化工学报 ›› 2025, Vol. 76 ›› Issue (2): 543-553.DOI: 10.11949/0438-1157.20241047

• 热力学 • 上一篇

李奕菲1( ), 苏沿霏1, 尹甜2, 姜浩强3, 许志明1, 张霖宙1(

), 苏沿霏1, 尹甜2, 姜浩强3, 许志明1, 张霖宙1( ), 史权1(

), 史权1( ), 徐春明1

), 徐春明1

收稿日期:2024-09-19

修回日期:2024-10-16

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

张霖宙,史权

作者简介:李奕菲(1995—),女,博士研究生,Liyifei_CUP@126.com

基金资助:

Yifei LI1( ), Yanfei SU1, Tian YIN2, Haoqiang JIANG3, Zhiming XU1, Linzhou ZHANG1(

), Yanfei SU1, Tian YIN2, Haoqiang JIANG3, Zhiming XU1, Linzhou ZHANG1( ), Quan SHI1(

), Quan SHI1( ), Chunming XU1

), Chunming XU1

Received:2024-09-19

Revised:2024-10-16

Online:2025-03-25

Published:2025-03-10

Contact:

Linzhou ZHANG, Quan SHI

摘要:

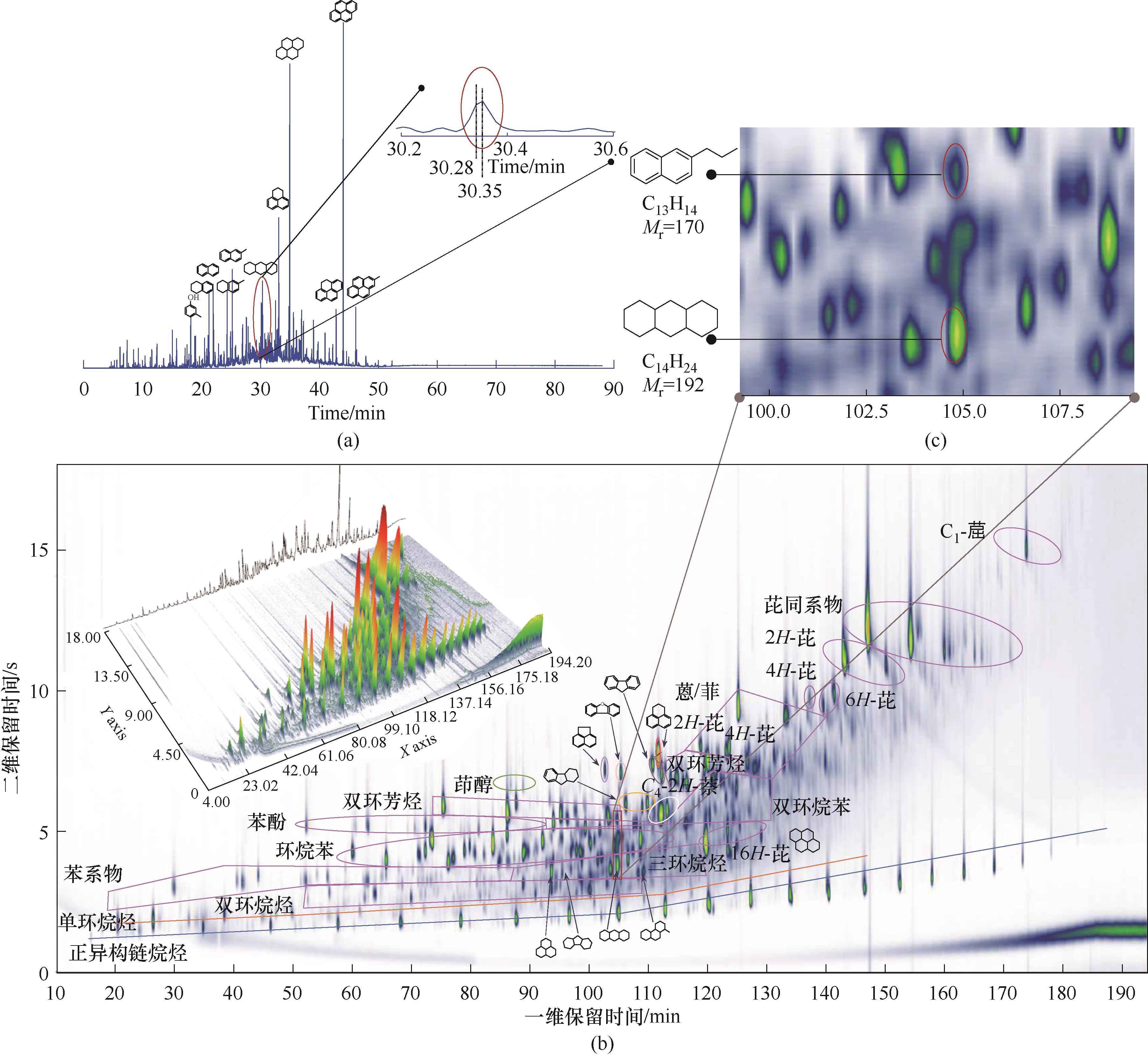

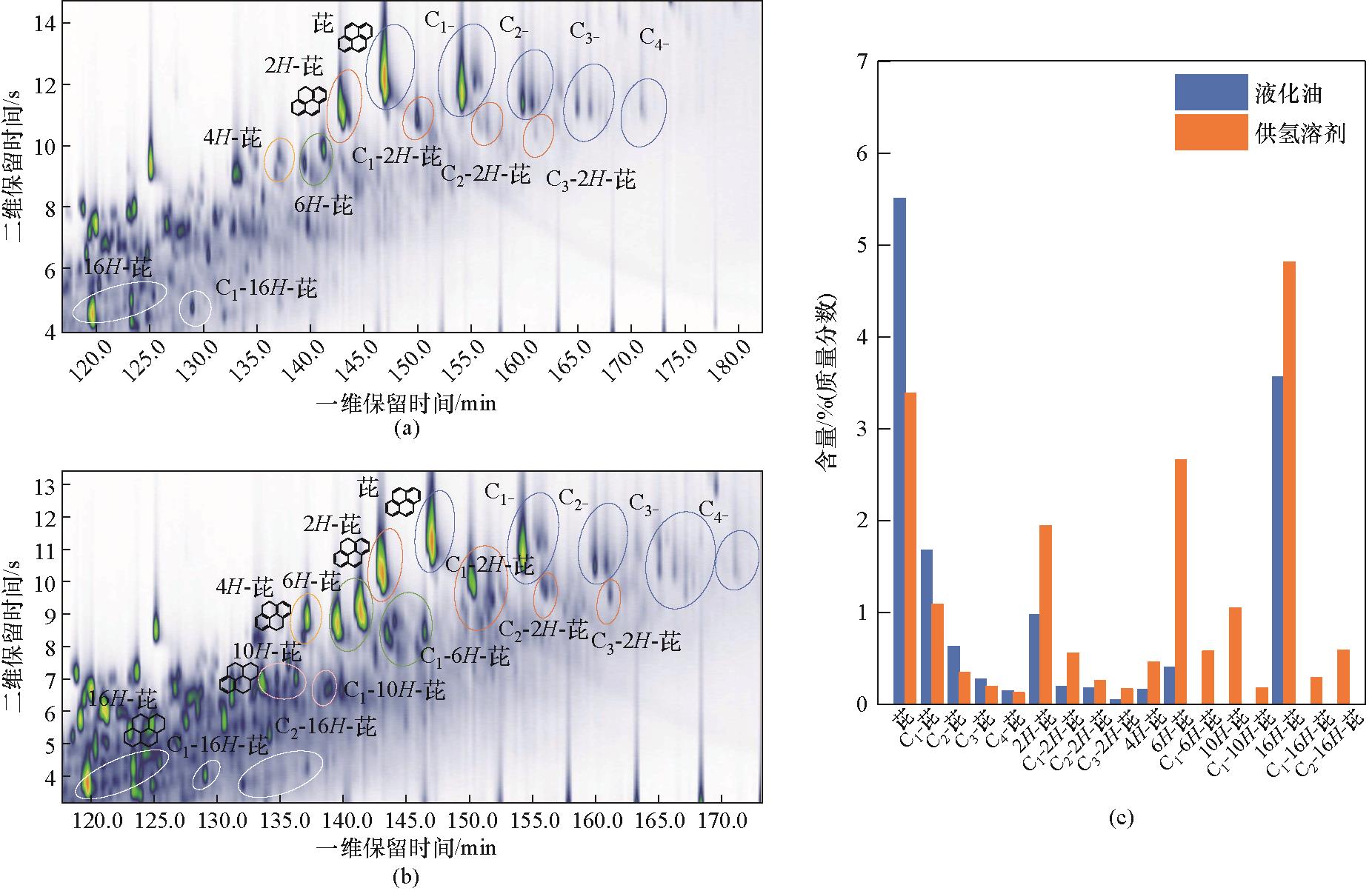

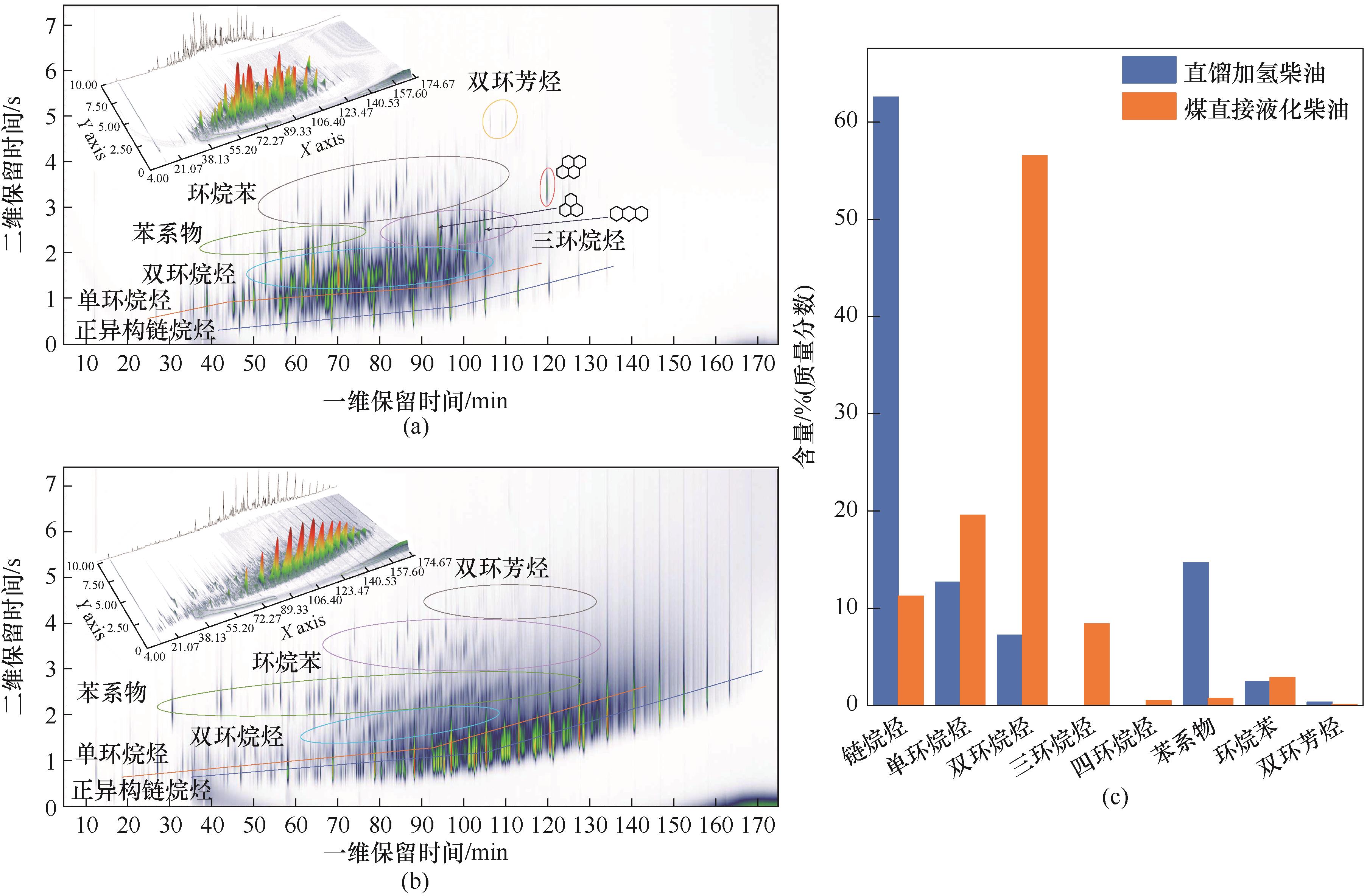

煤直接液化产物分子组成复杂,探究产物的详细分子组成对煤制油工艺的优化具有重要意义。建立了煤液化油及其加氢过程产物的全二维气相色谱-飞行时间质谱/氢火焰离子化检测器(GC×GC-TOF MS/FID)分子层次的组成和结构定性定量表征方法,揭示了煤液化加氢反应规律。GC×GC-TOF MS液化油分子组成表征技术通过分子极性在二维上的差异初步解决了一维色谱中多个化合物因保留时间相近共逸出的问题。煤液化油加氢后环烷烃含量增加,芳烃含量减少。在循环溶剂中主要通过三环、四环芳烃分子不同程度的氢化分子起到溶氢供氢的作用。另外,针对煤直接液化石脑油和柴油也建立了GC×GC-TOF MS/FID烃族组成表征,与直馏加氢汽柴油的族组成含量相比,煤直接液化产物中含有较多的环烷烃化合物。

中图分类号:

李奕菲, 苏沿霏, 尹甜, 姜浩强, 许志明, 张霖宙, 史权, 徐春明. 基于GC×GC-TOF MS的煤液化产物油分子组成结构表征[J]. 化工学报, 2025, 76(2): 543-553.

Yifei LI, Yanfei SU, Tian YIN, Haoqiang JIANG, Zhiming XU, Linzhou ZHANG, Quan SHI, Chunming XU. Molecular composition and structure characterization of coal liquefaction product oil based on GC×GC-TOF MS[J]. CIESC Journal, 2025, 76(2): 543-553.

| 项目 | GC×GC实验条件 |

|---|---|

| 色谱柱1 | HP-PONA 50 m×0.2 mm×0.5 µm |

| 色谱柱2 | BPX-50 2.5 m×0.1 mm×0.1 µm |

| 柱流量 | 恒流0.6 ml/min |

| 进样量和分流比 | 0.05 µl,100∶1 |

| 柱箱 | 40℃(5 min)-1.5℃/min-150/280/310℃(10 min) |

| 进样口温度 | 250℃/300℃ |

| 调制器周期 | 石脑油6 s,柴油8 s,改质料16 s,液化油和供氢溶剂18 s |

表1 GC×GC实验条件

Table 1 GC×GC experimental conditions

| 项目 | GC×GC实验条件 |

|---|---|

| 色谱柱1 | HP-PONA 50 m×0.2 mm×0.5 µm |

| 色谱柱2 | BPX-50 2.5 m×0.1 mm×0.1 µm |

| 柱流量 | 恒流0.6 ml/min |

| 进样量和分流比 | 0.05 µl,100∶1 |

| 柱箱 | 40℃(5 min)-1.5℃/min-150/280/310℃(10 min) |

| 进样口温度 | 250℃/300℃ |

| 调制器周期 | 石脑油6 s,柴油8 s,改质料16 s,液化油和供氢溶剂18 s |

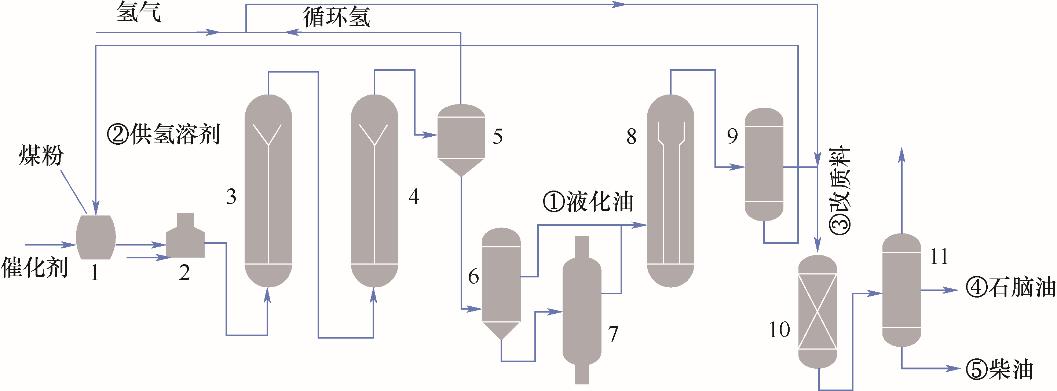

图1 煤直接液化工艺物料流程示意图[33]1—煤浆罐;2—加热炉;3,4—悬浮床反应器;5—分离器;6—常压蒸馏塔;7—减压蒸馏塔;8—沸腾床反应器;9—分离塔;10—固定床反应器;11—分离塔

Fig.1 Material flow diagram of coal direct liquefaction process[33]

图3 煤液化油(a) GC-MS和(b) GC×GC-TOF MS总离子流图,(c) GC×GC-TOF MS局部放大图

Fig.3 Coal liquefaction oil (a) GC-MS and (b) GC×GC-TOF MS total ion chromatogram, (c) GC×GC-TOF MS partial enlarged chromatogram

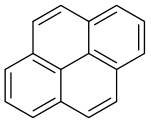

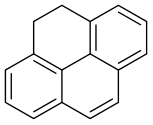

图5 (a)煤液化油和(b)供氢溶剂芘同系数及其加氢化合物GC×GC-TOF MS谱图,(c) GC×GC-FID含量柱状图

Fig.5 GC×GC-TOF MS spectra of (a) coal liquefaction oil and (b) hydrogen donor solvent pyrene and its hydrogenated compounds, (c) GC×GC-FID content histogram

图6 (a)煤直接液化柴油和(b)直馏加氢柴油GC×GC-TOF MS谱图,(c) GC×GC-FID含量柱状图

Fig.6 GC×GC-TOF MS spectra of (a) direct coal liquefaction diesel and (b) straight-run hydrogenated diesel, (c) GC × GC-FID content histogram

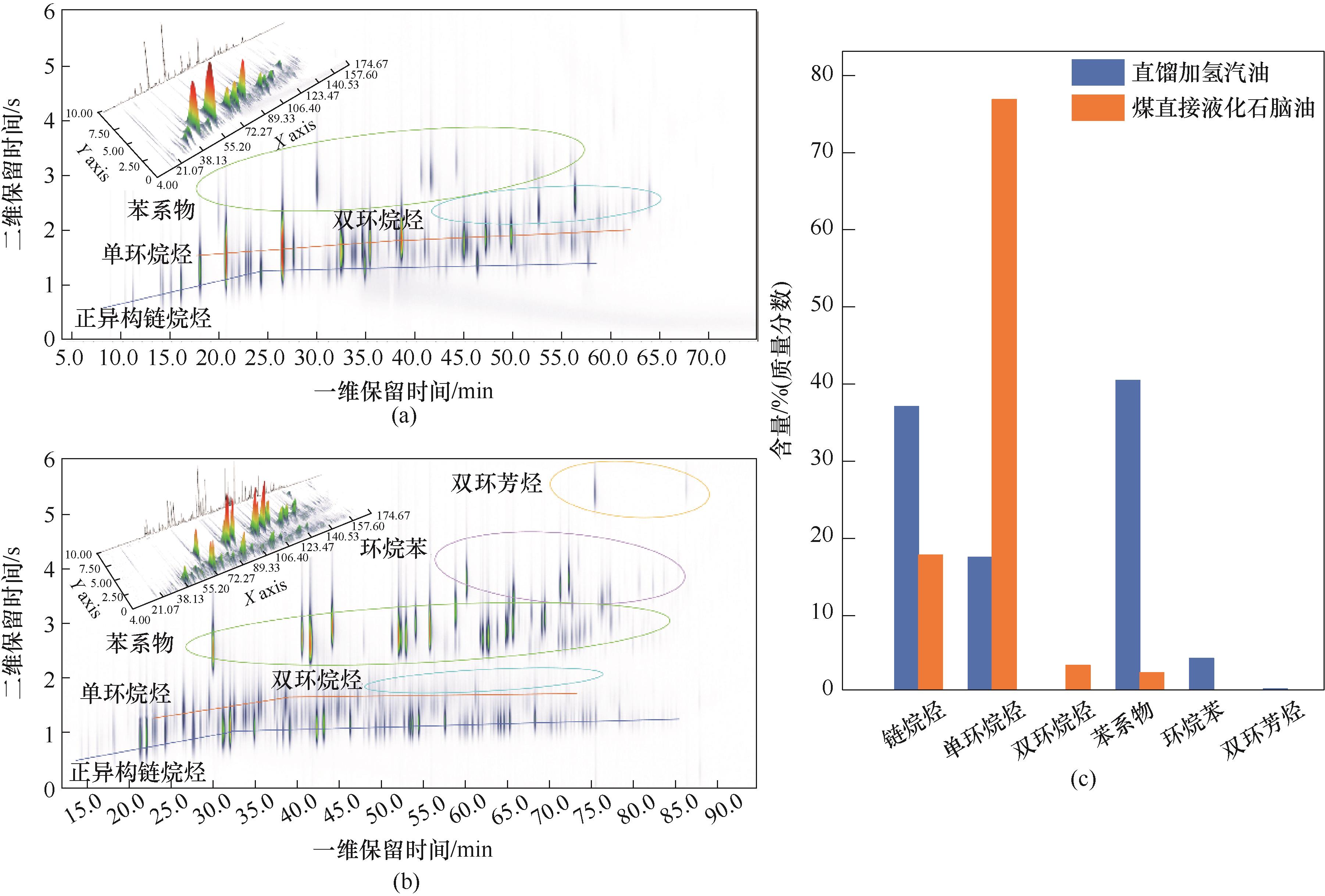

图7 (a)煤直接液化石脑油和(b)直馏加氢汽油GC×GC-TOF MS谱图,(c) GC×GC-FID含量柱状图

Fig.7 GC×GC-TOF MS spectra of (a) direct coal liquefaction gasoline and (b) straight-run hydrogenated gasoline, (c) GC × GC-FID content histogram

| 编号 | 名称 | 分子式 | 分子量 | 分子结构 | 1D (min) / 2D (s) | 含量 |

|---|---|---|---|---|---|---|

| 1 | 正十五烷 | C15H32 | 212.3 |  | 105.2/2.2 | 27.1 |

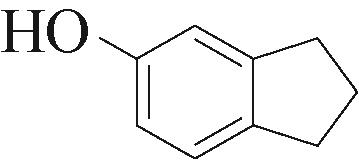

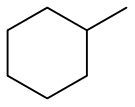

| 2 | 甲基环己烷 | C7H14 | 98.1 |  | 26.6/2.2 | 16.6 |

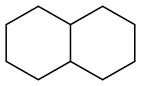

| 3 | 十氢化萘 | C10H18 | 138.1 |  | 64.1/2.8 | 7.8 |

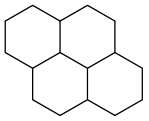

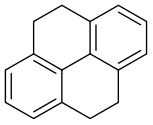

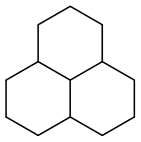

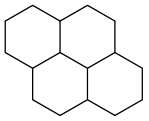

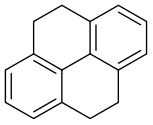

| 4 | 十二氢非那烯 | C13H22 | 178.2 |  | 93.8/3.5 | 14.0 |

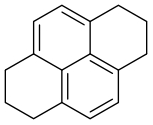

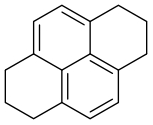

| 5 | 16H-芘 | C16H26 | 218.2 |  | 119.9/4.4 | 112.6 |

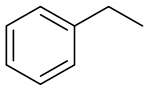

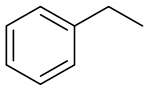

| 6 | 乙苯 | C8H10 | 106.1 |  | 41.6/3.5 | 6.1 |

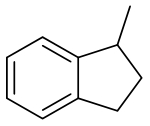

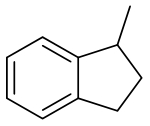

| 7 | 1-甲基茚满 | C10H12 | 132.1 |  | 65.9/4.0 | 11.3 |

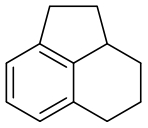

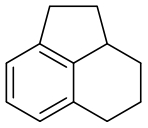

| 8 | 1,2,2a,3,4,5-六氢苊烯 | C12H14 | 158.1 |  | 94.1/5.3 | 20.0 |

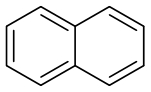

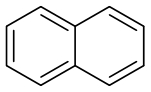

| 9 | 萘 | C10H8 | 128.1 |  | 75.5/5.9 | 20.6 |

| 10 | 3-(1,1-二甲基乙基)-1,2-二氢萘 | C14H18 | 186.1 |  | 112.1/5.6 | 70.7 |

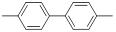

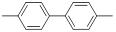

| 11 | 4,4′-二甲基联苯 | C10H18 | 182.1 |  | 120.2/7.3 | 39.4 |

| 12 | 芴 | C13H10 | 166.1 |  | 110.9/7.3 | 23.4 |

| 13 | 9,10-二氢蒽 | C14H12 | 180.1 |  | 119.0/7.9 | 9.4 |

| 14 | 1,2,3,4-四氢蒽 | C14H14 | 182.1 |  | 123.2/7.9 | 18.7 |

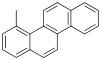

| 15 | 2-甲基蒽 | C15H12 | 192.1 |  | 133.1/9.1 | 24.8 |

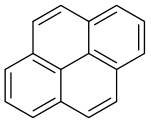

| 16 | 芘 | C16H10 | 202.1 |  | 147.2/11.7 | 276.5 |

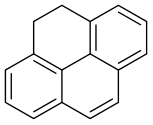

| 17 | 4,5-二氢芘 | C16H12 | 204.1 |  | 143.3/11.0 | 30.5 |

| 18 | 4,5,9,10-四氢芘 | C16H14 | 206.1 |  | 137.3/9.8 | 5.9 |

| 19 | 1,2,3,6,7,8-六氢芘 | C16H16 | 208.1 |  | 141.5/9.9 | 13.5 |

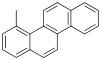

| 20 | 4-甲基䓛 | C19H14 | 242.1 |  | 173.9/14.9 | 13.1 |

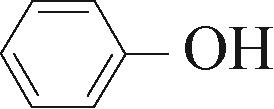

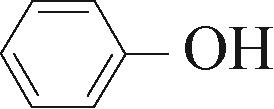

| 21 | 苯酚 | C6H6O | 94.0 |  | 52.4/5.6 | 5.4 |

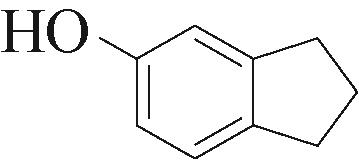

| 22 | 5-茚醇 | C9H10O | 134.1 |  | 89.0/6.8 | 2.6 |

表A1 煤液化油代表性分子信息

Table A1 Representative molecular information of coal liquefaction oil

| 编号 | 名称 | 分子式 | 分子量 | 分子结构 | 1D (min) / 2D (s) | 含量 |

|---|---|---|---|---|---|---|

| 1 | 正十五烷 | C15H32 | 212.3 |  | 105.2/2.2 | 27.1 |

| 2 | 甲基环己烷 | C7H14 | 98.1 |  | 26.6/2.2 | 16.6 |

| 3 | 十氢化萘 | C10H18 | 138.1 |  | 64.1/2.8 | 7.8 |

| 4 | 十二氢非那烯 | C13H22 | 178.2 |  | 93.8/3.5 | 14.0 |

| 5 | 16H-芘 | C16H26 | 218.2 |  | 119.9/4.4 | 112.6 |

| 6 | 乙苯 | C8H10 | 106.1 |  | 41.6/3.5 | 6.1 |

| 7 | 1-甲基茚满 | C10H12 | 132.1 |  | 65.9/4.0 | 11.3 |

| 8 | 1,2,2a,3,4,5-六氢苊烯 | C12H14 | 158.1 |  | 94.1/5.3 | 20.0 |

| 9 | 萘 | C10H8 | 128.1 |  | 75.5/5.9 | 20.6 |

| 10 | 3-(1,1-二甲基乙基)-1,2-二氢萘 | C14H18 | 186.1 |  | 112.1/5.6 | 70.7 |

| 11 | 4,4′-二甲基联苯 | C10H18 | 182.1 |  | 120.2/7.3 | 39.4 |

| 12 | 芴 | C13H10 | 166.1 |  | 110.9/7.3 | 23.4 |

| 13 | 9,10-二氢蒽 | C14H12 | 180.1 |  | 119.0/7.9 | 9.4 |

| 14 | 1,2,3,4-四氢蒽 | C14H14 | 182.1 |  | 123.2/7.9 | 18.7 |

| 15 | 2-甲基蒽 | C15H12 | 192.1 |  | 133.1/9.1 | 24.8 |

| 16 | 芘 | C16H10 | 202.1 |  | 147.2/11.7 | 276.5 |

| 17 | 4,5-二氢芘 | C16H12 | 204.1 |  | 143.3/11.0 | 30.5 |

| 18 | 4,5,9,10-四氢芘 | C16H14 | 206.1 |  | 137.3/9.8 | 5.9 |

| 19 | 1,2,3,6,7,8-六氢芘 | C16H16 | 208.1 |  | 141.5/9.9 | 13.5 |

| 20 | 4-甲基䓛 | C19H14 | 242.1 |  | 173.9/14.9 | 13.1 |

| 21 | 苯酚 | C6H6O | 94.0 |  | 52.4/5.6 | 5.4 |

| 22 | 5-茚醇 | C9H10O | 134.1 |  | 89.0/6.8 | 2.6 |

| 1 | Zhao L T, Liu Z T, Cheng L. How will China's coal industry develop in the future? A quantitative analysis with policy implications[J]. Energy, 2021, 235: 121406. |

| 2 | 李然, 田磊, 石洪宇, 等. 全球石油消费超疫情前水平 我国成品油市场格局加速演变——2023年国内外石油市场发展形势及2024年展望[J]. 中国能源, 2024, 46(S1): 30-42. |

| Li R, Tian L, Shi H Y, et al. Global oil consumption exceeds pre pandemic levels, and the pattern of China's oil market is accelerating its evolution—the situation and outlook of domestic and global oil markets in 2023[J]. Energy of China, 2024, 46(S1): 30-42. | |

| 3 | 孙宝东, 滕霄云, 张帆, 等. 2024年中国能源供需形势研判[J]. 中国煤炭, 2024, 50(4): 20-26. |

| Sun B D, Teng X Y, Zhang F, et al. Research on China's energy supply and demand situation in 2024[J]. China Coal, 2024, 50(4): 20-26. | |

| 4 | 李泽根. 煤制油液化化工工艺研究[J]. 山西化工, 2023, 43(3): 85-86, 94. |

| Li Z G. Study on chemical technology of coal to liquid liquefaction[J]. Shanxi Chemical Industry, 2023, 43(3): 85-86, 94. | |

| 5 | 郭云飞. 煤制油现状及高质量发展途径研究: 煤直接液化技术高质量发展研究[J]. 内蒙古石油化工, 2021, 47(9): 4-8. |

| Guo Y F. Status of coal to oil and its research on high quality development approach—study on high quality development of direct coal liquefaction technology[J]. Inner Mongolia Petrochemical Industry, 2021, 47(9): 4-8. | |

| 6 | Xu J, Yang Y, Li Y W. Recent development in converting coal to clean fuels in China[J]. Fuel, 2015, 152: 122-130. |

| 7 | Zhang D H, Wang J Q, Lin Y G, et al. Present situation and future prospect of renewable energy in China[J]. Renewable and Sustainable Energy Reviews, 2017, 76: 865-871. |

| 8 | 王洪学, 舒歌平, 杨葛灵, 等. 神华煤直接液化工艺供氢溶剂研究[J]. 应用化工, 2019, 48(10): 2462-2464, 2469. |

| Wang H X, Shu G P, Yang G L, et al. Research on hydrogen-donor solvent for Shenhua direct coal liquefaction[J]. Applied Chemical Industry, 2019, 48(10): 2462-2464, 2469. | |

| 9 | 王建立, 康开通, 高山松, 等. 煤直接液化循环溶剂供氢性影响因素研究[J]. 中国煤炭, 2020, 46(5): 68-73. |

| Wang J L, Kang K T, Gao S S, et al. Study on influencing factors of hydrogen supply of circulating solvent in direct coal liquefaction[J]. China Coal, 2020, 46(5): 68-73. | |

| 10 | Begon V. Structural effects of sample ageing in hydrocracked coal liquefaction extracts[J]. Fuel, 2000, 79(12): 1423-1429. |

| 11 | Lamey S C, Hesbach P A, White K D. Liquid fuel analyses using high-performance liquid chromatography and gas chromatography-mass spectroscopy[J]. Energy & Fuels, 1991, 5(1): 222-226. |

| 12 | 沈峰, 劳敏. GC-MS定性定量分析煤液化油的加氢产物[J]. 石化技术, 2022, 29(1): 13-14. |

| Shen F, Lao M. Qualitative and quantitative analysis of hydrogenation products of coal liquefied oil by GC-MS[J]. Petrochemical Industry Technology, 2022, 29(1): 13-14. | |

| 13 | Padlo D M, Subramanian R B, Kugler E L. Hydrocarbon class analysis of coal-derived liquids using high performance liquid chromatography[J]. Fuel Processing Technology, 1996, 49(1/2/3): 247-258. |

| 14 | McKinney D E, Clifford D J, Hou L, et al. High performance liquid chromatography (HPLC) of coal liquefaction process streams using normal-phase separation with diode array detection[J]. Energy & Fuels, 1995, 9(1): 90-96. |

| 15 | 蔺华林, 张德祥, 彭俊, 等. 神华煤直接液化循环油的分析表征[J]. 燃料化学学报, 2007, 35(1): 104-108. |

| Lin H L, Zhang D X, Peng J, et al. Analysis and characterization of recycled oil from direct liquefaction of Shenhua coal[J]. Journal of Fuel Chemistry and Technology, 2007, 35(1): 104-108. | |

| 16 | 王薇, 舒歌平, 章序文, 等. 煤直接液化过程中供氢溶剂的组成分析[J]. 煤炭转化, 2018, 4: 48-55. |

| Wang W, Shu G P, Zhang X W, et al. Composition of hydrogen donor solvent in the coal direct liquefaction process[J]. Coal Conversion, 2018, 4: 48-55. | |

| 17 | 王永刚, 周建明, 王彩红, 等. 先锋煤和神华煤直接液化油的组成[J]. 煤炭学报, 2006, 31(1): 81-84. |

| Wang Y G, Zhou J M, Wang C H, et al. Direct liquefaction oil products distribution of Xianfeng and Shenhua coals[J]. Journal of China Coal Society, 2006, 31(1): 81-84. | |

| 18 | 杨小龙, 刘新颖, 陈林江. GC/MS测定煤直接液化油品烃类组成和多环芳烃含量[J]. 内蒙古石油化工, 2023, 49(6): 21-24, 51. |

| Yang X L, Liu X Y, Chen L J. Determination of hydrocarbon composition and polycyclic aromatic hydrocarbon content in direct coal liquefaction oil products with GC/MS[J]. Inner Mongolia Petrochemical Industry, 2023, 49(6): 21-24, 51. | |

| 19 | 李群花, 姜元博, 杜一平, 等. 中心切割二维GC-MS法测定煤直接液化加氢改质油组成[J]. 分析测试学报, 2013, 32(5): 527-534. |

| Li Q H, Jiang Y B, Du Y P, et al. Composition determination of coal direct liquefaction hydrotreated oil by heart-cutting two-dimensional GC-MS[J]. Journal of Instrumental Analysis, 2013, 32(5): 527-534. | |

| 20 | 李群花, 姜元博, 胡慧廉, 等. 气相色谱-质谱结合活数据库法测定煤直接液化加氢改质油中C7~C9馏分的组成[J]. 理化检验-化学分册, 2014, 50(9): 1086-1091. |

| Li Q H, Jiang Y B, Hu H L, et al. Determination of components in fraction of C7—C9 of the coal-liquefied and hydrogenated oil by GC-MS in combination with the method of live database[J]. Physical Testing and Chemical Analysis Part B: Chemical Analysis, 2014, 50(9): 1086-1091. | |

| 21 | Wang J L, Xie L Y, Peng Y F, et al. Molecular composition of direct coal liquefaction products obtained from the Shenhua industrial plant[J]. Fuel, 2024, 357: 129735. |

| 22 | Hoque M S, Johnson T, de la Mata P, et al. Analysis of hydrothermal aging water of fire-protective fabrics using GC × GC-TOFMS and FID[J]. Fibers and Polymers, 2024, 25(5): 1925-1948. |

| 23 | 孙鑫源, 李长秀. 全二维气相色谱技术在石油馏分组成分析中的应用研究进展[J].石油化工, 2023, 52(7): 1019-1027. |

| Sun X Y, Li C X. Research advances in application of comprehensive two-dimensional gas chromatography technology in composition analysis of petroleum fractions[J]. Petrochemical Technology, 2023, 52(7): 1019-1027. | |

| 24 | Hamilton J F, Lewis A C, Millan M, et al. Comprehensive two-dimensional gas chromatography coupled to time-of-flight mass spectrometry of coal liquids produced during a coal liquefaction process[J]. Energy & Fuels, 2007, 21(1): 286-294. |

| 25 | Omais B, Courtiade M, Charon N G, et al. Characterization of oxygenated species in coal liquefaction products: an overview[J]. Energy & Fuels, 2010, 24(11): 5807-5816. |

| 26 | Omais B, Courtiade M, Charon N G, et al. Investigating comprehensive two-dimensional gas chromatography conditions to optimize the separation of oxygenated compounds in a direct coal liquefaction middle distillate[J]. Journal of Chromatography A, 2011, 1218(21): 3233-3240. |

| 27 | Omais B, Courtiade M, Charon N, et al. Using gas chromatography to characterize a direct coal liquefaction naphtha[J]. Journal of Chromatography A, 2012, 1226: 61-70. |

| 28 | Stihle J, Uzio D, Lorentz C, et al. Detailed characterization of coal-derived liquids from direct coal liquefaction on supported catalysts[J]. Fuel, 2012, 95: 79-87. |

| 29 | 高山松, 李群花, 舒歌平, 等. 煤直接液化循环溶剂中饱和烃的分子组成及分布特点[J]. 煤炭转化, 2020, 43(2): 17-25. |

| Gao S S, Li Q H, Shu G P, et al. Molecular composition and distribution characteristics of saturated hydrocarbons in direct coal liquefaction circulating solvent[J]. Coal Conversion, 2020, 43(2): 17-25. | |

| 30 | 牛鲁娜, 刘泽龙, 周建, 等. 全二维气相色谱-飞行时间质谱分析焦化柴油中饱和烃的分子组成[J]. 色谱, 2014, 32(11): 1236-1241. |

| Niu L N, Liu Z L, Zhou J, et al. Molecular composition of saturated hydrocarbons in diesels by comprehensive two-dimensional gas chromatography coupled with time-of-flight mass spectrometry[J]. Chinese Journal of Chromatography, 2014, 32(11): 1236-1241. | |

| 31 | 牛鲁娜, 刘泽龙, 周建, 等. 全二维气相色谱-飞行时间质谱鉴定柴油馏分中烯烃化合物[J]. 石油学报(石油加工), 2014, 30(5): 851-860. |

| Niu L N, Liu Z L, Zhou J, et al. Identification and characterization of olefins in diesel by using comprehensive two-dimensional gas chromatography coupled with time-of-flight mass spectrometry[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2014, 30(5): 851-860. | |

| 32 | 孙鑫源, 李长秀, 钱钦, 等. 全二维气相色谱测定汽油馏分中芳烃详细组成[J]. 石油学报(石油加工), 2024, 40(4): 1085-1097. |

| Sun X Y, Li C X, Qian Q, et al. Determination of individual aromatic components in gasoline fraction by comprehensive two-dimensional gas chromatography[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2024, 40(4): 1085-1097. | |

| 33 | 李小强, 刘永, 秦光书. 神华煤直接液化示范项目的进展及发展方向[J]. 煤化工, 2015, 43(4): 12-15, 37. |

| Li X Q, Liu Y, Qin G S. Progress and development direction of Shenhua coal direct liquefaction demonstration project[J]. Coal Chemical Industry, 2015, 43(4): 12-15, 37. | |

| 34 | 贾振斌, 刘永. 煤直接液化产品的组成、特性及应用[J]. 中国煤炭, 2020, 46(5): 81-86. |

| Jia Z B, Liu Y. Composition, characteristics and application of direct coal liquefaction products[J]. China Coal, 2020, 46(5): 81-86. |

| [1] | 杨晨, 毛伟, 董兴宗, 田松, 赵锋伟, 吕剑. 选择性加氢脱氯合成烯烃研究进展[J]. 化工学报, 2025, 76(1): 53-70. |

| [2] | 胡德政, 王榕, 王世栋, 杨文菲, 张宏伟, 袁珮. 兼具加氢和脱硫活性的富含Ni δ+非晶态NiP@γ-Al2O3催化剂的构筑及其用于石油树脂加氢的性能研究[J]. 化工学报, 2024, 75(9): 3152-3162. |

| [3] | 杨露, 刘聪聪, 孟彤彤, 张博远, 杨腾飞, 邓文安, 王晓斌. 分散型催化剂在煤/重油共炼体系中的加氢抑焦作用[J]. 化工学报, 2024, 75(7): 2556-2564. |

| [4] | 黄志鸿, 周利, 柴士阳, 吉旭. 耦合加氢装置优化的多周期氢网络集成[J]. 化工学报, 2024, 75(5): 1951-1965. |

| [5] | 丁禹, 杨昌泽, 李军, 孙会东, 商辉. 原子尺度钼系加氢脱硫催化剂的研究进展与展望[J]. 化工学报, 2024, 75(5): 1735-1749. |

| [6] | 韩宇, 周乐, 张鑫, 罗勇, 孙宝昌, 邹海魁, 陈建峰. 高黏附性Pd/SiO2/NF整体式催化剂的制备及加氢性能研究[J]. 化工学报, 2024, 75(4): 1533-1542. |

| [7] | 周琳, 叶斌, 孙心怡, 孔令鑫, 徐艳, 赵玉军. 介孔碳负载Ni催化剂催化顺酐加氢反应研究[J]. 化工学报, 2024, 75(11): 4264-4273. |

| [8] | 颜诗宇, 高姣姣, 杨太顺, 谢尚志, 杨艳娟, 徐晶. 钌基催化剂配位环境对聚乙烯氢解性能的影响[J]. 化工学报, 2024, 75(10): 3588-3599. |

| [9] | 潘越, 刘相洋, 黄奕晨, 李江涛, 邱丽, 李瑞丰, 李莎, 闫晓亮. Ni/Al2O3与ZnO距离对含硫菲加氢性能的影响[J]. 化工学报, 2024, 75(10): 3548-3556. |

| [10] | 王龙龙, 秦志峰, 班红艳, 李乃珍, 杜朕屹, 于峰, 翟志强, 吴琼笑. Al2O3载体孔结构优化:提升FeMo/Al2O3催化剂在焦炉煤气加氢脱硫性能[J]. 化工学报, 2024, 75(10): 3623-3638. |

| [11] | 李泓宇, 刘祥坤, 施尧, 曹约强, 钱刚, 段学志. 颗粒分辨的乙炔选择性加氢固定床反应器数值模拟[J]. 化工学报, 2024, 75(10): 3610-3622. |

| [12] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [13] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [14] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [15] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号