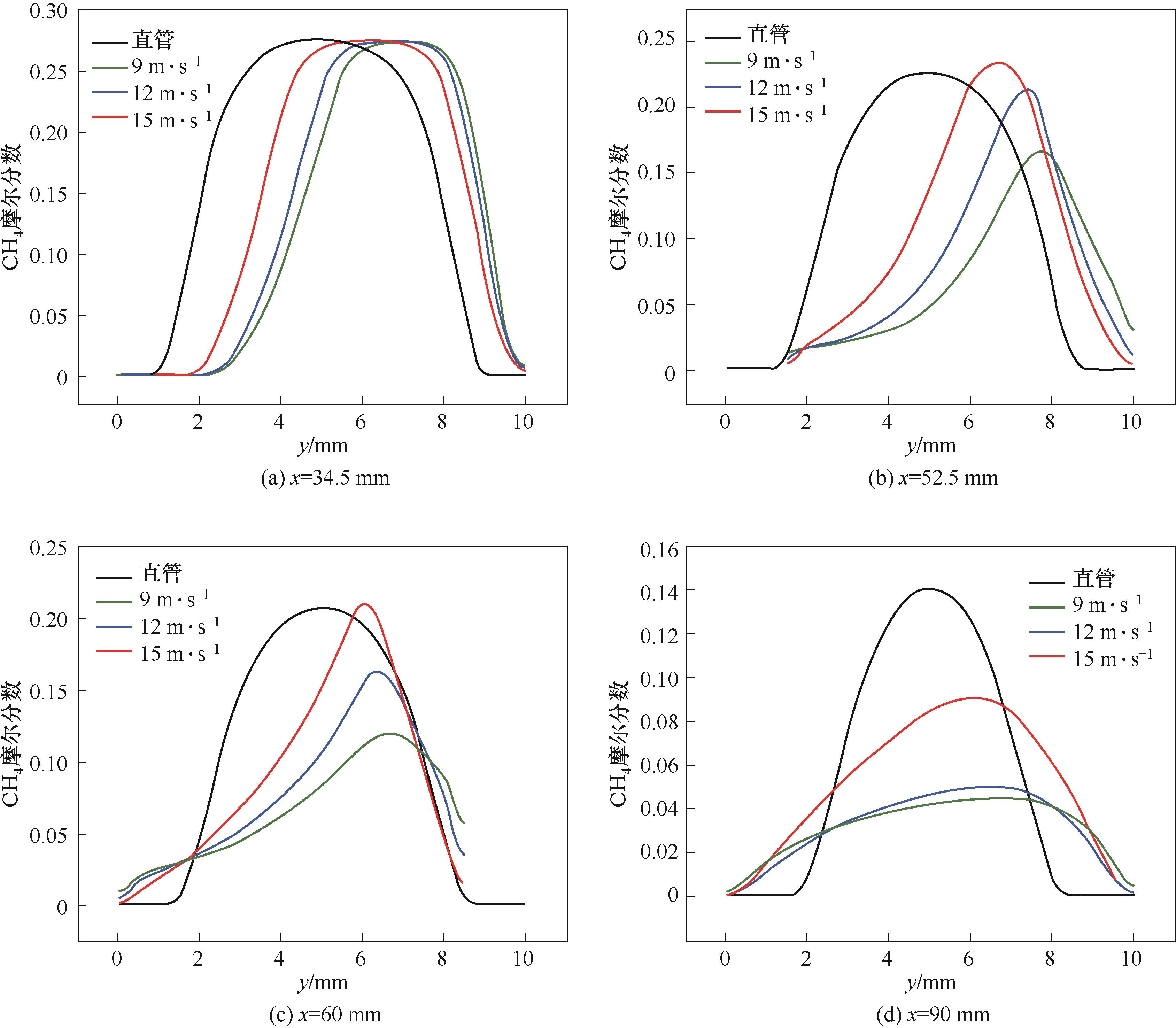

图7 无优化(直管)和优化后反应器内的甲烷摩尔分数分布对比

Fig.7 Comparison of CH4 mole fraction distribution for the base case(straight tube) and the optimization case in the reactor

| H/mm | 增加的转化率/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 m·s-1 | 2 m·s-1 | 3 m·s-1 | 4 m·s-1 | 5 m·s-1 | 6 m·s-1 | 7 m·s-1 | 8 m·s-1 | 9 m·s-1 | |

| 1.0 | 0.14 | 0.15 | 0.20 | 0.31 | 0.42 | 0.51 | 0.61 | 0.68 | 0.80 |

| 1.5 | 0.31 | 0.31 | 0.37 | 0.51 | 0.68 | 0.81 | 0.90 | 0.98 | 1.05 |

| 2.0 | 0.31 | 0.32 | 0.39 | 0.53 | 0.70 | 0.84 | 0.93 | 1.01 | 1.11 |

表2 不同挡板高度在不同射流流速下甲烷增加的转化率

Table 2 The increase of methane conversion rate for different baffle heights at different jet flow rates

| H/mm | 增加的转化率/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 m·s-1 | 2 m·s-1 | 3 m·s-1 | 4 m·s-1 | 5 m·s-1 | 6 m·s-1 | 7 m·s-1 | 8 m·s-1 | 9 m·s-1 | |

| 1.0 | 0.14 | 0.15 | 0.20 | 0.31 | 0.42 | 0.51 | 0.61 | 0.68 | 0.80 |

| 1.5 | 0.31 | 0.31 | 0.37 | 0.51 | 0.68 | 0.81 | 0.90 | 0.98 | 1.05 |

| 2.0 | 0.31 | 0.32 | 0.39 | 0.53 | 0.70 | 0.84 | 0.93 | 1.01 | 1.11 |

图8 不同角度及不同射流流速下甲烷增加的转化率(相同流速下,以1.5 mm挡板、0°夹角结构下甲烷转化率为基准进行比较)

Fig.8 Increase of methane conversion rate in different angles and different jet flow rates

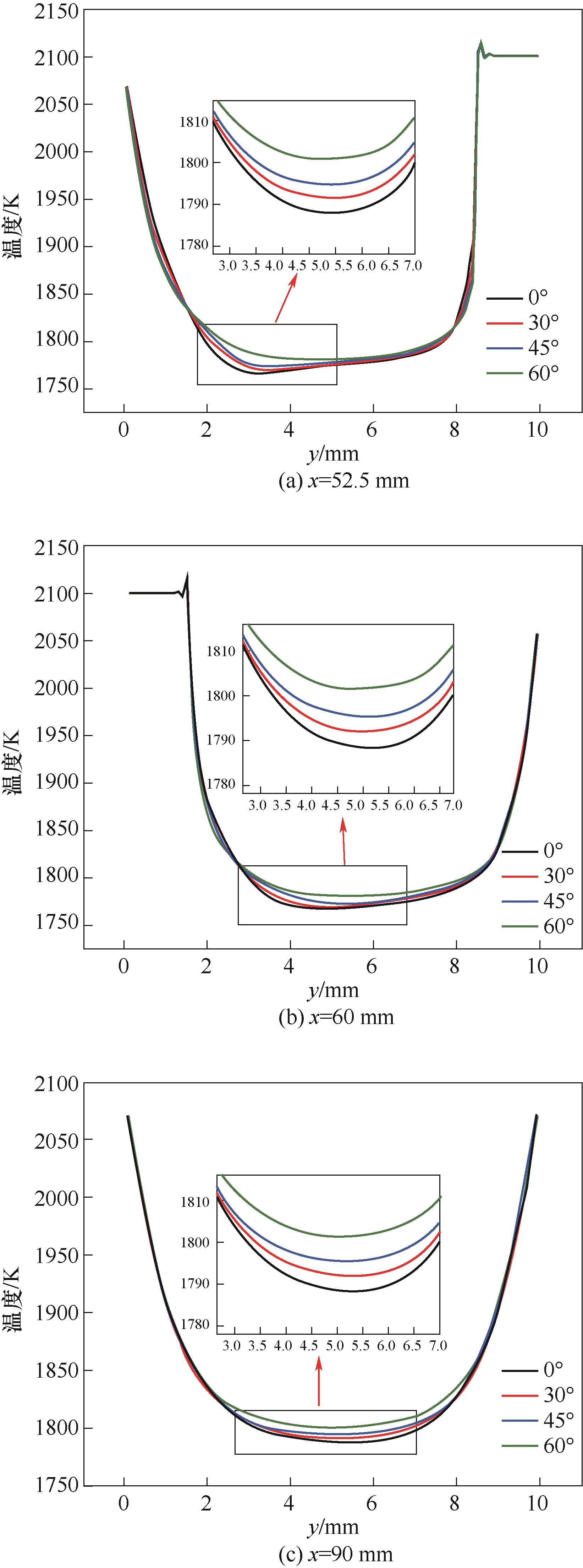

图9 流速5 m·s-1下无优化(0°)和优化后(30°,45°,60°)反应器内的温度分布对比

Fig.9 Comparison of temperature distribution in the reactor without optimization(0°) and after optimization(30°,45°,60°)at a flow rate of 5 m·s-1

| 1 | Behzadi A, Habibollahzade A, Ahmadi P, et al. Multi-objective design optimization of a solar based system for electricity, cooling, and hydrogen production[J]. Energy, 2019, 169: 696-709. |

| 2 | Wang M Y, Wang Z, Gong X Z, et al. The intensification technologies to water electrolysis for hydrogen production — a review [J]. Renewable and Sustainable Energy Reviews, 2014, 29: 573-588. |

| 3 | 张伶, 陈红梅, 魏子栋. 过渡金属氧化物催化析氧反应研究进展[J]. 化工学报, 2020, 71(9): 3876-3904. |

| Zhang L, Chen H M, Wei Z D. Recent advance in transition metal oxide-based materials for oxygen evolution reaction electrocatalysts[J]. CIESC Journal, 2020, 71(9): 3876-3904. | |

| 4 | 常明, 陈爱平, 何洪波, 等. 层层组装修饰Ni片阳极的光催化辅助电解水制氢[J]. 化工学报, 2012, 63(7): 2195-2201. |

| Chang M, Chen A P, He H B, et al. Ni anode modified by layer by layer assembly and its application in water electrolysis assisted by photocatalysis[J]. CIESC Journal, 2012, 63(7): 2195-2201. | |

| 5 | 钱宇, 杨思宇, 贾小平, 等. 能源和化工系统的全生命周期评价和可持续性研究[J]. 化工学报, 2013, 64(1): 133-147. |

| Qian Y, Yang S Y, Jia X P, et al. Life cycle assessment and sustainability of energy and chemical processes[J]. CIESC Journal, 2013, 64(1): 133-147. | |

| 6 | 曾亮, 巩金龙. 化学链重整直接制氢技术进展[J]. 化工学报, 2015, 66(8): 2854-2862. |

| Zeng L, Gong J L. Advances in chemical looping reforming for direct hydrogen production[J]. CIESC Journal, 2015, 66(8): 2854-2862. | |

| 7 | Qiao C Z. Status and development of hydrogen production from carbonaceous energy sources[J]. Energy Conservation & Environmental Protection in Transportation, 2010, 2: 40-43. |

| 8 | Villafán-Vidales H I, Arancibia-Bulnes C A, Riveros-Rosas D, et al. An overview of the solar thermochemical processes for hydrogen and syngas production: reactors, and facilities[J]. Renewable and Sustainable Energy Reviews, 2017, 75: 894-908. |

| 9 | Abanades S, Flamant G. Experimental study and modeling of a high-temperature solar chemical reactor for hydrogen production from methane cracking[J]. International Journal of Hydrogen Energy, 2007, 32(10/11): 1508-1515. |

| 10 | Maag G, Zanganeh G, Steinfeld A. Solar thermal cracking of methane in a particle-flow reactor for the co-production of hydrogen and carbon[J]. International Journal of Hydrogen Energy, 2009, 34(18): 7676-7685. |

| 11 | Z'Graggen A, Haueter P, Trommer D, et al. Hydrogen production by steam-gasification of petroleum coke using concentrated solar power(Ⅱ): Reactor design, testing, and modeling[J]. International Journal of Hydrogen Energy, 2006, 31(6): 797-811. |

| 12 | Abanades S, Kimura H, Otsuka H. A drop-tube particle-entrained flow solar reactor applied to thermal methane splitting for hydrogen production[J]. Fuel, 2015, 153: 56-66. |

| 13 | Abanades S, Kimura H, Otsuka H. Hydrogen production from thermo-catalytic decomposition of methane using carbon black catalysts in an indirectly-irradiated tubular packed-bed solar reactor[J]. International Journal of Hydrogen Energy, 2014, 39(33): 18770-18783. |

| 14 | Rodat S, Abanades S, Sans J L, et al. A pilot-scale solar reactor for the production of hydrogen and carbon black from methane splitting[J]. International Journal of Hydrogen Energy, 2010, 35(15): 7748-7758. |

| 15 | Abanades S, Kimura H, Otsuka H. Hydrogen production from CO2-free thermal decomposition of methane: design and on-sun testing of a tube-type solar thermochemical reactor[J]. Fuel Processing Technology, 2014, 122: 153-162. |

| 16 | Rodat S, Abanades S, Flamant G. Co-production of hydrogen and carbon black from solar thermal methane splitting in a tubular reactor prototype[J]. Solar Energy, 2011, 85(4): 645-652. |

| 17 | Valdés-Parada F J, Romero-Paredes H, Espinosa-Paredes G. Numerical simulation of a tubular solar reactor for methane cracking[J]. International Journal of Hydrogen Energy, 2011, 36(5): 3354-3363. |

| 18 | Patrianakos G, Kostoglou M, Konstandopoulos A. One-dimensional model of solar thermal reactors for the co-production of hydrogen and carbon black from methane decomposition[J]. International Journal of Hydrogen Energy, 2011, 36(1): 189-202. |

| 19 | Caliot C, Flamant G, Patrianakos G, et al. Two-dimensional model of methane thermal decomposition reactors with radiative heat transfer and carbon particle growth[J]. AIChE Journal, 2012, 58(8): 2545-2556. |

| 20 | Cao X P, Jia S K, Avellaneda J M, et al. An optimization method to find the thermodynamic limit on enhancement of solar thermal decomposition of methane[J]. International Journal of Hydrogen Energy, 2019, 44(31): 16164-16175. |

| 21 | McGillis W R, Carey V P. On the role of Marangoni effects on the critical heat flux for pool boiling of binary mixtures[J]. Journal of Heat Transfer, 1996, 118(1): 103-109. |

| 22 | Eastman J A, Choi S U S, Li S, et al. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles[J]. Applied Physics Letters, 2001, 78(6): 718-720. |

| 23 | 余徽, 印永祥, 戴晓雁. 等离子体射流裂解甲烷制乙炔的数值模拟[J]. 化工学报, 2006, 57(10): 2319-2326. |

| Yu H, Yin Y X, Dai X Y. Numerical simulation of methane conversion to acetylene in plasma jet reactor[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(10): 2319-2326. | |

| 24 | Chen Q, Meng J. Field synergy analysis and optimization of the convective mass transfer in photocatalytic oxidation reactors[J]. International Journal of Heat and Mass Transfer, 2008, 51(11/12): 2863-2870. |

| 25 | Wang J L, Feng X Y, Yu T. A geometric approach to support vector regression and its application to fermentation process fast modeling[J]. Chinese Journal of Chemical Engineering, 2012, 20(4): 715-722. |

| 26 | Rodat S, Abanades S, Coulié J, et al. Kinetic modelling of methane decomposition in a tubular solar reactor[J]. Chemical Engineering Journal, 2009, 146(1): 120-127. |

| 27 | Hirsch D, Steinfeld A. Solar hydrogen production by thermal decomposition of natural gas using a vortex-flow reactor[J]. International Journal of Hydrogen Energy, 2004, 29(1): 47-55. |

| 28 | Nezzari B, Gomri R. Study of cracking of methane for hydrogen production using concentrated solar energy[J]. International Journal of Hydrogen Energy, 2020, 45(1): 135-148. |

| 29 | Kogan A. Production of hydrogen and carbon by solar thermal methane splitting(Ⅱ): Room temperature simulation tests of seeded solar reactor[J]. International Journal of Hydrogen Energy, 2004, 29(12): 1227-1236. |

| 30 | Ozalp N, Ibrik K, Al-Meer M. Kinetics and heat transfer analysis of carbon catalyzed solar cracking process[J]. Energy, 2013, 55: 74-81. |

| 31 | Ozalp N, Kanjirakat A. A computational fluid dynamics study on the effect of carbon particle seeding for the improvement of solar reactor performance[J]. Journal of Heat Transfer, 2010, 132(12): 1229-1241. |

| 32 | Seinfeld J H, Pandis S N, Noone K. Atmospheric chemistry and physics: from air pollution to climate change[J]. Physics Today, 1998, 51(10): 88-90. |

| 33 | Kostoglou M, Karabelas A J. Evaluation of numerical methods for simulating an evolving particle size distribution in growth processes[J]. Chemical Engineering Communications, 1995, 136(1): 177-199. |

| 34 | Jia S, Zhang C, Yuan X, et al. An optimization approach to find the thermodynamic limit on convective mass transfer enhancement for a given viscous dissipation[J]. Chemical Engineering Science, 2016, 146: 26-34. |

| [1] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [2] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [3] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [4] | 刘晓洋, 喻健良, 侯玉洁, 闫兴清, 张振华, 吕先舒. 螺旋微通道对掺氢甲烷爆轰传播的影响[J]. 化工学报, 2023, 74(7): 3139-3148. |

| [5] | 周小文, 杜杰, 张战国, 许光文. 基于甲烷脉冲法的Fe2O3-Al2O3载氧体还原特性研究[J]. 化工学报, 2023, 74(6): 2611-2623. |

| [6] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [7] | 朱兵国, 何吉祥, 徐进良, 彭斌. 冷却条件下渐扩/渐缩管内超临界压力二氧化碳的传热特性[J]. 化工学报, 2023, 74(3): 1062-1072. |

| [8] | 胡晗, 杨亮, 李春晓, 刘道平. 天然烟浸滤液水合物法储甲烷动力学研究[J]. 化工学报, 2023, 74(3): 1313-1321. |

| [9] | 张伟政, 赵吉军, 马学忠, 张琦璇, 庞益祥, 张俊涛. 湍流效应对高速机械密封端面型槽冷却性能影响分析[J]. 化工学报, 2023, 74(3): 1228-1238. |

| [10] | 彭晓婉, 郭笑楠, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8浆液法分离CH4/N2的双吸收-吸附塔工艺流程建模与模拟[J]. 化工学报, 2023, 74(2): 784-795. |

| [11] | 廖珊珊, 张少刚, 陶骏骏, 刘家豪, 汪金辉. 竖直射流火撞击障碍管道数值模拟分析[J]. 化工学报, 2022, 73(9): 4226-4234. |

| [12] | 王永倩, 王平, 程康, 毛晨林, 刘文锋, 尹智成, Ferrante Antonio. 氨气/甲烷贫预混旋转湍流火焰稳定性及NO生成[J]. 化工学报, 2022, 73(9): 4087-4094. |

| [13] | 沈嘉辉, 王侃宏, 郁达伟, 胡大洲, 魏源送. 游离氨调理污泥厌氧消化优化产甲烷过程与强化有机物释放[J]. 化工学报, 2022, 73(9): 4147-4155. |

| [14] | 张建伟, 高伟峰, 董鑫, 冯颖. 浸没式撞击流反应器流场涡特性的数值研究[J]. 化工学报, 2022, 73(8): 3553-3564. |

| [15] | 王利民, 郭舒宇, 向星, 付少童. 湍流系统的能量最小多尺度模型研究进展[J]. 化工学报, 2022, 73(6): 2415-2426. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号