化工学报 ›› 2022, Vol. 73 ›› Issue (11): 5078-5087.DOI: 10.11949/0438-1157.20220937

黄笑乐1( ), 杨甫2,3, 韩磊1, 宁星1, 李瑞宇1,4, 董凌霄1, 曹虎生5, 邓磊1(

), 杨甫2,3, 韩磊1, 宁星1, 李瑞宇1,4, 董凌霄1, 曹虎生5, 邓磊1( ), 车得福1

), 车得福1

收稿日期:2022-07-05

修回日期:2022-08-22

出版日期:2022-11-05

发布日期:2022-12-06

通讯作者:

邓磊

作者简介:黄笑乐(1997—),男,博士研究生,1969912151@qq.com

基金资助:

Xiaole HUANG1( ), Fu YANG2,3, Lei HAN1, Xing NING1, Ruiyu LI1,4, Lingxiao DONG1, Husheng CAO5, Lei DENG1(

), Fu YANG2,3, Lei HAN1, Xing NING1, Ruiyu LI1,4, Lingxiao DONG1, Husheng CAO5, Lei DENG1( ), Defu CHE1

), Defu CHE1

Received:2022-07-05

Revised:2022-08-22

Online:2022-11-05

Published:2022-12-06

Contact:

Lei DENG

摘要:

采用X射线CT(computed tomography)成像仪对富油煤(长焰煤)进行了三维表征,建立了统计孔径分布(PSD)的等效孔隙网络模型(PNM),研究了压力梯度和流动方向对渗流过程的影响。结果表明:孔隙、矿物和基质分别占总体积的11.30%、1.03%和87.67%,连通孔隙率为5.13%。孔隙等效半径在3~8 μm内的数量占89.23%,平均配位数为2.87,孔隙连通性较差。等效半径小于2 μm的喉道数占73%,喉道的等效长度主要分布在10~30 μm之间。在相同压力梯度下,三个方向的孔隙压力、渗流速度和流动路径分布不同,表现出各向异性。随着压力梯度的增大,渗流速度逐渐增大,且渗流速度随压力的变化呈现明显的非线性关系。三个方向上的调和平均渗透率为0.1403 mD,这与前人测得的榆神府矿区富油煤渗透率(0.1345 mD)相差在5%以内。

中图分类号:

黄笑乐, 杨甫, 韩磊, 宁星, 李瑞宇, 董凌霄, 曹虎生, 邓磊, 车得福. 富油煤(长焰煤)孔隙结构三维表征及渗流模拟[J]. 化工学报, 2022, 73(11): 5078-5087.

Xiaole HUANG, Fu YANG, Lei HAN, Xing NING, Ruiyu LI, Lingxiao DONG, Husheng CAO, Lei DENG, Defu CHE. 3D characterization of pore structure and seepage simulation of tar-rich coal (long flame coal)[J]. CIESC Journal, 2022, 73(11): 5078-5087.

| 元素分析/% | 工业分析/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cd | Hd | Od | Nd | St,d | FCad | Mad | Aad | Vad | |

| 81.28 | 4.42 | 10.12 | 0.89 | 0.52 | 63.16 | 6.01 | 2.60 | 28.23 | |

表1 富油煤的工业分析和元素分析

Table 1 Ultimate and proximate analyses of tar-rich coal

| 元素分析/% | 工业分析/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cd | Hd | Od | Nd | St,d | FCad | Mad | Aad | Vad | |

| 81.28 | 4.42 | 10.12 | 0.89 | 0.52 | 63.16 | 6.01 | 2.60 | 28.23 | |

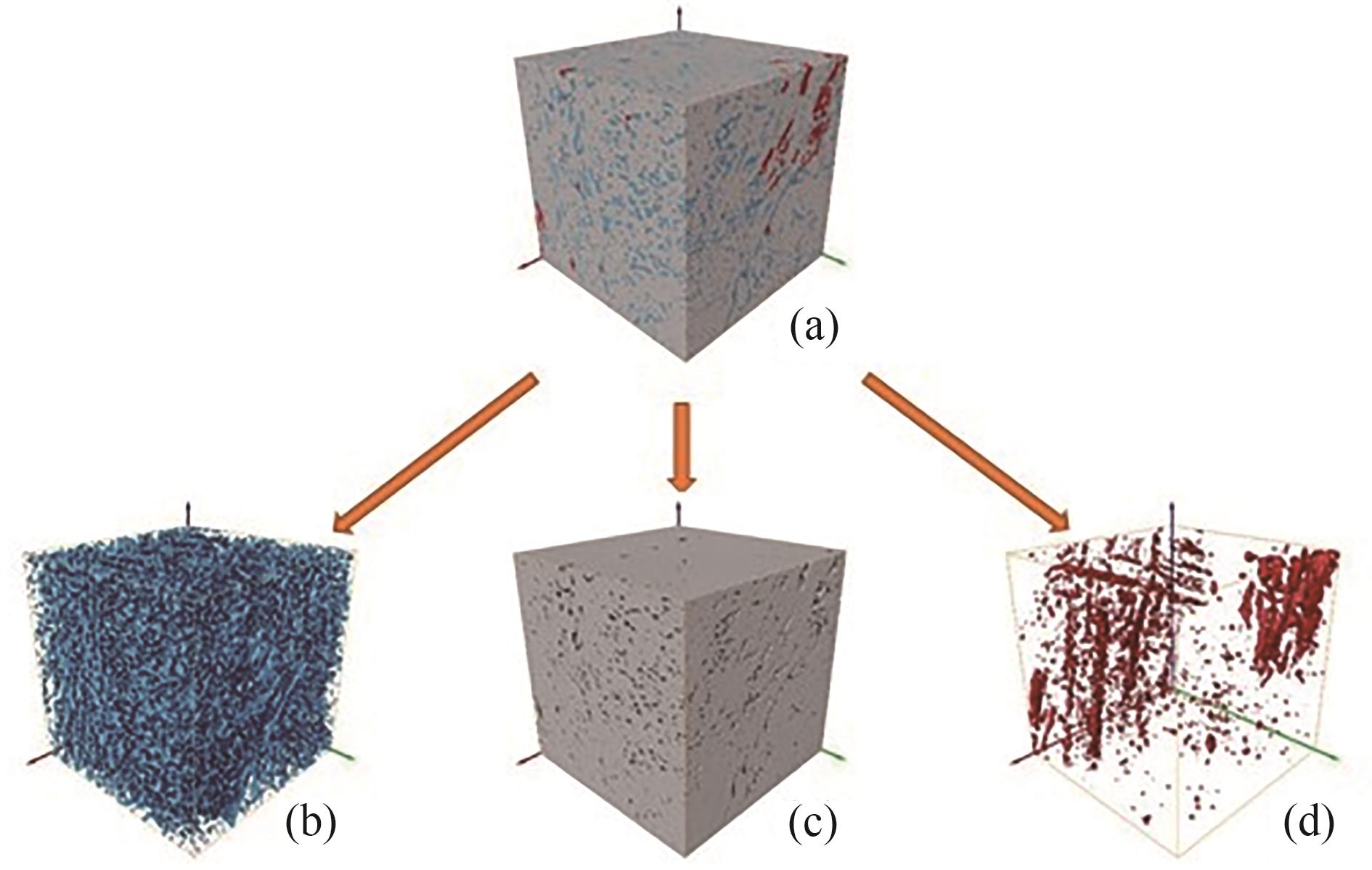

图3 富油煤三维数字模型(a)完整模型;(b)孔隙模型;(c)基质模型;(d)矿物质模型

Fig.3 3D digital model of tar-rich coal(a) complete model; (b) pore model; (c) matrix model; (d) mineral model

| 组分 | 体积 分数/% | 各组分 体积/μm3 | 总体积/ μm3 | 各组分 体素 | 总体素 |

|---|---|---|---|---|---|

| 孔隙 | 11.30 | 1731600 | 15326000 | 4844250 | 42875000 |

| 矿物质 | 1.03 | 157900 | 15326000 | 441723 | 42875000 |

| 煤基质 | 87.67 | 13437000 | 15326000 | 37589000 | 42875000 |

表2 富油煤样各组分含量

Table 2 Content of various components in tar-rich coal samples

| 组分 | 体积 分数/% | 各组分 体积/μm3 | 总体积/ μm3 | 各组分 体素 | 总体素 |

|---|---|---|---|---|---|

| 孔隙 | 11.30 | 1731600 | 15326000 | 4844250 | 42875000 |

| 矿物质 | 1.03 | 157900 | 15326000 | 441723 | 42875000 |

| 煤基质 | 87.67 | 13437000 | 15326000 | 37589000 | 42875000 |

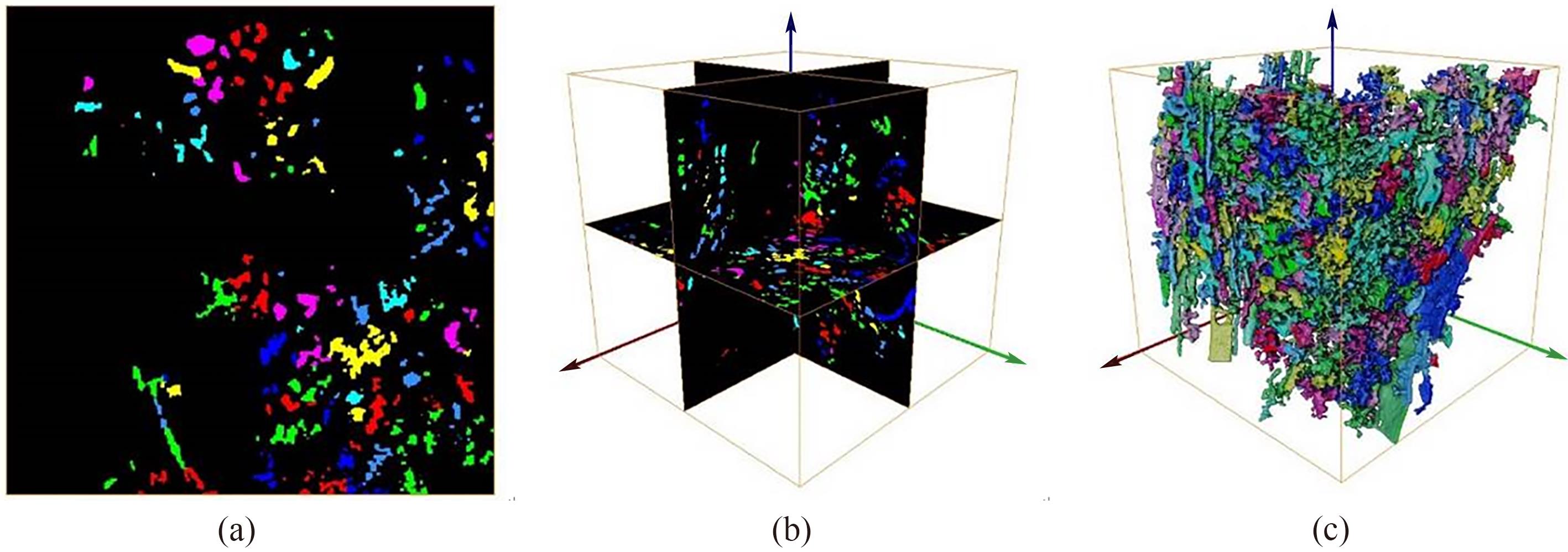

图4 连通孔的分离和标记示意图(a) XY方向的连通孔;(b)三维正交切片;(c)连通孔的体绘制

Fig.4 Separation and labeling of connected pores(a) connected pores in XY direction; (b) 3D orthogonal slice; (c) volume rendering of connected pores

图6 PNM的孔径分布(PSD)图(a)孔隙当量半径;(b)孔隙配位数;(c)喉道等效半径;(d)喉道长度

Fig.6 Pore size distribution (PSD) of PNM(a) pore equivalent radius; (b) pore coordination number; (c) throat equivalent radius; (d) throat length

| 参数 | 孔径/μm | 连通孔隙 体积/μm3 | 喉道 半径/μm | 喉道 长度/μm | 配位数 |

|---|---|---|---|---|---|

| 最大值 | 14.09 | 11727.11 | 11.04 | 75.51 | 16 |

| 最小值 | 2.51 | 66.49 | 0.19 | 6.40 | 0 |

| 平均值 | 5.80 | 1058.96 | 1.63 | 21.35 | 2.87 |

表3 孔隙网络模型定量参数

Table 3 Quantitative parameters of pore network model

| 参数 | 孔径/μm | 连通孔隙 体积/μm3 | 喉道 半径/μm | 喉道 长度/μm | 配位数 |

|---|---|---|---|---|---|

| 最大值 | 14.09 | 11727.11 | 11.04 | 75.51 | 16 |

| 最小值 | 2.51 | 66.49 | 0.19 | 6.40 | 0 |

| 平均值 | 5.80 | 1058.96 | 1.63 | 21.35 | 2.87 |

| 大小 | 渗流方向 | Q/(m3/s) | A/μm2 | ki /mD | 平均渗透率/mD | ||

|---|---|---|---|---|---|---|---|

| 几何 平均 | 算术 平均 | 调和 平均 | |||||

| 50×50×50体素 | X | 1.3118×10-10 | 1259.19 | 0.1458 | 0.1422 | 0.1441 | 0.1403 |

| Y | 1.0358×10-10 | 1259.19 | 0.1151 | ||||

| Z | 1.5421×10-10 | 1259.19 | 0.1714 | ||||

表4 不同方向上的渗透率模拟结果

Table 4 Permeability simulation results in different directions

| 大小 | 渗流方向 | Q/(m3/s) | A/μm2 | ki /mD | 平均渗透率/mD | ||

|---|---|---|---|---|---|---|---|

| 几何 平均 | 算术 平均 | 调和 平均 | |||||

| 50×50×50体素 | X | 1.3118×10-10 | 1259.19 | 0.1458 | 0.1422 | 0.1441 | 0.1403 |

| Y | 1.0358×10-10 | 1259.19 | 0.1151 | ||||

| Z | 1.5421×10-10 | 1259.19 | 0.1714 | ||||

| 模拟类型 | 氮气密度 ρ/(kg/m3) | 气体动力黏度 μ/(Pa⋅s) | 进口压力 Pin/MPa | 出口压力 Pout/MPa |

|---|---|---|---|---|

| 稳态 | 0.3698 | 3.9434×10-5 | 1.1 | 0.1 |

表5 模拟的基本参数

Table 5 Basic parameters of simulation

| 模拟类型 | 氮气密度 ρ/(kg/m3) | 气体动力黏度 μ/(Pa⋅s) | 进口压力 Pin/MPa | 出口压力 Pout/MPa |

|---|---|---|---|---|

| 稳态 | 0.3698 | 3.9434×10-5 | 1.1 | 0.1 |

| 1 | 王双明, 孙强, 乔军伟, 等. 论煤炭绿色开采的地质保障[J]. 煤炭学报, 2020, 45(1): 8-15. |

| Wang S M, Sun Q, Qiao J W, et al. Geological guarantee of coal green mining[J]. Journal of China Coal Society, 2020, 45(1): 8-15. | |

| 2 | 中国石油集团经济技术研究院. 2021年国内外油气行业发展报告[M]. 北京: 石油工业出版社, 2022. |

| CNPC Institute of Economic Technology. Report on Domestic and International Oil and Gas Industry in 2021[M]. Beijing: Petroleum Industry Press, 2022. | |

| 3 | 王韶华. 基于低碳经济的我国能源结构优化研究[D]. 哈尔滨: 哈尔滨工程大学, 2013. |

| Wang S H. Research on the optimization of China's energy structure based on low-carbon economy[D]. Harbin: Harbin Engineering University, 2013. | |

| 4 | Yang H, Ma L. Study on distribution law and occurrence characteristics of rich oil in Zichang Mining area[J]. World Scientific Research Journal, 2020,6(1). |

| 5 | 马丽, 王双明, 段中会, 等. 陕西省富油煤资源潜力及开发建议[J]. 煤田地质与勘探, 2022, 50(2): 1-8. |

| Ma L, Wang S M, Duan Z H, et al. Potential of oil-rich coal resources in Shaanxi Province and its new development suggestion[J]. Coal Geology & Exploration, 2022, 50(2): 1-8. | |

| 6 | Clayton J L, Rice D D, Michael G E. Oil-generating coals of the San Juan Basin, new Mexico and Colorado, USA[J]. Organic Geochemistry, 1991, 17(6): 735-742. |

| 7 | Kang Z Q, Zhao Y S, Yang D. Review of oil shale in situ conversion technology[J]. Applied Energy, 2020, 269: 115121. |

| 8 | Xin C Y, Lu L, Shi B B, et al. Numerical investigation of local thermal non-equilibrium effects in coal porous media with cryogenic nitrogen injection[J]. International Journal of Thermal Sciences, 2018, 133: 32-40. |

| 9 | Wen H, Lu J H, Xiao Y, et al. Temperature dependence of thermal conductivity, diffusion and specific heat capacity for coal and rocks from coalfield[J]. Thermochimica Acta, 2015, 619: 41-47. |

| 10 | 杨海平, 陈汉平, 鞠付栋, 等. 热解温度对神府煤热解与气化特性的影响[J]. 中国电机工程学报, 2008, 28(8): 40-45. |

| Yang H P, Chen H P, Ju F D, et al. Influence of temperature on coal pyrolysis and char gasification[J]. Proceedings of the CSEE, 2008, 28(8): 40-45. | |

| 11 | 周长冰, 万志军, 张源, 等. 气煤热力耦合变形与孔隙演化特征的实验研究[J]. 中南大学学报(自然科学版), 2014, 45(7): 2440-2446. |

| Zhou C B, Wan Z J, Zhang Y, et al. Experimental study on coupled thermo-mechanical deformation and pore evolution feature of gas coal[J]. Journal of Central South University (Science and Technology), 2014, 45(7): 2440-2446. | |

| 12 | Zhao Y X, Sun Y F, Liu S M, et al. Pore structure characterization of coal by NMR cryoporometry[J]. Fuel, 2017, 190: 359-369. |

| 13 | Zhang R, Ai T, Li H G, et al. 3D reconstruction method and connectivity rules of fracture networks generated under different mining layouts[J]. International Journal of Mining Science and Technology, 2013, 23(6): 863-871. |

| 14 | Fan N, Wang J R, Deng C B, et al. Quantitative characterization of coal microstructure and visualization seepage of macropores using CT-based 3D reconstruction[J]. Journal of Natural Gas Science and Engineering, 2020, 81: 103384. |

| 15 | Zhu L Q, Zhang C, Zhang C M, et al. Challenges and prospects of digital core-reconstruction research[J]. Geofluids, 2019, 2019: 7814180. |

| 16 | 王刚, 杨鑫祥, 张孝强, 等. 基于DTM阈值分割法的孔裂隙煤岩体瓦斯渗流数值模拟[J]. 岩石力学与工程学报, 2016, 35(1): 119-129. |

| Wang G, Yang X X, Zhang X Q, et al. Numerical simulation of gas flow in pores and fissures of coal based on segmentation of DTM threshold[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(1): 119-129. | |

| 17 | Yao Y B, Liu D M, Che Y, et al. Non-destructive characterization of coal samples from China using microfocus X-ray computed tomography[J]. International Journal of Coal Geology, 2009, 80(2): 113-123. |

| 18 | Ni X M, Miao J, Lv R S, et al. Quantitative 3D spatial characterization and flow simulation of coal macropores based on μCT technology[J]. Fuel, 2017, 200: 199-207. |

| 19 | 乔俊程, 曾溅辉, 夏宇轩, 等. 微纳米孔隙网络中天然气充注的三维可视化物理模拟[J]. 石油勘探与开发, 2022, 49(2): 306-318. |

| Qiao J C, Zeng J H, Xia Y X, et al. A three dimensional visualized physical simulation for natural gas charging in the micro-nano pore system[J]. Petroleum Exploration and Development, 2022, 49(2): 306-318. | |

| 20 | Wang G, Shen J N, Liu S M, et al. Three-dimensional modeling and analysis of macro-pore structure of coal using combined X-ray CT imaging and fractal theory[J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 123: 104082. |

| 21 | Jing Y, Armstrong R T, Mostaghimi P. Digital coal: generation of fractured cores with microscale features[J]. Fuel, 2017, 207: 93-101. |

| 22 | 陆韬杰, 胥蕊娜, 姜培学. 基于低场核磁共振的煤粉动态吸附测量[J]. 化工学报, 2020, 71(S2): 195-200. |

| Lu T J, Xu R N, Jiang P X. Dynamic adsorption measurement of coal particles based on low field NMR[J]. CIESC Journal, 2020, 71(S2): 195-200. | |

| 23 | 李伟, 要惠芳, 刘鸿福, 等. 基于显微CT的不同煤体结构煤三维孔隙精细表征[J]. 煤炭学报, 2014, 39(6): 1127-1132. |

| Li W, Yao H F, Liu H F, et al. Advanced characterization of three-dimensional pores in coals with different coal-body structure by micro-CT[J]. Journal of China Coal Society, 2014, 39(6): 1127-1132. | |

| 24 | 范楠. 煤孔隙结构多尺度表征及其对瓦斯运移特性影响的实验研究[D]. 阜新: 辽宁工程技术大学, 2021. |

| Fan N. Experimental study on multi-scale pore structure characterization of coal and its effect on gas migration characteristics[D]. Fuxin: Liaoning Technical University, 2021. | |

| 25 | 焦华喆, 王树飞, 吴爱祥, 等. 膏体浓密床层孔隙结构剪切演化与连通机理[J]. 中南大学学报(自然科学版), 2019, 50(5): 1173-1180. |

| Jiao H Z, Wang S F, Wu A X, et al. Shear evolution and connected mechanism of pore structure in thickening bed of paste[J]. Journal of Central South University (Science and Technology), 2019, 50(5): 1173-1180. | |

| 26 | 苗杰. 低渗煤岩大孔隙结构三维重构及渗流模拟[D]. 焦作: 河南理工大学, 2017. |

| Miao J. 3D reconstruction and seepage simulation of macropores structure in low permeability coal[D]. Jiaozuo: Henan Polytechnic University, 2017. | |

| 27 | 王刚, 沈俊男, 褚翔宇, 等. 基于CT三维重建的高阶煤孔裂隙结构综合表征和分析[J]. 煤炭学报, 2017, 42(8): 2074-2080. |

| Wang G, Shen J N, Chu X Y, et al. Characterization and analysis of pores and fissures of high-rank coal based on CT three-dimensional reconstruction[J]. Journal of China Coal Society, 2017, 42(8): 2074-2080. | |

| 28 | 申艳军, 王旭, 赵春虎, 等. 榆神府矿区富油煤多尺度孔隙结构特征[J]. 煤田地质与勘探, 2021, 49(3): 33-41. |

| Shen Y J, Wang X, Zhao C H, et al. Experimental study on multi-scale pore structure characteristics of tar-rich coal in Yushenfu mining area[J]. Coal Geology & Exploration, 2021, 49(3): 33-41. | |

| 29 | 王志国, 冯艳, 杨文哲, 等. 基于REV的孔隙型多孔介质导热分析模型[J]. 化工学报, 2020, 71(S2): 118-126. |

| Wang Z G, Feng Y, Yang W Z, et al. Thermal conductivity analysis model of porous media based on REV[J]. CIESC Journal, 2020, 71(S2): 118-126. | |

| 30 | 师庆民, 王双明, 王生全, 等. 神府南部延安组富油煤多源判识规律[J]. 煤炭学报, 2022, 47(5): 2057-2066. |

| Shi Q M, Wang S M, Wang S Q, et al. Multi-source identification and internal relationship of tar-rich coal of the Yan'an formation in the south of Shenfu[J]. Journal of China Coal Society, 2022, 47(5): 2057-2066. | |

| 31 | 陈书荣, 王达健, 张雄飞, 等. 多孔介质孔隙结构的网络模型应用[J]. 计算机与应用化学, 2001, 18(S1): 531-535. |

| Chen S R, Wang D J, Zhang X F, et al. Applications of network models for pore structure medias[J]. Computers and Applied Chemistry, 2001, 18(S1): 531-535. | |

| 32 | 高慧梅, 姜汉桥, 陈民锋. 多孔介质孔隙网络模型的应用现状[J]. 大庆石油地质与开发, 2007, 26(2): 74-79. |

| Gao H M, Jiang H Q, Chen M F. Application on pore network model of porous media[J]. Petroleum Geology & Oilfield Development in Daqing, 2007, 26(2): 74-79. | |

| 33 | 马斌, 马跃征, 史琳. 孔隙特性参数对排驱过程影响的实验研究[J]. 化工学报, 2018, 69(8): 3436-3442. |

| Ma B, Ma Y Z, Shi L. Experimental study on pore characters effect on drainage process[J]. CIESC Journal, 2018, 69(8): 3436-3442. | |

| 34 | 尹升华, 王雷鸣, 陈勋, 等. 不同堆体结构下矿岩散体内溶液渗流规律[J]. 中南大学学报(自然科学版), 2018, 49(4): 949-956. |

| Yin S H, Wang L M, Chen X, et al. Seepage law of solution inside ore granular under condition of different heap constructions[J]. Journal of Central South University (Science and Technology), 2018, 49(4): 949-956. | |

| 35 | 车禹恒. 基于X-ray μCT扫描的煤孔隙瓦斯微观渗流各向异性特征研究[J]. 矿业安全与环保, 2021, 48(4): 12-17. |

| Che Y H. Research on the anisotropic characteristics of gas microscopic seepage in coal pores based on X-ray μCT scanning[J]. Mining Safety & Environmental Protection, 2021, 48(4): 12-17. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [9] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [10] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [11] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [12] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [13] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [14] | 于源, 陈薇薇, 付俊杰, 刘家祥, 焦志伟. 几何相似涡流空气分级机环形区流场变化规律研究及预测[J]. 化工学报, 2023, 74(6): 2363-2373. |

| [15] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号