化工学报 ›› 2022, Vol. 73 ›› Issue (11): 4928-4937.DOI: 10.11949/0438-1157.20220806

收稿日期:2022-06-10

修回日期:2022-09-07

出版日期:2022-11-05

发布日期:2022-12-06

通讯作者:

王禹晨

作者简介:刘坐东(1985—),男,博士,讲师,liuzuodong@neepu.edu.cn

基金资助:

Zuodong LIU( ), Yuchen WANG(

), Yuchen WANG( ), Weiwei XING, Bo ZHAO, Zhiming XU

), Weiwei XING, Bo ZHAO, Zhiming XU

Received:2022-06-10

Revised:2022-09-07

Online:2022-11-05

Published:2022-12-06

Contact:

Yuchen WANG

摘要:

换热设备颗粒污垢一般指悬浮在流体中的固体颗粒在换热面上的积聚。开发了一种Ni-P-TiO2防垢型复合改性表面,并将之用于板式换热器抑制纳米MgO颗粒污垢在换热表面的积聚。基于搭建的板式换热器颗粒污垢热阻动态监测实验系统,研究了不同冷却水流速(0.1~0.3 m/s)、入口温度(30~40℃)及纳米MgO浓度(100~400 mg/L)对Ni-P-TiO2复合改性换热表面抑垢特性的影响。结果表明,随着流速的增加,污垢热阻渐近值减小了27.85%~34.41%;随着冷却水入口温度的升高,污垢热阻渐近值减小了25.15%~39.14%;随着MgO颗粒浓度的增加,热阻渐近值减小了26.15%~45.36%。结合Ni-P-TiO2复合改性表面的表面能分析了其表面的抑垢性能,发现制备的Ni-P-TiO2复合改性表面的表面能与纳米MgO颗粒污垢层的表面能相接近,符合Zhao提出的“最优表面能”抑垢理论。与常规板式换热器不锈钢表面相比,Ni-P-TiO2复合改性表面不仅抑制了颗粒污垢的积聚,还降低了颗粒污垢的固着强度,使得积聚其上的颗粒污垢更容易被剥离换热表面,实现了换热表面持久高效抑垢。

中图分类号:

刘坐东, 王禹晨, 邢维维, 赵波, 徐志明. 复合改性表面抑制颗粒污垢积聚特性分析[J]. 化工学报, 2022, 73(11): 4928-4937.

Zuodong LIU, Yuchen WANG, Weiwei XING, Bo ZHAO, Zhiming XU. Analysis of composite modified surface inhibiting particle fouling accumulation characteristics[J]. CIESC Journal, 2022, 73(11): 4928-4937.

| 材料 | 板片尺寸/mm | 波纹 形式 | 波纹深度/mm | 当量直径/mm | 单流道 截面积/m2 | 角孔直径φ/mm | 板片厚度/mm | 换热面积/m2 | 波纹夹角/(o) |

|---|---|---|---|---|---|---|---|---|---|

| 316不锈钢 | 258×100 | 人字形 | 2 | 4 | 0.000167 | 20 | 0.6 | 0.15 | 120 |

表1 板式换热器的尺寸参数

Table 1 Parameters of plate heat exchanger

| 材料 | 板片尺寸/mm | 波纹 形式 | 波纹深度/mm | 当量直径/mm | 单流道 截面积/m2 | 角孔直径φ/mm | 板片厚度/mm | 换热面积/m2 | 波纹夹角/(o) |

|---|---|---|---|---|---|---|---|---|---|

| 316不锈钢 | 258×100 | 人字形 | 2 | 4 | 0.000167 | 20 | 0.6 | 0.15 | 120 |

| 表面 | 接触角θ/(°) | 表面能/(mJ/m2) | |||||

|---|---|---|---|---|---|---|---|

| θw | θDi | θEG | γLW | γ- | γ+ | γTOT | |

| 316不锈钢 | 95.6 | 25.7 | 48.5 | 44.56 | 2.29 | 0.81 | 47.09 |

| Ni-P-TiO2 | 98.7 | 47.6 | 71.0 | 35.58 | 0.66 | 0.05 | 35.93 |

表2 换热表面接触角和表面能

Table 2 Contact angle and surface energy of heat exchange surface

| 表面 | 接触角θ/(°) | 表面能/(mJ/m2) | |||||

|---|---|---|---|---|---|---|---|

| θw | θDi | θEG | γLW | γ- | γ+ | γTOT | |

| 316不锈钢 | 95.6 | 25.7 | 48.5 | 44.56 | 2.29 | 0.81 | 47.09 |

| Ni-P-TiO2 | 98.7 | 47.6 | 71.0 | 35.58 | 0.66 | 0.05 | 35.93 |

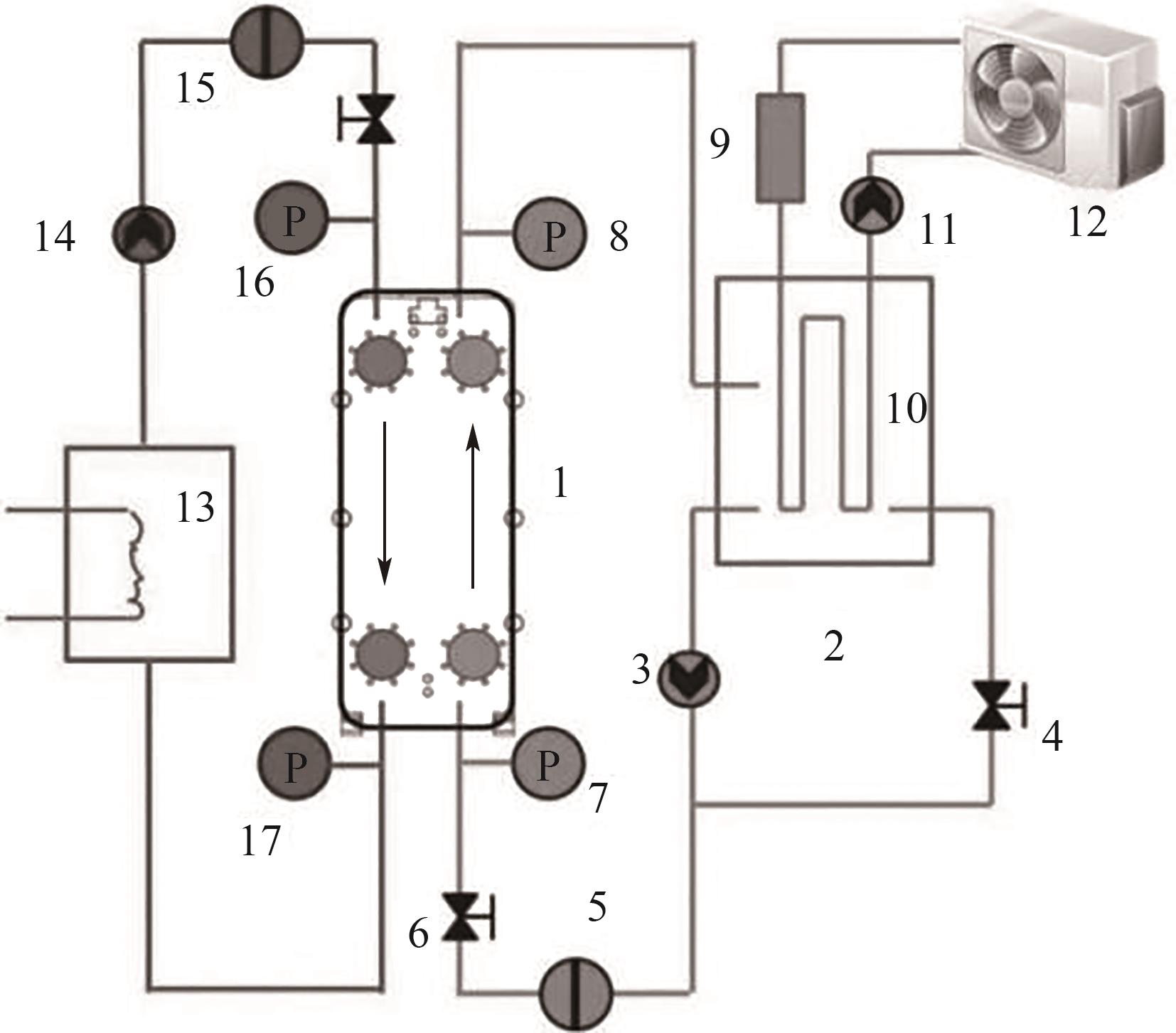

图2 实验系统1—板式换热器;2—低温介质水箱;3—低温介质循环泵;4—旁通阀;5—冷端电磁流量计;6—冷端平衡阀; 7—冷水进口压力表;8—冷水出口压力表;9—空冷水箱;10—散热器;11—空冷循环泵;12—换热扇;13—恒温水箱;14—高温介质循环泵;15—热端电磁流量计;16—热水进口压力表;17—热水出口压力表

Fig.2 Experimental system construction

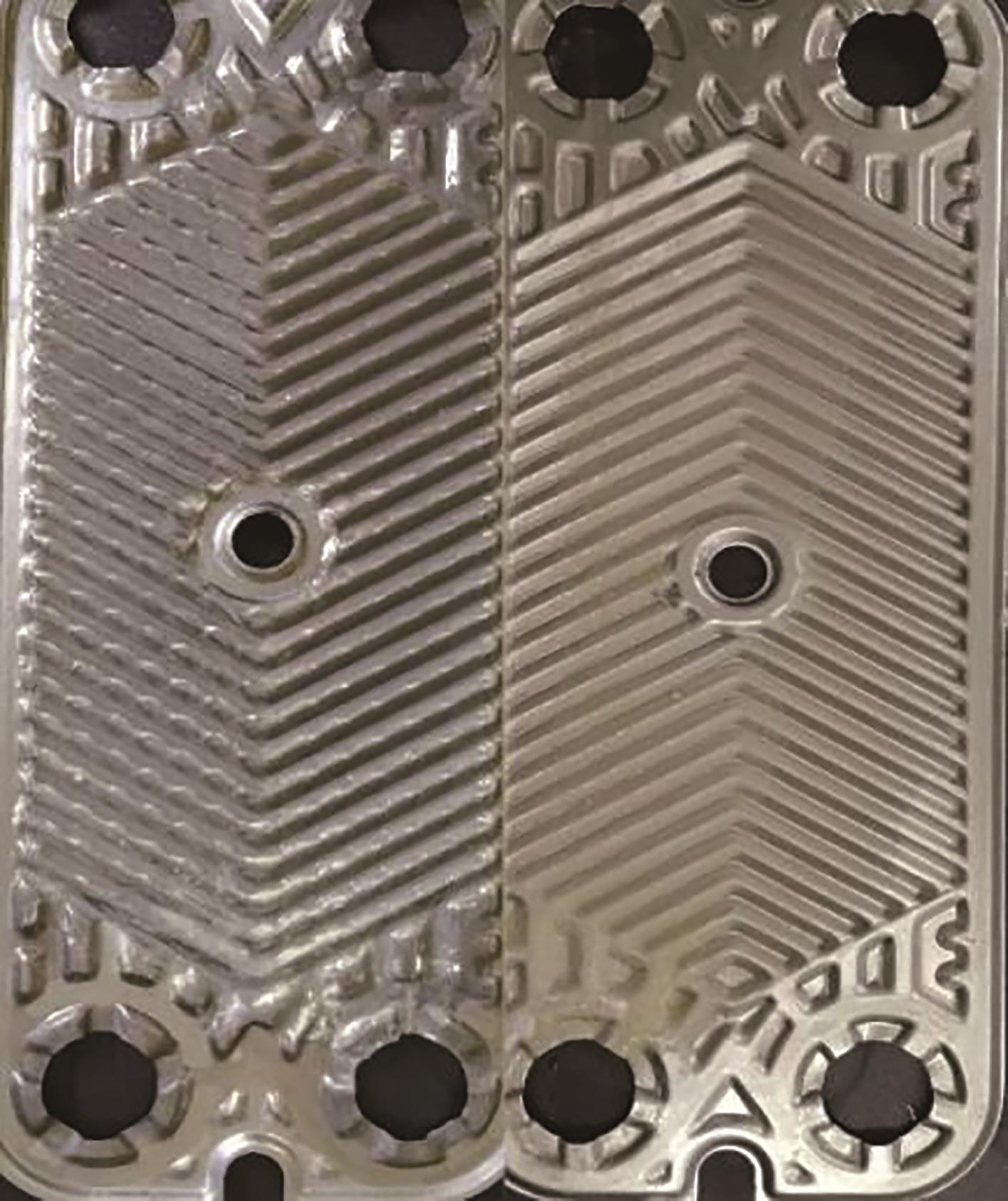

图10 MgO溶液的浓度为400 mg/L时板片实物图(左边为镀层;右边为光板)

Fig.10 Comparison of final fouling deposition between composite surface (left) and stainless steel plate (right) at MgO concentration of 400 mg/L

| 8 | Xu Z M, Wang J T, Wang L, et al. Experimental analysis on particulate fouling characteristics of alternating elliptical axis tube[J]. Chemical Industry and Engineering Progress, 2014, 33(4): 831-836. |

| 9 | 徐志明, 程永林, 王景涛, 等. 运行工况参数对四面体涡流发生器MgO颗粒污垢特性的影响[J]. 中国电机工程学报, 2018, 38(22): 6623-6632. |

| Xu Z M, Cheng Y L, Wang J T, et al. Effect of operating conditions on fouling characteristics of MgO particulate fouling with tetrahedral vortex generators[J]. Proceedings of the CSEE, 2018, 38(22): 6623-6632 | |

| 10 | Xu Z M, Liu Z D, Zhang Y L, et al. The experiment investigation of cooling-water fouling mechanism-associated water quality parameters in two kinds of heat exchanger[J]. Heat Transfer Engineering, 2016, 37(3/4): 290-301. |

| 11 | 张冠敏, 李冠球, 李蔚, 等. 板式换热器内颗粒污垢预测模型与实验[J]. 工程热物理学报, 2013, 34(9): 1715-1718. |

| Zhang G M, Li G Q, Li W, et al. Experimental and theoretical investigations about particulate fouling in plate heat exchangers[J]. Journal of Engineering Thermophysics, 2013, 34(9): 1715-1718. | |

| 12 | 李红霞, 李冠球, 李蔚. 管内颗粒污垢特性分析[J]. 浙江大学学报(工学版), 2012, 46(9): 1671-1677. |

| Li H X, Li G Q, Li W. Analysis of in tubes particulate fouling characteristic[J]. Journal of Zhejiang University (Engineering Science), 2012, 46(9): 1671-1677. | |

| 13 | 邢晓凯, 荆冬锋. CaCO3结垢过程控制机理分析[J]. 热能动力工程, 2007, 22(3): 336-339, 350. |

| Xing X K, Jing D F. An analysis of the mechanism governing the control of CaCO3 scale formation process[J]. Journal of Engineering for Thermal Energy and Power, 2007, 22(3): 336-339, 350. | |

| 14 | Nikkhah V, Sarafraz M M, Hormozi F, et al. Particulate fouling of CuO-water nanofluid at isothermal diffusive condition inside the conventional heat exchanger-experimental and modeling[J]. Experimental Thermal and Fluid Science, 2015, 60: 83-95. |

| 15 | Chamra L M, Webb R L. Modeling liquid-side particulate fouling in enhanced tubes[J]. International Journal of Heat and Mass Transfer, 1994, 37(4): 571-579. |

| 16 | Kasper R, Turnow J, Kornev N. Multiphase Eulerian-Lagrangian LES of particulate fouling on structured heat transfer surfaces[J]. International Journal of Heat and Fluid Flow, 2019, 79: 108462. |

| 17 | Deponte H, Kasper R, Schulte S, et al. Experimental and numerical approach to resolve particle deposition on dimpled heat transfer surfaces locally and temporally[J]. Chemical Engineering Science, 2020, 227: 115840. |

| 18 | Li N, Yang Q R, Yao E R, et al. Synergism between particulate and microbial fouling on a heat transfer surface using treated sewage water[J]. Applied Thermal Engineering, 2019, 150: 791-802. |

| 19 | Frota M N, Ticona E M, Neves A V, et al. On-line cleaning technique for mitigation of biofouling in heat exchangers: a case study of a hydroelectric power plant in Brazil[J]. Experimental Thermal and Fluid Science, 2014, 53: 197-206. |

| 20 | Rahmani K, Jadidian R, Haghtalab S. Evaluation of inhibitors and biocides on the corrosion, scaling and biofouling control of carbon steel and copper-nickel alloys in a power plant cooling water system[J]. Desalination, 2016, 393: 174-185. |

| 21 | Al-Bloushi M, Saththasivam J, Jeong S, et al. Effect of organic on chemical oxidation for biofouling control in pilot-scale seawater cooling towers[J]. Journal of Water Process Engineering, 2017, 20: 1-7. |

| 22 | Chen X M, Chen G H, Yue P L. Separation of pollutants from restaurant wastewater by electrocoagulation[J]. Separation and Purification Technology, 2000, 19(1/2): 65-76. |

| 23 | Edzwald J K, Haarhoff J. Seawater pretreatment for reverse osmosis: chemistry, contaminants, and coagulation[J]. Water Research, 2011, 45(17): 5428-5440. |

| 24 | Nagai T, Hiratsuka M, Alanazi A, et al. Anticorrosion of DLC coating in acid solutions[J]. Applied Surface Science, 2021, 552: 149373. |

| 25 | Pei M L, Pan C G, Wu D, et al. Surface hydrophilic-hydrophobic reversal coatings of polydimethylsiloxane-palygorskite nanosponges[J]. Applied Clay Science, 2020, 189: 105546. |

| 26 | Oldani V, Bianchi C L, Biella S, et al. Perfluoropolyethers coatings design for fouling reduction on heat transfer stainless-steel surfaces[J]. Heat Transfer Engineering, 2016, 37(2): 210-219. |

| 27 | Cheng Y H, Zou Y, Cheng L, et al. Effect of the microstructure on the properties of Ni-P deposits on heat transfer surface[J]. Surface and Coatings Technology, 2009, 203(12): 1559-1564. |

| 28 | Cheng Y H, Chen H Y, Zhu Z C, et al. Experimental study on the anti-fouling effects of Ni-Cu-P-PTFE deposit surface of heat exchangers[J]. Applied Thermal Engineering, 2014, 68(1/2): 20-25. |

| 1 | Schnöing L, Augustin W, Scholl S. Fouling mitigation in food processes by modification of heat transfer surfaces: a review[J]. Food and Bioproducts Processing, 2020, 121: 1-19. |

| 2 | Pourabdollah K. Fouling formation and under deposit corrosion of boiler firetubes[J]. Journal of Environmental Chemical Engineering, 2021, 9(1): 104552. |

| 3 | Awais M, Bhuiyan A A. Recent advancements in impedance of fouling resistance and particulate depositions in heat exchangers[J]. International Journal of Heat and Mass Transfer, 2019, 141: 580-603. |

| 4 | Sholahudin, Giannetti N, Yamaguchi S, et al. A cost effective and non-intrusive method for performance prediction of air conditioners under fouling and leakage effect[J]. Sustainable Energy Technologies and Assessments, 2020, 42: 100856. |

| 5 | 杨善让, 徐志明, 孙灵芳, 等. 换热设备污垢与对策[M]. 2版. 北京: 科学出版社, 2004. |

| Yang S R, Xu Z M, Sun L F, et al. Fouling and Countermeasures of Heat Exchanger[M]. 2nd ed. Beijing: Science Press, 2004. | |

| 6 | 国家统计局. 中华人民共和国2021年国民经济和社会发展统计公报[EB/OL].[2022-02-28]. . |

| National Bureau of Statistics. Statistical Bulletin of the People's Republic of China on National Economic and Social Development in 2021[EB/OL]. [2022-02-28]. . | |

| 7 | 徐志明, 董兵, 杜祥云, 等. 板式换热器颗粒污垢特性的实验研究[J]. 动力工程学报, 2013, 33(7): 539-543. |

| Xu Z M, Dong B, Du X Y, et al. Experimental study on particle fouling in plate heat exchangers[J]. Journal of Chinese Society of Power Engineering, 2013, 33(7): 539-543. | |

| 8 | 徐志明, 王景涛, 王磊, 等. 交叉缩放椭圆管颗粒污垢特性的实验分析[J]. 化工进展, 2014, 33(4): 831-836. |

| 29 | 杨倩鹏, 田磊, 常思远, 等. 换热表面镀银抑制微生物污垢综合分析[J]. 工程热物理学报, 2014, 35(2): 354-357. |

| Yang Q P, Tian L, Chang S Y, et al. Comprehensive analysis of heat transfer surface silver coating effects on biofouling inhibition[J]. Journal of Engineering Thermophysics, 2014, 35(2): 354-357. | |

| 30 | Ahn H S, Kim K M, Lim S T, et al. Anti-fouling performance of chevron plate heat exchanger by the surface modification[J]. International Journal of Heat and Mass Transfer, 2019, 144: 118634. |

| 31 | Jindal S, Anand S, Metzger L, et al. Short communication: a comparison of biofilm development on stainless steel and modified-surface plate heat exchangers during a 17-h milk pasteurization run[J]. Journal of Dairy Science, 2018, 101(4): 2921-2926. |

| 32 | Matjie R, Zhang S, Zhao Q, et al. Tailored surface energy of stainless steel plate coupons to reduce the adhesion of aluminium silicate deposit[J]. Fuel, 2016, 181: 573-578. |

| 33 | Aal A A, Hassan H B, Rahim M A A. Nanostructured Ni-P-TiO2 composite coatings for electrocatalytic oxidation of small organic molecules[J]. Journal of Electroanalytical Chemistry, 2008, 619/620: 17-25. |

| 34 | Novakovic J, Vassiliou P, Samara K, et al. Electroless NiP-TiO2 composite coatings: their production and properties[J]. Surface and Coatings Technology, 2006, 201(3/4): 895-901. |

| 35 | Chen W W, Gao W, He Y D. A novel electroless plating of Ni-P-TiO2 nano-composite coatings[J]. Surface and Coatings Technology, 2010, 204(15): 2493-2498. |

| 36 | Agarwala R C, Agarwala V. Electroless alloy/composite coatings: a review[J]. Sadhana, 2003, 28(3/4): 475-493. |

| 37 | Shibli S M A, Dilimon V S. Effect of phosphorous content and TiO2-reinforcement on Ni-P electroless plates for hydrogen evolution reaction[J]. International Journal of Hydrogen Energy, 2007, 32(12): 1694-1700. |

| 38 | Zhao Q, Liu C, Su X J, et al. Antibacterial characteristics of electroless plating Ni-P-TiO2 coatings[J]. Applied Surface Science, 2013, 274: 101-104. |

| 39 | Shao W, Zhao Q. Effect of corrosion rate and surface energy of silver coatings on bacterial adhesion[J]. Colloids and Surfaces B: Biointerfaces, 2010, 76(1): 98-103. |

| 40 | Liu C, Zhao Q. The CQ ratio of surface energy components influences adhesion and removal of fouling bacteria[J]. Biofouling, 2011, 27(3): 275-285. |

| 41 | 刘坐东, 李斯琪, 邢维维, 等. 板式换热器Ni-P-TiO2复合纳米镀层微生物污垢特性[J]. 化工学报, 2020, 71(8): 3535-3544. |

| Liu Z D, Li S Q, Xing W W, et al. Characteristics of microbial fouling on Ni-P-(nano) TiO2 composite coating of plate heat exchanger[J]. CIESC Journal, 2020, 71(8): 3535-3544. |

| [1] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [2] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [5] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [6] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [7] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [8] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [9] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [10] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [11] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [12] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [13] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [14] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [15] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号