化工学报 ›› 2024, Vol. 75 ›› Issue (11): 4162-4169.DOI: 10.11949/0438-1157.20240569

张德旺1,2( ), 赵乾坤1, 郭笑妮1, 尧超群1(

), 赵乾坤1, 郭笑妮1, 尧超群1( ), 陈光文1(

), 陈光文1( )

)

收稿日期:2024-05-28

修回日期:2024-07-05

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

尧超群,陈光文

作者简介:张德旺(2000—),男,硕士研究生,dwangzhang@dicp.ac.cn

基金资助:

Dewang ZHANG1,2( ), Qiankun ZHAO1, Xiaoni GUO1, Chaoqun YAO1(

), Qiankun ZHAO1, Xiaoni GUO1, Chaoqun YAO1( ), Guangwen CHEN1(

), Guangwen CHEN1( )

)

Received:2024-05-28

Revised:2024-07-05

Online:2024-11-25

Published:2024-12-26

Contact:

Chaoqun YAO, Guangwen CHEN

摘要:

利用传质在线表征技术研究了微通道内聚丙烯酰胺(PAAm)溶液为分散相的牛顿/非牛顿流体液-液两相流传质过程。首先探讨了两相流型,发现了一种独特的串状弹状流,并考察了PAAm浓度对弹状流、串状弹状流和环状流流型分布的影响。研究发现,牛顿流体和非牛顿流体液滴内的传质均受对流和扩散共同主导,但非牛顿流体的剪切变稀特性使液滴内的涡流和浓度分布发生显著改变。弹状液滴内的对流传质与流速、液滴长度和毛细管数相关。基于渗透理论,提出关联流量比和毛细管数的无量纲项以量化对流的影响,很好地预测了弹状流传质系数。

中图分类号:

张德旺, 赵乾坤, 郭笑妮, 尧超群, 陈光文. 微反应器内牛顿/非牛顿流体液-液两相流流动和传质研究[J]. 化工学报, 2024, 75(11): 4162-4169.

Dewang ZHANG, Qiankun ZHAO, Xiaoni GUO, Chaoqun YAO, Guangwen CHEN. Flow and mass transfer characteristics of Newtonian/non-Newtonian liquid-liquid flow in a microreactor[J]. CIESC Journal, 2024, 75(11): 4162-4169.

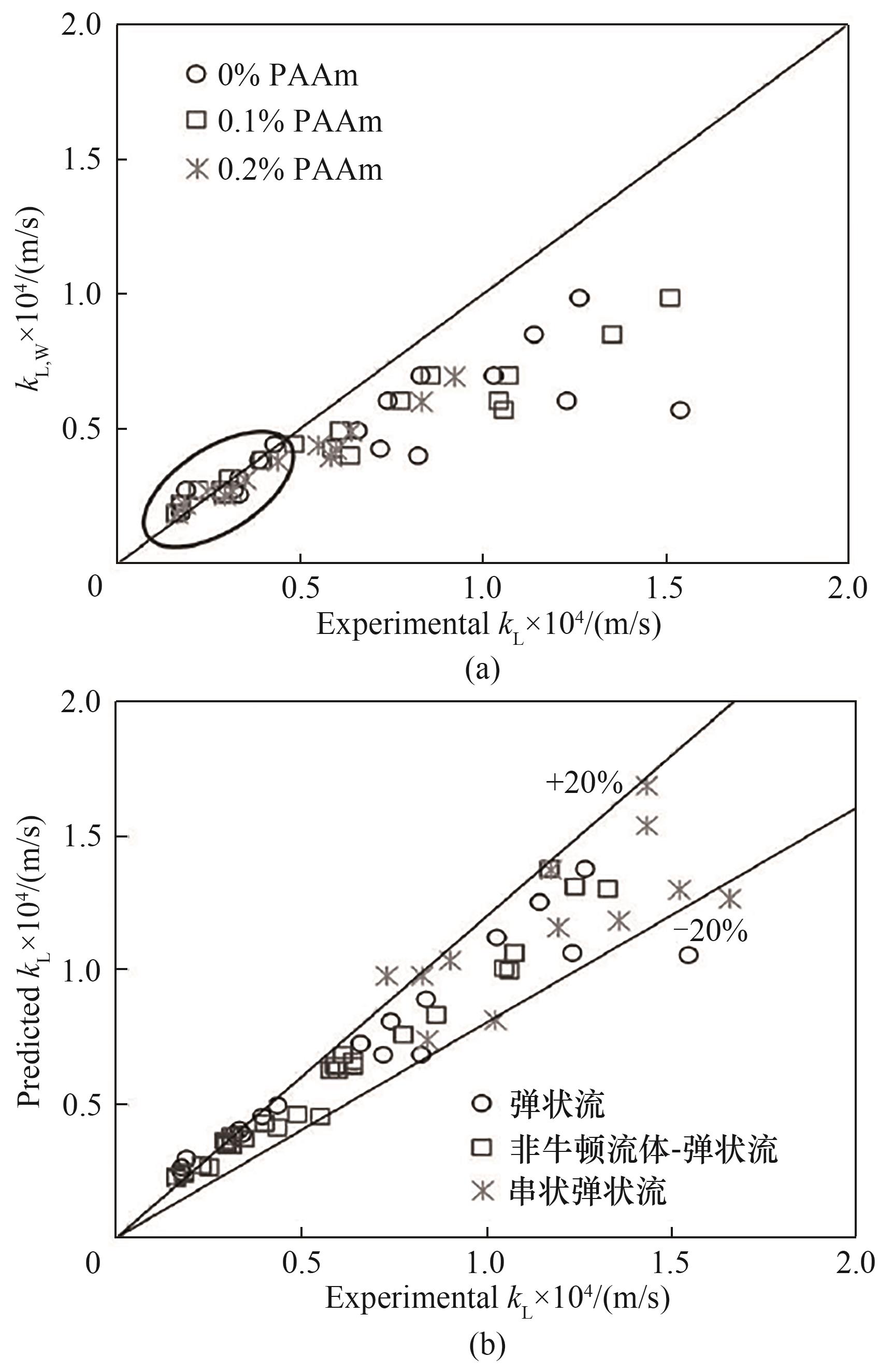

图8 传质预测性能:(a)传统基于渗透理论的关联式;(b)修正的关联式

Fig.8 Mass transfer prediction performance:(a) Traditional correlation based on penetration theory;(b) Modified correlation

| 1 | Adamo A, Beingessner R L, Behnam M, et al. On-demand continuous-flow production of pharmaceuticals in a compact, reconfigurable system[J]. Science, 2016, 352(6281): 61-67. |

| 2 | Hessel V, Kralisch D, Kockmann N, et al. Novel process windows for enabling, accelerating, and uplifting flow chemistry[J]. ChemSusChem, 2013, 6(5): 746-789. |

| 3 | Nghe P, Terriac E, Schneider M, et al. Microfluidics and complex fluids[J]. Lab on a Chip, 2011, 11(5): 788-794. |

| 4 | Hoang P H, Nguyen C T, Perumal J, et al. Droplet synthesis of well-defined block copolymers using solvent-resistant microfluidic device[J]. Lab on a Chip, 2011, 11(2): 329-335. |

| 5 | Liu Z D, Lu Y C, Yang B D, et al. Controllable preparation of poly(butyl acrylate) by suspension polymerization in a coaxial capillary microreactor[J]. Industrial & Engineering Chemistry Research, 2011, 50(21): 11853-11862. |

| 6 | Song Y, Song J N, Shang M J, et al. Hydrodynamics and mass transfer performance during the chemical oxidative polymerization of aniline in microreactors[J]. Chemical Engineering Journal, 2018, 353: 769-780. |

| 7 | Yang Z C, Bi Q C, Liu B, et al. Nitrogen/non-Newtonian fluid two-phase upward flow in non-circular microchannels[J]. International Journal of Multiphase Flow, 2010, 36(1): 60-70. |

| 8 | Fu T T, Ma Y G, Funfschilling D, et al. Gas-liquid flow stability and bubble formation in non-Newtonian fluids in microfluidic flow-focusing devices[J]. Microfluidics and Nanofluidics, 2011, 10(5): 1135-1140. |

| 9 | Fu T T, Ma Y G, Funfschilling D, et al. Bubble formation in non-Newtonian fluids in a microfluidic T-junction[J]. Chemical Engineering and Processing: Process Intensification, 2011, 50(4): 438-442. |

| 10 | Yang X H, Weldetsadik N T, Hayat Z, et al. Pressure drop of single phase flow in microchannels and its application in characterizing the apparent rheological property of fluids[J]. Microfluidics and Nanofluidics, 2019, 23(5): 75. |

| 11 | Musterd M, van Steijn V, Kleijn C R, et al. Calculating the volume of elongated bubbles and droplets in microchannels from a top view image[J]. RSC Advances, 2015, 5(21): 16042-16049. |

| 12 | Roumpea E, Chinaud M, Angeli P. Experimental investigations of non-Newtonian/Newtonian liquid-liquid flows in microchannels[J]. AIChE Journal, 2017, 63(8): 3599-3609. |

| 13 | Sontti S G, Atta A. CFD analysis of microfluidic droplet formation in non-Newtonian liquid[J]. Chemical Engineering Journal, 2017, 330: 245-261. |

| 14 | Chen Q, Li J K, Song Y, et al. Modeling of Newtonian droplet formation in power-law non-Newtonian fluids in a flow-focusing device[J]. Heat and Mass Transfer, 2020, 56(9): 2711-2723. |

| 15 | Rostami B, Morini G L. Experimental characterization of a micro cross-junction as generator of Newtonian and non-Newtonian droplets in silicone oil flow at low capillary numbers[J]. Experimental Thermal and Fluid Science, 2019, 103: 191-200. |

| 16 | 杜威. 微通道内非常规流体液滴生成与界面动力学研究[D]. 天津: 天津大学, 2017. |

| Du W. Study on droplet formation and interfacial dynamic in unconventional fluids in microchannels[D]. Tianjin: Tianjin University, 2017. | |

| 17 | Sun X, Zhu C Y, Fu T T, et al. Breakup dynamics of elastic droplet and stretching of polymeric filament in a T-junction[J]. Chemical Engineering Science, 2019, 206: 212-223. |

| 18 | Zhang Q D, Zhu C Y, Du W, et al. Formation dynamics of elastic droplets in a microfluidic T-junction[J]. Chemical Engineering Research and Design, 2018, 139: 188-196. |

| 19 | Lobasov A S, Minakov A V, Rudyak V Y. Flow modes of non-Newtonian fluids with power-law rheology in a T-shaped micromixer[J]. Theoretical Foundations of Chemical Engineering, 2018, 52(3): 393-403. |

| 20 | Yang H E, Yao G C, Wen D S. Efficient mixing enhancement by orthogonal injection of shear-thinning fluids in a micro serpentine channel at low Reynolds numbers[J]. Chemical Engineering Science, 2021, 235: 116368. |

| 21 | Zhao Q K, Ma H Y, Liu Y Y, et al. Hydrodynamics and mass transfer of Taylor bubbles flowing in non-Newtonian fluids in a microchannel[J]. Chemical Engineering Science, 2021, 231: 116299. |

| 22 | Liu Y Y, Zhao Q K, Yue J, et al. Effect of mixing on mass transfer characterization in continuous slugs and dispersed droplets in biphasic slug flow microreactors[J]. Chemical Engineering Journal, 2021, 406: 126885. |

| 23 | Yao C Q, Ma H Y, Zhao Q K, et al. Mass transfer in liquid-liquid Taylor flow in a microchannel: local concentration distribution, mass transfer regime and the effect of fluid viscosity[J]. Chemical Engineering Science, 2020, 223: 115734. |

| 24 | Yao C Q, Zhao Y C, Ma H Y, et al. Two-phase flow and mass transfer in microchannels: a review from local mechanism to global models[J]. Chemical Engineering Science, 2021, 229: 116017. |

| 25 | Liu Y Y, Yao C Q, Yang L X, et al. A colorimetric technique to characterize mass transfer during liquid-liquid slug flow in circular capillaries[J]. MethodsX, 2021, 8: 101346. |

| 26 | Liu Y Y, Yue J, Xu C, et al. Hydrodynamics and local mass transfer characterization under gas-liquid-liquid slug flow in a rectangular microchannel[J]. AIChE Journal, 2020, 66(2): e16805. |

| 27 | 刘希明, 田玉芹, 刘伟伟, 等. 部分水解聚丙烯酰胺和聚乙烯醇混合溶液的流变性[J]. 油田化学, 2020, 37(1): 115-120. |

| Liu X M, Tian Y Q, Liu W W, et al. Rheological properties of partially hydrolyzed polyacrylamide and poly(vinyl alcohol) mixed solutions[J]. Oilfield Chemistry, 2020, 37(1): 115-120. | |

| 28 | Lohse M, Alper E, Quicker G, et al. Diffusivity and solubility of carbondioxide in diluted polymer solutions[J]. AIChE Journal, 1981, 27(4): 626-631. |

| 29 | Yang L X, Dietrich N, Hébrard G, et al. Optical methods to investigate the enhancement factor of an oxygen-sensitive colorimetric reaction using microreactors[J]. AIChE Journal, 2017, 63(6): 2272-2284. |

| 30 | Roudet M, Loubiere K, Gourdon C, et al. Hydrodynamic and mass transfer in inertial gas-liquid flow regimes through straight and meandering millimetric square channels[J]. Chemical Engineering Science, 2011, 66(13): 2974-2990. |

| 31 | Dietrich N, Loubière K, Jimenez M, et al. A new direct technique for visualizing and measuring gas-liquid mass transfer around bubbles moving in a straight millimetric square channel[J]. Chemical Engineering Science, 2013, 100: 172-182. |

| 32 | Yao C Q, Zhao Y C, Chen G W. Multiphase processes with ionic liquids in microreactors: hydrodynamics, mass transfer and applications[J]. Chemical Engineering Science, 2018, 189: 340-359. |

| 33 | Zhao C X, Middelberg A P J. Two-phase microfluidic flows[J]. Chemical Engineering Science, 2011, 66(7): 1394-1411. |

| 34 | Zhang Q, Liu H C, Zhao S N, et al. Hydrodynamics and mass transfer characteristics of liquid-liquid slug flow in microchannels: the effects of temperature, fluid properties and channel size[J]. Chemical Engineering Journal, 2019, 358: 794-805. |

| 35 | Garstecki P, Fuerstman M J, Stone H A, et al. Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up[J]. Lab on a Chip, 2006, 6(3): 437-446. |

| 36 | Yao C Q, Liu Y Y, Xu C, et al. Formation of liquid-liquid slug flow in a microfluidic T-junction: effects of fluid properties and leakage flow[J]. AIChE Journal, 2018, 64(1): 346-357. |

| 37 | Du W, Fu T T, Duan Y F, et al. Breakup dynamics for droplet formation in shear-thinning fluids in a flow-focusing device[J]. Chemical Engineering Science, 2018, 176: 66-76. |

| 38 | Scheiff F, Holbach A, Agar D W. Slug flow of ionic liquids in capillary microcontactors: fluid dynamic intensification for solvent extraction[J]. Chemical Engineering & Technology, 2013, 36(6): 975-984. |

| [1] | 郭骐瑞, 任丽媛, 陈康, 黄翔宇, 马卫华, 肖乐勤, 周伟良. 用于HTPB推进剂浆料的静态混合管数值模拟[J]. 化工学报, 2024, 75(S1): 206-216. |

| [2] | 刘律, 刘洁茹, 范亮亮, 赵亮. 基于层流效应的被动式颗粒分离微流控方法研究[J]. 化工学报, 2024, 75(S1): 67-75. |

| [3] | 李焱, 郑利军, 张恩勇, 王云飞. 深水海底管道软管内部流体渗透特性模型与试验研究[J]. 化工学报, 2024, 75(S1): 118-125. |

| [4] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [5] | 杨子驰, 谢冰琪, 石瑞莘, 雷虹, 陈晨, 周才金, 张吉松. 套管膜式微反应器内高效安全的气液传质-反应过程研究进展[J]. 化工学报, 2024, 75(9): 3011-3027. |

| [6] | 王冉, 王焕, 熊晓云, 关慧敏, 郑云锋, 陈彩琳, 秦玉才, 宋丽娟. FCC催化剂传质强化活性位利用效率的可视化分析[J]. 化工学报, 2024, 75(9): 3198-3209. |

| [7] | 罗欣怡, 徐强, 佘永璐, 聂腾飞, 郭烈锦. 光电分解水制氢气泡动力学特性及其传质机理研究[J]. 化工学报, 2024, 75(9): 3083-3093. |

| [8] | 曹佳蕾, 孙立岩, 曾德望, 尹凡, 高子翔, 肖睿. 双流化床化学链制氢反应器的数值模拟[J]. 化工学报, 2024, 75(8): 2865-2874. |

| [9] | 丁家琦, 刘海涛, 赵普, 朱香凝, 王晓放, 谢蓉. 煤炭超临界水制氢反应器内多相流场智能滚动预测研究[J]. 化工学报, 2024, 75(8): 2886-2896. |

| [10] | 金虎, 杨帆, 戴梦瑶. 基于格子Boltzmann方法的液滴在圆柱壁面上运动过程研究[J]. 化工学报, 2024, 75(8): 2897-2908. |

| [11] | 左磊, 王军锋, 高健, 王道睿. 电场调控生物柴油液滴燃烧行为[J]. 化工学报, 2024, 75(8): 2983-2990. |

| [12] | 吴邦汉, 林定标, 陆海峰, 郭晓镭, 刘海峰. 竖直管气动物流传输系统管道压降和传送瓶输送特性[J]. 化工学报, 2024, 75(7): 2465-2473. |

| [13] | 杨锦蕊, 郑宏飞, 马兴龙, 金日辉, 梁深. 两级叠置式加湿除湿海水淡化装置性能研究[J]. 化工学报, 2024, 75(7): 2446-2454. |

| [14] | 王金山, 王世学, 朱禹. 冷却表面温差对高温质子交换膜燃料电池性能的影响[J]. 化工学报, 2024, 75(5): 2026-2035. |

| [15] | 冯彬彬, 卢明佳, 黄志宏, 常译文, 崔志明. 碳载体在质子交换膜燃料电池中的应用及优化[J]. 化工学报, 2024, 75(4): 1469-1484. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号