化工学报 ›› 2025, Vol. 76 ›› Issue (2): 504-518.DOI: 10.11949/0438-1157.20240992

• 综述与专论 • 上一篇

杨晋宁1( ), 王卫凡2(

), 王卫凡2( ), 徐冬1(

), 徐冬1( ), 刘毅1, 翁小涵1, 原野2, 王志2(

), 刘毅1, 翁小涵1, 原野2, 王志2( )

)

收稿日期:2024-09-02

修回日期:2024-10-02

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

徐冬,王志

作者简介:杨晋宁(1984—),女,硕士,工程师,jinning.yang@ceic.com基金资助:

Jinning YANG1( ), Weifan WANG2(

), Weifan WANG2( ), Dong XU1(

), Dong XU1( ), Yi LIU1, Xiaohan WENG1, Ye YUAN2, Zhi WANG2(

), Yi LIU1, Xiaohan WENG1, Ye YUAN2, Zhi WANG2( )

)

Received:2024-09-02

Revised:2024-10-02

Online:2025-03-25

Published:2025-03-10

Contact:

Dong XU, Zhi WANG

摘要:

工业烟道气是全球碳排放的主要来源之一,也是碳捕集技术的重点应用领域。综述了工业烟道气碳捕集领域中的膜技术放大研究进展。首先,介绍了CO2/N2分离膜的工作原理。其次,总结了化石能源发电厂、水泥厂、钢铁厂烟道气的来源与成分,并分析了在这些烟道气碳捕集过程中膜分离技术所面临的挑战。然后,对烟道气碳捕集膜的放大生产、烟道气碳捕集膜组件研究、工业烟道气碳捕集膜放大测试进行现状介绍和问题分析。最后,展望了膜技术在工业烟道气碳捕集中的发展方向,包括实现CO2分离混合基质膜放大、针对钢铁厂烟道气的CO分离膜的开发以及膜组件的优化。旨在为学者们提供工业烟气碳捕捉膜放大的最新研究进展和未来方向。

中图分类号:

杨晋宁, 王卫凡, 徐冬, 刘毅, 翁小涵, 原野, 王志. 工业烟道气碳捕集膜技术放大研究进展[J]. 化工学报, 2025, 76(2): 504-518.

Jinning YANG, Weifan WANG, Dong XU, Yi LIU, Xiaohan WENG, Ye YUAN, Zhi WANG. Progress in the scale-up research of membrane technologies for industrial flue gas carbon capture[J]. CIESC Journal, 2025, 76(2): 504-518.

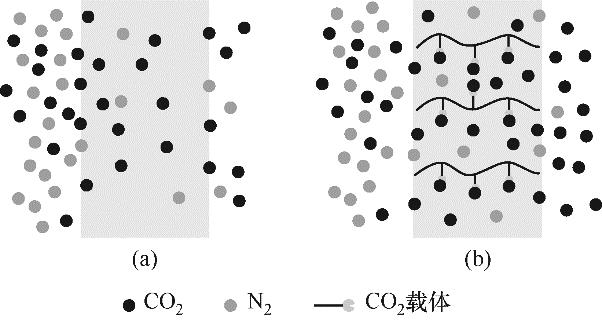

图2 以溶解扩散(a)和促进传递(b)为机理的CO2/N2分离膜的分离过程示意图

Fig.2 Schematic diagram of the separation process for CO2/N2 separation membranes based on the mechanisms of solution-diffusion (a) and facilitated transport (b)

| 烟道气参数 | 天然气联合循环电厂 | 硬煤发电厂 | 褐煤发电厂 |

|---|---|---|---|

| 压力/atm | 1 | 1 | 1 |

| CO2/% | 3.89 | 13.3 | 14 |

| N2/% | 75.34 | 71.62 | 69.61 |

| H2O/% | 8.21 | 11.25 | 13.04 |

| O2/% | 12.56 | 3.81 | 3.35 |

| NO x /10-6 | 24 | 97 | 80 |

| SO x /10-6 | 0 | 50 | 40 |

表1 不同的化石燃料发电厂烟道气组成[22]

Table 1 Composition of flue gas from different fossil fuel power plants[22]

| 烟道气参数 | 天然气联合循环电厂 | 硬煤发电厂 | 褐煤发电厂 |

|---|---|---|---|

| 压力/atm | 1 | 1 | 1 |

| CO2/% | 3.89 | 13.3 | 14 |

| N2/% | 75.34 | 71.62 | 69.61 |

| H2O/% | 8.21 | 11.25 | 13.04 |

| O2/% | 12.56 | 3.81 | 3.35 |

| NO x /10-6 | 24 | 97 | 80 |

| SO x /10-6 | 0 | 50 | 40 |

| 组成 | Norcem水泥厂 | San Antonio水泥厂 |

|---|---|---|

| CO2 | 17%~20% | 29.58% |

| N2 | 50%~63% | 48.95% |

| H2O | 11%~18% | 11.20% |

| O2 | 9%~12% | 10.22% |

| SO2 | 0~130 mg/m3(标准状况) | 0.04% |

| NO x | 180~250 mg/m3(标准状况) | 0.01% |

表2 水泥厂烟道气组成[26-27]

Table 2 Composition of flue gas from cement plants[26-27]

| 组成 | Norcem水泥厂 | San Antonio水泥厂 |

|---|---|---|

| CO2 | 17%~20% | 29.58% |

| N2 | 50%~63% | 48.95% |

| H2O | 11%~18% | 11.20% |

| O2 | 9%~12% | 10.22% |

| SO2 | 0~130 mg/m3(标准状况) | 0.04% |

| NO x | 180~250 mg/m3(标准状况) | 0.01% |

| 成分 | 含量/% |

|---|---|

| CO2 | 17~25 |

| CO | 20~28 |

| N2 | 50~55 |

| H2 | 1~5 |

表3 典型的高炉-转炉工艺钢铁厂烟道气主要成分[33]

Table 3 Main components of flue gas from a typical blast furnace-basic oxygen furnace steelmaking process[33]

| 成分 | 含量/% |

|---|---|

| CO2 | 17~25 |

| CO | 20~28 |

| N2 | 50~55 |

| H2 | 1~5 |

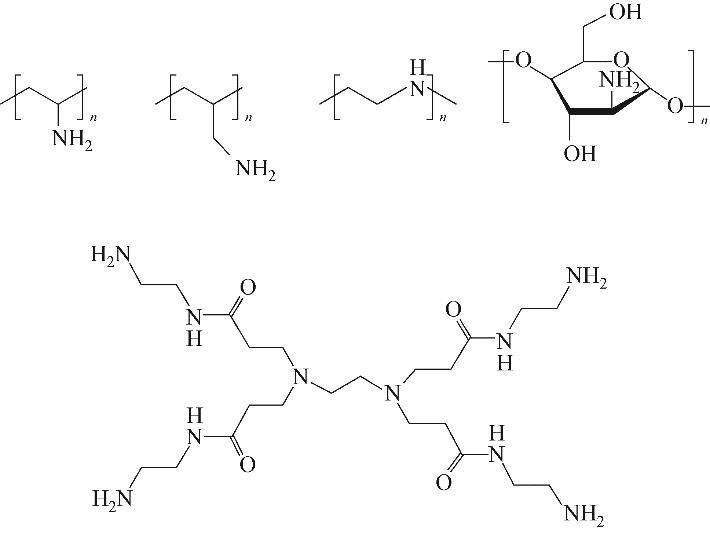

图6 常见的用于制备CO2分离促进传递膜的多胺基聚合物化学结构

Fig.6 Chemical structures of common polyamine-based polymers used for preparing CO2 separation membrane with facilitated transport

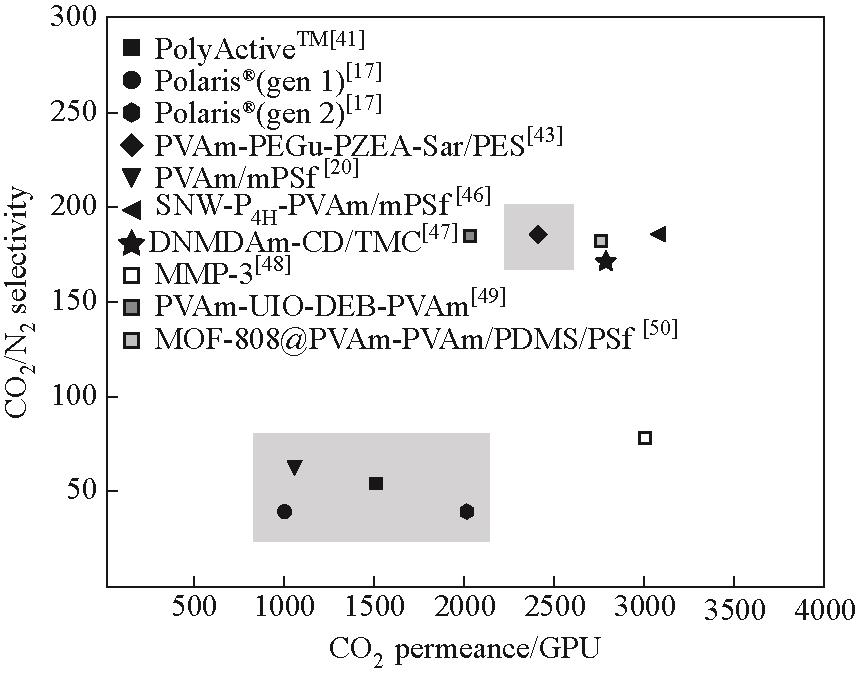

图7 文献报道的放大制备的CO2/N2分离膜(灰色区域内)与实验室规模的高性能CO2/N2分离膜性能对比

Fig.7 The performance comparison chart of CO2/N2 separation membranes fabricated on a large scale reported in the literature (inside the gray area) and high-performance CO2/N2 separation membranes at laboratory scale

| 膜分离层材料 | 组件膜面积 | 组件类型 | 文献 |

|---|---|---|---|

| PVAm | 1.5 m2 | 板框式 | [ |

| PolyActiveTM | 12.5 m2 | 板框式 | [ |

| PVAm | 300 cm2 | 卷式 | [ |

| PVAm | 1.4 m2 | 卷式 | [ |

| PVAm | 2.94 m2 | 卷式 | [ |

| PVAm | 35 m2 | 卷式 | [ |

| PolarisTM | — | 卷式 | [ |

| PVAm | 0.4 m2 | 卷式 | [ |

| PVAm | 5 m2 | 卷式 | [ |

| PVAm | 25 m2, 31 m2 | 卷式 | [ |

| PVA/ProK | 200 cm2 | 中空纤维 | [ |

| PVAm | 4.2 m2 | 中空纤维 | [ |

| SHPAA/PVA/pGO | 200 cm2 | 中空纤维 | [ |

表4 CO2/N2分离膜组件汇总

Table 4 Summary of CO2/N2 separation membrane modules

| 膜分离层材料 | 组件膜面积 | 组件类型 | 文献 |

|---|---|---|---|

| PVAm | 1.5 m2 | 板框式 | [ |

| PolyActiveTM | 12.5 m2 | 板框式 | [ |

| PVAm | 300 cm2 | 卷式 | [ |

| PVAm | 1.4 m2 | 卷式 | [ |

| PVAm | 2.94 m2 | 卷式 | [ |

| PVAm | 35 m2 | 卷式 | [ |

| PolarisTM | — | 卷式 | [ |

| PVAm | 0.4 m2 | 卷式 | [ |

| PVAm | 5 m2 | 卷式 | [ |

| PVAm | 25 m2, 31 m2 | 卷式 | [ |

| PVA/ProK | 200 cm2 | 中空纤维 | [ |

| PVAm | 4.2 m2 | 中空纤维 | [ |

| SHPAA/PVA/pGO | 200 cm2 | 中空纤维 | [ |

| 气源 | 规模① | 膜分离层材料 | 能耗或成本 | CO2捕集率/% | CO2纯度/% | 文献 |

|---|---|---|---|---|---|---|

| 天然气电厂 | 1000 m3/d(标准状况) | PES | — | 70~95 | 95~99 | [ |

| 燃煤电厂 | 1.5 m2 | PVAm | — | — | 75 | [ |

| 水泥厂 | 1.5 m2 | PVAm | 333.6 kWh | 60~70 | 72 | [ |

| 燃煤电厂 | — | PRISM | — | — | — | [ |

| 燃煤电厂 | 12.5 m2 | PolyActivetmTM | — | 42.7 | 68.2 | [ |

| 燃煤电厂 | 1 t/d | Polaris® | — | 90 | 70 | [ |

| 水泥厂 | 18 m2 | PVAm | 333.6 kWh | 80 | 95 | [ |

| 燃煤电厂 | 8.4 m2 | PVAm | — | — | 60 | [ |

| 燃煤电厂 | 1.4 m2 | PVAm/PZEA-Sar | — | 40 | 94.5 | [ |

| 燃煤电厂 | 75 m2 | PVAm | 809 kWh | 60.7 | 87.2 | [ |

| 燃煤电厂 | 50000 m3/d(标准状况) | PVAm | 844.6 kWh | 81.1 | 96.6 | [ |

| 水泥厂 | 200 cm2 | SHPAA/ PVA/pGO | 89.11 EUR/t CO2 | — | 55 | [ |

表5 中试及以上规模的水泥厂和化石能源发电厂烟道气碳捕集膜技术项目情况

Table 5 Carbon capture membrane technology projects for flue gas at pilot scale and above in cement plants and fossil fuel power plants

| 气源 | 规模① | 膜分离层材料 | 能耗或成本 | CO2捕集率/% | CO2纯度/% | 文献 |

|---|---|---|---|---|---|---|

| 天然气电厂 | 1000 m3/d(标准状况) | PES | — | 70~95 | 95~99 | [ |

| 燃煤电厂 | 1.5 m2 | PVAm | — | — | 75 | [ |

| 水泥厂 | 1.5 m2 | PVAm | 333.6 kWh | 60~70 | 72 | [ |

| 燃煤电厂 | — | PRISM | — | — | — | [ |

| 燃煤电厂 | 12.5 m2 | PolyActivetmTM | — | 42.7 | 68.2 | [ |

| 燃煤电厂 | 1 t/d | Polaris® | — | 90 | 70 | [ |

| 水泥厂 | 18 m2 | PVAm | 333.6 kWh | 80 | 95 | [ |

| 燃煤电厂 | 8.4 m2 | PVAm | — | — | 60 | [ |

| 燃煤电厂 | 1.4 m2 | PVAm/PZEA-Sar | — | 40 | 94.5 | [ |

| 燃煤电厂 | 75 m2 | PVAm | 809 kWh | 60.7 | 87.2 | [ |

| 燃煤电厂 | 50000 m3/d(标准状况) | PVAm | 844.6 kWh | 81.1 | 96.6 | [ |

| 水泥厂 | 200 cm2 | SHPAA/ PVA/pGO | 89.11 EUR/t CO2 | — | 55 | [ |

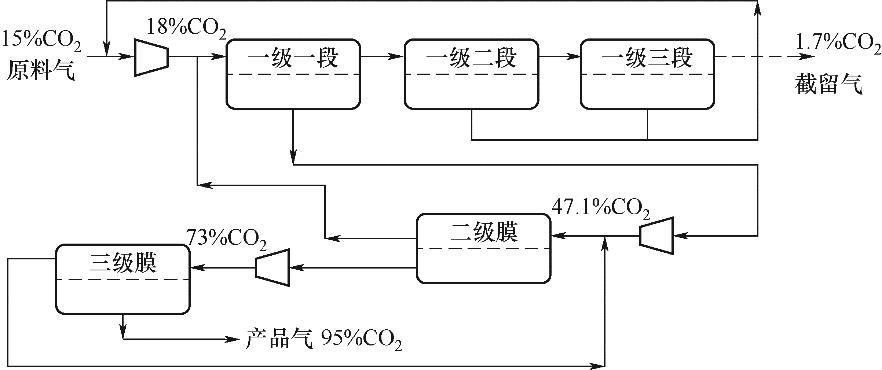

图10 三级耦合三段的膜法燃煤电厂烟气碳捕集工业示范装置工艺流程图[65]

Fig.10 Process flow diagram of a three-stage coupled, three-section membrane-based industrial demonstration system for flue gas carbon capture in coal-fired power plants[65]

图11 50000 m3/d(标准状况)烟气膜法碳捕集工业示范装置[51]

Fig.11 Photographs of the industrial membrane demonstration plant for CO2 capture at a flue gas treating capacity of 50000 m3/d[51]

| 膜材料 | 膜过程 | CO2捕集率/% | CO2纯度/% | 文献 |

|---|---|---|---|---|

| PVAm | 两级膜过程 | 79~97 | — | [ |

| Polaris® | 两级膜过程 | 99 | 95 | [ |

| PVAm | 两级膜过程 | 95.5 | 94 | [ |

| PolarisTM | 两级膜过程 | 80 | 81 | [ |

| PVAm | 两级膜过程 | 81.5 | 80.7 | [ |

表6 钢铁厂废气碳捕集膜技术的模拟和实验研究

Table 6 Simulation and experimental studies of carbon capture membrane technology for steel plant flue gas

| 膜材料 | 膜过程 | CO2捕集率/% | CO2纯度/% | 文献 |

|---|---|---|---|---|

| PVAm | 两级膜过程 | 79~97 | — | [ |

| Polaris® | 两级膜过程 | 99 | 95 | [ |

| PVAm | 两级膜过程 | 95.5 | 94 | [ |

| PolarisTM | 两级膜过程 | 80 | 81 | [ |

| PVAm | 两级膜过程 | 81.5 | 80.7 | [ |

| 1 | Dai Z D, Deng L Y. Membranes for CO2 capture and separation: progress in research and development for industrial applications[J]. Separation and Purification Technology, 2024, 335: 126022. |

| 2 | IEA. Global CO emissions by sector, 2019—2022[EB/OL]. France: International Energy Agency, 2023[2024-05-28]. . |

| 3 | Haites E. Carbon taxes and greenhouse gas emissions trading systems: what have we learned?[J]. Climate Policy, 2018, 18(8): 955-966. |

| 4 | Pulselli R M, Broersma S, Martin C L, et al. Future city visions. The energy transition towards carbon-neutrality: lessons learned from the case of Roeselare, Belgium[J]. Renewable and Sustainable Energy Reviews, 2021, 137: 110612. |

| 5 | Gür T M. Carbon dioxide emissions, capture, storage and utilization: review of materials, processes and technologies[J]. Progress in Energy and Combustion Science, 2022, 89: 100965. |

| 6 | Figueroa J D, Fout T, Plasynski S, et al. Advances in CO2 capture technology—the U.S. department of e n e r g y ' s carbon sequestration program[J]. International Journal of Greenhouse Gas Control, 2008, 2(1): 9-20. |

| 7 | 科学技术部社会发展司, 中国 21 世纪议程管理中心. 中国碳捕集利用与封存技术发展路线图(2019)[M]. 北京: 科学出版社, 2019: 2-10. |

| Ministry of Science and Tecnology of the People's Republic of China, Department of Science and Technology for Social Development, the Administrative Center for China's Genda 21. Roadmap for Carbon Capture, Utilization and Storage Technology Development in China(2019)[M]. Beijing: Science Press, 2019: 2-10. | |

| 8 | Merkel T C, Lin H Q, Wei X T, et al. Power plant post-combustion carbon dioxide capture: an opportunity for membranes[J]. Journal of Membrane Science, 2010, 359(1): 126-139. |

| 9 | Shao L, Low B T, Chung T S, et al. Polymeric membranes for the hydrogen economy: contemporary approaches and prospects for the future[J]. Journal of Membrane Science, 2009, 327(1/2): 18-31. |

| 10 | Powell C E, Qiao G G. Polymeric CO2/N2 gas separation membranes for the capture of carbon dioxide from power plant flue gases[J]. Journal of Membrane Science, 2006, 279(1/2): 1-49. |

| 11 | Basu S, Khan A L, Cano-odena A, et al. Membrane-based technologies for biogas separations[J]. Chemical Society Reviews, 2010, 39(2): 750-768. |

| 12 | Liu J Y, Hou X D, Park H B, et al. High-performance polymers for membrane CO2/N2 separation[J]. Chemistry-A European Journal, 2016, 22(45): 15980-15990. |

| 13 | Tong Z, Winston Ho W S. Facilitated transport membranes for CO2 separation and capture[J]. Separation Science and Technology, 2017, 52(2): 156-167. |

| 14 | 王湛, 王志, 高学理. 膜分离技术基础[M]. 3版. 北京: 化学工业出版社, 2019: 13-14. |

| Wang Z, Wang Z, Gao X L. Fundamental of Membrane Separation Tecnology[M]. 3rd ed. Beijing: Chemical Industry Press, 2019: 13-14. | |

| 15 | Baker R W. Future directions of membrane gas separation technology[J]. Industrial & Engineering Chemistry Research, 2002, 41(6): 1393-1411. |

| 16 | Yave W, Car A, Wind J, et al. Nanometric thin film membranes manufactured on square meter scale: ultra-thin films for CO2 capture[J]. Nanotechnology, 2010, 21(39): 395301. |

| 17 | Merkel T C, Wei X T, He Z J, et al. Selective exhaust gas recycle with membranes for CO2 capture from natural gas combined cycle power plants[J]. Industrial & Engineering Chemistry Research, 2013, 52(3): 1150-1159. |

| 18 | He X Z, Lindbråthen A, Kim T J, et al. Pilot testing on fixed-site-carrier membranes for CO2 capture from flue gas[J]. International Journal of Greenhouse Gas Control, 2017, 64: 323-332. |

| 19 | Han Y, Ho W S W. Moving beyond 90% carbon capture by highly selective membrane processes[J]. Membranes, 2022, 12(4): 399. |

| 20 | Sheng M L, Dong S L, Qiao Z H, et al. Large-scale preparation of multilayer composite membranes for post-combustion CO2 capture[J]. Journal of Membrane Science, 2021, 636: 119595. |

| 21 | 中国电力企业联合会. 中国电力行业年度发展报告2023[EB/OL]. 北京: 中国电力企业联合会, 2023[2024-05-27]. . |

| China Electricity Council. China power industry annual development report 2023[EB/OL]. Beijing: China Electricity Council, 2023[2024-05-27]. . | |

| 22 | Bui M, Adjiman C S, Bardow A, et al. Carbon capture and storage (CCS): the way forward[J]. Energy & Environmental Science, 2018, 11(5): 1062-1176. |

| 23 | Du J X, Yang W, Xu L L, et al. Review on post-combustion CO2 capture by amine blended solvents and aqueous ammonia[J]. Chemical Engineering Journal, 2024, 488: 150954. |

| 24 | Notz R J, Tönnies I, McCann N, et al. CO2 capture for fossil fuel-fired power plants[J]. Chemical Engineering & Technology, 2011, 34(2): 163-172. |

| 25 | Benhelal E, Zahedi G, Shamsaei E, et al. Global strategies and potentials to curb CO2 emissions in cement industry[J]. Journal of Cleaner Production, 2013, 51: 142-161. |

| 26 | Bjerge L M, Brevik P. CO2 capture in the cement industry, Norcem CO2 capture project (Norway)[J]. Energy Procedia, 2014, 63: 6455-6463. |

| 27 | Plaza M G, Martinez S, Rubiera F. CO2 capture, use, and storage in the cement industry: state of the art and expectations[J]. Energies, 2020, 13(21): 5692. |

| 28 | Wang M, Lawal A, Stephenson P, et al. Post-combustion CO2 capture with chemical absorption: a state-of-the-art review[J]. Chemical Engineering Research and Design, 2011, 89(9): 1609-1624. |

| 29 | Han Y, Wu D Z, Winston Ho W S. Simultaneous effects of temperature and vacuum and feed pressures on facilitated transport membrane for CO2/N2 separation[J]. Journal of Membrane Science, 2019, 573: 476-484. |

| 30 | Chen T-Y, Winston Ho W S. Effects of pressure and temperature on CO2 facilitation of amino acid salt-containing membranes for post-combustion carbon capture[J]. Journal of Membrane Science, 2024, 689: 122166. |

| 31 | 张琦, 沈佳林, 许立松. 中国钢铁工业碳达峰及低碳转型路径[J]. 钢铁, 2021, 56(10): 152-163. |

| Zhang Q, Shen J L, Xu L S. Carbon peak and low-carbon transition path of China's iron and steel industry[J]. Iron & Steel, 2021, 56(10): 152-163 | |

| 32 | Carpenter A. CO2 abatement in the iron and steel industry[R]. London, UK: IEA Clean Coal Centre, 2012. |

| 33 | Ramírez-Santos Á A, Castel C, Favre E. Utilization of blast furnace flue gas: opportunities and challenges for polymeric membrane gas separation processes[J]. Journal of Membrane Science, 2017, 526: 191-204. |

| 34 | Liu M, Nothling M D, Zhang S, et al. Thin film composite membranes for postcombustion carbon capture: polymers and beyond[J]. Progress in Polymer Science, 2022, 126: 101504. |

| 35 | Scholes C A, Qader A, Stevens G W, et al. Membrane pilot plant trials of CO2 separation from flue gas[J]. Greenhouse Gases: Science and Technology, 2015, 5(3): 229-237. |

| 36 | Lau C H, Li P, Li F Y, et al. Reverse-selective polymeric membranes for gas separations[J]. Progress in Polymer Science, 2013, 38(5): 740-766. |

| 37 | Car A, Stropnik C, Yave W, et al. Tailor-made polymeric membranes based on segmented block copolymers for CO2 separation[J]. Advanced Functional Materials, 2008, 18(18): 2815-2823. |

| 38 | Lee J H, Jung J P, Jang E, et al. CO2-philic PBEM-g-POEM comb copolymer membranes: synthesis, characterization and CO2/N2 separation[J]. Journal of Membrane Science, 2016, 502: 191-201. |

| 39 | Wang Y H, Ma Z W, Zhang X R, et al. Mixed-matrix membranes consisting of Pebax and novel nitrogen-doped porous carbons for CO2 separation[J]. Journal of Membrane Science, 2022, 644: 120182. |

| 40 | Ma Y N, He X Y, Xu S S, et al. Enhanced 2-D MOFs nanosheets/PES-g-PEG mixed matrix membrane for efficient CO2 separation[J]. Chemical Engineering Research and Design, 2022, 180: 79-89. |

| 41 | Brinkmann T, Lilleparg J, Notzke H, et al. Development of CO2 selective poly(ethylene oxide)-based membranes: from laboratory to pilot plant scale[J]. Engineering, 2017, 3(4): 485-493. |

| 42 | Chen K K, Han Y, Zhang Z E, et al. Enhancing membrane performance for CO2 capture from flue gas with ultrahigh MW polyvinylamine[J]. Journal of Membrane Science, 2021, 628: 119215. |

| 43 | Yang Y T, Han Y, Zou C L, et al. A commercial-size prototype of countercurrent spiral-wound membrane module for flue gas CO2 capture[J]. Journal of Membrane Science, 2024, 696: 122520. |

| 44 | Yuan Y, Pan Y R, Sheng M L, et al. Synthesis and optimization of high-performance amine-based polymer for CO2 separation[J]. Chinese Journal of Chemical Engineering, 2022, 50: 168-176. |

| 45 | Liu Y T, Ren Y X, Ma H Z, et al. Advanced organic molecular sieve membranes for carbon capture: current status, challenges and prospects[J]. Advanced Membranes, 2022, 2: 100028. |

| 46 | Wang W F, Yuan Y, Shi F, et al. Enhancing dispersibility of nanofiller via polymer-modification for preparation of mixed matrix membrane with high CO2 separation performance[J]. Journal of Membrane Science, 2023, 683: 121791. |

| 47 | Li N, Wang Z, Wang J X. Biomimetic hydroxypropyl-β- cyclodextrin (Hβ-CD)/polyamide (PA) membranes for CO2 separation[J]. Journal of Membrane Science, 2023, 668: 121211. |

| 48 | Qiao Z H, Zhao S, Sheng M L, et al. Metal-induced ordered microporous polymers for fabricating large-area gas separation membranes[J]. Nature Materials, 2019, 18(2): 163-168. |

| 49 | Yuan Y, Yang Y, Shi F, et al. Polymer-modified nanofillers for enhancing CO2 separation performance of MMMs: a comparative study on the role of bridging ligands[J]. Journal of Membrane Science, 2024, 711: 123220. |

| 50 | Ge C Q, Sheng M L, Yuan Y, et al. Pore-optimized MOF-808 made through a facile method using for fabrication of high-performance mixed matrix composite CO2 capture membranes[J]. Carbon Capture Science & Technology, 2024, 10: 100156. |

| 51 | 伍泓宇. 碳捕集膜组件及装置构建研究[D]. 天津: 天津大学, 2023. |

| Wu H Y. Construction of membrane modules and plants for CO2 capture[D]. Tianjin: Tianjin University, 2023. | |

| 52 | Sandru M, Kim T J, Capala W, et al. Pilot scale testing of polymeric membranes for CO2 capture from coal fired power plants[J]. Energy Procedia, 2013, 37: 6473-6480. |

| 53 | Pohlmann J, Bram M, Wilkner K, et al. Pilot scale separation of CO2 from power plant flue gases by membrane technology[J]. International Journal of Greenhouse Gas Control, 2016, 53: 56-64. |

| 54 | Salim W, Vakharia V, Chen Y X, et al. Fabrication and field testing of spiral-wound membrane modules for CO2 capture from flue gas[J]. Journal of Membrane Science, 2018, 556: 126-137. |

| 55 | Han Y, Salim W, Chen K K, et al. Field trial of spiral-wound facilitated transport membrane module for CO2 capture from flue gas[J]. Journal of Membrane Science, 2019, 575: 242-251. |

| 56 | Chen K K, Salim W, Han Y, et al. Fabrication and scale-up of multi-leaf spiral-wound membrane modules for CO2 capture from flue gas[J]. Journal of Membrane Science, 2020, 595: 117504. |

| 57 | White L S, Amo K D, Wu T, et al. Extended field trials of Polaris sweep modules for carbon capture[J]. Journal of Membrane Science, 2017, 542: 217-225. |

| 58 | 乔志华. 强化高压下CO2分离膜渗透选择性能研究[D]. 天津: 天津大学, 2015. |

| Qiao Z H. Performance improvement of CO2 separation membrane at high pressure[D]. Tianjin: Tianjin University, 2015. | |

| 59 | Wu H Y, Li Q H, Guo B S, et al. Industrial-scale spiral-wound facilitated transport membrane modules for post-combustion CO2 capture: development, investigation and optimization[J]. Journal of Membrane Science, 2023, 670: 121368. |

| 60 | Dai Z D, Fabio S, Giuseppe Marino N, et al. Field test of a pre-pilot scale hollow fiber facilitated transport membrane for CO2 capture[J]. International Journal of Greenhouse Gas Control, 2019, 86: 191-200. |

| 61 | Janakiram S, Santinelli F, Costi R, et al. Field trial of hollow fiber modules of hybrid facilitated transport membranes for flue gas CO2 capture in cement industry[J]. Chemical Engineering Journal, 2021, 413: 127405. |

| 62 | Choi S H, Kim J H, Lee Y. Pilot-scale multistage membrane process for the separation of CO2 from LNG-fired flue gas[J]. Separation and Purification Technology, 2013, 110: 170-180. |

| 63 | White L S, Wei X T, Pande S, et al. Extended flue gas trials with a membrane-based pilot plant at a one-ton-per-day carbon capture rate[J]. Journal of Membrane Science, 2015, 496: 48-57. |

| 64 | Hägg M B, Lindbråthen A, He X, et al. Pilot demonstration-reporting on CO2 capture from a cement plant using hollow fiber process[J]. Energy Procedia, 2017, 114: 6150-6165. |

| 65 | Wu H Y, Li Q H, Sheng M L, et al. Membrane technology for CO2 capture: from pilot-scale investigation of two-stage plant to actual system design[J]. Journal of Membrane Science, 2021, 624: 119137. |

| 66 | Lindqvist K, Roussanaly S, Anantharaman R. Multi-stage membrane processes for CO2 capture from cement industry[J]. Energy Procedia, 2014, 63: 6476-6483. |

| 67 | Lie J A, Vassbotn T, Hägg M B, et al. Optimization of a membrane process for CO2 capture in the steelmaking industry[J]. International Journal of Greenhouse Gas Control, 2007, 1(3): 309-317. |

| 68 | Luca A V, Petrescu L. Membrane technology applied to steel production: investigation based on process modelling and environmental tools[J]. Journal of Cleaner Production, 2021, 294: 126256. |

| 69 | Baker R W, Freeman B, Kniep J, et al. CO2 capture from cement plants and steel mills using membranes[J]. Industrial & Engineering Chemistry Research, 2018, 57(47): 15963-15970. |

| 70 | Wang B, Qiao Z H, Xu J Y, et al. Unobstructed ultrathin gas transport channels in composite membranes by interfacial self-assembly[J]. Advanced Materials, 2020, 32(22): 1907701. |

| 71 | Tan X Y, Robijns S, Thür R, et al. Truly combining the advantages of polymeric and zeolite membranes for gas separations[J]. Science, 2022, 378(6625): 1189-1194. |

| 72 | Volkov A V, Bakhtin D S, Kulikov L A, et al. Stabilization of gas transport properties of PTMSP with porous aromatic framework: effect of annealing[J]. Journal of Membrane Science, 2016, 517: 80-90. |

| 73 | An H, Park S, Kwon H T, et al. A new superior competitor for exceptional propylene/propane separations: ZIF-67 containing mixed matrix membranes[J]. Journal of Membrane Science, 2017, 526: 367-376. |

| 74 | Cao X C, Qiao Z H, Wang Z, et al. Enhanced performance of mixed matrix membrane by incorporating a highly compatible covalent organic framework into poly(vinylamine) for hydrogen purification[J]. International Journal of Hydrogen Energy, 2016, 41(21): 9167-9174. |

| 75 | Wang Z G, Tian Y Y, Fang W X, et al. Constructing strong interfacial interactions under mild conditions in MOF-incorporated mixed matrix membranes for gas separation[J]. ACS Applied Materials & Interfaces, 2021, 13(2): 3166-3174. |

| 76 | Checchetto R, Scarpa M, de Angelis M G, et al. Mixed gas diffusion and permeation of ternary and quaternary CO2/CO/N2/O2 gas mixtures in Matrimid®, polyetherimide and poly(lactic acid) membranes for CO2/CO separation[J]. Journal of Membrane Science, 2022, 659: 120768. |

| 77 | Liu Q, Chen M G, Chen G N, et al. Molecular design of two-dimensional graphdiyne membrane for selective transport of CO2 and H2 over CH4, N2, and CO[J]. Journal of Membrane Science, 2023, 675: 121557. |

| 78 | Wang T, Zeng S M, Gu Z L. Crown ether nanopores in graphene membranes for highly efficient CO2/CH4 and CO2/CO separation: a theoretical study[J]. ACS Applied Nano Materials, 2023, 6(13): 12372-12380. |

| 79 | Kim N U, Kim J H, Park B R, et al. Solid-state facilitated transport membrane for CO/N2 separation based on PHMEP-co-PAA comb-like copolymer: experimental and molecular simulation study[J]. Journal of Membrane Science, 2021, 620: 118939. |

| 80 | Min S B, Kang M, Han Y J, et al. Chitosan/Ag(Ⅰ) thin-film composite membranes with high CO/N2 separation performance by facilitated transport: effect of preparation and operation conditions[J]. Separation and Purification Technology, 2024, 328: 124931. |

| 81 | Feng S C, Wu Y Y, Luo J Q, et al. AgBF4/[emim][BF4] supported ionic liquid membrane for carbon monoxide/nitrogen separation[J]. Journal of Energy Chemistry, 2019, 29: 31-39. |

| 82 | Kang M, Kim K C, Min S B, et al. Highly CO-selective mixed-matrix membranes incorporated with Ag nanoparticle-impregnated MIL-101 metal-organic frameworks[J]. Chemical Engineering Journal, 2022, 435: 134803. |

| [1] | 韩启沃, 刘永峰, 裴普成, 张璐, 姚圣卓. 工作温度对PEMFC水分布、质子传输及性能影响分析[J]. 化工学报, 2025, 76(1): 374-384. |

| [2] | 张俊杰, 陈源, 李运堂, 李孝禄, 王冰清, 彭旭东. 超椭圆织构浮动坝箔片端面气膜密封动态性能分析与优化[J]. 化工学报, 2025, 76(1): 296-310. |

| [3] | 李雨诗, 陈源, 李运堂, 彭旭东, 王冰清, 李孝禄. 新型柔性坝箔片端面气膜密封变形协调分析及性能智能优化[J]. 化工学报, 2025, 76(1): 324-334. |

| [4] | 陈森洋, 靳蒲航, 谭志明, 谢公南. 质子交换膜燃料电池中蛇形流道液滴运动数值仿真研究[J]. 化工学报, 2024, 75(S1): 183-194. |

| [5] | 谢慧慧, 姜佳鑫, 王鑫, 李正, 郭鑫, 吕欣然, 王凌云, 刘杨. 深共晶溶剂聚合物包覆膜传输分离铂、钯的研究[J]. 化工学报, 2024, 75(S1): 235-243. |

| [6] | 邱知, 谭明. 聚离子液体膜的制备及其在低钠高钾健康酱油中的应用[J]. 化工学报, 2024, 75(S1): 244-250. |

| [7] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [8] | 张丽萍, 孟晓荣, 宋锦峰, 杜金晶. VO2@KH550/570@PS复合薄膜的制备及其热致相变性能[J]. 化工学报, 2024, 75(9): 3348-3359. |

| [9] | 陈引, 赵霄, 杜王芳, 杨竹强, 李凯, 赵建福. 喷雾冷却液膜流动特性测试方案优化及传热规律分析[J]. 化工学报, 2024, 75(8): 2734-2743. |

| [10] | 王皓宇, 杨杨, 荆文婕, 杨斌, 唐雨, 刘毅. 不同旋流器作用下气液螺旋环状流动特性研究[J]. 化工学报, 2024, 75(8): 2744-2755. |

| [11] | 王倩倩, 李冰, 郑伟波, 崔国民, 赵兵涛, 明平文. 氢燃料电池局部动态特征三维模型[J]. 化工学报, 2024, 75(8): 2812-2820. |

| [12] | 白炳林, 杜燊, 李明佳, 张传琪. 基于水相剥离的单壁碳纳米管薄膜透光和导电特性[J]. 化工学报, 2024, 75(7): 2680-2687. |

| [13] | 周文轩, 刘珍, 张福建, 张忠强. 高通量-高截留率时间维度膜法水处理机理研究[J]. 化工学报, 2024, 75(7): 2583-2593. |

| [14] | 霍宗伟, 牛亚宾, 潘艳秋. 油水膜分离中高黏度油滴行为研究和影响因素分析[J]. 化工学报, 2024, 75(6): 2262-2273. |

| [15] | 张文焱, 刘浩, 宋伟龙, 赵频, 王新华. 不同粒径UiO-66混掺改性TFN-FO膜的构建及性能评价[J]. 化工学报, 2024, 75(5): 1920-1928. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号