• •

杨耀勇1( ), 汪泉2,3(

), 汪泉2,3( ), 李瑞2,3, 徐建设2, 冯鼎玉2, 胡彬2

), 李瑞2,3, 徐建设2, 冯鼎玉2, 胡彬2

收稿日期:2025-08-04

修回日期:2025-11-03

出版日期:2025-11-05

通讯作者:

汪泉

作者简介:杨耀勇(1998—),男,博士研究生,2458260953@qq.com

基金资助:

Yaoyong YANG1( ), Quan WANG2,3(

), Quan WANG2,3( ), Rui LI2,3, Jianshe XU2, Dingyu FENG2, Bing HU2

), Rui LI2,3, Jianshe XU2, Dingyu FENG2, Bing HU2

Received:2025-08-04

Revised:2025-11-03

Online:2025-11-05

Contact:

Quan WANG

摘要:

爆炸抛撒干水灭火是一种新型的灭火方式,在不破坏干水材料微观结构的前提下,实现抛撒药剂的高效、均匀扩散,是该领域面临的关键技术挑战之一。本研究使用干水作为灭火剂,以不同质量分数的聚偏氟乙烯 (PVDF) 与Al/KIO4超声混合作为抛撒药剂,通过扫描电镜(SEM)、透射电镜(TEM)、X射线衍射仪(XRD)、能谱分析(EDS)对Al/KIO4-PVDF微观结构进行表征,采用差示量热仪实验、敞开环境下燃烧实验、PMMA管燃烧实验、密闭爆发器实验、静电感度实验对Al/KIO4-PVDF热稳定性、燃速、产气性能和感度测试,并抛撒干水灭火实验。结果表明:PVDF包覆于Al外部亦填充于Al、KIO4间,可调控抛撒药的能量输出,其中Al/KIO4与PVDF质量比为95:5时性能最佳,其燃速、压力峰值、加压速率较Al/KIO4分别提高了44.7%、33.7%、32.5%,该抛撒药剂没有破坏结冷胶干水的核壳结构,抛撒结冷胶干水灭火效率高,750 mg抛撒药剂抛撒500 g结冷胶干水仅65 ms可扑灭20 cm油盘中正庚烷火焰。

杨耀勇, 汪泉, 李瑞, 徐建设, 冯鼎玉, 胡彬. 干水材料抛撒药剂的性能及应用[J]. 化工学报, DOI: 10.11949/0438-1157.20250871.

Yaoyong YANG, Quan WANG, Rui LI, Jianshe XU, Dingyu FENG, Bing HU. Performance and application of specialized dry water material spraying agents[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250871.

| Al | KIO4 | PVDF |

|---|---|---|

| 0.46 g | 1.54 g | 0.00 g(0%) |

| 0.46 g | 1.52 g | 0.02 g(1%) |

| 0.45 g | 1.49 g | 0.06 g(3%) |

| 0.44 g | 1.46 g | 0.10 g(5%) |

| 0.43 g | 1.43 g | 0.14 g(7%) |

| 0.42 g | 1.40 g | 0.18 g(9%) |

表1 实验配比

Table 1 Experimental ratios

| Al | KIO4 | PVDF |

|---|---|---|

| 0.46 g | 1.54 g | 0.00 g(0%) |

| 0.46 g | 1.52 g | 0.02 g(1%) |

| 0.45 g | 1.49 g | 0.06 g(3%) |

| 0.44 g | 1.46 g | 0.10 g(5%) |

| 0.43 g | 1.43 g | 0.14 g(7%) |

| 0.42 g | 1.40 g | 0.18 g(9%) |

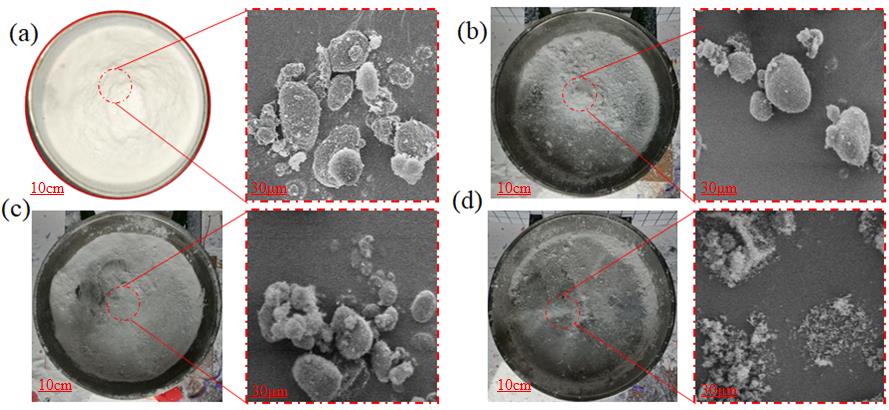

图11 抛撒前后不同干水粒径和形貌变化(a) the morphology of carrageenan dry water (b) the morphology of carrageenan dry water after Al/KIO₄-3%PVDF dispersion (c) the morphology of carrageenan dry water after Al/KIO₄-5%PVDF dispersion (d) the morphology of carrageenan dry water after RDX dispersion(e) changes in dry water particle size before and after dispersal (f) changes in carrageenan dry water particle size before and after dispersal

Fig.11 Changes in different dry water particle size and morphology before and after dispersal

| [1] | Wang X, Jiang J C, Wang Y Q, et al. Efficacy evaluation of bicarbonate formulations dry water fire extinguishing agents[J]. Journal of Loss Prevention in the Process Industries, 2024, 92: 105444. |

| [2] | Wang Y Y, Zhu F H, Zhou H L, et al. Development of a novel dry-water fire extinguishing agent containing additives[J]. Journal of Thermal Analysis and Calorimetry, 2024, 149(18): 10179-10192. |

| [3] | Wang Y, Zhu G Q, Chai G Q, et al. Experimental study on the effect of release pressure on the extinguishing efficiency of dry water[J]. Case Studies in Thermal Engineering, 2021, 26: 101177. |

| [4] | 王尧鑫, 龙仁荣, 张庆明, 等. 双层复合材料爆炸圆筒内爆载荷作用变形特征数值模拟[J]. 兵工学报, 2020, 41(S2): 189-199. |

| Wang Y X, Long R R, Zhang Q M, et al. Numerical simulation analysis of deformation characteristics of double-layered metal-plastic cylindrical shells under internal explosive loading[J]. Acta Armamentarii, 2020, 41(S2): 189-199. | |

| [5] | Shi K W, Guo X D, Chen L, et al. Alcohol-thermal synthesis of approximately core-shell structured Al@CuO nanothermite with improved heat-release and combustion characteristics[J]. Combustion and Flame, 2021, 228: 331-339. |

| [6] | Valliappan S, Swiatkiewicz J, Puszynski J A. Reactivity of aluminum nanopowders with metal oxides[J]. Powder Technology, 2005, 156(2-3): 164-169. |

| [7] | Ilunga K, del Fabbro O, Yapi L, et al. The effect of Si–Bi2O3 on the ignition of the Al–CuO thermite[J]. Powder Technology, 2011, 205(1-3): 97-102. |

| [8] | Guo X G, Liang T T, Islam M L, et al. Highly reactive thermite energetic materials: preparation, characterization, and applications: a review[J]. Molecules, 2023, 28(6): 2520. |

| [9] | Hu Y J, Shi H T, Li T, et al. Underwater pressure waves generated by electrical exploding wire ignited energetic materials: Parametric study and formulation optimization[J]. Powder Technology, 2023, 419: 118335. |

| [10] | Hu T J, Zhao Y L, Wang K X, et al. The development of an on-chip microinitiator with a built-in safety-and-arming device[J]. Review of Scientific Instruments, 2021, 92(2): 025007. |

| [11] | Polis M, Stolarczyk A, Glosz K, et al. Quo vadis, nanotHermite a review of recent progress[J]. Materials, 2022, 15(9): 3215. |

| [12] | Roddy M A, Huang P H A. A solid-state gas generator actuated deorbiter for cubesats[J]. Journal of Microelectromechanical Systems, 2019, 28(6): 1068-1079. |

| [13] | Wang H Y, DeLisio J B, Jian G Q, et al. Electrospray formation and combustion characteristics of iodine-containing Al/CuO nanotHermite microparticles[J]. Combustion and Flame, 2015, 162(7): 2823-2829. |

| [14] | Li X Y, Guerieri P, Zhou W B, et al. Direct deposit laminate nanocomposites with enhanced propellent properties[J]. ACS Applied Materials & Interfaces, 2015, 7(17): 9103-9109. |

| [15] | Jian G Q, Liu L, Zachariah M R. Facile aerosol route to hollow CuO spheres and its superior performance as an oxidizer in nanoenergetic gas generators[J]. Advanced Functional Materials, 2013, 23(10): 1341-1346. |

| [16] | Ma X X, Li Y X, Hussain I, et al. Core–shell structured nanoenergetic materials: preparation and fundamental properties[J]. Advanced Materials, 2020, 32(30): 2001291. |

| [17] | Kang X L, Zhang J B, Zhang Q, et al. Studies on ignition and afterburning processes of KClO4/Mg pyrotechnics heated in air[J]. Journal of Thermal Analysis and Calorimetry, 2012, 109(3): 1333-1340. |

| [18] | Wu C W, Sullivan K, Chowdhury S, et al. Encapsulation of perchlorate salts within metal oxides for application as nanoenergetic oxidizers[J]. Advanced Functional Materials, 2012, 22(1): 78-85. |

| [19] | Zhou W B, DeLisio J B, Wang X Z, et al. Reaction mechanisms of potassium oxysalts based energetic composites[J]. Combustion and Flame, 2017, 177: 1-9. |

| [20] | Lewis W K, Harruff B A, Gord J R, et al. Chemical dynamics of aluminum nanoparticles in ammonium nitrate and ammonium perchlorate matrices: enhanced reactivity of organically capped aluminum[J]. The Journal of Physical Chemistry C, 2011, 115(1): 70-77. |

| [21] | Nie H Q, Pisharath S, Hng H H. Combustion of fluoropolymer coated Al and Al–Mg alloy powders[J]. Combustion and Flame, 2020, 220: 394-406. |

| [22] | Li Y N, Wang B L, Han Z W. Energy evolution mechanism of a PVDF activated nano-aluminum based metastable intermixed composites[J]. Journal of Alloys and Compounds, 2023, 966: 171586. |

| [23] | Cohen N S, Fleming R W, Derr R L. Role of binders in solid propellant combustion[J]. AIAA Journal, 1974, 12(2): 212-218. |

| [24] | Kubota N.; Serizawa C. Combustion of magnesium/polytetrafluoroethylene[J]. Journal of Propulsion and Power, 1987, 3(4): 303-307. |

| [25] | Koch E C. Metal-fluorocarbon-pyrolants: III. development and application of magnesium/teflon/viton (MTV)[J]. Propellants, Explosives, Pyrotechnics, 2002, 27(5): 262-266. |

| [26] | Rehwoldt M C, Wang Y J, Xu F Y, et al. High-temperature interactions of metal oxides and a PVDF binder[J]. ACS Applied Materials & Interfaces, 2022, 14(7): 8938-8946. |

| [27] | Pantoya M L, Dean S W. The influence of alumina passivation on nano-Al/Teflon reactions[J]. Thermochimica Acta, 2009, 493(1): 109-110. |

| [28] | Mulamba O, Pantoya M L. Exothermic surface chemistry on aluminum particles promoting reactivity[J]. Applied Surface Science, 2014, 315: 90-94. |

| [29] | McCollum J, Morey A M, Iacono S T. Morphological and combustion study of interface effects in aluminum-poly(vinylidene fluoride) composites[J]. Materials & Design, 2017, 134: 64-70. |

| [30] | Yang H T, Huang C, Chen H H. Tuning reactivity of nanoaluminum with fluoropolymer via electrospray deposition[J]. Journal of Thermal Analysis and Calorimetry, 2017, 127(3): 2293-2299. |

| [31] | Huang S, Pan M, Deng S, et al. Modified micro‐emulsion synthesis of highly dispersed Al/PVDF composites with enhanced combustion properties[J]. Advanced Engineering Materials, 2019, 21(5):1801330. |

| [32] | Asay B, Son S, Busse J, et al. Ignition characteristics of metastable intermolecular composites[J]. Propellants, Explosives, Pyrotechnics, 2004, 29(4): 216-219. |

| [33] | Yan S, Jian G Q, Zachariah M R. Electrospun nanofiber-based thermite textiles and their reactive properties[J]. ACS Applied Materials & Interfaces, 2012, 4(12): 6432-6435. |

| [34] | Jain S, Yehia O, Qiao L. Flame speed enhancement of solid nitrocellulose monopropellant coupled with graphite at microscales[J]. Journal of Applied Physics, 2016, 119(9): 094904. |

| [35] | Fahd A, Baranovsky A, Dubois C, et al. Superior performance of quaternary NC/GO/Al/KClO4 nanotHermite for high speed impulse small-scale propulsion applications[J]. Combustion and Flame, 2021, 232: 111527. |

| [36] | Kim K J, Jung H, Kim J H, et al. Nanoenergetic material-on-multiwalled carbon nanotubes paper chip as compact and flexible igniter[J]. Carbon, 2017, 114: 217-223. |

| [37] | Young A, Beom K, Hoon K, et al. A micro-chip initiator with controlled combustion reactivity realized by integrating Al/CuO nanothermite composites on a microhotplate platform[J]. Journal of Micromechanics and Microengineering, 2016, 26(1): 015002. |

| [38] | Wang H Y, Jacob R J, DeLisio J B, et al. Assembly and encapsulation of aluminum NP's within AP/NC matrix and their reactive properties[J]. Combustion and Flame, 2017, 180: 175-183. |

| [39] | Kim M, Kim Y J, Cho Y C, et al. Simultaneous measurements of volume, pressure, optical images, and crystal structure with a dynamic diamond anvil cell: a real-time event monitoring system[J]. Review of Scientific Instruments, 2023, 94(11): 113904. |

| [40] | Hossein Keshavarz M, Moghadas M, Kavosh Tehrani M. Relationship between the electrostatic sensitivity of nitramines and their molecular structure[J]. Propellants, Explosives, Pyrotechnics, 2009, 34(2): 136-141. |

| [41] | Greason W D. Electrostatic discharge characteristics for the human body and circuit packs[J]. Journal of Electrostatics, 2003, 59(3): 285-300. |

| [42] | Dai J, Xu J B, Wang F, et al. Facile formation of nitrocellulose-coated Al/Bi2O3 nanothermites with excellent energy output and improved electrostatic discharge safety[J]. Materials & Design, 2018, 143: 93-103. |

| [43] | Tian S Y, Qin B T, Ma D, et al. Suppressive effects of alkali metal salt modified dry water material on methane-air explosion[J]. Energy, 2023, 285: 129547. |

| [44] | Xue C L, Jiang H P, Zhu C C, et al. A novel dry water with perfluorohexanone for explosion suppression of AlH3 [J]. Chemical Engineering Science, 2023, 271: 118575. |

| [1] | 唐银香, 朱风, 范莹莹, 龙雨欣, 代雍, 邓春玲, 黄小凤. 制备条件对改性电石渣低温共脱除COS和CS2的影响[J]. 化工学报, 2025, 76(7): 3639-3650. |

| [2] | 卢煦旸, 徐强, 康浩鹏, 史健, 曹泽水, 郭烈锦. 化学链制氢系统中磁铁矿氧载体的CO还原特性研究[J]. 化工学报, 2025, 76(7): 3286-3294. |

| [3] | 彭健, 沈鲁恺, 王立坤, 忻利宏, 刘涌, 赵高凌, 马赛男, 韩高荣. 钨酸盐纳米材料的制备及其在电致变色领域的研究进展[J]. 化工学报, 2025, 76(6): 2451-2468. |

| [4] | 杨盛华, 孙阳杰, 薛晓君, 米杰, 王建成, 冯宇. 缺陷型金属氧化物脱除气体污染物研究进展[J]. 化工学报, 2025, 76(6): 2469-2482. |

| [5] | 安昊天, 韩章烨, 陆慕瑶, 周阿武, 李建荣. 推进MOF产业化应用:宏量制备与成型[J]. 化工学报, 2025, 76(5): 2011-2025. |

| [6] | 朱迪, 高守建, 方望熹, 靳健. 水蒸气诱导相分离构筑海绵孔结构超亲水聚醚砜膜及其油/水乳液分离性能研究[J]. 化工学报, 2025, 76(5): 2397-2409. |

| [7] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [8] | 蔡本安, 张建新, 龙城君, 杜乔琛, 车勋建, 张义迎, 蔡伟华. 喷雾闪蒸制备微纳米颗粒[J]. 化工学报, 2025, 76(3): 1334-1345. |

| [9] | 李奕菲, 苏沿霏, 尹甜, 姜浩强, 许志明, 张霖宙, 史权, 徐春明. 基于GC×GC-TOF MS的煤液化产物油分子组成结构表征[J]. 化工学报, 2025, 76(2): 543-553. |

| [10] | 胡术刚, 田国庆, 刘文娟, 徐广飞, 刘华清, 张建, 王艳龙. 纳米零价铁的制备及氧化还原技术的应用进展[J]. 化工学报, 2024, 75(9): 3041-3055. |

| [11] | 代艳辉, 熊启钊, 房强, 杨东晓, 王毅, 陈杨, 李晋平, 李立博. 原位蒸汽辅助法用于一步制备多级孔Cu-BTC[J]. 化工学报, 2024, 75(9): 3329-3337. |

| [12] | 常蕊, 邢蕊蕊, 闫学海. 基于非共价化学的绿色生物可循环肽材料[J]. 化工学报, 2024, 75(4): 1317-1332. |

| [13] | 吴希, 孙博, 刘银东, 齐传磊, 陈凯毅, 王路海, 许崇, 李永峰. 钠离子电池沥青基碳负极材料制备技术研究进展[J]. 化工学报, 2024, 75(4): 1270-1283. |

| [14] | 刘恺轩, 姜沁源, 汪菲, 李润, 朱平, 王康康, 臧永路, 赵彦龙, 张如范. 高密度超长碳纳米管的可控制备:进展与展望[J]. 化工学报, 2024, 75(4): 1355-1369. |

| [15] | 陈展珠, 叶锦华, 王智彬, 杨智, 贾莉斯, 陈颖. 三维分形集成共轴流通道实现液滴高效生成[J]. 化工学报, 2024, 75(12): 4442-4452. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号