化工学报 ›› 2024, Vol. 75 ›› Issue (2): 484-492.DOI: 10.11949/0438-1157.20231089

收稿日期:2023-10-24

修回日期:2023-12-13

出版日期:2024-02-25

发布日期:2024-04-10

通讯作者:

张一帆

作者简介:李乃良(1983—),男,博士,讲师,linailiang@cumt.edu.cn

基金资助:

Nailiang LI( ), Changsong LIU, Xueping DU, Yifan ZHANG(

), Changsong LIU, Xueping DU, Yifan ZHANG( ), Dongtai HAN

), Dongtai HAN

Received:2023-10-24

Revised:2023-12-13

Online:2024-02-25

Published:2024-04-10

Contact:

Yifan ZHANG

摘要:

基于多尺度方法和Hurst分析方法,分析了严重段塞流的多尺度结构及其非线性特征。以空气、水两相混合物作为实验介质,利用高速数据采集板获得了集输立管内气液两相严重段塞流的压差波动信号。使用db4小波在1~8尺度下对压差信号进行分解和重构,提取不同尺度的系统动力学特征,发现严重段塞流气液喷发和液体回落的瞬态过程主要体现在d5~d8尺度的细节信号上。通过对压差波动信号不同尺度下的分解信号进行Hurst指数分析,发现严重段塞流存在显著的双分形特征,同时受正持久性和反持久性两种动力学因素的制约,但概貌分量和细节分量表现出截然相反的分形结构,概貌分量具有正持久性,而细节分量具有反持久性。d1尺度下的细节分量描述了微尺度的气泡与气泡之间的相互作用;d2~d5尺度下的细节分量描述了微尺度的液体与气泡之间的相互作用;d6~d8尺度下的细节分量描述了宏尺度的气液两相与管壁之间的相互作用。压差波动信号的能量主要分布于宏尺度上。

中图分类号:

李乃良, 刘常松, 杜雪平, 张一帆, 韩东太. 基于Hurst指数的严重段塞流多尺度分形特性[J]. 化工学报, 2024, 75(2): 484-492.

Nailiang LI, Changsong LIU, Xueping DU, Yifan ZHANG, Dongtai HAN. Analysis of multi-scale fractal characteristics of severe slugging based on Hurst exponent[J]. CIESC Journal, 2024, 75(2): 484-492.

| No. | Wavelet | Scale | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | Mean | ||

| 1 | db2 | 2.686 | 2.605 | 2.667 | 2.667 | 2.734 | 2.405 | 2.277 | 2.572 |

| 2 | db3 | 2.836 | 1.919 | 2.025 | 1.961 | 2.234 | 1.366 | 1.244 | 1.949 |

| 3 | db4 | 2.299 | 1.885 | 1.778 | 1.647 | 1.675 | 1.105 | 1.031 | 1.631 |

| 4 | db5 | 2.541 | 1.905 | 1.969 | 1.739 | 1.454 | 1.266 | 1.188 | 1.723 |

| 5 | db6 | 3.143 | 2.060 | 1.957 | 1.869 | 1.892 | 1.426 | 1.297 | 1.949 |

| 6 | db7 | 2.301 | 1.877 | 1.802 | 1.619 | 2.071 | 1.282 | 1.168 | 1.732 |

| 7 | db8 | 2.342 | 1.918 | 1.962 | 1.671 | 1.552 | 1.183 | 1.081 | 1.678 |

| 8 | db9 | 2.943 | 1.924 | 1.929 | 1.887 | 1.492 | 1.267 | 1.153 | 1.793 |

| 9 | db10 | 2.556 | 1.976 | 1.859 | 1.634 | 1.965 | 1.341 | 1.211 | 1.932 |

表1 不同紧支集的Daubechies小波对压差波动信号的分解误差(×10-9)

Table 1 Decomposition error of Daubechies wavelet with different compact supports for pressure difference fluctuation signals(×10-9)

| No. | Wavelet | Scale | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | Mean | ||

| 1 | db2 | 2.686 | 2.605 | 2.667 | 2.667 | 2.734 | 2.405 | 2.277 | 2.572 |

| 2 | db3 | 2.836 | 1.919 | 2.025 | 1.961 | 2.234 | 1.366 | 1.244 | 1.949 |

| 3 | db4 | 2.299 | 1.885 | 1.778 | 1.647 | 1.675 | 1.105 | 1.031 | 1.631 |

| 4 | db5 | 2.541 | 1.905 | 1.969 | 1.739 | 1.454 | 1.266 | 1.188 | 1.723 |

| 5 | db6 | 3.143 | 2.060 | 1.957 | 1.869 | 1.892 | 1.426 | 1.297 | 1.949 |

| 6 | db7 | 2.301 | 1.877 | 1.802 | 1.619 | 2.071 | 1.282 | 1.168 | 1.732 |

| 7 | db8 | 2.342 | 1.918 | 1.962 | 1.671 | 1.552 | 1.183 | 1.081 | 1.678 |

| 8 | db9 | 2.943 | 1.924 | 1.929 | 1.887 | 1.492 | 1.267 | 1.153 | 1.793 |

| 9 | db10 | 2.556 | 1.976 | 1.859 | 1.634 | 1.965 | 1.341 | 1.211 | 1.932 |

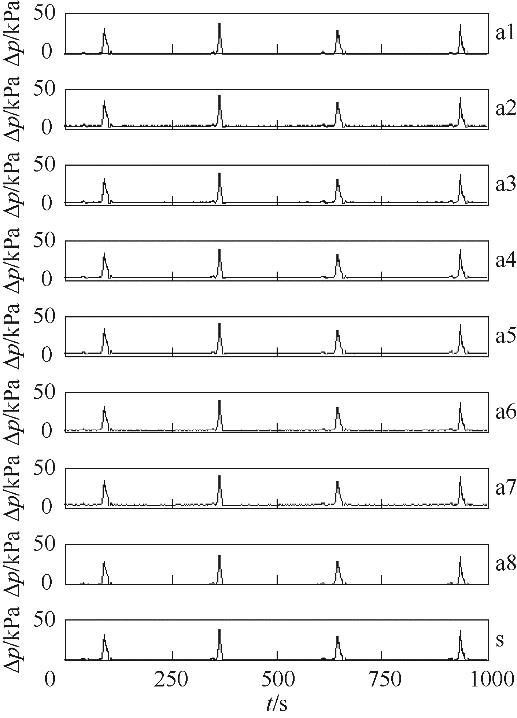

图5 压差信号概貌分量8尺度分解结果(UGS = 0.25 m/s, ULS = 0.09 m/s)

Fig.5 Approximate components decomposed using Daubechies fourth order wavelet on differential pressure of severe slug flow for 8 scales (UGS = 0.25 m/s, ULS = 0.15 m/s)

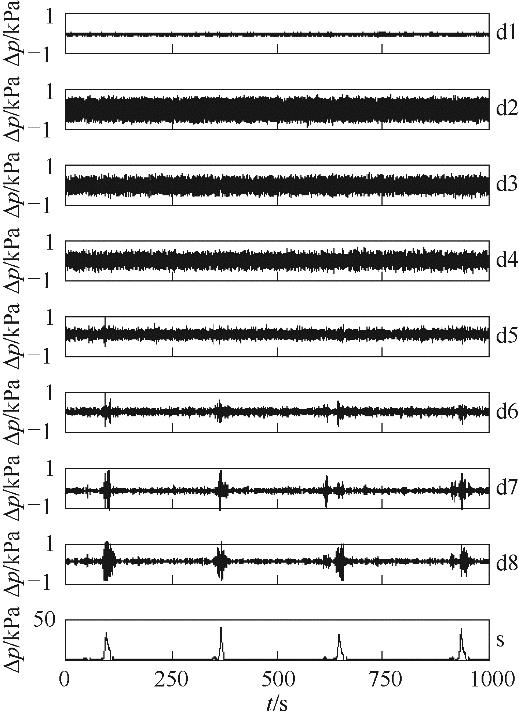

图6 压差信号细节分量8尺度分解结果(UGS = 0.25 m/s, ULS = 0.09 m/s)

Fig.6 Detail components decomposed using Daubechies fourth order wavelet on differential pressure of severe slug flow for 8 scales (UGS = 0.25 m/s, ULS = 0.09 m/s)

| No. | UGS/(m/s) | ULS/(m/s) | Micro-scale/% | Meso-scale/% | Macro-scale/% |

|---|---|---|---|---|---|

| 1 | 0.07 | 0.09 | 5.34 | 21.37 | 73.29 |

| 2 | 0.25 | 0.09 | 3.42 | 25.92 | 70.66 |

| 3 | 0.7 | 0.09 | 1.52 | 28.91 | 69.57 |

| 4 | 0.11 | 0.06 | 4.66 | 22.35 | 72.99 |

| 5 | 0.23 | 0.07 | 3.51 | 21.37 | 75.12 |

| 6 | 0.31 | 0.07 | 2.81 | 20.66 | 76.53 |

| 7 | 0.56 | 0.08 | 6.82 | 23.67 | 69.51 |

| 8 | 0.62 | 0.11 | 5.19 | 21.26 | 73.55 |

| 9 | 0.91 | 0.12 | 4.29 | 24.16 | 71.55 |

| 10 | 1.17 | 0.12 | 3.47 | 27.91 | 68.62 |

表2 压差波动信号的三尺度能量分布

Table 2 Three scales energy distribution of pressure difference fluctuation signals

| No. | UGS/(m/s) | ULS/(m/s) | Micro-scale/% | Meso-scale/% | Macro-scale/% |

|---|---|---|---|---|---|

| 1 | 0.07 | 0.09 | 5.34 | 21.37 | 73.29 |

| 2 | 0.25 | 0.09 | 3.42 | 25.92 | 70.66 |

| 3 | 0.7 | 0.09 | 1.52 | 28.91 | 69.57 |

| 4 | 0.11 | 0.06 | 4.66 | 22.35 | 72.99 |

| 5 | 0.23 | 0.07 | 3.51 | 21.37 | 75.12 |

| 6 | 0.31 | 0.07 | 2.81 | 20.66 | 76.53 |

| 7 | 0.56 | 0.08 | 6.82 | 23.67 | 69.51 |

| 8 | 0.62 | 0.11 | 5.19 | 21.26 | 73.55 |

| 9 | 0.91 | 0.12 | 4.29 | 24.16 | 71.55 |

| 10 | 1.17 | 0.12 | 3.47 | 27.91 | 68.62 |

| 1 | 魏纳, 白睿玲, 周守为, 等. 碳达峰目标下中国深海天然气水合物开发战略[J]. 天然气工业, 2022, 42(2): 156-165. |

| Wei N, Bai R L, Zhou S W, et al. China's deepwater gas hydrate development strategies under the goal of carbon peak[J]. Natural Gas Industry, 2022, 42(2): 156-165. | |

| 2 | 李清平, 周守为, 赵佳飞, 等. 天然气水合物开采技术研究现状与展望[J]. 中国工程科学, 2022, 24(3): 214-224. |

| Li Q P, Zhou S W, Zhao J F, et al. Research status and prospects of natural gas hydrate exploitation technology[J]. Strategic Study of CAE, 2022, 24(3): 214-224. | |

| 3 | 李鹏, 张旭辉, 刘乐乐, 等. 深海天然气水合物机械-热联合开采方法研究综述[J]. 力学学报, 2022, 54(8): 2269-2286. |

| Li P, Zhang X H, Liu L L, et al. Review on the mechanical-thermal combined exploitation methods of deep sea natural gas hydrate[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(8): 2269-2286. | |

| 4 | 宫敬, 史博会, 陈玉川, 等. 含天然气水合物的海底多相管输及其堵塞风险管控[J]. 天然气工业, 2020, 40(12): 133-142. |

| Gong J, Shi B H, Chen Y C, et al. Submarine multiphase pipeline transport containing natural gas hydrate and its plugging risk prevention and control[J]. Natural Gas Industry, 2020, 40(12): 133-142. | |

| 5 | 李焱, 李清平, 喻西崇, 等. 海底管道内部流动引起的流致振动问题研究进展[J]. 中国海上油气, 2021, 33(1): 208-215. |

| Li Y, Li Q P, Yu X C, et al. Research progress of flow-induced vibration caused by internal flow in submarine pipeline[J]. China Offshore Oil and Gas, 2021, 33(1): 208-215. | |

| 6 | 高岳, 朱红钧, 颜知音, 等. 变工况气液段塞流诱导的柔性立管振动响应[J]. 振动工程学报, 2023, 36(4): 1044-1053. |

| Gao Y, Zhu H J, Yan Z Y, et al. Slug flow-induced vibration of a flexible catenary riser model with variable gas-liquid flows[J]. Journal of Vibration Engineering, 2023, 36(4): 1044-1053. | |

| 7 | 刘培林, 刘飞龙. 深水油气田水下生产系统双管输送流动安全研究: 以流花21-2油田为例[J]. 中国海上油气, 2021, 33(4): 156-163. |

| Liu P L, Liu F L. Research on flow assurance of double pipeline transportation in subsea production system of deepwater oil and gas field: a case study of LH21-2 oilfield[J]. China Offshore Oil and Gas, 2021, 33(4): 156-163. | |

| 8 | Luo X M, He L M, Ma H W. Flow pattern and pressure fluctuation of severe slugging in pipeline-riser system[J]. Chinese Journal of Chemical Engineering, 2011, 19(1): 26-32. |

| 9 | 姚添, 郭烈锦, 徐强, 等. 基于压差信号融合特征的集输立管流型识别研究[J]. 工程热物理学报, 2020, 41(12): 3014-3019. |

| Yao T, Guo L J, Xu Q, et al. Investigation on flow regimes recognition in pipeline-riser based on fusion features of differential pressure signals[J]. Journal of Engineering Thermophysics, 2020, 41(12): 3014-3019. | |

| 10 | 张雪梅, 徐强, 郭烈锦. 严重段塞流立管压差信号的周期特性分析[J]. 工程热物理学报, 2021, 42(12): 3195-3200. |

| Zhang X M, Xu Q, Guo L J. Analysis of periodic characters of severe slugging with riser pressure differential signal[J]. Journal of Engineering Thermophysics, 2021, 42(12): 3195-3200. | |

| 11 | Taitel Y. Stability of severe slugging[J]. International Journal of Multiphase Flow, 1986, 12(2): 203-217. |

| 12 | 王鑫, 郭烈锦, 何利民. 集输管路上升管系统严重段塞流液塞特征[J]. 工程热物理学报, 2008, 29(8): 1339-1342. |

| Wang X, Guo L J, He L M. Characteristics of liquid slug in severe slugging at pipeline-riser system[J]. Journal of Engineering Thermophysics, 2008, 29(8): 1339-1342. | |

| 13 | Li N L, Guo L J, Li W S. Gas-liquid two-phase flow patterns in a pipeline-riser system with an S-shaped riser[J]. International Journal of Multiphase Flow, 2013, 55: 1-10. |

| 14 | 王冬旭, 胡其会, 李玉星, 等. 大起伏角度下V形管道段塞流流型特性[J]. 科学技术与工程, 2020, 20(28): 11574-11579. |

| Wang D X, Hu Q H, Li Y X, et al. Study on the characteristics of slug flow in V-type pipeline with great angle[J]. Science Technology and Engineering, 2020, 20(28): 11574-11579. | |

| 15 | 罗小明, 何利民, 马华伟. 上升管系统中严重段塞流的液塞速度特性[J]. 化工学报, 2009, 60(7): 1656-1660. |

| Luo X M, He L M, Ma H W. Slug velocity of severe slugging in pipeline-riser system[J]. CIESC Journal, 2009, 60(7): 1656-1660. | |

| 16 | 常英杰, 赵向远, 吴全红, 等. 长距离集输立管中严重段塞流频率特性研究[J]. 工程热物理学报, 2022, 43(1): 98-103. |

| Chang Y J, Zhao X Y, Wu Q H, et al. Study on severe slugging frequency characteristics in a long pipeline-riser system[J]. Journal of Engineering Thermophysics, 2022, 43(1): 98-103. | |

| 17 | 李乃良, 李文升, 郭烈锦. 集输-S型立管内气液两相流流型的PSD特征[J]. 工程热物理学报, 2012, 33(7): 1160-1162. |

| Li N L, Li W S, Guo L J. PSD characteristics of gas-liquid two-phase flow in pipeline S-shaped flexible riser[J]. Journal of Engineering Thermophysics, 2012, 33(7): 1160-1162. | |

| 18 | 刘威志, 徐强, 郭烈锦. 集输立管气液两相流压力波动特性及小波分析[J]. 工程热物理学报, 2019, 40(8): 1820-1825. |

| Liu W Z, Xu Q, Guo L J. Pressure fluctuation characteristics of gas and liquid two phase flow in pipeline-riser system and wavelet analysis[J]. Journal of Engineering Thermophysics, 2019, 40(8): 1820-1825. | |

| 19 | Malekzadeh R, Mudde R F, Henkes R A W M. Dual-frequency severe slugging in horizontal pipeline-riser systems[J]. Journal of Fluids Engineering, 2012, 134(12): 121301. |

| 20 | Azevedo G R, Baliño J L, Andreolli I. Nonlinear stability analysis for severe slugging in an air-water two-phase flow[J]. International Journal of Multiphase Flow, 2023, 159: 104334. |

| 21 | 孙斌, 许明飞, 段晓松. 水平管内气液两相泡状流的多尺度分形分析[J]. 中国电机工程学报, 2011, 31(14): 77-83. |

| Sun B, Xu M F, Duan X S. Multi-scale fractal characteristic analysis of gas-liquid two-phase bubbly flow in horizontal pipe[J]. Proceedings of the CSEE, 2011, 31(14): 77-83. | |

| 22 | 白博峰, 陈学俊. 垂直上升管泡状流压力波动的多尺度分析[J]. 工程热物理学报, 2004, 25(3): 427-430. |

| Bai B F, Chen X J. Multi-scale analysis of pressure fluctuation in vertical upward bubbly flow[J]. Journal of Engineering Thermophysics, 2004, 25(3): 427-430. | |

| 23 | 李乃良, 李文升, 郭烈锦, 等. S型柔性立管内空气-水两相流流型特征的实验研究[J]. 西安交通大学学报, 2011, 45(7): 100-105. |

| Li N L, Li W S, Guo L J, et al. Experimental study on flow patterns of air-water two-phase flow in S-shaped flexible riser[J]. Journal of Xi'an Jiaotong University, 2011, 45(7): 100-105. | |

| 24 | 付飞飞, 许传龙, 王式民. 密相气力输送中气固两相流动特性多源信息分析[J]. 化工学报, 2012, 63(10): 3070-3079. |

| Fu F F, Xu C L, Wang S M. Multi-sensors integration for flow characterization of dense phase pneumatic conveying of coal powder[J]. CIESC Journal, 2012, 63(10): 3070-3079. | |

| 25 | Saini S, Banerjee J. Recurrence analysis of pressure signals for identification of intermittent flow sub-regimes[J]. Journal of Petroleum Science and Engineering, 2021, 204: 108758. |

| 26 | Sheikhi A, Sotudeh-Gharebagh R, Mostoufi N, et al. Experimental investigation on the hydrodynamics of a gas-liquid-solid fluidized bed using vibration signature and pressure fluctuation analyses[J]. International Journal of Heat and Fluid Flow, 2013, 42: 190-199. |

| 27 | 李爽, 李玉星, 王冬旭, 等. 上倾管高黏油气两相流型及压降特性[J]. 化工学报, 2020, 71(3): 983-996. |

| Li S, Li Y X, Wang D X, et al. Flow patterns and pressure drop characteristics on high-viscosity oil and gas two-phase flow in upward pipe[J]. CIESC Journal, 2020, 71(3): 983-996. | |

| 28 | 董芳, 金宁德, 宗艳波, 等. 两相流流型动力学特征多尺度递归定量分析[J]. 物理学报, 2008, 57(10): 6145-6154. |

| Dong F, Jin N D, Zong Y B, et al. Multi-scale recurrence quantification analysis of the dynamic characteristics of two-phase flow pattern[J]. Acta Physica Sinica, 2008, 57(10): 6145-6154. | |

| 29 | 赵宁, 张琳, 牛立娜, 等. 垂直上升气液环状流液膜参数多尺度分析[J]. 河北大学学报(自然科学版), 2019, 39(6): 579-586. |

| Zhao N, Zhang L, Niu L N, et al. Multi-scale analysis of liquid film parameter in vertical gas-liquid annular flow[J]. Journal of Hebei University (Natural Science Edition), 2019, 39(6): 579-586. | |

| 30 | 房贤仕, 李秋英, 陈杰, 等. 管内气液两相流流型研究现状与发展[J]. 东北电力大学学报, 2022, 42(4): 1-7. |

| Fang X S, Li Q Y, Chen J, et al. A review on flow pattern of gas-liquid two-phase flow in tubes[J]. Journal of Northeast Electric Power University, 2022, 42(4): 1-7. |

| [1] | 刘志鹏, 赵长颖, 吴睿, 张智昊. 基于水电解制氢的梯度多孔传输层中气液流动可视化实验研究[J]. 化工学报, 2024, 75(2): 520-530. |

| [2] | 詹小斌, 王会彬, 蒋亚龙, 史铁林. 声共振混合器高黏度流体混合的功耗特性研究[J]. 化工学报, 2024, 75(2): 531-542. |

| [3] | 刘起超, 张世博, 周云龙, 李昱庆, 陈聪, 冉议文. 起伏振动水平管气液两相流型及转变机理[J]. 化工学报, 2024, 75(2): 493-504. |

| [4] | 崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| [5] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [6] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [9] | 史昊鹏, 钟达文, 廉学新, 张君峰. 朝下多尺度沟槽翅片结构表面沸腾换热实验研究[J]. 化工学报, 2023, 74(7): 2880-2888. |

| [10] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [11] | 李艳辉, 丁邵明, 白周央, 张一楠, 于智红, 邢利梅, 高鹏飞, 王永贞. 非常规服役超临界锅炉的微纳尺度腐蚀动力学模型建立及应用[J]. 化工学报, 2023, 74(6): 2436-2446. |

| [12] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [13] | 刘道银, 陈柄岐, 张祖扬, 吴琰. 颗粒聚团结构对曳力特性影响的数值模拟[J]. 化工学报, 2023, 74(6): 2351-2362. |

| [14] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [15] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号