化工学报 ›› 2025, Vol. 76 ›› Issue (2): 897-908.DOI: 10.11949/0438-1157.20241095

• 材料化学工程与纳米技术 • 上一篇

陈弋翀1,2( ), 贾星雨1, 钟文宇1, 施俞晖1, 彭瑶1, 孙嘉阳1, 胡冬冬1, 赵玲1,2(

), 贾星雨1, 钟文宇1, 施俞晖1, 彭瑶1, 孙嘉阳1, 胡冬冬1, 赵玲1,2( )

)

收稿日期:2024-09-30

修回日期:2024-12-04

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

赵玲

作者简介:陈弋翀(1994—),男,博士,特聘副研究员,chenyc@ecust.edu.cn

基金资助:

Yichong CHEN1,2( ), Xingyu JIA1, Wenyu ZHONG1, Yuhui SHI1, Yao PENG1, Jiayang SUN1, Dongdong HU1, Ling ZHAO1,2(

), Xingyu JIA1, Wenyu ZHONG1, Yuhui SHI1, Yao PENG1, Jiayang SUN1, Dongdong HU1, Ling ZHAO1,2( )

)

Received:2024-09-30

Revised:2024-12-04

Online:2025-03-25

Published:2025-03-10

Contact:

Ling ZHAO

摘要:

具有梯度结构的发泡材料因创新结构设计和潜在多功能性受广泛研究。本工作以热塑性聚氨酯(TPU)为研究对象,通过一次升温发泡与二次卸压发泡制备了具有梯度泡孔结构的高倍率TPU发泡材料,并且探究了发泡条件影响机制。微观形貌表征显示,当发泡时间较短时,因基体中存在的温度梯度,可制得两侧孔径大、中间孔径小的梯度发泡材料,延长发泡时间则因温差降低制备出均匀发泡材料。力学性能测试结果表明,相较于均匀发泡材料,梯度发泡材料能量损失系数略高,但两者的相对差值随着发泡倍率的增高而降低,且具有更高的回弹率和更低的硬度,展现出高发泡倍率下优异的缓冲性能和回弹性。这为优化TPU发泡材料制备工艺提供了理论基础和实践指导,对TPU实现高性能、轻量化发展具有重要作用。

中图分类号:

陈弋翀, 贾星雨, 钟文宇, 施俞晖, 彭瑶, 孙嘉阳, 胡冬冬, 赵玲. 具有梯度结构的微孔热塑性聚氨酯及其性能[J]. 化工学报, 2025, 76(2): 897-908.

Yichong CHEN, Xingyu JIA, Wenyu ZHONG, Yuhui SHI, Yao PENG, Jiayang SUN, Dongdong HU, Ling ZHAO. Microcellular thermoplastic polyurethane with gradient structure and its properties[J]. CIESC Journal, 2025, 76(2): 897-908.

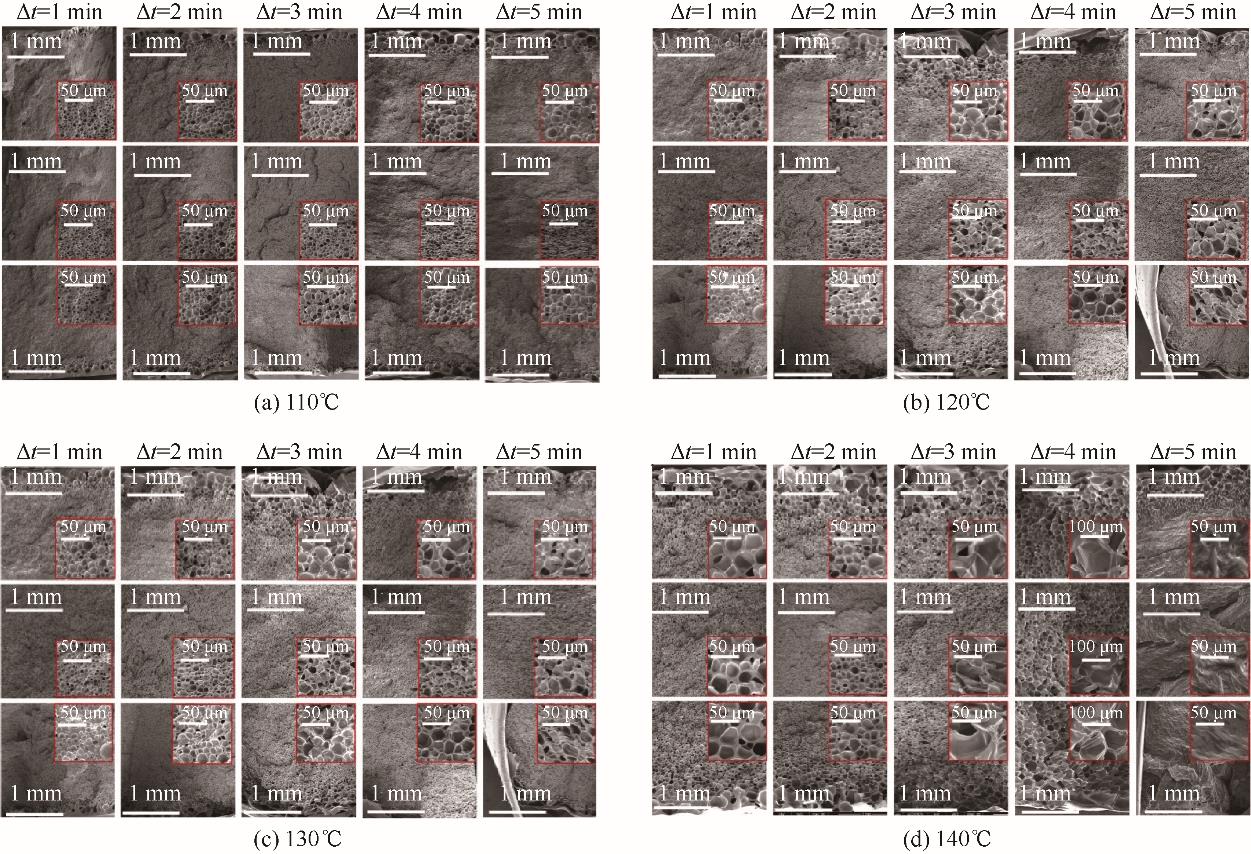

图5 一次升温发泡后一定饱和压力(5 MPa)、不同发泡温度下制备的发泡样品收缩后的微观形貌

Fig.5 Microstructure of foaming materials prepared at different foaming temperatures under a certain saturation pressure (5 MPa) after shrinkage following the primary temperature rising foaming

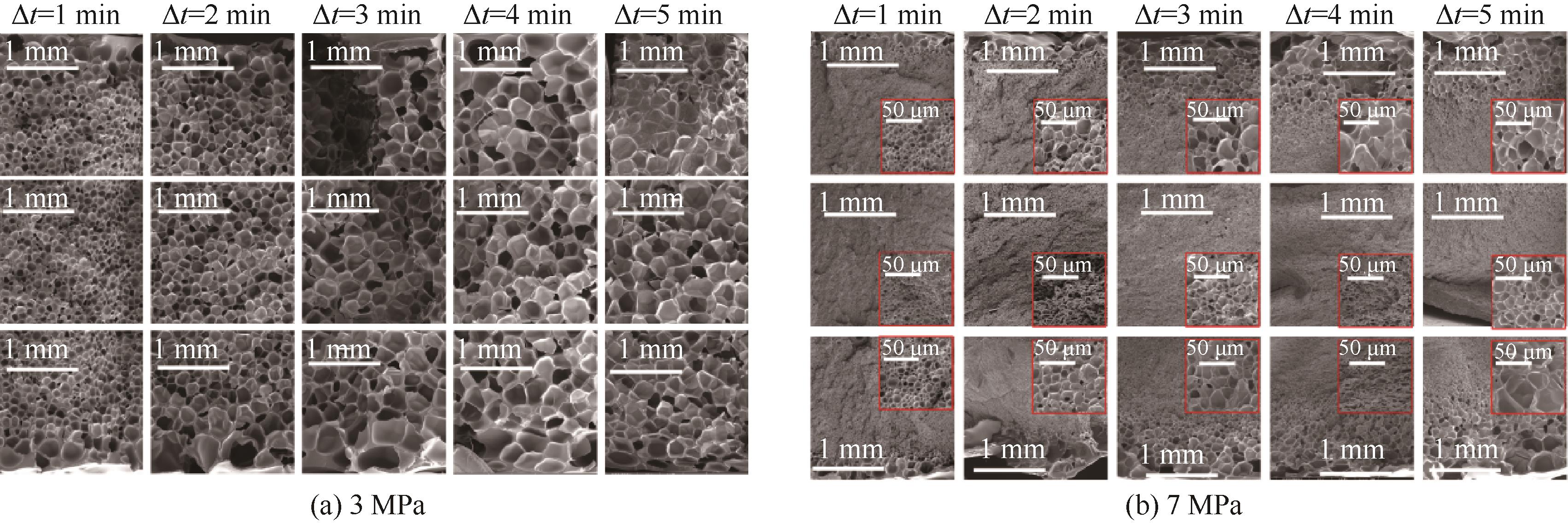

图6 一次升温发泡后一定发泡温度(130℃)、不同饱和压力下制备的发泡样品收缩后的微观形貌

Fig.6 Microstructure of foaming materials prepared at different saturation pressures under a foaming temperature (130℃) after shrinkage following the primary temperature rising foaming

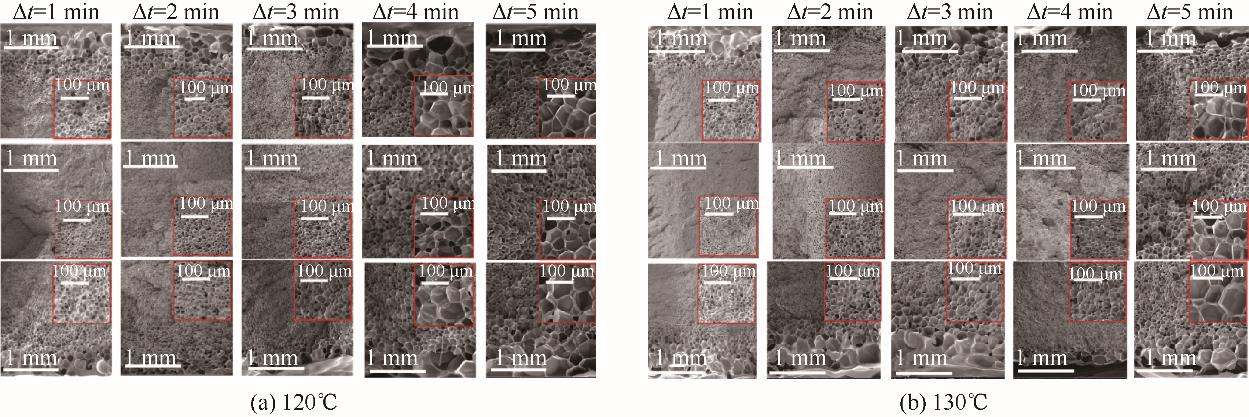

图7 二次卸压发泡后一定饱和压力(5MPa)、不同发泡温度下制备的发泡样品的微观形貌

Fig.7 Microstructure of foaming materials prepared at different foaming temperatures under a certain saturation pressure (5 MPa) after secondary depressurization foaming

| 1 | Zhai W T, Jiang J J, Park C B. A review on physical foaming of thermoplastic and vulcanized elastomers[J]. Polymer Reviews, 2022, 62(1): 95-141. |

| 2 | Iba H, Nishikawa Y, Urayama K. Nonlinear stress-strain behavior of elastomer foams investigated by various types of deformation[J]. Polymer, 2016, 83: 190-198. |

| 3 | Lan B, Li P Z, Yang Q, et al. Dynamic self generation of hydrogen bonding and relaxation of polymer chain segment in stabilizing thermoplastic polyurethane microcellular foams[J]. Materials Today Communications, 2020, 24: 101056. |

| 4 | Belmonte P, Ramos M J, Rodríguez J F, et al. Transformation of TPU elastomers into TPU foams using supercritical CO2. A new reprocessing approach[J]. The Journal of Supercritical Fluids, 2023, 192: 105806. |

| 5 | Yu C T, Lai C C, Wang F M, et al. Fabrication of thermoplastic polyurethane (TPU)/thermoplastic amide elastomer (TPAE) composite foams with supercritical carbon dioxide and their mechanical properties[J]. Journal of Manufacturing Processes, 2019, 48: 127-136. |

| 6 | Ge C B, Wang S P, Zheng W G, et al. Preparation of microcellular thermoplastic polyurethane (TPU) foam and its tensile property[J]. Polymer Engineering & Science, 2018, 58(S1): E158-E166. |

| 7 | Zhai Y, Yu Y F, Zhou K K, et al. Flexible and wearable carbon black/thermoplastic polyurethane foam with a pinnate-veined aligned porous structure for multifunctional piezoresistive sensors[J]. Chemical Engineering Journal, 2020, 382: 122985. |

| 8 | Belmonte P, Céspedes M, Ramos M J, et al. Foaming of thermoplastic polyurethane using supercritical CO2 and N2: antishrinking strategy[J]. The Journal of Supercritical Fluids, 2024, 211: 106311. |

| 9 | Lu Q W, Macosko C W. Comparing the compatibility of various functionalized polypropylenes with thermoplastic polyurethane (TPU)[J]. Polymer, 2004, 45(6): 1981-1991. |

| 10 | Xing S W, Lv C F, Lin M J, et al. A flexible superhydrophobic thermoplastic polyurethane porous surface with good self-cleaning function prepared by supercritical CO2 foaming[J]. The Journal of Supercritical Fluids, 2024, 210: 106294. |

| 11 | Fei Y P, Jiang R T, Fang W, et al. Highly sensitive large strain cellulose/multiwalled carbon nanotubes (MWCNTs)/thermoplastic polyurethane (TPU) nanocomposite foams: from design to performance evaluation[J]. The Journal of Supercritical Fluids, 2022, 188: 105653. |

| 12 | Koizumi M, Niino M. Overview of FGM research in Japan[J]. MRS Bulletin, 1995, 20(1): 19-21. |

| 13 | Shi H Y, Zhou P, Li J, et al. Functional gradient metallic biomaterials: techniques, current scenery, and future prospects in the biomedical field[J]. Frontiers in Bioengineering and Biotechnology, 2021, 8: 616845. |

| 14 | Liu Z Q, Meyers M A, Zhang Z F, et al. Functional gradients and heterogeneities in biological materials: design principles, functions, and bioinspired applications[J]. Progress in Materials Science, 2017, 88: 467-498. |

| 15 | Miao X G, Sun D. Graded/gradient porous biomaterials[J]. Materials, 2010, 3(1): 26-47. |

| 16 | Long L C, Wang Z K, Chen K. Analysis of the hollow structure with functionally gradient materials of moso bamboo[J]. Journal of Wood Science, 2015, 61(6): 569-577. |

| 17 | Frey M, Biffi G, Adobes-Vidal M, et al. Tunable wood by reversible interlocking and bioinspired mechanical gradients[J]. Advanced Science, 2019, 6(10): 1802190. |

| 18 | Li X Y, Lu L, Li J G, et al. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys[J]. Nature Reviews Materials, 2020, 5: 706-723. |

| 19 | Mao A R, Chen J W, Bu X C, et al. Bamboo-inspired structurally efficient materials with a large continuous gradient[J]. Small, 2023, 19(35): 2301144. |

| 20 | Gao X L, Chen Y C, Chen P, et al. Supercritical CO2 foaming and shrinkage resistance of thermoplastic polyurethane/modified magnesium borate whisker composite[J]. Journal of CO2 Utilization, 2022, 57: 101887. |

| 21 | Wang G L, Liu J X, Zhao J C, et al. Structure-gradient thermoplastic polyurethane foams with enhanced resilience derived by microcellular foaming[J]. The Journal of Supercritical Fluids, 2022, 188: 105667. |

| 22 | Mannella G A, Conoscenti G, Carfì Pavia F, et al. Preparation of polymeric foams with a pore size gradient via thermally induced phase separation (TIPS)[J]. Materials Letters, 2015, 160: 31-33. |

| 23 | Zhu L J, Wang G L, Xu Z R, et al. A new microcellular foaming strategy to develop structure-gradient thermoplastic polyurethane foams with enhanced elasticity[J]. Materials & Design, 2023, 234: 112325. |

| 24 | Zhou C C, Wang P, Li W. Fabrication of functionally graded porous polymer via supercritical CO2 foaming[J]. Composites Part B: Engineering, 2011, 42(2): 318-325. |

| 25 | Jiang J J, Zhou M N, Li Y Z, et al. Cell structure and hardness evolutions of TPU foamed sheets with high hardness via a temperature rising foaming process[J]. The Journal of Supercritical Fluids, 2022, 188: 105654. |

| 26 | Ngo M T, Dickmann J S, Hassler J C, et al. A new experimental system for combinatorial exploration of foaming of polymers in carbon dioxide: the gradient foaming of PMMA[J]. The Journal of Supercritical Fluids, 2016, 109: 1-19. |

| 27 | Wang W, Liao X, He Y S, et al. Thermoplastic polyurethane/polytetrafluoroethylene composite foams with enhanced mechanical properties and anti-shrinkage capability fabricated with supercritical carbon dioxide[J]. The Journal of Supercritical Fluids, 2020, 163: 104861. |

| 28 | Zhang R, Huang K, Hu S F, et al. Improved cell morphology and reduced shrinkage ratio of ETPU beads by reactive blending[J]. Polymer Testing, 2017, 63: 38-46. |

| 29 | Nofar M, Batı B, Küçük E B, et al. Effect of soft segment molecular weight on the microcellular foaming behavior of TPU using supercritical CO2 [J]. The Journal of Supercritical Fluids, 2020, 160: 104816. |

| 30 | Chen Y C, Li D Y, Zhang H, et al. Antishrinking strategy of microcellular thermoplastic polyurethane by comprehensive modeling analysis[J]. Industrial & Engineering Chemistry Research, 2021, 60(19): 7155-7166. |

| 31 | Chen Y C, Zhong W Y, Jia X Y, et al. Microcellular thermoplastic polyurethane (TPU) with multimodal cell structure fabricated based on pressure swing strategy and its compressive mechanical properties[J]. Industrial & Engineering Chemistry Research, 2024, 63(19): 8833-8845. |

| 32 | Zhong W Y, Hu D D, Jia X Y, et al. A novel semi-continuous preparation mode of ultra-low density thermoplastic polyurethane foam[J]. Chemical Engineering Journal, 2024, 481: 148402. |

| 33 | Chu C C, Yeh S K, Peng S P, et al. Preparation of microporous thermoplastic polyurethane by low-temperature supercritical CO2 foaming[J]. Journal of Cellular Plastics, 2017, 53(2): 135-150. |

| 34 | Li R S, Lee J H, Wang C D, et al. Solubility and diffusivity of CO2 and N2 in TPU and their effects on cell nucleation in batch foaming[J]. The Journal of Supercritical Fluids, 2019, 154: 104623. |

| 35 | Sun F K, Zhou M H, Yi F F, et al. Facile fabrication of lightweight and high expanded TPU/PBS bead blend foam with segregated microcellular network for reduced shrinkage and enhanced interface bonding[J]. The Journal of Supercritical Fluids, 2024, 212: 106334. |

| 36 | Lee Y H, Lee C W, Chou C H, et al. Sustainable polyamide elastomers from a bio-based dimer diamine for fabricating highly expanded and facilely recyclable microcellular foams via supercritical CO2 foaming[J]. European Polymer Journal, 2021, 160: 110765. |

| 37 | Lu J W, Zhang H, Chen Y M, et al. Effect of chain relaxation on the shrinkage behavior of TPEE foams fabricated with supercritical CO2 [J]. Polymer, 2022, 256: 125262. |

| 38 | Chen Y C, Yu J B, Ling Y J, et al. Comprehensive analysis of mechanical properties of microcellular polypropylene: experiment and simulation[J]. Polymer Testing, 2022, 116: 107812. |

| [1] | 翟紫航, 蒋杰, 李锦锦, 赵玲, 奚桢浩. 基于2,5-呋喃二甲酸的三元无规共聚酯PBSF的制备与性能[J]. 化工学报, 2025, 76(2): 868-878. |

| [2] | 李文宝, 胡锦鹏, 杜淼, 潘鹏举, 单国荣. 强韧P(SBMA-co-AAc)/SiO2复合水凝胶海洋防污减阻涂层[J]. 化工学报, 2025, 76(2): 787-796. |

| [3] | 宫政, 高秀鲁, 赵玲, 胡冬冬. 超临界CO2发泡PBAT/PLA复合材料及其形状记忆性能[J]. 化工学报, 2025, 76(2): 888-896. |

| [4] | 李雨诗, 陈源, 李运堂, 彭旭东, 王冰清, 李孝禄. 新型柔性坝箔片端面气膜密封变形协调分析及性能智能优化[J]. 化工学报, 2025, 76(1): 324-334. |

| [5] | 赵振刚, 周梦瑶, 金典, 张大骋. 基于泡沫碳扩散层的直接甲醇燃料电池改性研究[J]. 化工学报, 2024, 75(S1): 259-266. |

| [6] | 徐宏标, 杨亮, 李子栋, 刘道平. 盐水微滴/泡沫铜复合体系中甲烷水合物生成动力学研究[J]. 化工学报, 2024, 75(9): 3287-3296. |

| [7] | 毛宇飞, 曹飞, 上官燕琴. 超临界压力流体管内湍流对流传热的计算方法[J]. 化工学报, 2024, 75(8): 2821-2830. |

| [8] | 杨艳, 郭亚丽, 于硕文, 潘泊年, 沈胜强. 液氨喷射泵热力性能的计算分析[J]. 化工学报, 2024, 75(6): 2134-2142. |

| [9] | 关朝阳, 黄国庆, 张一喃, 陈宏霞, 杜小泽. 泡沫铜导离气泡强化流动沸腾换热实验研究[J]. 化工学报, 2024, 75(5): 1765-1776. |

| [10] | 周康, 王建新, 于海, 魏朝良, 范丰奇, 车昕昊, 张磊. 基于分子动力学模拟的矿物基础油泡沫破裂性能研究[J]. 化工学报, 2024, 75(4): 1668-1678. |

| [11] | 丁相斐, 丘晓琳, 朱喜成, 张佳伟, 陈锦华. pH响应性气体渗透CNC/PBAT复合膜的制备与性能[J]. 化工学报, 2024, 75(3): 1040-1051. |

| [12] | 孙瑞, 田华, 吴子睿, 孙孝存, 舒歌群. 二氧化碳混合工质临界参数计算模型对比研究[J]. 化工学报, 2024, 75(2): 439-449. |

| [13] | 王永涛, 毛建拥, 胡柏剡, 王欣雨, 刘佳欣, 姚加, 李浩然. 超临界反应及超临界流体参与的反应研究与应用进展[J]. 化工学报, 2024, 75(11): 3973-3986. |

| [14] | 庄晟逸, 李成伟, 向文超, 徐俊波, 杨超. 负泊松比结构的改进设计及其在航空航天中的应用[J]. 化工学报, 2024, 75(11): 3951-3972. |

| [15] | 贾海林, 曾锦祥, 潘荣锟, 潘仕利, 周凯旋. 无氟泡沫灭火剂真火实验与分子动力学模拟[J]. 化工学报, 2024, 75(10): 3825-3834. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号