化工学报 ›› 2024, Vol. 75 ›› Issue (1): 292-301.DOI: 10.11949/0438-1157.20230848

王雪杰( ), 崔国庆(

), 崔国庆( ), 王文涵, 杨扬, 王淙恺, 姜桂元(

), 王文涵, 杨扬, 王淙恺, 姜桂元( ), 徐春明(

), 徐春明( )

)

收稿日期:2023-08-17

修回日期:2023-12-12

出版日期:2024-01-25

发布日期:2024-03-11

通讯作者:

姜桂元,徐春明

作者简介:王雪杰(1996—),女,博士研究生,sddzwangxuejie@163.com基金资助:

Xuejie WANG( ), Guoqing CUI(

), Guoqing CUI( ), Wenhan WANG, Yang YANG, Congkai WANG, Guiyuan JIANG(

), Wenhan WANG, Yang YANG, Congkai WANG, Guiyuan JIANG( ), Chunming XU(

), Chunming XU( )

)

Received:2023-08-17

Revised:2023-12-12

Online:2024-01-25

Published:2024-03-11

Contact:

Guiyuan JIANG, Chunming XU

摘要:

高效储氢技术研发是实现氢能规模化应用的关键。甲基环己烷(MCH)作为理想的有机液体储氢介质,具有质量储氢密度高、储运安全方便等优势,但其脱氢过程仍存在反应温度高、效率低等难题,开发高效脱氢催化剂并引入有效的过程强化是解决上述问题的关键。以不同焙烧温度得到的氮掺杂多孔碳(NPC)作为载体,通过浸渍法制备了系列NPC负载Pt的催化剂(Pt/NPC),在新型电内加热(IEH)模式下,研究了其对MCH脱氢反应性能的影响规律。研究结果表明,随着NPC焙烧温度的升高,Pt2+占比先增加后减少,并在550℃达到最大值。在MCH脱氢反应中,Pt2+占比与反应速率呈近似线性正相关。在优化的Pt/NPC催化剂上,IEH模式下的释氢速率约为传统外加热(CEH)模式的3倍。组合温度测量、反应热与传热计算、性能评价和原位红外表征结果阐明了IEH模式下高的加热速率与传热速率,以及增强的MCH吸附是提升催化性能的重要原因。本研究可为新型电内加热反应方式及与之相匹配高效催化剂的设计研发提供指导。

中图分类号:

王雪杰, 崔国庆, 王文涵, 杨扬, 王淙恺, 姜桂元, 徐春明. 电内加热Pt/NPC催化剂高效催化甲基环己烷脱氢反应研究[J]. 化工学报, 2024, 75(1): 292-301.

Xuejie WANG, Guoqing CUI, Wenhan WANG, Yang YANG, Congkai WANG, Guiyuan JIANG, Chunming XU. Study on highly efficient methylcyclohexane dehydrogenation over Pt/NPC catalysts by internal electric heating[J]. CIESC Journal, 2024, 75(1): 292-301.

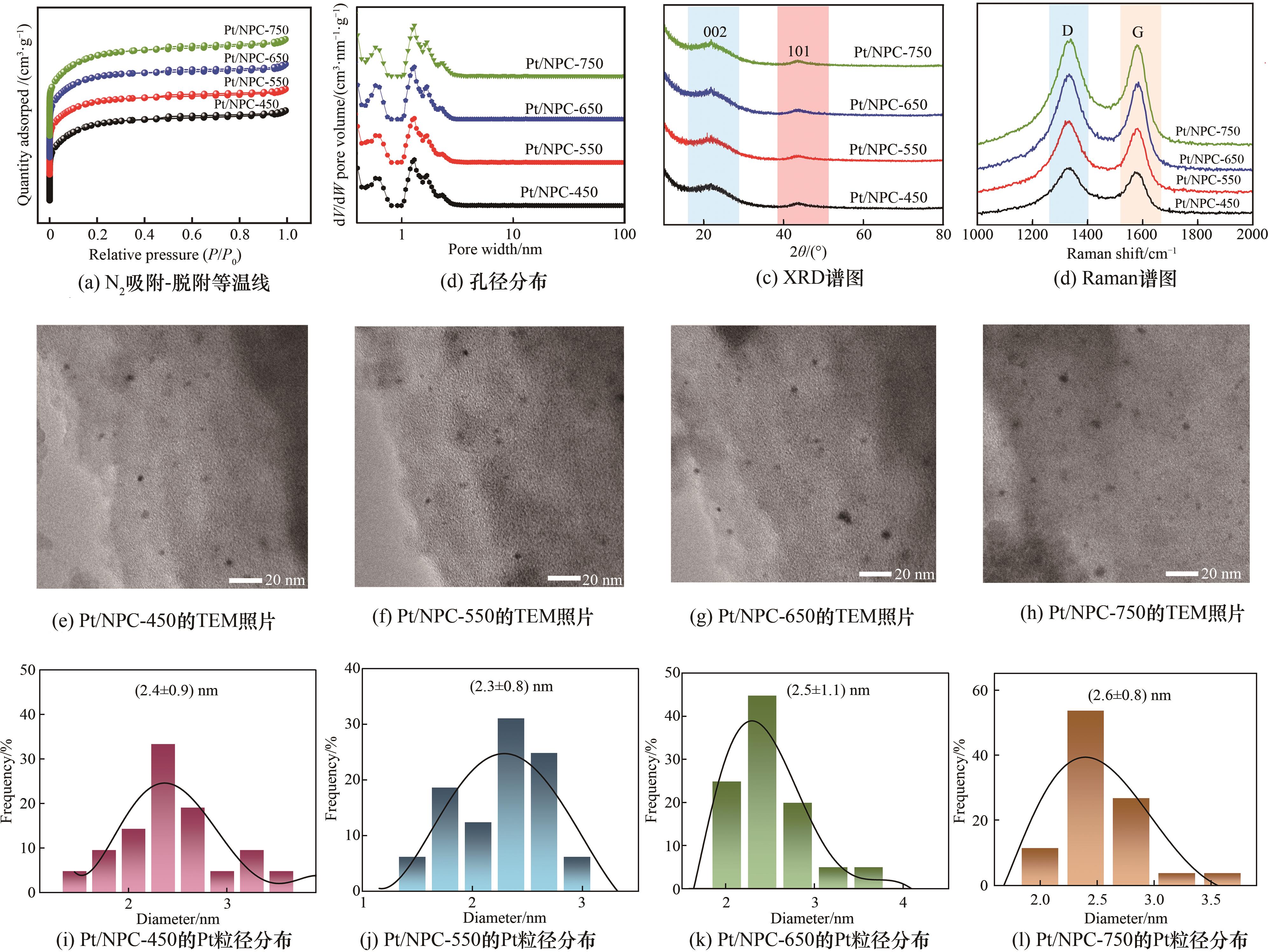

图1 Pt/NPC基系列催化剂的N2吸附-脱附等温线、孔径分布、XRD谱图、拉曼谱图、TEM照片及Pt粒径分布

Fig.1 N2 adsorption-desorption isotherms and pore size distribution curves, XRD patterns, Raman spectra, TEM images and Pt particle size distribution of Pt/NPC based catalysts

| 样品 | SBET/(m2·g-1) | dBJH/nm | Pt质量分数/% | ID/IG | 分散度/% | N含量/% | [Pt2+/(Pt0+Pt2+)]/% |

|---|---|---|---|---|---|---|---|

| Pt/NPC-450 | 1254 | 1.9 | 0.96 | 1.07 | 62.5 | 1.68 | 50.1 |

| Pt/NPC-550 | 1296 | 2.0 | 0.98 | 1.10 | 65.3 | 1.93 | 55.4 |

| Pt/NPC-650 | 1250 | 1.9 | 1.03 | 1.08 | 64.2 | 1.86 | 53.0 |

| Pt/NPC-750 | 1238 | 1.9 | 1.04 | 1.05 | 61.9 | 1.69 | 48.2 |

表1 Pt/NPC基系列催化剂的织构性质

Table 1 Textural parameters of Pt/NPC based catalysts

| 样品 | SBET/(m2·g-1) | dBJH/nm | Pt质量分数/% | ID/IG | 分散度/% | N含量/% | [Pt2+/(Pt0+Pt2+)]/% |

|---|---|---|---|---|---|---|---|

| Pt/NPC-450 | 1254 | 1.9 | 0.96 | 1.07 | 62.5 | 1.68 | 50.1 |

| Pt/NPC-550 | 1296 | 2.0 | 0.98 | 1.10 | 65.3 | 1.93 | 55.4 |

| Pt/NPC-650 | 1250 | 1.9 | 1.03 | 1.08 | 64.2 | 1.86 | 53.0 |

| Pt/NPC-750 | 1238 | 1.9 | 1.04 | 1.05 | 61.9 | 1.69 | 48.2 |

| 催化剂 | 温度/℃ | MCH进料量/(ml·min-1) | Pt负载量/ %(质量分数) | MCH转化率/% | 释氢速率/ (mmol·g-1·min-1) | 文献 |

|---|---|---|---|---|---|---|

| Pt/NPC-550-CEH | 300 | 0.05 | 1.00 | 18.0 | 1086.0 | this work |

| Pt/NPC-550-IEH | 300 | 0.05 | 1.00 | 60.0 | 3620.0 | this work |

| Pt/PTC-S | 300 | 0.03 | 0.20 | 84.3 | 991.5 | [ |

| Pt/Al2O3/FF-IEH | 300 | 0.02 | 0.69 | 59.0 | 2060.0 | [ |

| Pt/CS | 320 | 0.03 | 0.37 | 87.0 | 575.0 | [ |

| Pt/SBA-15 | 300 | 0.03 | 3.00 | 65.0 | 314.0 | [ |

| Pt/Ce-Mg-Al-O | 300 | 0.10 | 0.35 | 49.8 | 686.9 | [ |

| Pt/CeO2 | 350 | 0.05 | 0.15 | 23.3 | 2509 | [ |

| Pt3(Fe0.75Zn0.25)/SiO2 | 350 | 0.06 | 3.00 | 71.2 | 757.0 | [ |

| Pt/pyrolytic waste activated carbon | 300 | 0.03 | 0.40 | 95.0 | 307.0 | [ |

| Pt/coconut activated carbon | 300 | 0.03 | 1.00 | 42.0 | 608.2 | [ |

| Pt/GAC-S | 300 | 0.03 | 0.20 | 63.0 | 741.1 | [ |

表2 Pt/NPC-550催化剂与其他Pt基催化剂的MCH脱氢性能对比

Table 2 Comparison of MCH dehydrogenation over Pt/NPC-550 catalyst and other reported Pt-based catalysts

| 催化剂 | 温度/℃ | MCH进料量/(ml·min-1) | Pt负载量/ %(质量分数) | MCH转化率/% | 释氢速率/ (mmol·g-1·min-1) | 文献 |

|---|---|---|---|---|---|---|

| Pt/NPC-550-CEH | 300 | 0.05 | 1.00 | 18.0 | 1086.0 | this work |

| Pt/NPC-550-IEH | 300 | 0.05 | 1.00 | 60.0 | 3620.0 | this work |

| Pt/PTC-S | 300 | 0.03 | 0.20 | 84.3 | 991.5 | [ |

| Pt/Al2O3/FF-IEH | 300 | 0.02 | 0.69 | 59.0 | 2060.0 | [ |

| Pt/CS | 320 | 0.03 | 0.37 | 87.0 | 575.0 | [ |

| Pt/SBA-15 | 300 | 0.03 | 3.00 | 65.0 | 314.0 | [ |

| Pt/Ce-Mg-Al-O | 300 | 0.10 | 0.35 | 49.8 | 686.9 | [ |

| Pt/CeO2 | 350 | 0.05 | 0.15 | 23.3 | 2509 | [ |

| Pt3(Fe0.75Zn0.25)/SiO2 | 350 | 0.06 | 3.00 | 71.2 | 757.0 | [ |

| Pt/pyrolytic waste activated carbon | 300 | 0.03 | 0.40 | 95.0 | 307.0 | [ |

| Pt/coconut activated carbon | 300 | 0.03 | 1.00 | 42.0 | 608.2 | [ |

| Pt/GAC-S | 300 | 0.03 | 0.20 | 63.0 | 741.1 | [ |

| 1 | Sun Q M, Wang N, Xu Q, et al. Nanopore-supported metal nanocatalysts for efficient hydrogen generation from liquid-phase chemical hydrogen storage materials[J]. Advanced Materials, 2020, 32(44): 2001818-2001860. |

| 2 | Wang C L, Astruc D. Recent developments of nanocatalyzed liquid-phase hydrogen generation[J]. Chemical Society Reviews, 2021, 50(5): 3437-3484. |

| 3 | Zheng J, Zhou H, Wang C G, et al. Current research progress and perspectives on liquid hydrogen rich molecules in sustainable hydrogen storage[J]. Energy Storage Materials, 2021, 35: 695-722. |

| 4 | Meng J C, Zhou F, Ma H X, et al. A review of catalysts for methylcyclohexane dehydrogenation[J]. Topics in Catalysis, 2021, 64(7): 509-520. |

| 5 | Preuster P, Papp C, Wasserscheid P. Liquid organic hydrogen carriers (LOHCs): toward a hydrogen-free hydrogen economy[J]. Accounts of Chemical Research, 2017, 50(1): 74-85. |

| 6 | Acharya D, Ng D, Xie Z L. Recent advances in catalysts and membranes for MCH dehydrogenation: a mini review[J]. Membranes, 2021, 11(12): 955-975. |

| 7 | Ye H L, Wang T C, Liu S X, et al. Fabrication of Pt-loaded catalysts supported on the functionalized pyrolytic activated carbon derived from waste tires for the high performance dehydrogenation of methylcyclohexane and hydrogen production[J]. Catalysts, 2022, 12(2): 211-223. |

| 8 | Yang X, Song Y, Cao T T, et al. The double tuning effect of TiO2 on Pt catalyzed dehydrogenation of methylcyclohexane[J]. Molecular Catalysis, 2020, 492: 110971-110979. |

| 9 | Zhang X T, He N, Lin L, et al. Study of the carbon cycle of a hydrogen supply system over a supported Pt catalyst: methylcyclohexane-toluene-hydrogen cycle[J]. Catalysis Science & Technology, 2020, 10(4): 1171-1181. |

| 10 | Murata K, Kurimoto N, Yamamoto Y, et al. Structure-property relationships of Pt-Sn nanoparticles supported on Al2O3 for the dehydrogenation of methylcyclohexane[J]. ACS Applied Nano Materials, 2021, 4(5): 4532-4541. |

| 11 | Li Y M, Liu Z Y, Zhang Q Y, et al. Influence of carbonization temperature on cobalt-based nitrogen-doped carbon nanopolyhedra derived from ZIF-67 for nonoxidative propane dehydrogenation[J]. Petroleum Science, 2023, 20(1): 559-568. |

| 12 | 李宇明, 刘梓烨, 张启扬, 等. 氮掺杂碳材料的制备及其在催化领域中的应用[J]. 化工学报, 2021, 72(8): 3919-3932. |

| Li Y M, Liu Z Y, Zhang Q Y, et al. Preparation of nitrogen-doped carbon materials and their applications in catalysis[J]. CIESC Journal, 2021, 72(8): 3919-3932. | |

| 13 | 孙明慧, 陈静圆, 肖南, 等. 煤基富氮层级多孔碳制备及其催化脱硫性能[J]. 化工学报, 2020, 71(2): 660-668. |

| Sun M H, Chen J Y, Xiao N, et al. Preparation of hierarchical nitrogen-rich porous carbon from coal tar for catalytic desulfurization[J]. CIESC Journal, 2020, 71(2): 660-668. | |

| 14 | Zhou Y L, Wei F F, Qi H F, et al. Peripheral-nitrogen effects on the Ru1 centre for highly efficient propane dehydrogenation[J]. Nature Catalysis, 2022, 5(12): 1145-1156. |

| 15 | Li Y M, Zhang Q Y, Yu X, et al. Efficient Fe based catalyst with nitrogen doped carbon material modification for propane non-oxidative dehydrogenation[J]. Carbon Resources Conversion, 2020, 3: 140-144. |

| 16 | Dou L G, Yan C J, Zhong L S, et al. Enhancing CO2 methanation over a metal foam structured catalyst by electric internal heating[J]. Chemical Communications, 2020, 56(2): 205-208. |

| 17 | Badakhsh A, Kwak Y, Lee Y J, et al. A compact catalytic foam reactor for decomposition of ammonia by the Joule-heating mechanism[J]. Chemical Engineering Journal, 2021, 426: 130802-130809. |

| 18 | Zhang Y X, Mei X Y, Wang J, et al. A prototype for catalytic removal of formaldehyde and CO in a compact air cleaner powered by portable electricity[J]. Materials Advances, 2020, 1(9): 3582-3588. |

| 19 | Mei X Y, Zhu X B, Zhang Y X, et al. Decreasing the catalytic ignition temperature of diesel soot using electrified conductive oxide catalysts[J]. Nature Catalysis, 2021, 4(12): 1002-1011. |

| 20 | Liu K, Li K, Xu D J, et al. Catalytic combustion of lean methane assisted by electric field over Pd/Co3O4 catalysts at low temperature[J]. Journal of Shanghai Jiaotong University (Science), 2018, 23(1): 8-17. |

| 21 | Wang K, Zeng Y J, Lin W Z, et al. Energy-efficient catalytic removal of formaldehyde enabled by precisely Joule-heated Ag/Co3O4@mesoporous-carbon monoliths[J]. Carbon, 2020, 167: 709-717. |

| 22 | Wismann S T, Engbæk J S, Vendelbo S B, et al. Electrified methane reforming: a compact approach to greener industrial hydrogen production[J]. Science, 2019, 364(6442): 756-759. |

| 23 | Wang W H, Cui G Q, Yan C J, et al. Boosting methylcyclohexane dehydrogenation over Pt-based structured catalysts by internal electric heating[J]. Nano Research, 2023, 16: 12215-12222. |

| 24 | Dong Q, Yao Y G, Cheng S C, et al. Programmable heating and quenching for efficient thermochemical synthesis[J]. Nature, 2022, 605(7910): 470-476. |

| 25 | Wang X J, Song X Y, Li S P, et al. High capacitive energy storage of nest-like porous graphene microspheres electrode with high mass loading[J]. ChemSusChem, 2019, 12(18): 4249-4256. |

| 26 | Sun Y H, Zhang G J, Xu Y, et al. Catalytic performance of dioxide reforming of methane over Co/AC-N catalysts: effect of nitrogen doping content and calcination temperature[J]. International Journal of Hydrogen Energy, 2019, 44(31): 16424-16435. |

| 27 | Li S P, Yang Z P, Wu M Z, et al. Extraordinary compatibility to mass loading and rate capability of hierarchically porous carbon nanorods electrode derived from the waste tire pyrolysis oil[J]. Energy & Environmental Materials, 2022, 5(4): 1238-1250. |

| 28 | Wang X J, Song X Y, Li S P, et al. The cyclic regeneration of templates during the preparation of mesoporous graphene fibers with excellent capacitive behavior in the fluidized-bed chemical vapor deposition process[J]. Chemical Engineering Science, 2020, 221: 115657-115668. |

| 29 | Wang J, Liu H, Fan S G, et al. Size-dependent catalytic cyclohexane dehydrogenation with platinum nanoparticles on nitrogen-doped carbon[J]. Energy & Fuels, 2020, 34(12): 16542-16551. |

| 30 | Cao Y Q, Fu W Z, Ren Z H, et al. Tailoring electronic properties and kinetics behaviors of Pd/N-CNTs catalysts for selective hydrogenation of acetylene[J]. AIChE Journal, 2020, 66(4): 16857-16868. |

| 31 | Wang F, Jiang J C, Wang K, et al. Hydrotreatment of lipid model for diesel-like alkane using nitrogen-doped mesoporous carbon-supported molybdenum carbide[J]. Applied Catalysis B: Environmental, 2019, 242: 150-160. |

| 32 | Zhong G Y, Xu S R, Chao J, et al. Biomass-derived nitrogen-doped porous carbons activated by magnesium chloride as ultrahigh-performance supercapacitors[J]. Industrial & Engineering Chemistry Research, 2020, 59(50): 21756-21767. |

| 33 | Li A T, Yao D W, Yang Y W, et al. Active Cu0-Cu σ + sites for the hydrogenation of carbon-oxygen bonds over Cu/CeO2 catalysts[J]. ACS Catalysis, 2022, 12(2): 1315-1325. |

| 34 | Ouyang S C, Wang L W, Du X W, et al. In situ synthesis of highly-active Pt nanoclusters via thermal decomposition for high-temperature catalytic reactions[J]. RSC Advances, 2016, 6(55): 49777-49781. |

| 35 | Chen A B, Zhang W P, Li X Y, et al. One-pot encapsulation of Pt nanoparticles into the mesochannels of SBA-15 and their catalytic dehydrogenation of methylcyclohexane[J]. Catalysis Letters, 2007, 119(1): 159-164. |

| 36 | Wang W Y, Miao L, Wu K, et al. Hydrogen evolution in the dehydrogenation of methylcyclohexane over Pt/Ce-Mg-Al-O catalysts derived from their layered double hydroxides[J]. International Journal of Hydrogen Energy, 2019, 44(5): 2918-2925. |

| 37 | Chen L M, Verma P, Hou K P, et al. Reversible dehydrogenation and rehydrogenation of cyclohexane and methylcyclohexane by single site platinum catalyst[J]. Nature Communications, 2022, 13(1): 1092-1101. |

| 38 | Nakaya Y, Miyazaki M, Yamazoe S, et al. Active, selective, and durable catalyst for alkane dehydrogenation based on a well-designed trimetallic alloy[J]. ACS Catalysis, 2020, 10(9): 5163-5172. |

| 39 | Zhang C, Liang X Q, Liu S X. Hydrogen production by catalytic dehydrogenation of methylcyclohexane over Pt catalysts supported on pyrolytic waste tire char[J]. International Journal of Hydrogen Energy, 2011, 36(15): 8902-8907. |

| 40 | Li X Y, Ma D, Bao X H. Dispersion of Pt catalysts supported on activated carbon and their catalytic performance in methylcyclohexane dehydrogenation[J]. Chinese Journal of Catalysis, 2008, 29(3): 259-263. |

| 41 | Ye H L, Liu S X, Zhang C, et al. Dehydrogenation of methylcyclohexane over Pt-based catalysts supported on functional granular activated carbon[J]. RSC Advances, 2021, 11(47): 29287-29297. |

| 42 | Takise K, Sato A, Ogo S, et al. Low-temperature selective catalytic dehydrogenation of methylcyclohexane by surface protonics[J]. RSC Advances, 2019, 9(48): 27743-27748. |

| [1] | 朱娇, 栾丽萍, 从深震, 刘新磊. 氢气分离有机膜[J]. 化工学报, 2024, 75(1): 138-158. |

| [2] | 张家琳, 徐大为, 高越, 李新刚. 泡沫镍负载CeO2改性CuO催化剂的碳烟燃烧性能研究[J]. 化工学报, 2024, 75(1): 312-321. |

| [3] | 张强, 王宪飞, 王凯, 骆广生, 路忠凯. 非金属催化剂在环氧化物和环状酸酐共聚中的研究进展[J]. 化工学报, 2024, 75(1): 60-73. |

| [4] | 王欣雨, 王永涛, 姚加, 李浩然. 电子顺磁共振技术在化工基础研究中的应用进展[J]. 化工学报, 2024, 75(1): 74-82. |

| [5] | 闫可欣, 姜洪涛, 高维群, 郭晓晖, 孙伟振, 赵玲. 电子级多晶硅原料中痕量硼磷杂质的脱除研究进展[J]. 化工学报, 2024, 75(1): 83-94. |

| [6] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [7] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [8] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [9] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [10] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [11] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [12] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [13] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [14] | 陆俊凤, 孙怀宇, 王艳磊, 何宏艳. 离子液体界面极化及其调控氢键性质的分子机理[J]. 化工学报, 2023, 74(9): 3665-3680. |

| [15] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号