化工学报 ›› 2019, Vol. 70 ›› Issue (11): 4268-4277.DOI: 10.11949/j.issn.0438-1157.20190569

收稿日期:2019-05-27

修回日期:2019-08-09

出版日期:2019-11-05

发布日期:2019-11-05

通讯作者:

王晨光

作者简介:吴小平(1990—),男,博士,研究助理,基金资助:

Xiaoping WU( ),Chenguang WANG(

),Chenguang WANG( ),Qi ZHANG,Qiying LIU,Xinghua ZHANG,Longlong MA

),Qi ZHANG,Qiying LIU,Xinghua ZHANG,Longlong MA

Received:2019-05-27

Revised:2019-08-09

Online:2019-11-05

Published:2019-11-05

Contact:

Chenguang WANG

摘要:

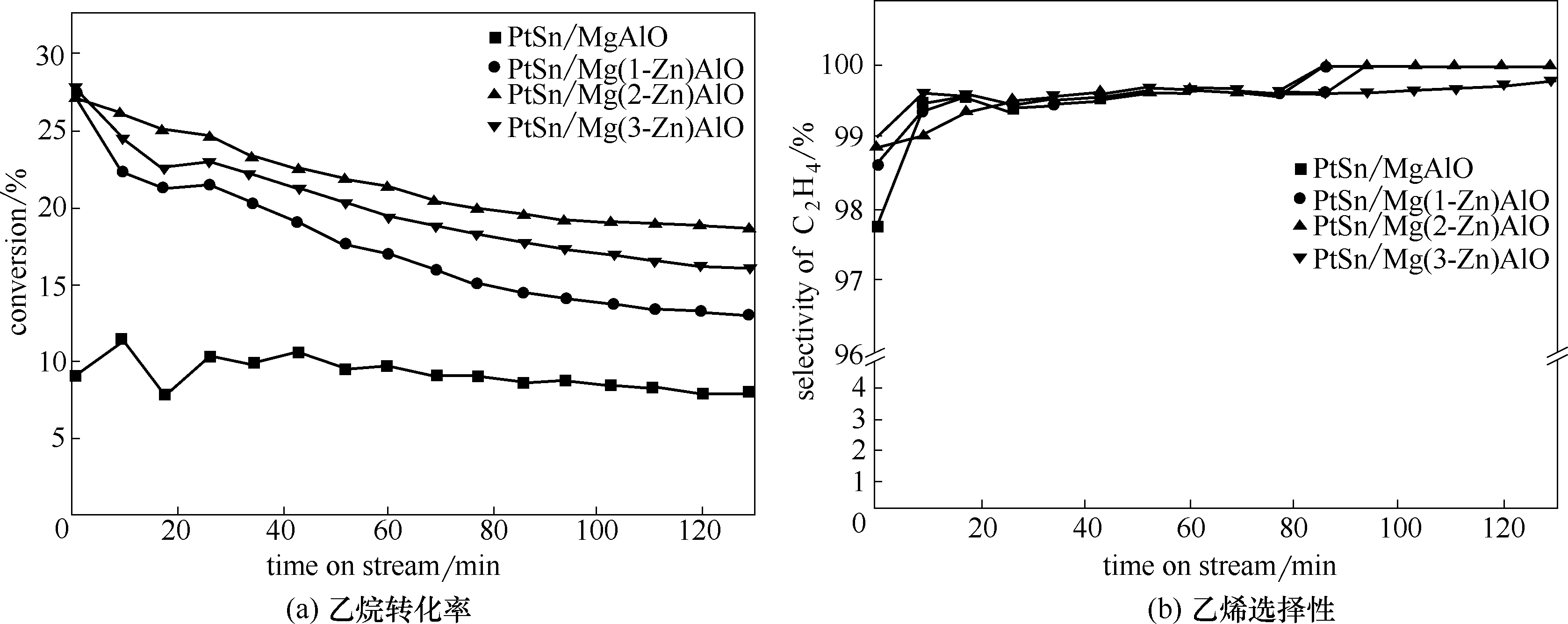

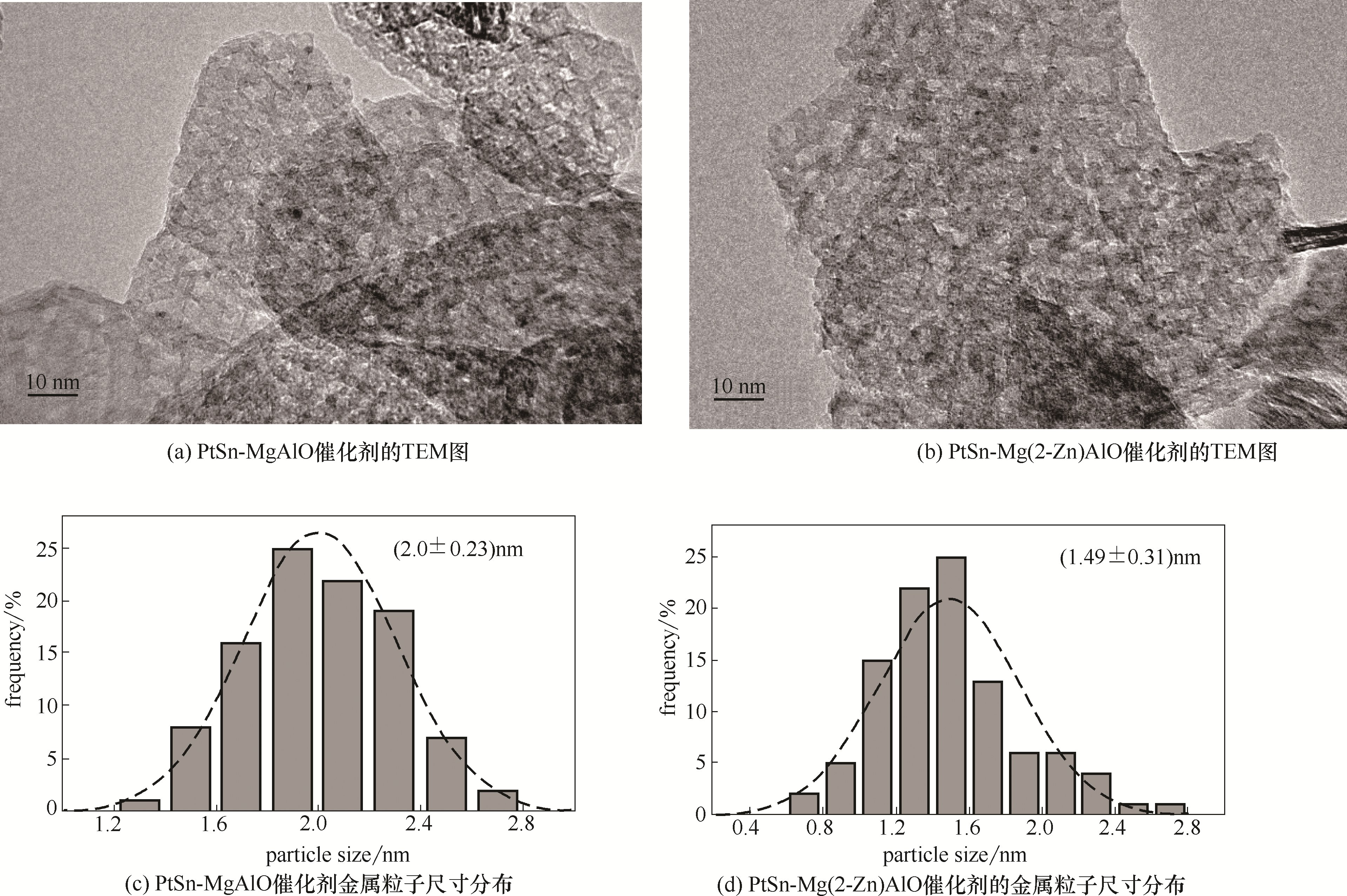

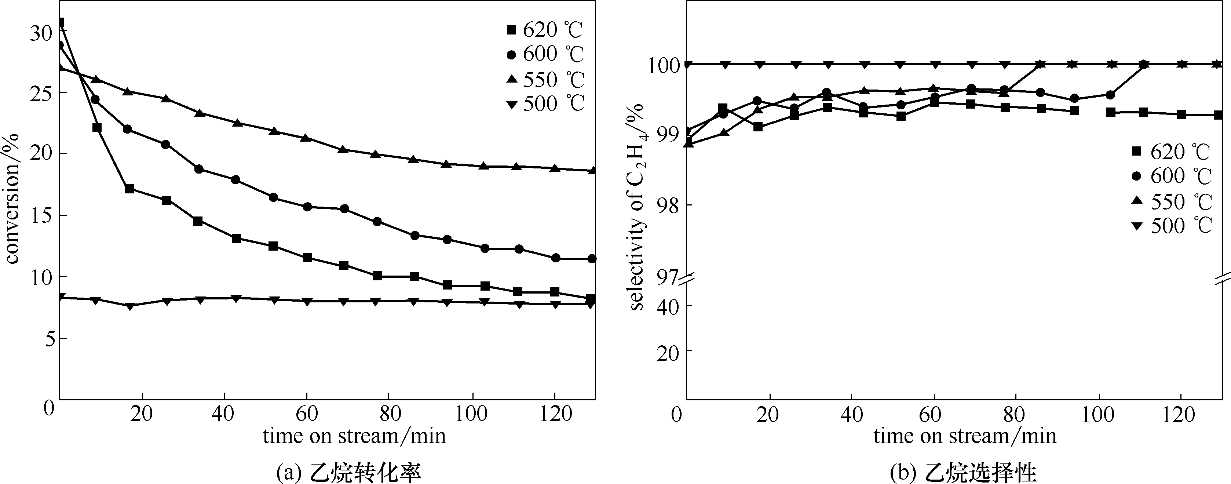

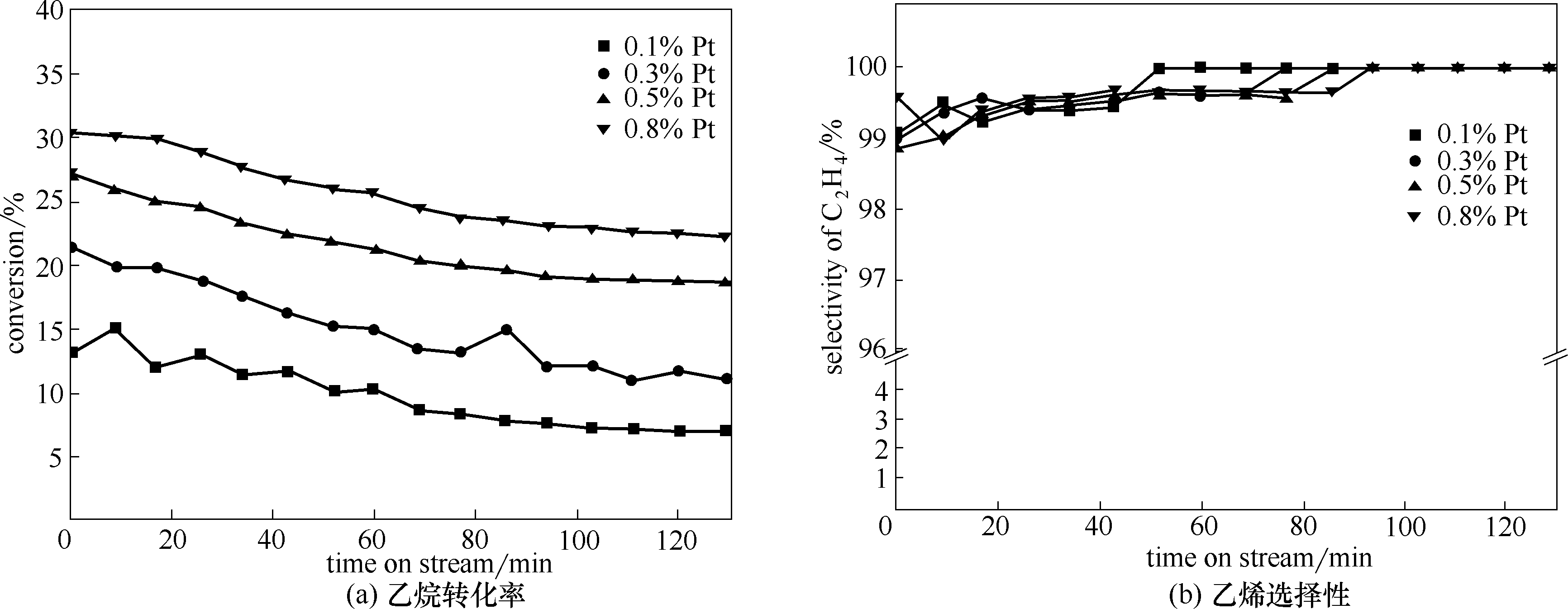

采用阴离子交换法合成了一系列不同Zn和Pt含量的PtSn-Mg(Zn)AlO催化剂用于乙烷脱氢反应。实验结果表明,在水滑石载体中掺杂少量的Zn对乙烷脱氢反应有明显影响。当Zn含量为2%(质量)时Pt基催化剂活性性能最优,在550℃时乙烷初始转化率达到27.1%,2 h平均转化率为21.6%。BET和SEM结果表明PtSn-Mg(Zn)AlO催化剂比PtSn-MgAlO催化剂比表面积更大,TEM结果显示,PtSn-Mg(Zn)AlO催化剂和PtSn-MgAlO催化剂的金属颗粒的平均直径分别为(1.49±0.31)nm 和(2.0±0.23)nm,说明Zn的掺杂在一定程度上改变了催化剂的结构,能减小Pt颗粒的尺寸,更好地分散Pt颗粒,从而改善乙烷催化脱氢反应性能。此外,考察温度对乙烷脱氢反应性能影响,发现温度越高乙烷初始转化率越高,但催化剂越易失活;考察Pt负载量对乙烷脱氢反应性能的影响,发现增加Pt含量并不能使乙烷转化率得到相应倍数的增加,即增加Pt含量反而使Pt的利用率降低了,因此适量降低PtSn-Mg(2-Zn)AlO催化剂中Pt含量对研究乙烷脱氢反应有深远意义。

中图分类号:

吴小平, 王晨光, 张琦, 刘琪英, 张兴华, 马隆龙. PtSn-Mg(Zn)AlO催化剂应用于乙烷脱氢反应研究[J]. 化工学报, 2019, 70(11): 4268-4277.

Xiaoping WU, Chenguang WANG, Qi ZHANG, Qiying LIU, Xinghua ZHANG, Longlong MA. Study on ethane dehydrogenation over PtSn-Mg(Zn)AlO catalyst[J]. CIESC Journal, 2019, 70(11): 4268-4277.

图2 不同Zn负载量的PtSn-Mg(x-Zn)AlO催化剂对乙烷脱氢反应性能的影响

Fig.2 Effect of Zn loading on catalytic performances of PtSn-Mg(x-Zn)AlO catalysts in ethane dehydrogenation reaction

| Catalyst | Specific area A/(m2·g-1) | Pore volume v/(cm3·g-1) |

|---|---|---|

| PtSn-MgAlO | 172.2 | 0.65 |

| PtSn-Mg(1-Zn)AlO | 210.3 | 0.74 |

| PtSn-Mg(2-Zn)AlO | 227.5 | 0.81 |

| PtSn-Mg(3-Zn)AlO | 225.6 | 0.79 |

表1 PtSn-Mg(x-Zn)AlO催化剂BET比表面积和孔容

Table 1 BET surface area and pore volume of PtSn-Mg(x-Zn)AlO catalysts

| Catalyst | Specific area A/(m2·g-1) | Pore volume v/(cm3·g-1) |

|---|---|---|

| PtSn-MgAlO | 172.2 | 0.65 |

| PtSn-Mg(1-Zn)AlO | 210.3 | 0.74 |

| PtSn-Mg(2-Zn)AlO | 227.5 | 0.81 |

| PtSn-Mg(3-Zn)AlO | 225.6 | 0.79 |

图5 PtSn-MgAlO催化剂及PtSn-Mg(2-Zn)AlO催化剂的TEM图和金属粒子尺寸分布

Fig.5 TEM images and size distribution of metal particles of PtSn-MgAlO catalyst and PtSn-Mg(2-Zn)AlO catalyst

| Catalyst | Metal dispersion /% |

|---|---|

| PtSn-MgAlO | 27.7 |

| PtSn-Mg(1-Zn)AlO | 43.2 |

| PtSn-Mg(2-Zn)AlO | 54.3 |

| PtSn-Mg(3-Zn)AlO | 61.5 |

表2 PtSn-Mg(x-Zn)AlO催化剂金属分散度

Table 2 Metal dispersion values of PtSn-Mg(x-Zn)AlO catalysts determined

| Catalyst | Metal dispersion /% |

|---|---|

| PtSn-MgAlO | 27.7 |

| PtSn-Mg(1-Zn)AlO | 43.2 |

| PtSn-Mg(2-Zn)AlO | 54.3 |

| PtSn-Mg(3-Zn)AlO | 61.5 |

图7 温度对PtSn-Mg(2-Zn)AlO催化剂催化乙烷脱氢反应性能的影响

Fig.7 Effect of temperature on catalytic performances of PtSn-Mg(2-Zn)AlO catalysts in ethane dehydrogenation reaction

图8 不同Pt负载量的x-PtSn-Mg(2-Zn)AlO催化剂对乙烷脱氢反应性能的影响

Fig.8 Effect of Pt loading on catalytic performances of x-PtSn-Mg(2-Zn)AlO catalysts in ethane dehydrogenation reaction

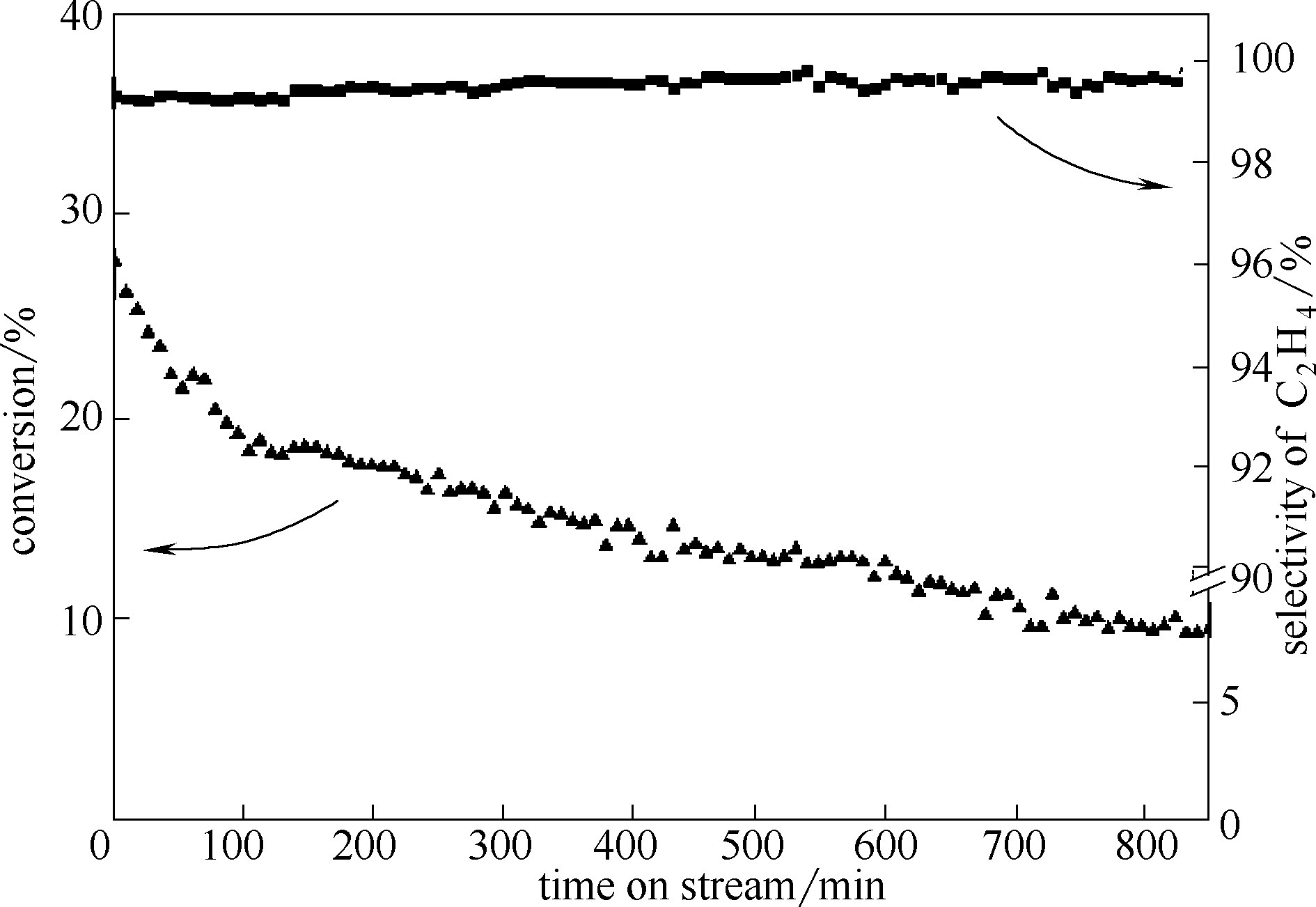

图10 PtSn-Mg(2-Zn)AlO乙烷脱氢反应稳定性实验中乙烷转化率与乙烯选择性随时间的变化

Fig.10 Ethane conversion and ethene selectivity of ethane dehydrogenation reaction for PtSn-Mg(2-Zn)AlO catalysts in stability tests

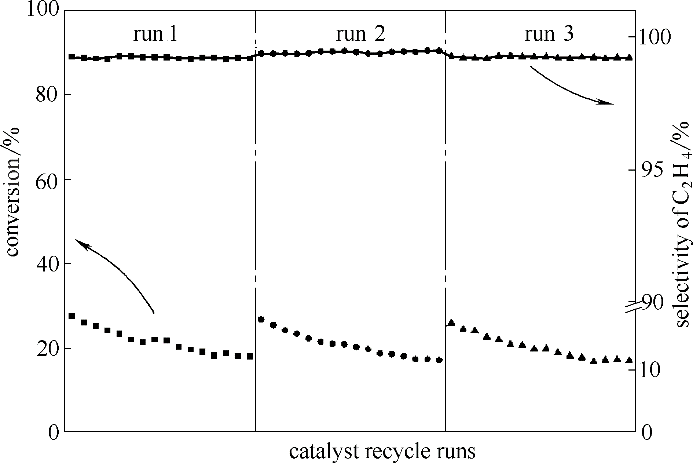

图11 PtSn-Mg(2-Zn)AlO乙烷脱氢反应循环再生实验中乙烷转化率与乙烯选择性随时间的变化

Fig.11 Ethane conversion and ethene selectivity of ethane dehydrogenation reaction for PtSn-Mg(2-Zn)AlO catalysts in reaction-regeneration cycles

| 1 | SattlerJ J H B, Ruiz-MartinezJ, Santillan-JimenezE, et al. Catalytic dehydrogenation of light alkanes on metals and metal oxides[J]. Chemical Reviews, 2014, 114(20): 10613-10653. |

| 2 | 张海娟, 高杰, 张浩楠, 等. 低碳烷烃深加工制烯烃技术的研究进展[J]. 石油化工, 2016, 45(12): 1411-1419. |

| ZhangH J, GaoJ, ZhangH N, et al. Progresses in processes and catalysts for dehydrogenation of light paraffins to olefins[J]. Petrochemical Technology, 2016, 45(12): 1411-1419. | |

| 3 | LongL L, LangW Z, LiuX, et al. Improved catalytic stability of PtSnIn/xCa-Al catalysts for propane dehydrogenation to propylene[J]. Chemical Engineering Journal, 2014, 257: 209-217. |

| 4 | 郭秋双, 蔡奇, 孙彦民, 等. 低碳烷烃脱氢催化剂的研究进展[J]. 无机盐工业, 2016, 48(8): 11-15. |

| GuoQ S, CaiQ, SunY M, et al. Research progress of low carbon alkane dehydrogenation catalyst[J]. Inorganic Chemical Industry, 2016, 48(8): 11-15. | |

| 5 | WuJ, SharadaS M, HoC, et al. Ethane and propane dehydrogenation over PtIr/Mg(Al)O[J]. Applied Catalysis A-General, 2015, 506: 25-32. |

| 6 | CavaniF, BallariniN, CericolaA. Oxidative dehydrogenation of ethane and propane: how far from commercial implementation?[J]. Catalysis Today, 2007, 127: 113-131. |

| 7 | DongA H, WangK, ZhuS Z, et al. Facile preparation of PtSn-La/Al2O3 catalyst with large pore size and its improved catalytic performance for isobutane dehydrogenation[J]. Fuel Processing Technology, 2017, 158: 218-225. |

| 8 | DengL D, MiuraH, ShishidoT, et al. Elucidating strong metal-support interactions in Pt-Sn/SiO2 catalyst and its consequences for dehydrogenation of lower alkanes[J]. Journal of Catalysis, 2018, 365: 277-291. |

| 9 | ChengM, ZhaoH H, YangJ, et al. Synthesis and catalytic performance of a dual-sites Fe-Zn catalyst based on ordered mesoporous Al2O3 for isobutane dehydrogenation[J]. Catalysis Letters, 2019, 149(5): 1326-1336. |

| 10 | JangE J, LeeJ, JeongH Y, et al. Controlling the acid-base properties of alumina for stable PtSn-based propane dehydrogenation catalysts[J]. Applied Catalysis A-General, 2019, 572: 1-8. |

| 11 | PhamH N, SattlerJ J H B, WeckhuysenB M, et al. Role of Sn in the regeneration of Pt/gamma-Al2O3 light alkane dehydrogenation catalysts[J]. ACS Catalysis, 2016, 6(4): 2257-2264. |

| 12 | DixitM, KostetskyyP, MpourmpakisG. Structure-activity relationships in alkane dehydrogenation on gamma-Al2O3: site-dependent reactions[J]. ACS Catalysis, 2018, 8(12): 11570-11578. |

| 13 | BaronettiG T, DemiguelS R, ScelzaO A, et al. State of metallic phase in Pt-Sn/Al2O3 catalysts prepared by different deposition techniques[J]. Applied Catalysis, 1986, 24: 109-116. |

| 14 | LiuG, ZengL, ZhaoZ J, et al. Platinum-modified ZnO/Al2O3 for propane dehydrogenation: minimized platinum usage and improved catalytic stability[J]. ACS Catalysis, 2016, 6(4): 2158-2162. |

| 15 | SzetoK C, JonesZ R, MerleN, et al. A strong support effect in selective propane dehydrogenation catalyzed by Ga(i-Bu)(3) grafted onto gamma-alumina and silica[J]. ACS Catalysis, 2018, 8(8): 7566-7577. |

| 16 | YangK, YinY B, LaiS S, et al. Aromatization of n-butane and i-butane over PtSnK/ZSM-5 catalysts: influence of SiO2/Al2O3 ratio[J]. Catalysis Letters, 2018, 148(11): 3570-3582. |

| 17 | LiuX, LangW Z, LongL L, et al. Improved catalytic performance in propane dehydrogenation of PtSn/gamma-Al2O3 catalysts by doping indium[J]. Chemical Engineering Journal, 2014, 247: 183-192. |

| 18 | XiaK, LangW Z, LiP P, et al. The properties and catalytic performance of PtIn/Mg(Al)O catalysts for the propane dehydrogenation reaction: effects of pH value in preparing Mg(Al)O supports by the co-precipitation method[J]. Journal of Catalysis, 2016, 338: 104-114. |

| 19 | ShenL L, XiaK, LangW Z, et al. The effects of calcination temperature of support on PtIn/Mg(Al)O catalysts for propane dehydrogenation reaction[J]. Chemical Engineering Journal, 2017, 324: 336-346. |

| 20 | 王延臻, 王鹏成, 段红玲, 等. 铂锡催化剂用于混合低碳烷烃脱氢生产异丁烯化[J]. 化工学报, 2011, 62(11): 3143-3148. |

| WangY Z, WangP C, DuanH L, et al. Platinum-tin catalysts for dehydrogenation of mixed low hydrocarb ons into isobutene[J]. CIESC Journal, 2011, 62(11): 3143-3148. | |

| 21 | XiongH F, LinS, GoetzeJ, et al. Thermally stable and regenerable platinum-tin clusters for propane dehydrogenation prepared by atom trapping on ceria[J]. Angewandte Chemie-International Edition, 2017, 56(31): 8986-8991. |

| 22 | SaeedizadM, SahebdelfarS, MansourpourZ. Deactivation kinetics of platinum-based catalysts in dehydrogenation of higher alkanes[J]. Chemical Engineering Journal, 2009, 154: 76-81. |

| 23 | SunP P, SiddiqiG, ViningW C, et al. Novel Pt/Mg(In)(Al)O catalysts for ethane and propane dehydrogenation[J]. Journal of Catalysis, 2011, 282(1): 165-174. |

| 24 | FangS Q, ZhangK T, WangC G, et al. The properties and catalytic performance of PtSn/Mg(x-Ga)AlO catalysts for ethane dehydrogenation[J]. RSC Advances, 2017, 7(37): 22836-22844. |

| 25 | ZhangQ, ZhangK T, ZhangS H, et al. Ga3+-stabilized Pt in PtSn-Mg(Ga)(Al)O catalyst for promoting ethane dehydrogenation[J]. Journal of Catalysis, 2018, 368: 79-88. |

| 26 | ZhangY W, ZhouY M, TangM H, et al. Effect of La calcination temperature on catalytic performance of PtSnNaLa/ZSM-5 catalyst for propane dehydrogenation[J]. Chemical Engineering Journal, 2012, 181: 530-537. |

| 27 | WuJ, PengZ M, BellA T. Effects of composition and metal particle size on ethane dehydrogenation over PtxSn100-x/Mg(Al)O (70 <= x <= 100)[J]. Journal of Catalysis, 2014, 311: 161-168. |

| 28 | GalvitaV, SiddiqiG, SunP P, et al. Ethane dehydrogenation on Pt/Mg(Al)O and PtSn/Mg(Al)O catalysts[J]. Journal of Catalysis, 2010, 271: 209-219. |

| 29 | 陈领鹏, 田志鹏, 吕微, 等. 离子交换法制备Pt-SnE / Mg(Al)O催化剂及其烷烃催化脱氢性能[J]. 燃料化学学报, 2016, 44 (5): 597-606. |

| ChenL P, TianZ P, LyuW, et al. Preparation of Pt-SnE/Mg(Al)O catalyst by anion exchange method and its performance in alkane dehydrogenation[J]. Journal of Fuel Chemistry and Technology, 2016, 44 (5): 597-606. | |

| 30 | BelskayaO B, StepanovaL N, GulyaevaT I, et al. Zinc influence on the formation and properties of Pt/Mg(Zn)AlOx catalysts synthesized from layered hydroxides[J]. Journal of Catalysis, 2016, 341: 13-23. |

| 31 | WangY J, WangY M, WangS R, et al. Propane dehydrogenation over PtSn catalysts supported on ZnO-modified MgAl2O4[J]. Catalysis Letters, 2009, 132: 472-479. |

| 32 | LupanO, EmelchenkoG A, UrsakiV V, et al. Synthesis and characterization of ZnO nanowires for nanosensor applications[J]. Materials Research Bulletin, 2010, 45: 1026-1032. |

| 33 | 郭秋双, 杨玉旺, 李晓云, 等. 丙烷脱氢制丙烯 Cr2O3/Al2O3催化剂的失活研究[J]. 无机盐工业, 2019, 51(4): 86-89. |

| GuoQ S, YangY W, LiX Y, et al. Deactivation of propane dehydrogenation to produce propylene Cr2O3/Al2O3 catalysts[J]. Inorganic Chemical Industry, 2019, 51(4): 86-89. |

| [1] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [2] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [3] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [4] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [5] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [6] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [7] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [8] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [9] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [10] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [11] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [12] | 王辰, 史秀锋, 武鲜凤, 魏方佳, 张昊虹, 车寅, 吴旭. 氧化还原法制备Mn3O4催化剂及其甲苯催化氧化性能与机理研究[J]. 化工学报, 2023, 74(6): 2447-2457. |

| [13] | 李勇, 高佳琦, 杜超, 赵亚丽, 李伯琼, 申倩倩, 贾虎生, 薛晋波. Ni@C@TiO2核壳双重异质结的构筑及光热催化分解水产氢[J]. 化工学报, 2023, 74(6): 2458-2467. |

| [14] | 周继鹏, 何文军, 李涛. 异形催化剂上乙烯催化氧化失活动力学反应工程计算[J]. 化工学报, 2023, 74(6): 2416-2426. |

| [15] | 张希庆, 王琰婷, 徐彦红, 常淑玲, 孙婷婷, 薛定, 张立红. Mg量影响的纳米片负载Pt-In催化异丁烷脱氢性能[J]. 化工学报, 2023, 74(6): 2427-2435. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号