化工学报 ›› 2022, Vol. 73 ›› Issue (2): 792-800.DOI: 10.11949/0438-1157.20211281

收稿日期:2021-09-03

修回日期:2021-10-30

出版日期:2022-02-05

发布日期:2022-02-18

通讯作者:

陈珺

作者简介:魏朋(1995—),男,硕士研究生,基金资助:

Peng WEI( ),Jun CHEN(

),Jun CHEN( ),Zhiguo WANG,Fei LIU

),Zhiguo WANG,Fei LIU

Received:2021-09-03

Revised:2021-10-30

Online:2022-02-05

Published:2022-02-18

Contact:

Jun CHEN

摘要:

在模拟移动床的实际工作过程中,由于进料浓度和温度变化以及色谱柱填充不一致等因素影响,初始工艺参数作业下的分离性能可能会出现下降。首先对模拟移动床的机理模型进行了分析;然后在色谱分离平衡理论的基础上,使用有限元正交配置法求解模型得到新的工艺参数点;最后以果葡糖浆组分分离为对象,使用所提方法求解有扰动作用时的优化工艺参数,结果显示果糖纯度的合格率从81%提高到99%,证明其具有良好的鲁棒性。

中图分类号:

魏朋, 陈珺, 王志国, 刘飞. 基于平衡理论的模拟移动床工艺参数鲁棒寻优[J]. 化工学报, 2022, 73(2): 792-800.

Peng WEI, Jun CHEN, Zhiguo WANG, Fei LIU. Robust optimization of process parameters of simulated moving bed based on equilibrium theory[J]. CIESC Journal, 2022, 73(2): 792-800.

| 模型参数 | 工艺参数 | ||

|---|---|---|---|

| 柱分布结构 | 2-2-2-2 | A的进料浓度 | 0.5 g/ml |

| 组分数 | 2 | B的进料浓度 | 0.5 g/ml |

| 柱长 | 53.6 cm | 进料液流量 | 0.0200 ml/s |

| 柱直径 | 2.6 cm | 洗脱液流量 | 0.0414 ml/s |

| 空隙率 | 0.38 | 提取液流量 | 0.0348 ml/s |

| 轴向扩散系数 | 0.0381 cm2/s | 提余液流量 | 0.0266 ml/s |

| A的Henry系数 | 0.54 | 循环液流量 | 0.0981 ml/s |

| B的Henry系数 | 0.28 | 切换时间 | 1552 s |

表1 模拟移动床模型参数及工艺参数

Table 1 Model parameters and process parameters of simulated moving bed

| 模型参数 | 工艺参数 | ||

|---|---|---|---|

| 柱分布结构 | 2-2-2-2 | A的进料浓度 | 0.5 g/ml |

| 组分数 | 2 | B的进料浓度 | 0.5 g/ml |

| 柱长 | 53.6 cm | 进料液流量 | 0.0200 ml/s |

| 柱直径 | 2.6 cm | 洗脱液流量 | 0.0414 ml/s |

| 空隙率 | 0.38 | 提取液流量 | 0.0348 ml/s |

| 轴向扩散系数 | 0.0381 cm2/s | 提余液流量 | 0.0266 ml/s |

| A的Henry系数 | 0.54 | 循环液流量 | 0.0981 ml/s |

| B的Henry系数 | 0.28 | 切换时间 | 1552 s |

图7 随机扰动作用下生成的300组正态分布值(L,ε)运行在初始工艺参数下得到的产品纯度和回收率(图(a)和(b)中的蓝点代表各自的性能达标,红点代表未达标;图(c)中的红点代表模型参数的原始值,蓝点代表正态分布值)

Fig.7 The product purity and recovery rate obtained by running 300 sets of normal distribution values ??(L,ε) generated under the random disturbance action under the initial process parameters

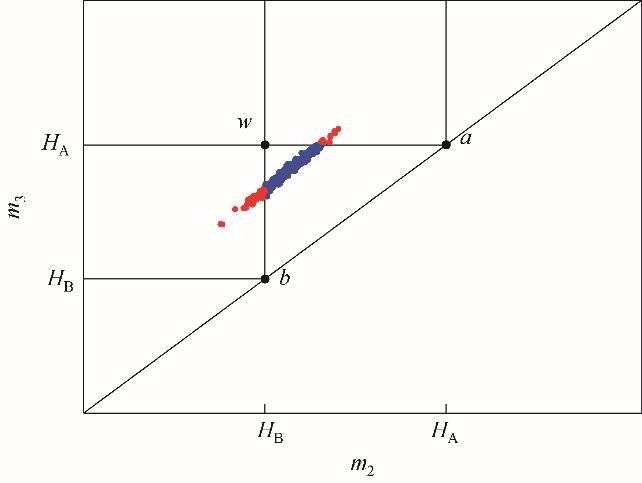

图8 初始工艺参数下样本点(L,ε)对应的流量比在m2-m3平面上的分布(红点代表落在了完全分离区域的外面,蓝点代表落在了完全分离区域的里面)

Fig.8 Distribution of the flow ratio corresponding to the sample point (L,ε) on the m2-m3 plane at the initial process parameters

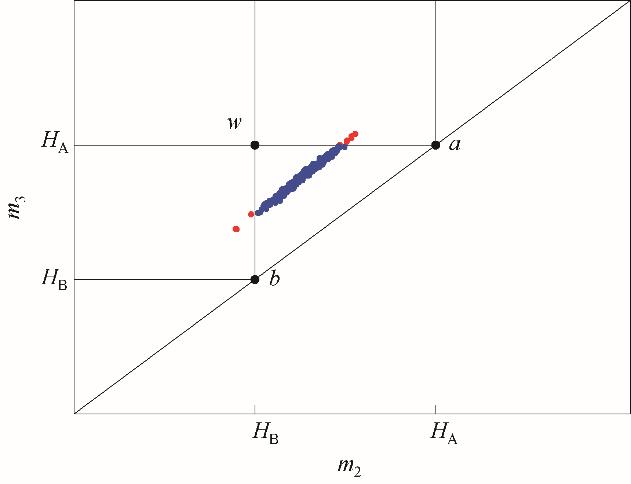

图9 鲁棒工艺参数下样本点(L,ε)对应的流量比在m2-m3平面上的分布(红点代表落在了完全分离区域的外面,蓝点代表落在了完全分离区域的里面)

Fig.9 Distribution of the flow ratio corresponding to the sample point (L,ε) on the m2-m3 plane at the robust process parameters

图10 随机扰动作用下生成的300组正态分布值(L,ε)运行在鲁棒工艺参数下得到的产品纯度和回收率(图(a)和(b)中的蓝点代表各自的性能达标,红点代表未达标;图(c)中的红点代表模型参数的原始值,蓝点代表正态分布值)

Fig.10 The product purity and recovery rate obtained by running 300 sets of normal distribution values (L,ε) generated under the random disturbance action under the robust process parameters

| 1 | 刘斌杰. 模拟移动床分离红霉素A和红霉素C的研究[D]. 上海: 华东理工大学, 2019. |

| Liu B J. Separation of erythromycin A and erythromycin C by simulated moving bed process[D]. Shanghai: East China University of Science and Technology, 2019. | |

| 2 | Broughton D, Gerhold C. Continuous sorption process employing fixed bed of sorbent and moving inlets and outlets: US2985589[P]. 1961. |

| 3 | 胡蓉. 二甲苯吸附分离过程建模与优化[D]. 上海: 华东理工大学, 2015. |

| Hu R. Modeling and optimization of xylene adsorption separation process[D]. Shanghai: East China University of Science and Technology, 2015. | |

| 4 | Aniceto J P S, Silva C M. Simulated moving bed strategies and designs: from established systems to the latest developments[J]. Separation & Purification Reviews, 2015, 44(1): 41-73. |

| 5 | Kim K M, Han K W, Kim S I, et al. Simulated moving bed with a product column for improving the separation performance[J]. Journal of Industrial and Engineering Chemistry, 2020, 88: 328-338. |

| 6 | Klatt K U, Hanisch F, Dünnebier G. Model-based control of a simulated moving bed chromatographic process for the separation of fructose and glucose[J]. Journal of Process Control, 2002, 12(2): 203-219. |

| 7 | Lee J, Shin N C, Lim Y, et al. Modeling and simulation of a simulated moving bed for adsorptive para-xylene separation[J]. Korean Journal of Chemical Engineering, 2010, 27(2): 609-618. |

| 8 | van Duc Long N, Le T H, Kim J I, et al. Separation of D-psicose and D-fructose using simulated moving bed chromatography[J]. Journal of Separation Science, 2009, 32(11): 1987-1995. |

| 9 | Ribeiro A E, Gomes P S, Pais L S, et al. Chiral separation of ketoprofen enantiomers by preparative and simulated moving bed chromatography[J]. Separation Science and Technology, 2011, 46(11): 1726-1739. |

| 10 | Li Y, Yu W F, Ding Z Y, et al. Equilibrium and kinetic differences of XOS2-XOS7 in xylo-oligosaccharides and their effects on the design of simulated moving bed purification process[J]. Separation and Purification Technology, 2019, 215: 360-367. |

| 11 | Sulaymon A H, Abid B A, Al-Najar J A. Removal of lead copper chromium and cobalt ions onto granular activated carbon in batch and fixed-bed adsorbers[J]. Chemical Engineering Journal, 2009, 155(3): 647-653. |

| 12 | Li Y, Ding Z Y, Wang J, et al. A comparison between simulated moving bed and sequential simulated moving bed system based on multi-objective optimization[J]. Chemical Engineering Science, 2020, 219: 115562. |

| 13 | Shen Y H, Fu Q, Zhang D H, et al. A systematic simulation and optimization of an industrial-scale p-xylene simulated moving bed process[J]. Separation and Purification Technology, 2018, 191: 48-60. |

| 14 | Li Y, Xu J, Yu W F, et al. Multi-objective optimization of sequential simulated moving bed for the purification of xylo-oligosaccharides[J]. Chemical Engineering Science, 2020, 211: 115279. |

| 15 | Matos J, Faria R P V, Nogueira I B R, et al. Optimization strategies for chiral separation by true moving bed chromatography using particles swarm optimization (PSO) and new parallel PSO variant[J]. Computers & Chemical Engineering, 2019, 123: 344-356. |

| 16 | 胡蓉, 杨明磊, 钱锋. 基于多目标教学优化算法在二甲苯吸附分离过程优化中的应用[J]. 化工学报, 2015, 66(1): 326-332. |

| Hu R, Yang M L, Qian F. Optimization of xylene adsorption separation process based on multi-objective teaching-learning-based optimization algorithm[J]. CIESC Journal, 2015, 66(1): 326-332. | |

| 17 | Degerman M, Jakobsson N, Nilsson B. Designing robust preparative purification processes with high performance[J]. Chemical Engineering & Technology, 2008, 31(6): 875-882. |

| 18 | Borg N, Westerberg K, Andersson N, et al. Effects of uncertainties in experimental conditions on the estimation of adsorption model parameters in preparative chromatography[J]. Computers & Chemical Engineering, 2013, 55: 148-157. |

| 19 | Nestola P, Silva R J S, Peixoto C, et al. Robust design of adenovirus purification by two-column, simulated moving-bed, size-exclusion chromatography[J]. Journal of Biotechnology, 2015, 213: 109-119. |

| 20 | Palani S, Gueorguieva L, Rinas U, et al. Recombinant protein purification using gradient-assisted simulated moving bed hydrophobic interaction chromatography(I): Selection of chromatographic system and estimation of adsorption isotherms[J]. Journal of Chromatography A, 2011, 1218(37): 6396-6401. |

| 21 | Degerman M, Westerberg K, Nilsson B. A model-based approach to determine the design space of preparative chromatography[J]. Chemical Engineering & Technology, 2009, 32(8): 1195-1202. |

| 22 | Minceva M, Rodrigues A E. Modeling and simulation of a simulated moving bed for the separation of p-xylene[J]. Industrial & Engineering Chemistry Research, 2002, 41(14): 3454-3461. |

| 23 | Silva A D, Mariani V C, de Souza A A U, et al. Numerical study of n-pentane separation using adsorption column[J]. Brazilian Archives of Biology and Technology, 2005, 48(s): 267-274. |

| 24 | Araújo J M M, Rodrigues R C R, Mota J P B. Use of single-column models for efficient computation of the periodic state of a simulated moving-bed process[J]. Industrial & Engineering Chemistry Research, 2006, 45(15): 5314-5325. |

| 25 | Cui S X, Gao G, Jiang L J, et al. Non-matching grid interface treatment for the space-time conservation element and solution element method[J]. Procedia Engineering, 2012, 31: 1115-1124. |

| 26 | Arora S, Dhaliwal S S, Kukreja V K. Solution of two point boundary value problems using orthogonal collocation on finite elements[J]. Applied Mathematics and Computation, 2005, 171(1): 358-370. |

| 27 | Arora S, Dhaliwal S S, Kukreja V K. Simulation of washing of packed bed of porous particles by orthogonal collocation on finite elements[J]. Computers & Chemical Engineering, 2006, 30(6/7): 1054-1060. |

| 28 | Storti G, Mazzotti M, Morbidelli M, et al. Robust design of binary countercurrent adsorption separation processes[J]. AIChE Journal, 1993, 39(3): 471-492. |

| 29 | Beyer P L, Caviar E M, McCallum R W. Fructose intake at current levels in the United States may cause gastrointestinal distress in normal adults[J]. Journal of the American Dietetic Association, 2005, 105(10): 1559-1566. |

| 30 | Katsuo S, Mazzotti M. Intermittent simulated moving bed chromatography(Ⅱ): Separation of Tröger's base enantiomers[J]. Journal of Chromatography A, 2010, 1217(18): 3067-3075. |

| 31 | 沈圆辉. 对二甲苯模拟移动床分离过程的模拟与优化[D]. 天津: 天津大学, 2016. |

| Shen Y H. Simulation and optimization of simulated moving bed process for p-xylene separation[D]. Tianjin: Tianjin University, 2016. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [3] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [4] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [5] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [6] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [9] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [10] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [11] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [12] | 朱兴驰, 郭志远, 纪志永, 汪婧, 张盼盼, 刘杰, 赵颖颖, 袁俊生. 选择性电渗析镁锂分离过程模拟优化[J]. 化工学报, 2023, 74(6): 2477-2485. |

| [13] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [14] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| [15] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号