化工学报 ›› 2025, Vol. 76 ›› Issue (2): 484-503.DOI: 10.11949/0438-1157.20240746

• 综述与专论 • 上一篇

张鑫源( ), 何呈祥, 李亚婷, 朱春英, 马友光, 付涛涛(

), 何呈祥, 李亚婷, 朱春英, 马友光, 付涛涛( )

)

收稿日期:2024-07-02

修回日期:2024-07-25

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

付涛涛

作者简介:张鑫源(2000—), 男, 硕士研究生, zxy_07140815@tju.edu.cn

基金资助:

Xinyuan ZHANG( ), Chengxiang HE, Yating LI, Chunying ZHU, Youguang MA, Taotao FU(

), Chengxiang HE, Yating LI, Chunying ZHU, Youguang MA, Taotao FU( )

)

Received:2024-07-02

Revised:2024-07-25

Online:2025-03-25

Published:2025-03-10

Contact:

Taotao FU

摘要:

微通道内液液非均相体系传质行为的研究对明确传质机理,进一步提高传质效率,促进微通道装置在连续流动化学合成、生物医学和溶剂萃取等领域的工业化应用十分重要。介绍了用于微通道内传质研究的指标参数及其影响因素,总结归纳了微通道内液液体系传质研究的技术方法及其相关原理,包括探究两相流动行为、相内传质和相间传质的模拟方法,评价微通道装置整体传质性能的离线实验方法与实时检测微通道内流体速度场和浓度场的在线实验方法,并对未来用于微通道内液液体系传质研究的模拟和实验方法的发展方向提出建议。

中图分类号:

张鑫源, 何呈祥, 李亚婷, 朱春英, 马友光, 付涛涛. 微通道内液液非均相传质的模拟和实验研究方法进展[J]. 化工学报, 2025, 76(2): 484-503.

Xinyuan ZHANG, Chengxiang HE, Yating LI, Chunying ZHU, Youguang MA, Taotao FU. Advances in simulation and experimental research methods for mass transfer of liquid-liquid heterogeneous system in microchannels[J]. CIESC Journal, 2025, 76(2): 484-503.

| 无量纲数 | 定义式 | 物理意义 |

|---|---|---|

| 毛细数(Ca) | 表征黏性力与界面张力的相对大小 | |

| Reynolds数(Re) | 表征惯性力与黏性力的相对大小 | |

| Weber数(We) | 表征惯性力与界面张力的相对大小 |

表1 常用的无量纲数

Table1 Commonly used dimensionless numbers

| 无量纲数 | 定义式 | 物理意义 |

|---|---|---|

| 毛细数(Ca) | 表征黏性力与界面张力的相对大小 | |

| Reynolds数(Re) | 表征惯性力与黏性力的相对大小 | |

| Weber数(We) | 表征惯性力与界面张力的相对大小 |

| 预测式 | 变量意义 | 文献 |

|---|---|---|

μCH——环己烷黏度,Pa·s Vs——段塞速度,m/s σCH——环己烷-水的界面张力,N/m | [ | |

δ——膜厚,mm d——微通道直径,mm μc——连续相黏度,Pa·s ρc——连续相密度,kg/m3 umix——两相总流速,m/s γ——界面张力,N/m | [ | |

ρ——连续相密度,kg/m3 μ——连续相黏度,Pa·s dh——微通道直径,mm | [ |

表2 液膜厚度预测式

Table 2 Liquid film thickness prediction formula

| 预测式 | 变量意义 | 文献 |

|---|---|---|

μCH——环己烷黏度,Pa·s Vs——段塞速度,m/s σCH——环己烷-水的界面张力,N/m | [ | |

δ——膜厚,mm d——微通道直径,mm μc——连续相黏度,Pa·s ρc——连续相密度,kg/m3 umix——两相总流速,m/s γ——界面张力,N/m | [ | |

ρ——连续相密度,kg/m3 μ——连续相黏度,Pa·s dh——微通道直径,mm | [ |

| 预测式 | 微通道装置 | 文献 |

|---|---|---|

| 直微通道 | [ | |

| 并行直微通道 | ||

| 蛇形微通道(Dh=319 μm) | [ | |

| 分裂重组微通道(Dh=184 μm) | ||

| T型微通道 | [ | |

| 十字聚焦微通道 |

表3 微通道内平均体积传质系数预测式

Table 3 Prediction formula of average volume mass transfer coefficient in microchannel

| 预测式 | 微通道装置 | 文献 |

|---|---|---|

| 直微通道 | [ | |

| 并行直微通道 | ||

| 蛇形微通道(Dh=319 μm) | [ | |

| 分裂重组微通道(Dh=184 μm) | ||

| T型微通道 | [ | |

| 十字聚焦微通道 |

| 类型 | 微通道装置 | 模拟方法 | 研究内容 | 文献 |

|---|---|---|---|---|

| 两相流 | 具有突然扩张/收缩腔的微通道 | VOF | 微腔通道内液液两相流速、液滴形状和流场涡度的演变情况 | [ |

| 周期膨胀微通道 | LSM | 微腔通道内流动液滴的内循环情况 | [ | |

| 相内传质 | 十字聚焦微通道 | VOF+UDS | 微通道内表观流速对混合效率的影响 | [ |

| T型微通道 | VOF+SMT | 黏度比对微通道内液滴内循环的影响 | [ | |

| 蛇形微通道 | VOF+UDS | 弯曲半径和分散相分数对液滴内混合的影响 | [ | |

| 带有内壁脊的蛇形微通道 | VOF+SMT | 微通道内液滴内混合的机理以及脊宽和脊数对不同尺寸液滴内部混合的影响 | [ | |

| 凹凸蛇形微通道 | VOF+SMT | 凹凸结构尺寸、布局和数量对液滴内部混合的影响 | [ | |

| T结正弦微通道 | VOF+SMT | 促进液滴内部混合的机理和混合效率探究 | [ | |

| 蛇形微通道 | VOF+MTE | 不同通道截面形状和通道截面横向比对液滴内部混合效率和反应效果的影响 | [ | |

| 相间传质 | T型微通道 | VOF+C-CST | 不同流型下进行萃取的传质机理和效果研究 | [ |

| 十字聚焦微通道 | VOF+UDF | 微通道内部分互溶体系的液滴形成机理、传质机理以及弯曲通道增强传质机理的研究 | [ | |

| 固定液滴形状的微通道计算域 | MTE | 通道尺寸和操作条件对界面面积、萃取效率、体积传质系数和双相反应的影响 | [ | |

| 含SK内构件的T型微通道 | EMP+PBE+SMT | 不同流速下微通道内液滴的动态尺寸分布、流体动力学行为和传质行为研究 | [ |

表4 微通道内液液非均相体系传质研究所用的模拟方法、通道装置和主要研究内容

Table 4 Simulation methods, channel devices and main research contents for mass transfer of liquid-liquid heterogeneous systems in microchannels

| 类型 | 微通道装置 | 模拟方法 | 研究内容 | 文献 |

|---|---|---|---|---|

| 两相流 | 具有突然扩张/收缩腔的微通道 | VOF | 微腔通道内液液两相流速、液滴形状和流场涡度的演变情况 | [ |

| 周期膨胀微通道 | LSM | 微腔通道内流动液滴的内循环情况 | [ | |

| 相内传质 | 十字聚焦微通道 | VOF+UDS | 微通道内表观流速对混合效率的影响 | [ |

| T型微通道 | VOF+SMT | 黏度比对微通道内液滴内循环的影响 | [ | |

| 蛇形微通道 | VOF+UDS | 弯曲半径和分散相分数对液滴内混合的影响 | [ | |

| 带有内壁脊的蛇形微通道 | VOF+SMT | 微通道内液滴内混合的机理以及脊宽和脊数对不同尺寸液滴内部混合的影响 | [ | |

| 凹凸蛇形微通道 | VOF+SMT | 凹凸结构尺寸、布局和数量对液滴内部混合的影响 | [ | |

| T结正弦微通道 | VOF+SMT | 促进液滴内部混合的机理和混合效率探究 | [ | |

| 蛇形微通道 | VOF+MTE | 不同通道截面形状和通道截面横向比对液滴内部混合效率和反应效果的影响 | [ | |

| 相间传质 | T型微通道 | VOF+C-CST | 不同流型下进行萃取的传质机理和效果研究 | [ |

| 十字聚焦微通道 | VOF+UDF | 微通道内部分互溶体系的液滴形成机理、传质机理以及弯曲通道增强传质机理的研究 | [ | |

| 固定液滴形状的微通道计算域 | MTE | 通道尺寸和操作条件对界面面积、萃取效率、体积传质系数和双相反应的影响 | [ | |

| 含SK内构件的T型微通道 | EMP+PBE+SMT | 不同流速下微通道内液滴的动态尺寸分布、流体动力学行为和传质行为研究 | [ |

| 实验方法 | 特点及适用范围 | 测量尺度 | 响应时间 | 文献 |

|---|---|---|---|---|

反应法 | 离线检测方法,过程简单,操作容易,适用性强,可测定微通道装置整体的传质系数;通常选择中和、皂化或碱性水解等快速反应消除化学反应对传质过程的强化作用,可用于微通道装置整体传质性能的评价 | 毫米/厘米级 | 秒级 | [ |

萃取法 | 离线检测方法,特点与反应法相似,但是为物理过程,通过物质在两相间的传递测定微通道装置整体的传质系数;由于通道出口处两相不能及时分离,需采用外推法排除此过程两相间传质的影响,获得出口处目标相内传递物质的平均浓度 | 毫米/厘米级 | 秒级 | [ |

| 微分辨荧光诱导技术 | 测量快,波动小,灵敏度高,可获得单一平面液层内的浓度信息;但是设备昂贵,普适性弱,针对不同物系和微通道装置需重新标定荧光强度与物质浓度的关系,并且存在相间荧光强度的交叉干扰;常用于微通道内段塞流型下浓度场的实时监测 | 微米/毫米级 | 微秒/毫秒级 | [ |

比色技术 | 检测迅速,响应及时,较微分辨荧光诱导技术更实用,且更易实施;需根据特定的研究体系构建灰度与物质浓度的标准曲线,获取的浓度信息为多平面液层叠加后的结果;适于微通道内对称流动下浓度场的实时监测 | 微米/毫米级 | 微秒/毫秒级 | [ |

微粒成像测速技术 | 所用设备与微分辨荧光诱导技术类似,需根据测量尺度和操作条件选择合适的示踪剂粒径、浓度和激光脉冲时间间隔;示踪剂微粒的布朗运动会对速度求算产生影响,通过对多个示踪微粒速度的总体平均可减弱误差;该技术不适合数微米或纳米尺度下流体速度场的实时监测,因为此时与测量尺度适配的示踪微粒的剧烈布朗运动会导致流体速度求算的显著偏差 | 微米/毫米级 | 微秒/毫秒级 | [ |

表5 各种实验方法的特点、适用范围、测量尺度和响应时间

Table 5 Characteristics, applicability, measurement scales, and response times of various experimental methods

| 实验方法 | 特点及适用范围 | 测量尺度 | 响应时间 | 文献 |

|---|---|---|---|---|

反应法 | 离线检测方法,过程简单,操作容易,适用性强,可测定微通道装置整体的传质系数;通常选择中和、皂化或碱性水解等快速反应消除化学反应对传质过程的强化作用,可用于微通道装置整体传质性能的评价 | 毫米/厘米级 | 秒级 | [ |

萃取法 | 离线检测方法,特点与反应法相似,但是为物理过程,通过物质在两相间的传递测定微通道装置整体的传质系数;由于通道出口处两相不能及时分离,需采用外推法排除此过程两相间传质的影响,获得出口处目标相内传递物质的平均浓度 | 毫米/厘米级 | 秒级 | [ |

| 微分辨荧光诱导技术 | 测量快,波动小,灵敏度高,可获得单一平面液层内的浓度信息;但是设备昂贵,普适性弱,针对不同物系和微通道装置需重新标定荧光强度与物质浓度的关系,并且存在相间荧光强度的交叉干扰;常用于微通道内段塞流型下浓度场的实时监测 | 微米/毫米级 | 微秒/毫秒级 | [ |

比色技术 | 检测迅速,响应及时,较微分辨荧光诱导技术更实用,且更易实施;需根据特定的研究体系构建灰度与物质浓度的标准曲线,获取的浓度信息为多平面液层叠加后的结果;适于微通道内对称流动下浓度场的实时监测 | 微米/毫米级 | 微秒/毫秒级 | [ |

微粒成像测速技术 | 所用设备与微分辨荧光诱导技术类似,需根据测量尺度和操作条件选择合适的示踪剂粒径、浓度和激光脉冲时间间隔;示踪剂微粒的布朗运动会对速度求算产生影响,通过对多个示踪微粒速度的总体平均可减弱误差;该技术不适合数微米或纳米尺度下流体速度场的实时监测,因为此时与测量尺度适配的示踪微粒的剧烈布朗运动会导致流体速度求算的显著偏差 | 微米/毫米级 | 微秒/毫秒级 | [ |

| 研究物系 | 微通道装置 | 研究内容 | 文献 |

|---|---|---|---|

| 甲苯-乙酸-水 | 导线嵌入式同心微通道 | 流率、相比、初始乙酸浓度、嵌件形状和流型对传质的影响 | [ |

| 甲苯-乙酸-水 | T型直通道 T型螺旋通道 | 流速、通道直径、通道结构和机械振动对流型和传质的影响 | [ |

| 甲苯+N1932-钒离子-水 | Raydrop微通道装置 | 硫酸浓度和铬离子对界面和不同钒离子物种传质的影响 | [ |

| 正丁醇-琥珀酸-水 | 垂直T型微通道逆流萃取装置 | 相比、总流速和主通道内径对平均液滴直径、萃取效率和体积传质系数的影响 | [ |

| 正辛醇-丙酸-水 | 具有入口凹坑结构和主通道 凹坑阵列的T型微通道 | T型结处的凹坑直径、混合通道内的凹坑设计以及通道直径对传质系数和萃取效率的影响 | [ |

| 正辛醇-茜红素S-水 | 多环微通道 | 环直径、环数和环间距对传质的影响以及基于人工智能模型对萃取性能的准确预测 | [ |

| 正辛烷+正辛醇-苯酚-水 | 非对称阶跃T结微通道 | 对比了阶跃T结微通道与常规T型微通道的传质性能,提出一种采样检测方法量化液滴形成阶段和运动阶段的贡献 | [ |

| 十二烷-苯酚-水 | T型微通道 | 不同流型下的传质研究和机理分析 | [ |

| 十二烷-苯酚-水 | T型微通道 | 液滴长度、截面形状和当量通道直径对体积传质系数的影响 | [ |

| 正己烷-丙酸-水 | T型并行微通道 | 研究了并行微通道内的段塞形成、段塞体积、比表面积、萃取效率和传质系数,并与单通道进行了对比 | [ |

| 磷酸二(2-乙基己)酯+煤油-Cu2+-水 | 具有变形插入物的微通道 | 总流速、微通道内径、插入物直径和萃取液浓度对萃取效率和传质系数的影响 | [ |

| 乙酸乙酯-水 | T型微通道 | 微通道直径、水相流速和温度对乙酸乙酯在水相中传质系数的影响 | [ |

| TBP+煤油-磷酸-水 | 旋转螺旋微通道 | 流率、转速、平均液滴直径和平均停留时间对旋转螺旋微通道传质性能的影响与传质系数预测式的建立 | [ |

表6 萃取法研究微通道内液液非均相体系传质过程所用的物系、装置和主要研究内容

Table 6 System and device used in extraction method to study mass transfer process of liquid-liquid heterogeneous system in microchannels and main research contents

| 研究物系 | 微通道装置 | 研究内容 | 文献 |

|---|---|---|---|

| 甲苯-乙酸-水 | 导线嵌入式同心微通道 | 流率、相比、初始乙酸浓度、嵌件形状和流型对传质的影响 | [ |

| 甲苯-乙酸-水 | T型直通道 T型螺旋通道 | 流速、通道直径、通道结构和机械振动对流型和传质的影响 | [ |

| 甲苯+N1932-钒离子-水 | Raydrop微通道装置 | 硫酸浓度和铬离子对界面和不同钒离子物种传质的影响 | [ |

| 正丁醇-琥珀酸-水 | 垂直T型微通道逆流萃取装置 | 相比、总流速和主通道内径对平均液滴直径、萃取效率和体积传质系数的影响 | [ |

| 正辛醇-丙酸-水 | 具有入口凹坑结构和主通道 凹坑阵列的T型微通道 | T型结处的凹坑直径、混合通道内的凹坑设计以及通道直径对传质系数和萃取效率的影响 | [ |

| 正辛醇-茜红素S-水 | 多环微通道 | 环直径、环数和环间距对传质的影响以及基于人工智能模型对萃取性能的准确预测 | [ |

| 正辛烷+正辛醇-苯酚-水 | 非对称阶跃T结微通道 | 对比了阶跃T结微通道与常规T型微通道的传质性能,提出一种采样检测方法量化液滴形成阶段和运动阶段的贡献 | [ |

| 十二烷-苯酚-水 | T型微通道 | 不同流型下的传质研究和机理分析 | [ |

| 十二烷-苯酚-水 | T型微通道 | 液滴长度、截面形状和当量通道直径对体积传质系数的影响 | [ |

| 正己烷-丙酸-水 | T型并行微通道 | 研究了并行微通道内的段塞形成、段塞体积、比表面积、萃取效率和传质系数,并与单通道进行了对比 | [ |

| 磷酸二(2-乙基己)酯+煤油-Cu2+-水 | 具有变形插入物的微通道 | 总流速、微通道内径、插入物直径和萃取液浓度对萃取效率和传质系数的影响 | [ |

| 乙酸乙酯-水 | T型微通道 | 微通道直径、水相流速和温度对乙酸乙酯在水相中传质系数的影响 | [ |

| TBP+煤油-磷酸-水 | 旋转螺旋微通道 | 流率、转速、平均液滴直径和平均停留时间对旋转螺旋微通道传质性能的影响与传质系数预测式的建立 | [ |

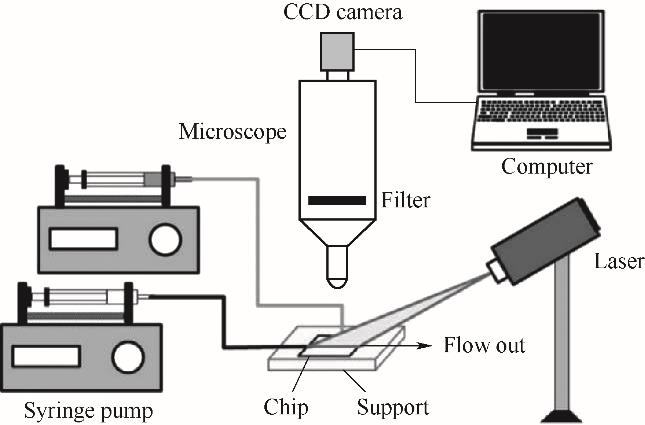

图11 运用micro-LIF技术研究微通道内非均相液液体系传质过程的典型实验装置示意图[28]

Fig.11 Schematic diagram of typical experimental device for studying mass transfer process of heterogeneous liquid systems in microchannels using micro-LIF technology [28]

| 1 | Singh K K, Renjith A U, Shenoy K T. Liquid-liquid extraction in microchannels and conventional stage-wise extractors: a comparative study[J]. Chemical Engineering and Processing: Process Intensification, 2015, 98: 95-105. |

| 2 | Hessel V, Kralisch D, Kockmann N, et al. Novel process windows for enabling, accelerating, and uplifting flow chemistry[J]. ChemSusChem, 2013, 6(5): 746-789. |

| 3 | Raji F, Kahani A, Sahabi M, et al. Investigating the effectiveness of the main channel in microfluidic liquid-liquid extraction process[J]. International Communications in Heat and Mass Transfer, 2023, 147: 106986. |

| 4 | Song J, Cui Y J, Wang Y J, et al. Accurate determination of the kinetics of toluene nitration in a liquid-liquid microflow system[J]. Journal of Flow Chemistry, 2023, 13(3): 311-323. |

| 5 | Zhao Y J, Cheng Y, Shang L R, et al. Microfluidic synthesis of barcode particles for multiplex assays[J]. Small, 2015, 11(2): 151-174. |

| 6 | Cao J L, Kürsten D, Krause K, et al. Application of micro-segmented flow for two-dimensional characterization of the combinatorial effect of zinc and copper ions on metal-tolerant Streptomyces strains[J]. Applied Microbiology and Biotechnology, 2013, 97(20): 8923-8930. |

| 7 | Zheng N, Zhou M Y, Du C H, et al. 5-Fluorouracil delivery from a novel three-dimensional micro-device: in vitro and in vivo evaluation[J]. Archives of Pharmacal Research, 2013, 36(12): 1487-1493. |

| 8 | Lee S H, Park M, Park C G, et al. Implantable micro-chip for controlled delivery of diclofenac sodium[J]. Journal of Controlled Release, 2014, 196: 52-59. |

| 9 | Huh Y S, Jeon S J, Lee E Z, et al. Microfluidic extraction using two phase laminar flow for chemical and biological applications[J]. Korean Journal of Chemical Engineering, 2011, 28(3): 633-642. |

| 10 | Wang K, Luo G S. Microflow extraction: a review of recent development[J]. Chemical Engineering Science, 2017, 169: 18-33. |

| 11 | Kashid M N, Renken A, Kiwi-Minsker L. Gas-liquid and liquid-liquid mass transfer in microstructured reactors[J]. Chemical Engineering Science, 2011, 66(17): 3876-3897. |

| 12 | Biswas K G, Patra R, Das G, et al. Effect of flow orientation on liquid-liquid slug flow in a capillary tube[J]. Chemical Engineering Journal, 2015, 262: 436-446. |

| 13 | Thulasidas T C, Abraham M A, Cerro R L. Flow patterns in liquid slugs during bubble-train flow inside capillaries[J]. Chemical Engineering Science, 1997, 52(17): 2947-2962. |

| 14 | Biswas K G, Das G, Ray S, et al. Mass transfer characteristics of liquid-liquid flow in small diameter conduits[J]. Chemical Engineering Science, 2015, 122: 652-661. |

| 15 | Tsaoulidis D, Dore V, Angeli P, et al. Flow patterns and pressure drop of ionic liquid-water two-phase flows in microchannels[J]. International Journal of Multiphase Flow, 2013, 54: 1-10. |

| 16 | Kashid M N, Renken A, Kiwi-Minsker L. Influence of flow regime on mass transfer in different types of microchannels[J]. Industrial & Engineering Chemistry Research, 2011, 50(11): 6906-6914. |

| 17 | Sattari-Najafabadi M, Nasr Esfahany M, Wu Z, et al. Mass transfer between phases in microchannels: a review[J]. Chemical Engineering and Processing: Process Intensification, 2018, 127: 213-237. |

| 18 | Yu S C, Zhang J, Li S W, et al. Mass transfer and droplet behaviors in liquid-liquid extraction process based on multi-scale perspective: a review[J]. Separations, 2023, 10(4): 264. |

| 19 | Qian J Y, Li X J, Wu Z, et al. A comprehensive review on liquid-liquid two-phase flow in microchannel: flow pattern and mass transfer[J]. Microfluidics and Nanofluidics, 2019, 23(10): 116. |

| 20 | Ghaini A, Kashid M N, Agar D W. Effective interfacial area for mass transfer in the liquid-liquid slug flow capillary microreactors[J]. Chemical Engineering and Processing: Process Intensification, 2010, 49(4): 358-366. |

| 21 | Kashid M N, Agar D W. Hydrodynamics of liquid-liquid slug flow capillary microreactor: flow regimes, slug size and pressure drop[J]. Chemical Engineering Journal, 2007, 131(1/2/3): 1-13. |

| 22 | Tsaoulidis D, Angeli P. Effect of channel size on liquid-liquid plug flow in small channels[J]. AIChE J., 2016, 62: 315-324. |

| 23 | Mac Giolla Eain M, Egan V, Punch J. Film thickness measurements in liquid-liquid slug flow regimes[J]. International Journal of Heat and Fluid Flow, 2013, 44: 515-523. |

| 24 | Kashid M N, Gerlach I, Goetz S, et al. Internal circulation within the liquid slugs of a liquid-liquid slug-flow capillary microreactor[J]. Industrial & Engineering Chemistry Research, 2005, 44 (14): 5003-5010. |

| 25 | Li Q, Angeli P. Experimental and numerical hydrodynamic studies of ionic liquid-aqueous plug flow in small channels[J]. Chemical Engineering Journal, 2017, 328: 717-736. |

| 26 | Kashid M N, Gupta A, Renken A, et al. Numbering-up and mass transfer studies of liquid-liquid two-phase microstructured reactors[J]. Chemical Engineering Journal, 2010, 158(2): 233-240. |

| 27 | Darekar M, Sen N, Singh K K, et al. Liquid-liquid extraction in microchannels with Zinc-D2EHPA system[J]. Hydrometallurgy, 2014, 144: 54-62. |

| 28 | Bai L, Zhao S F, Fu Y H, et al. Experimental study of mass transfer in water/ionic liquid microdroplet systems using micro-LIF technique[J]. Chemical Engineering Journal, 2016, 298: 281-290. |

| 29 | Tsaoulidis D, Angeli P. Effect of channel size on mass transfer during liquid-liquid plug flow in small scale extractors[J]. Chemical Engineering Journal, 2015, 262: 785-793. |

| 30 | Dessimoz A L, Cavin L, Renken A, et al. Liquid-liquid two-phase flow patterns and mass transfer characteristics in rectangular glass microreactors[J]. Chemical Engineering Science, 2008, 63(16): 4035-4044. |

| 31 | Wang J J, Wang J N, Feng L F, et al. Fluid mixing in droplet-based microfluidics with a serpentine microchannel[J]. RSC Advances, 2015, 5(126): 104138-104144. |

| 32 | Tice J D, Song H, Lyon A D, et al. Formation of droplets and mixing in multiphase microfluidics at low values of the Reynolds and the capillary numbers[J]. Langmuir, 2003, 19(22): 9127-9133. |

| 33 | Plouffe P, Roberge D M, Sieber J, et al. Liquid-liquid mass transfer in a serpentine micro-reactor using various solvents[J]. Chemical Engineering Journal, 2016, 285: 605-615. |

| 34 | Sattari-Najafabadi M, Nasr Esfahany M N. Intensification of liquid-liquid mass transfer in a circular microchannel in the presence of sodium dodecyl sulfate[J]. Chemical Engineering and Processing: Process Intensification, 2017, 117: 9-17. |

| 35 | Zhao Y C, Su Y H, Chen G W, et al. Effect of surface properties on the flow characteristics and mass transfer performance in microchannels[J]. Chemical Engineering Science, 2010, 65(5): 1563-1570. |

| 36 | Sattari-Najafabadi M, Nasr Esfahany M, Wu Z, et al. The effect of the size of square microchannels on hydrodynamics and mass transfer during liquid-liquid slug flow[J]. AIChE J, 2017, 63(11): 5019-5028. |

| 37 | Xu B J, Cai W F, Liu X L, et al. Mass transfer behavior of liquid-liquid slug flow in circular cross-section microchannel[J]. Chemical Engineering Research and Design, 2013, 91(7): 1203-1211. |

| 38 | Matsuoka A, Noishiki K, Mae K. Experimental study of the contribution of liquid film for liquid-liquid Taylor flow mass transfer in a microchannel[J]. Chemical Engineering Science, 2016, 155: 306-313. |

| 39 | Di Miceli Raimondi N, Prat L, Gourdon C, et al. Experiments of mass transfer with liquid-liquid slug flow in square microchannels[J]. Chemical Engineering Science, 2014, 105: 169-178. |

| 40 | Zhao S F, Wang W T, Zhang M X, et al. Three-dimensional simulation of mixing performance inside droplets in micro-channels by Lattice Boltzmann method[J]. Chemical Engineering Journal, 2012, 207: 267-277. |

| 41 | Aoki N, Tanigawa S, Mae K. A new index for precise design and advanced operation of mass transfer in slug flow[J]. Chemical Engineering Journal, 2011, 167(2/3): 651-656. |

| 42 | Özkan A, Erdem E Y. Numerical analysis of mixing performance in sinusoidal microchannels based on particle motion in droplets[J]. Microfluidics and Nanofluidics, 2015, 19(5): 1101-1108. |

| 43 | Xiong Q Q, Chen Z, Li S W, et al. Micro-PIV measurement and CFD simulation of flow field and swirling strength during droplet formation process in a coaxial microchannel[J]. Chemical Engineering Science, 2018, 185: 157-167. |

| 44 | Lan W J, Li S W, Wang Y J, et al. CFD simulation of droplet formation in microchannels by a modified level set method[J]. Industrial & Engineering Chemistry Research, 2014, 53(12): 4913-4921. |

| 45 | Olsson E, Kreiss G. A conservative level set method for two phase flow[J]. Journal of Computational Physics, 2005, 210(1): 225-246. |

| 46 | Chandra A K. Numerical investigations of two-phase flows through enhanced microchannels[J]. Chemical and Biochemical Engineering Quarterly, 2016, 30(2): 149-159. |

| 47 | Qian J Y, Li X J, Gao Z X, et al. Mixing efficiency analysis on droplet formation process in microchannels by numerical methods[J]. Processes, 2019, 7(1): 33. |

| 48 | Etminan A, Muzychka Y S, Pope K. Numerical investigation of gas-liquid and liquid-liquid Taylor flow through a circular microchannel with a sudden expansion[J]. The Canadian Journal of Chemical Engineering, 2022, 100(7): 1596-1612. |

| 49 | Yu Q, Chen X Y. Insight into the effects of smooth channels, sharp channels and channel bending angles on intra-droplet mass transfer behavior[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2022, 44(12): 592. |

| 50 | Xu Y Y, Zhao M, Paschke S, et al. Detailed investigations of the countercurrent multiphase (gas-liquid and gas-liquid-liquid) flow behavior by three-dimensional computational fluid dynamics simulations[J]. Industrial & Engineering Chemistry Research, 2014, 53(18): 7797-7809. |

| 51 | Rajesh V M, Buwa V V. Volume-of-fluid simulations of gas-liquid-liquid flows in minichannels[J]. Chemical Engineering Journal, 2018, 345: 688-705. |

| 52 | Hosseini F, Rahimi M. Computational fluid dynamics and experimental investigations on liquid-liquid mass transfer in T-type microchannels with different mixing channel barrier shapes[J]. Separation Science and Technology, 2020, 55(18): 3502-3516. |

| 53 | Cao W, Yang Q J, Mao Q, et al. Numerical simulation of vortex flow evolution during droplet formation in T-inlet microchannel[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 664: 131140. |

| 54 | Yu Q, Chen X Y. Insight into the dynamic mixing of droplets and plugs in droplet micro-mixer with Cantor fractal structure[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2023, 45(11): 571. |

| 55 | Edelmann C A, Le Clercq P C, Noll B. Numerical investigation of different modes of internal circulation in spherical drops: fluid dynamics and mass/heat transfer[J]. International Journal of Multiphase Flow, 2017, 95: 54-70. |

| 56 | Yin J, Kuhn S. Quantification of interfacial mass transfer during droplet formation in a microfluidic T-junction using VOF[J]. Chemical Engineering and Processing: Process Intensification, 2023, 190: 109414. |

| 57 | Francois M M, Cummins S J, Dendy E D, et al. A balanced-force algorithm for continuous and sharp interfacial surface tension models within a volume tracking framework[J]. Journal of Computational Physics, 2006, 213(1): 141-173. |

| 58 | Raeini A Q, Blunt M J, Bijeljic B. Modelling two-phase flow in porous media at the pore scale using the volume-of-fluid method[J]. Journal of Computational Physics, 2012, 231(17): 5653-5668. |

| 59 | Maes J, Soulaine C. A new compressive scheme to simulate species transfer across fluid interfaces using the Volume-of-Fluid method[J]. Chemical Engineering Science, 2018, 190: 405-418. |

| 60 | Zhang J Z, Lei L, Li H L, et al. Experimental and numerical studies of liquid-liquid two-phase flows in microchannel with sudden expansion/contraction cavities[J]. Chemical Engineering Journal, 2022, 433: 133820. |

| 61 | Han Y, Li H B, Fu T T, et al. Mass transfer intensification of slug flow by interfacial deformation at low flow rate in the microchannels with periodic expansion units[J]. Chemical Engineering Science, 2023, 275: 118743. |

| 62 | Qian J Y, Zhao L, Li X J, et al. Effect of droplet superficial velocity on mixing efficiency in a microchannel[J]. Journal of Zhejiang University: Science A, 2022, 23(10): 783-794. |

| 63 | Chao X, Xu F S, Yao C Q, et al. CFD simulation of internal flow and mixing within droplets in a T-junction microchannel[J]. Industrial & Engineering Chemistry Research, 2021, 60(16): 6038-6047. |

| 64 | Qian J Y, Li X J, Gao Z X, et al. Mixing efficiency and pressure drop analysis of liquid-liquid two phases flow in serpentine microchannels[J]. Journal of Flow Chemistry, 2019, 9(3): 187-197. |

| 65 | Cao X, Chen Y P. Design and numerical analysis of serpentine microchannel integrated with inner-wall ridges for enhanced droplet mixing[J]. Science China Technological Sciences, 2023, 66(2): 560-573. |

| 66 | Cao X, Zhou B, Yu C, et al. Droplet-based mixing characteristics in bumpy serpentine microchannel[J]. Chemical Engineering and Processing: Process Intensification, 2021, 159: 108246. |

| 67 | Yang L, Li S S, Liu J X, et al. Fluid mixing in droplet-based microfluidics with T junction and convergent-divergent sinusoidal microchannels[J]. Electrophoresis, 2018, 39(3): 512-520. |

| 68 | Ghazimirsaeed E, Madadelahi M, Dizani M, et al. Secondary flows, mixing, and chemical reaction analysis of droplet-based flow inside serpentine microchannels with different cross sections[J]. Langmuir, 2021, 37(17): 5118-5130. |

| 69 | Chen T Y, Desir P, Bracconi M, et al. Liquid-liquid microfluidic flows for ultrafast 5-hydroxymethyl furfural extraction[J]. Industrial & Engineering Chemistry Research, 2021, 60(9): 3723-3735. |

| 70 | Guo J Y, Cheng C J, Chen C F, et al. Mass transfer and size control of partially miscible fluid drops in a flow focusing microfluidic device[J]. Physics of Fluids, 2023, 35(6): 062010. |

| 71 | Cheng D, Chen F E. Experimental and numerical studies of the phase-transfer-catalyzed Wittig reaction in liquid-liquid slug-flow microchannels[J]. Industrial & Engineering Chemistry Research, 2020, 59(10): 4397-4410. |

| 72 | Cao Q, Zhou J F, Qian Y, et al. Three-dimensional model on liquid-liquid mass transfer of the kenics static mixer: considering dynamic droplet size distribution[J]. Industrial & Engineering Chemistry Research, 2023, 62(27): 10507-10522. |

| 73 | Yao C Q, Ma H Y, Zhao Q K, et al. Mass transfer in liquid-liquid Taylor flow in a microchannel: local concentration distribution, mass transfer regime and the effect of fluid viscosity[J]. Chemical Engineering Science, 2020, 223: 115734. |

| 74 | Widianto A Y, Lorenza V, Clarisa C, et al. Mass transfer phenomena of partially miscible liquids under liquid-liquid slug flow in a circular microchannel[J]. Chemical Engineering Research and Design, 2024, 205: 57-66. |

| 75 | Jaiswal P, Kumar Y, Panda D, et al. Vibration in microchannel causes greater enhancement of mass transfer in toluene-acetic acid-water system[J]. Industrial & Engineering Chemistry Research, 2021, 60(50): 18464-18476. |

| 76 | Matsuoka A, Mae K. Design strategy of a microchannel device for liquid-liquid extraction based on the relationship between mass transfer rate and two-phase flow pattern[J]. Chemical Engineering and Processing: Process Intensification, 2021, 160: 108297. |

| 77 | Zhang Q, Liu H C, Zhao S N, et al. Hydrodynamics and mass transfer characteristics of liquid-liquid slug flow in microchannels: the effects of temperature, fluid properties and channel size[J]. Chemical Engineering Journal, 2019, 358: 794-805. |

| 78 | Chen Z, Xiong Q Q, Li S W, et al. Experimental investigation of dynamic mass transfer during droplet formation using micro-LIF in a coaxial microchannel[J]. Chinese Journal of Chemical Engineering, 2021, 39: 51-58. |

| 79 | Angeli P, Tsaoulidis D, Hashi Weheliye W. Studies on mass transfer of europium(Ⅲ) in micro-channels using a micro Laser Induced Fluorescence technique[J]. Chemical Engineering Journal, 2019, 372: 1154-1163. |

| 80 | Rüttinger S, Spille C, Hoffmann M, et al. Laser-induced fluorescence in multiphase systems[J]. ChemBioEng Reviews, 2018, 5(4): 253-269. |

| 81 | Hirano H, Tsuzaki S, Obata H, et al. A colorimetric method for quantitative visualization of diffusion and internal circulation in liquid-liquid two-phase flow[J]. Chemical Engineering Science, 2022, 249: 117285. |

| 82 | Liu Y Y, Yao C Q, Yang L X, et al. A colorimetric technique to characterize mass transfer during liquid-liquid slug flow in circular capillaries[J]. MethodsX, 2021, 8: 101346. |

| 83 | Krieger W, Lamsfuß J, Zhang W, et al. Local mass transfer phenomena and chemical selectivity of gas-liquid reactions in capillaries[J]. Chemical Engineering & Technology, 2017, 40(11): 2134-2143. |

| 84 | Meinhart C D, Wereley S T, Santiago J G. PIV measurements of a microchannel flow[J]. Experiments in Fluids, 1999, 27(5): 414-419. |

| 85 | Sarrazin F, Loubière K, Prat L, et al. Experimental and numerical study of droplets hydrodynamics in MicroChannel[J]. AIChE Journal, 2006, 52(12): 4061-4070. |

| 86 | Al-Muhammad J, Tomas S, Ait-Mouheb N, et al. Micro-PIV characterization of the flow in a milli-labyrinth-channel used in drip irrigation[J]. Experiments in Fluids, 2018, 59(12): 181. |

| 87 | Zhu H B, Shen Z Y, Ni L, et al. Characterization of liquid-liquid two-phase flow patterns and mass transfer coefficients in Human-shaped microchannels[J]. Chemical Engineering and Processing: Process Intensification, 2024, 201: 109820. |

| 88 | Kumar U, Panda D, Biswas K G. Augmented mass transfer in liquid-liquid flow through microchannels of different geometries[J]. Chemical Engineering and Processing: Process Intensification, 2019, 137: 72-79. |

| 89 | Li L T, Zhang J S, Du C C, et al. Determination of the liquid/liquid mass transfer coefficient for each phase in microchannels[J]. Industrial & Engineering Chemistry Research, 2018, 57(27): 9028-9036. |

| 90 | Chen M, Jiao H Y, Li J, et al. Liquid-liquid two-phase flow in a wire-embedded concentric microchannel: flow pattern and mass transfer performance[J]. Chinese Journal of Chemical Engineering, 2023, 56: 281-289. |

| 91 | Wen J W, Liu H T, Luo J, et al. Mass transfer characteristics of vanadium species on the high-efficient solvent extraction of vanadium in microchannels/microreactors[J]. Separation and Purification Technology, 2023, 315: 123638. |

| 92 | Tang J, Zhang X B, Cai W F, et al. Liquid-liquid extraction based on droplet flow in a vertical microchannel[J]. Experimental Thermal and Fluid Science, 2013, 49: 185-192. |

| 93 | Hosseini Kakavandi F, Rahimi M, Jafari O, et al. Liquid-liquid two-phase mass transfer in T-type micromixers with different junctions and cylindrical pits[J]. Chemical Engineering and Processing: Process Intensification, 2016, 107: 58-67. |

| 94 | Hosseini F, Rahimi M. Experimental study and artificial intelligence modeling of liquid-liquid mass transfer in multiple-ring microchannels[J]. Korean Journal of Chemical Engineering, 2020, 37(3): 411-422. |

| 95 | Song J, Cheng B, Wang Y J, et al. A microfluidic chip structure with ultra-high liquid-liquid mass transfer performance[J]. Separation and Purification Technology, 2023, 324: 124440. |

| 96 | Singh S, Arun Kumar U K. Hydrodynamics and mass transfer studies of liquid-liquid two-phase flow in parallel microchannels[J]. International Journal of Multiphase Flow, 2022, 157: 104248. |

| 97 | Wang Q Y, Jin Y, Li J, et al. Study on liquid-liquid two-phase mass transfer characteristics in the microchannel with deformed insert[J]. Chinese Journal of Chemical Engineering, 2023, 54: 114-126. |

| 98 | Cao Y, Li J, Jin Y, et al. Liquid-liquid two-phase mass transfer characteristics in a rotating helical microchannel[J]. Chinese Journal of Chemical Engineering, 2019, 27(12): 2937-2947. |

| 99 | Vostretsov S, Yagodnitsyna A, Kovalev A, et al. Experimental study of mass transfer in a plug regime of immiscible liquid-liquid flow in a T-shaped microchannel[J]. Energies, 2023, 16(10): 4059. |

| 100 | Kinoshita H, Kaneda S, Fujii T, et al. Three-dimensional measurement and visualization of internal flow of a moving droplet using confocal micro-PIV[J]. Lab on a Chip, 2007, 7(3): 338-346. |

| 101 | Dietrich N, Loubière K, Jimenez M, et al. A new direct technique for visualizing and measuring gas-liquid mass transfer around bubbles moving in a straight millimetric square channel[J]. Chemical Engineering Science, 2013, 100: 172-182. |

| 102 | Malsch D, Kielpinski M, Merthan R, et al. μPIV-Analysis of Taylor flow in micro channels[J]. Chemical Engineering Journal, 2008, 135: S166-S172. |

| 103 | Durve M, Tiribocchi A, Bonaccorso F, et al. DropTrack-Automatic droplet tracking with YOLOv5 and DeepSORT for microfluidic applications[J]. Physics of Fluids, 2022, 34(8): 082003. |

| [1] | 张闯德, 陈黎. 优势通道对多孔介质中多相反应输运过程影响的孔隙尺度研究[J]. 化工学报, 2025, 76(1): 161-172. |

| [2] | 王瀚彬, 胡帅, 毕丰雷, 李隽森, 贺来宾. 新型波纹翅片金属氢化物反应器的放氢性能有限元分析[J]. 化工学报, 2025, 76(1): 221-230. |

| [3] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [4] | 李焱, 郑利军, 张恩勇, 王云飞. 深水海底管道软管内部流体渗透特性模型与试验研究[J]. 化工学报, 2024, 75(S1): 118-125. |

| [5] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [6] | 徐英宇, 杨国强, 彭璟, 孙海宁, 张志炳. 微界面高级氧化处理煤化工废水的研究[J]. 化工学报, 2024, 75(S1): 283-291. |

| [7] | 李雨霜, 王兴成, 温伯尧, 骆政园, 白博峰. 多孔介质中乳状液驱油的两相流动过程及其影响因素[J]. 化工学报, 2024, 75(S1): 56-66. |

| [8] | 刘律, 刘洁茹, 范亮亮, 赵亮. 基于层流效应的被动式颗粒分离微流控方法研究[J]. 化工学报, 2024, 75(S1): 67-75. |

| [9] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [10] | 陈超伟, 柳洋, 杜文静, 李金波, 史大阔, 辛公明. 局部热点下微肋通道流动传热特性[J]. 化工学报, 2024, 75(9): 3113-3121. |

| [11] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [12] | 曾港, 陈林, 杨董, 袁海专, 黄彦平. 矩形通道内超临界CO2局部热流场可视化实验[J]. 化工学报, 2024, 75(8): 2831-2839. |

| [13] | 曲玖哲, 杨鹏, 杨绪飞, 张伟, 宇波, 孙东亮, 王晓东. 硅基微柱簇阵列微通道流动沸腾实验研究[J]. 化工学报, 2024, 75(8): 2840-2851. |

| [14] | 曹佳蕾, 孙立岩, 曾德望, 尹凡, 高子翔, 肖睿. 双流化床化学链制氢反应器的数值模拟[J]. 化工学报, 2024, 75(8): 2865-2874. |

| [15] | 丁家琦, 刘海涛, 赵普, 朱香凝, 王晓放, 谢蓉. 煤炭超临界水制氢反应器内多相流场智能滚动预测研究[J]. 化工学报, 2024, 75(8): 2886-2896. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号