化工学报 ›› 2020, Vol. 71 ›› Issue (2): 736-745.DOI: 10.11949/0438-1157.20191264

马金凤1,2( ),曾玺2(

),曾玺2( ),王芳2,康国俊1(

),王芳2,康国俊1( ),武荣成2,许光文2,3

),武荣成2,许光文2,3

收稿日期:2019-10-24

修回日期:2019-12-13

出版日期:2020-02-05

发布日期:2020-02-05

通讯作者:

曾玺,康国俊

作者简介:马金凤(1992—),女,硕士研究生,基金资助:

Jinfeng MA1,2( ),Xi ZENG2(

),Xi ZENG2( ),Fang WANG2,Guojun KANG1(

),Fang WANG2,Guojun KANG1( ),Rongcheng WU2,Guangwen XU2,3

),Rongcheng WU2,Guangwen XU2,3

Received:2019-10-24

Revised:2019-12-13

Online:2020-02-05

Published:2020-02-05

Contact:

Xi ZENG,Guojun KANG

摘要:

针对煤快速热解研究中样品添加量少(mg级)、焦油收集难等问题,本研究利用压片法制备微薄厚度(mm级)的煤层,并采用红外加热装置考察大添加量(g级)、微薄煤层的快速热解特性。对比堆积煤样和不同煤压片厚度(1.5~3 mm)与个数(1~2)的压片煤样热解特性发现,压片煤层热解过程的二次反应受到明显抑制,焦油产率急剧增加,在1000℃时达9.96%,为格金分析的1.5倍,实现油气产量的同步增长。模拟蒸馏分析发现,堆积状态下焦油以沥青质为主,而微薄煤层制焦油含大量轻油、酚油、萘油、洗油和蒽油。GC-MS和FTIR分析表明,随煤层厚度和个数的减少,焦油组分和含量提高,芳香烃类和含氧官能团吸收增加,进一步验证煤快速热解过程中煤层厚度对焦油产率和品质的影响,揭示在二次反应充分抑制下煤高温热解的初级反应特性。

中图分类号:

马金凤, 曾玺, 王芳, 康国俊, 武荣成, 许光文. 煤红外快速热解过程中床层对二次反应的影响[J]. 化工学报, 2020, 71(2): 736-745.

Jinfeng MA, Xi ZENG, Fang WANG, Guojun KANG, Rongcheng WU, Guangwen XU. Effect of coal layer thickness on secondary reaction during its infrared rapid pyrolysis[J]. CIESC Journal, 2020, 71(2): 736-745.

Proximate analysis / %(mass) | Ultimate analysis/%(mass) | G-K/ %(mass) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vad | FCad | Cdaf | Hdaf | Sdaf | Ndaf | Odaf① | Tarad |

| 1.12 | 38.94 | 24.56 | 35.38 | 75.79 | 4.97 | 2.34 | 1.2 | 15.7 | 6.7 |

表1 实验用煤的工业分析、元素分析和格金分析

Table 1 Result of proximate, ultimate and G-K analyses of Datong coal

Proximate analysis / %(mass) | Ultimate analysis/%(mass) | G-K/ %(mass) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vad | FCad | Cdaf | Hdaf | Sdaf | Ndaf | Odaf① | Tarad |

| 1.12 | 38.94 | 24.56 | 35.38 | 75.79 | 4.97 | 2.34 | 1.2 | 15.7 | 6.7 |

| 序号 | 样品质量/g | 煤样 | 温度/℃ | 目的 | ||

|---|---|---|---|---|---|---|

| 样品状态 | 煤层厚度/ mm | 放置压片数量 | ||||

| 1 | 3 | 堆积 | 13 | — | 600~1000 | 文献常见方法 |

| 2 | 3 | 压片 | 3 | 1 | 600~1000 | 验证压片法抑制 二次反应可行性 |

| 3 | 3 | 压片 | 1.5 | 2 | 600~1000 | 验证临近煤层对 二次反应的影响 |

| 4 | 1.5 | 压片 | 1.5 | 1 | 600~1000 | 二次反应最小化研究 |

表2 热解实验条件汇总

Table 2 Detailed experiment conditions in this study

| 序号 | 样品质量/g | 煤样 | 温度/℃ | 目的 | ||

|---|---|---|---|---|---|---|

| 样品状态 | 煤层厚度/ mm | 放置压片数量 | ||||

| 1 | 3 | 堆积 | 13 | — | 600~1000 | 文献常见方法 |

| 2 | 3 | 压片 | 3 | 1 | 600~1000 | 验证压片法抑制 二次反应可行性 |

| 3 | 3 | 压片 | 1.5 | 2 | 600~1000 | 验证临近煤层对 二次反应的影响 |

| 4 | 1.5 | 压片 | 1.5 | 1 | 600~1000 | 二次反应最小化研究 |

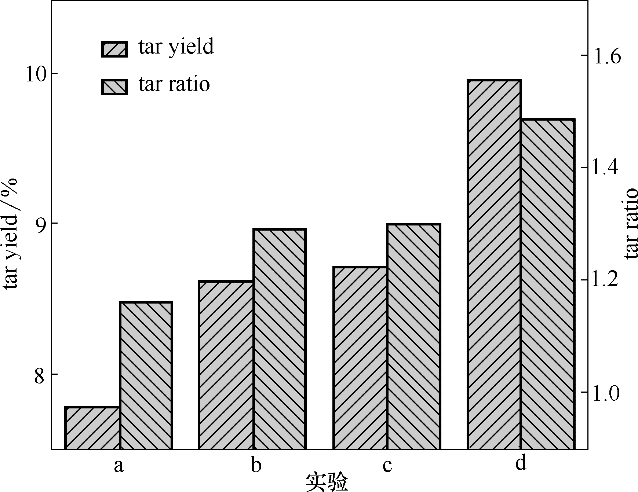

图8 1000℃高温下各热解实验的焦油产率及与理论产量的比值a—质量为3 g、堆积状态厚度为13 mm煤样热解实验; b—质量为3 g、厚度3 mm的煤压片热解实验; c—总质量为3 g、两个厚度为1.5 mm的煤压片热解实验; d—质量为1.5 g、单个厚度为1.5 mm的煤压片热解实验

Fig.8 Tar yield and ratio between experiment and theory yield at 1000℃ for different experiments

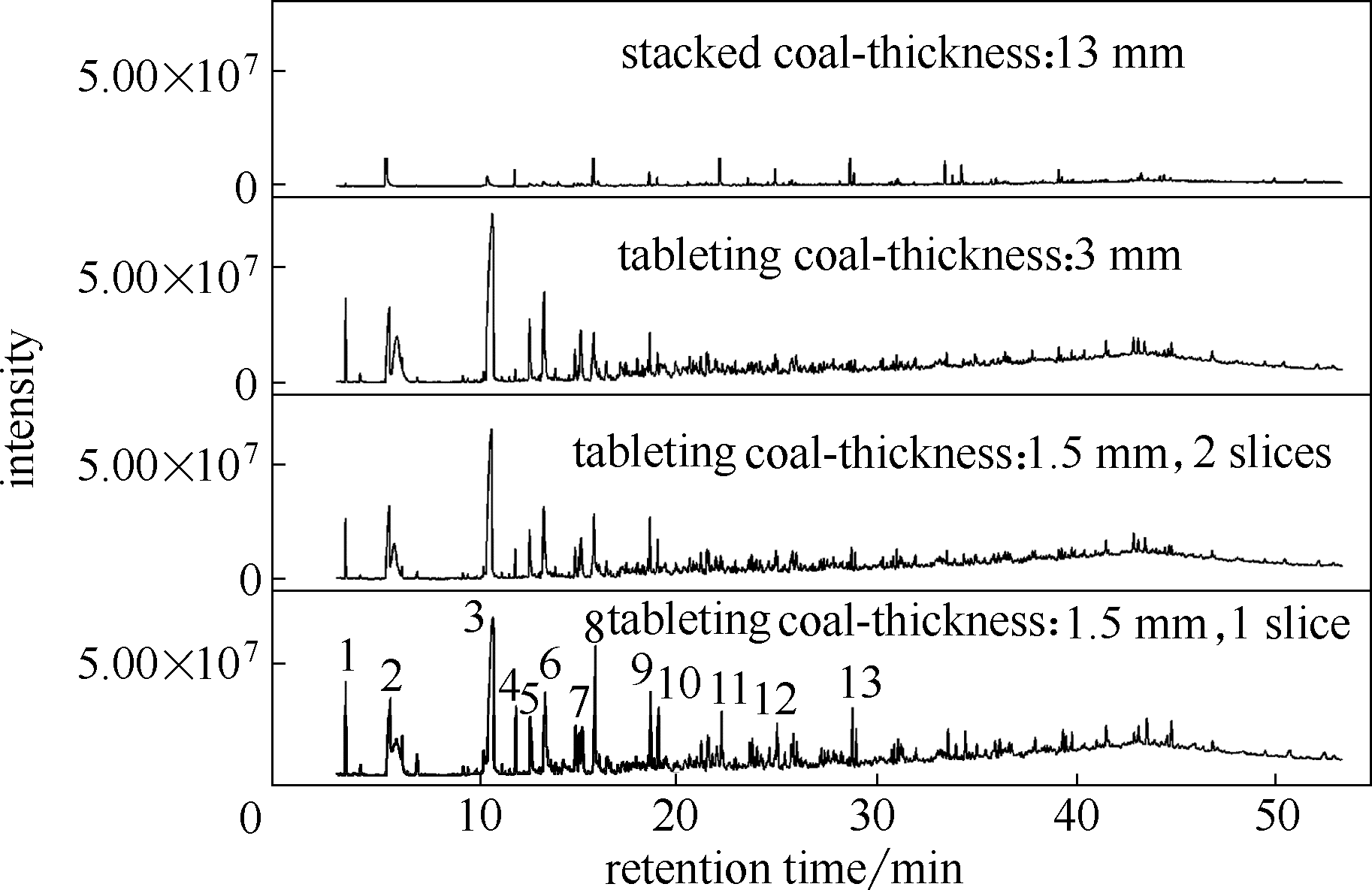

图10 1000℃时各焦油样品的GC-MS分析1—甲苯; 2—环己酮; 3—苯酚; 4—3-甲基苯酚; 5—2,4-二甲基苯酚; 6—3,5-二甲基苯酚; 7—7-甲基-1-萘酚; 8—2-甲基萘; 9—1-甲基萘; 10—萘; 11—2-萘酚; 12—菲; 13—3-甲基-5-乙基苯酚

Fig.10 GC-MS analysis of tar samples prepared at 1000℃

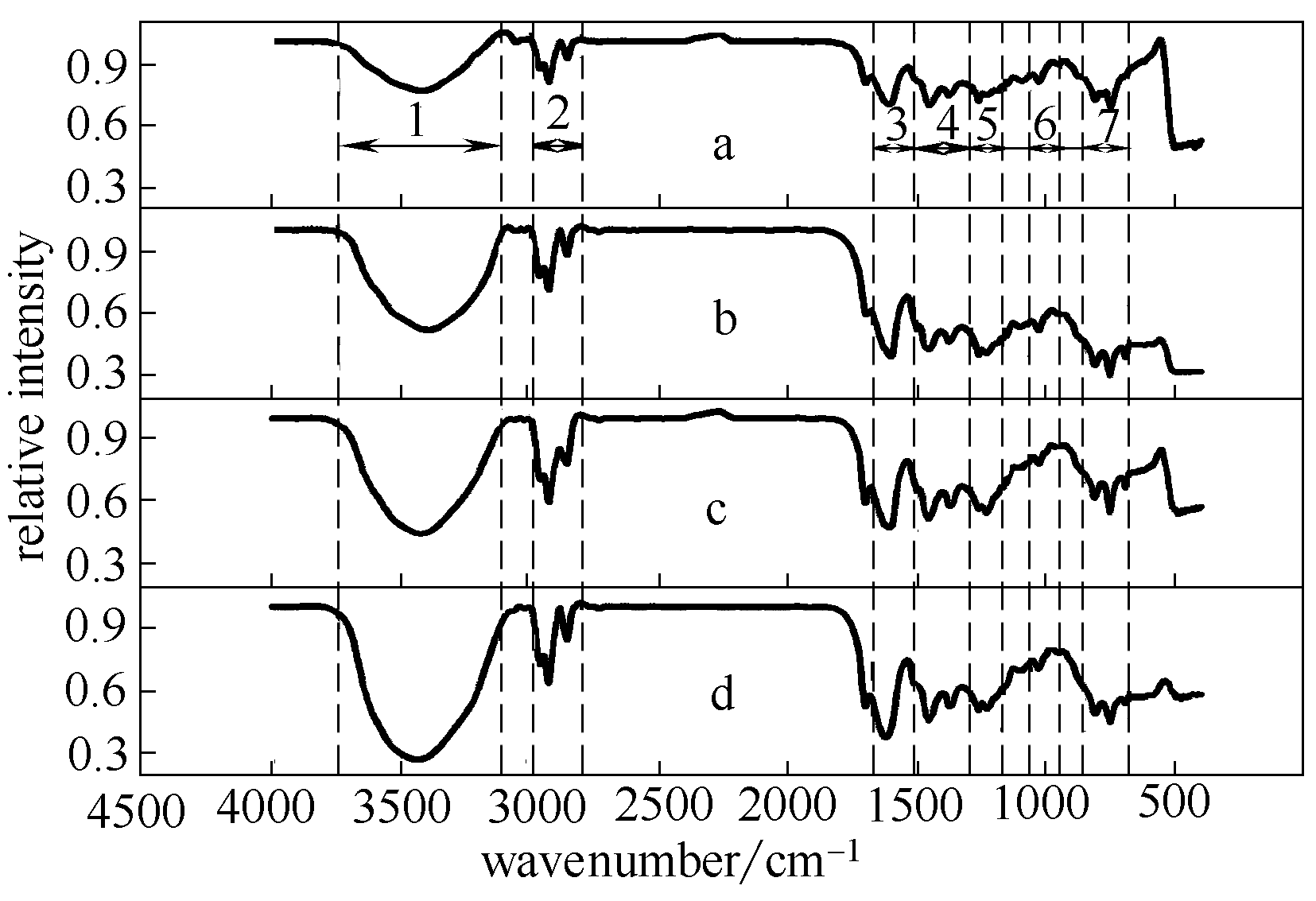

图11 1000℃下各实验制备焦油的FTIR分析a—质量为3 g、堆积状态厚度为13 mm的煤样热解实验; b—质量为3 g、厚度3 mm的煤压片热解实验; c—总质量为3 g、两个厚度为1.5 mm的煤压片热解实验; d—质量为1.5 g、单个厚度为1.5 mm的煤压片热解实验

Fig.11 FTIR analysis of tar samples from pyrolysis experiment at 1000℃

| 1 | 谢克昌, 李忠. 煤基燃料的制备与应用[J]. 化工学报, 2004, 55(9): 1393-1399. |

| Xie K C, Li Z. Production and application of coal-based fuel[J]. Journal of Chemical Industry and Engineering(China), 2004, 55(9): 1393-1399. | |

| 2 | Shi Z W, Jin L J, Zhou Y, et al. Effect of hydrothermal treatment on structure and liquefaction behavior of Baiyinhua coal[J]. Fuel Processing Technology, 2017, 167: 648-654. |

| 3 | 齐庆杰, 刘建忠, 曹欣玉, 等. 煤中氟分布与燃烧排放特性[J]. 化工学报, 2002, 53(6): 572-577. |

| Qi Q J, Liu J Z, Cao X Y, et al. Fluorine distribution characteristics in coal and behavior of fluorine during coal combustion[J]. Journal of Chemical Industry and Engineering(China), 2002, 53(6): 572-577. | |

| 4 | 翟建荣, 钟梅, 马凤云, 等. 水蒸气对煤焦油模化物裂解行为及析碳的影响[J]. 化工学报, 2019, 70(8): 2898-2908. |

| Zhai J R, Zhong M, Ma F Y, et al. Effect of steam atmosphere on cracking behavior and carbon deposition of coal tar model compounds[J]. CIESC Journal, 2019, 70(8): 2898-2908. | |

| 5 | Zhang Z Z, Chang H, Gao T, et al. Catalytic upgrading of coal pyrolysis volatiles over metal-loaded HZSM-5 catalysts in a fluidized bed reactor[J]. Journal of Analytical and Applied Pyrolysis, 2019, 139: 31-39. |

| 6 | 范洋, 李文英, 谢克昌. 褐煤热解-气化-制油系统的CO2减排策略[J]. 化工学报, 2015, 66(8): 3204-3209. |

| Fan Y, Li W Y, Xie K C. Strategies of lignite pyrolysis-gasification-oil system for CO2 emission reduction[J]. CIESC Journal, 2015, 66(8): 3204-3209. | |

| 7 | Li C Z. Importance of volatile-char interactions during the pyrolysis and gasification of low-rank fuels — a review[J]. Fuel, 2013, 112: 609-623. |

| 8 | 赵洪宇, 任善普, 贾晋炜, 等.褐煤经四氢化萘处理后的结构及热解-气化特性分析[J]. 化工学报, 2015, 66(10): 4193-4201. |

| Zhao H Y, Ren S P, Jia J W, et al. Analysis of structure and pyrolysis and gasification characteristics of lignite after tetrahydronaphthalene treatment[J]. CIESC Journal, 2015, 66(10): 4193-4201. | |

| 9 | Niu B, Jin L, Li Y, et al. Mechanism of hydrogen transfer and role of solvent during heating-up stage of direct coal liquefaction[J]. Fuel Processing Technology, 2017, 160: 130-135. |

| 10 | 刘振宇. 煤快速热解制油技术问题的化学反应工程根源: 逆向传热与传质[J]. 化工学报, 2016, 67(1): 1-5. |

| Liu Z Y. Origin of common problems in fast coal pyrolysis technologies for tar: the countercurrent flow of heat and volatiles[J]. CIESC Journal, 2016, 67(1): 1-5. | |

| 11 | Siramard S, Zhan J H, Han Z N, et al. Secondary cracking of volatile and its avoidance in infrared-heating pyrolysis reactor[J]. Carbon Resources Conversion, 2018, 1(3): 202-208. |

| 12 | Cheng S, Lai D G, Shi Z, et al. Suppressing secondary reactions of coal pyrolysis by reducing pressure and mounting internals in fixed-bed reactor[J]. Chinese Journal of Chemical Engineering, 2017, 25(4): 507-515. |

| 13 | Sotiropoulou R E P, Serafidou M, Skodras G. Thermal mercury removal from coals: effect of pyrolysis conditions and kinetic analysis[J]. Fuel, 2019, 238: 44-50. |

| 14 | Yu W H, Han S, Lei Z P, et al. The reaction behavior of volatiles generated from lignite pyrolysis[J]. Fuel, 2019, 244: 22-30. |

| 15 | Jamil K, Hayashi J I, Li C Z. Pyrolysis of a victorian brown coal and gasification of nascent char in CO2 atmosphere in a wire-mesh reactor[J]. Fuel, 2004, 83(7/8): 833-843. |

| 16 | Patwardhan P R, Dalluge D L, Shanks B H, et al. Distinguishing primary and secondary reactions of cellulose pyrolysis[J]. Bioresour. Technol., 2011, 102(8): 5265-5269. |

| 17 | Patwardhan P R, Satrio J A, Brown R C, et al. Product distribution from fast pyrolysis of glucose-based carbohydrates[J]. Journal of Analytical and Applied Pyrolysis, 2009, 86(2): 323-330. |

| 18 | Yao Q X, Li Y B, Tang X, et al. Separation of petroleum ether extracted residue of low temperature coal tar by chromatography column and structural feature of fractions by TG-FTIR and PY-GC/MS[J]. Fuel, 2019, 245: 122-130. |

| 19 | 杨燕梅, 张海, 吕俊复, 等. 基于Py-GC联用的煤快速热解实验研究[J]. 燃料化学学报, 2015, 43(1): 9-15. |

| Yang Y M, Zhang H, Lyu J F, et al. Experimental study on flash pyrolysis of pulverized coals in Py-GC[J]. Journal of Fuel Chemistry and Technology. 2015, 43(1): 9-15. | |

| 20 | Xu S P, Zeng X, Han Z N, et al. Quick pyrolysis of a massive coal sample via rapid infrared heating[J]. Applied Energy, 2019, 242: 732-740. |

| 21 | Zhao X Y, Feng X B, Cao J P, et al. Organic oxygen transformation during pyrolysis of Baiyinhua lignite[J]. Abstracts of Papers of the American Chemical Society, 2015, 117: 106-115. |

| 22 | 陈兆辉, 高士秋, 许光文. 煤热解过程分析与工艺调控方法[J]. 化工学报, 2017, 68(10): 3693-3707. |

| Chen Z H, Gao S Q, Xu G W. Analysis and control methods of coal pyrolysis process[J]. CIESC Journal, 2017, 68(10): 3693-3707. | |

| 23 | 徐春霞. 煤焦油的性质与加工利用[J]. 洁净煤技术, 2013, 19(5): 63-67. |

| Xu C X. Characteristics and processing utilization of coal tar [J]. Clean Coal Technology, 2013, 19(5): 63-67. | |

| 24 | 平传娟, 周俊虎, 程军, 等. 混煤热解过程中的表面形态[J]. 化工学报, 2007, 58(7): 1798-1804. |

| Ping C J, Zhou J H, Cheng J, et al. Surface structure of blended coals during pyrolysis[J]. Journal of Chemical Industry and Engineering(China), 2007, 58(7): 1798-1804. | |

| 25 | 李昌伦, 王永刚, 林雄超, 等. 内在矿物对高灰褐煤热解焦收率及特性的影响[J]. 煤炭学报, 2017, 42(8): 2157-2163. |

| Li C L, Wang Y G, Lin X C, et al. Impact of inherent minerals on the yield and properties of char from pyrolysis of the lignite with high ash content[J]. Journal of China Coal Society, 2017, 42(8): 2157-2163. | |

| 26 | Zeng D, Hu S T, Sayre A N, et al. On the rank-dependence of coal tar secondary reactions[J]. Proceedings of the Combustion Institute, 2011, 33(2): 1707-1714. |

| 27 | 张盛诚, 何榕. 单颗粒煤粉热解时焦油的二次反应和扩散[J]. 清华大学学报(自然科学版), 2016, 56(6): 605-610. |

| Zhang S C, He R. Secondary reaction and diffusion of tar during single coal particle pyrolysis[J]. J. Tsinghua Univ. (Sci. & Tech.), 2016, 56(6: 605-610. | |

| 28 | 何柯佳, 范浩杰, 刘翔, 等. 二次热解对污泥热解产物影响的研究[J]. 锅炉技术, 2017, 48(1): 75-80. |

| He K J, Fan H J, Liu X, et al. The second reaction of pyrolysis volatiles from sewage sludges in a fixed-bed reactor[J]. Boiler Technology, 2017, 48(1): 75-80. | |

| 29 | Zhang Y Q, Pan D F, Qu X, et al. Secondary catalytic effect of circulating ash on the primary volatiles from slow and fast pyrolysis of coal[J]. Energy & Fuels, 2018, 32(2): 1328-1335. |

| 30 | Chen Z H, Li Y J, Lai D G, et al. Coupling coal pyrolysis with char gasification in a multi-stage fluidized bed to co-produce high-quality tar and syngas[J]. Applied Energy, 2018, 215: 348-355. |

| 31 | Ding L, Zhou Z J, Dai Z H, et al. Effects of coal drying on the pyrolysis and in-situ gasification characteristics of lignite coals[J]. Applied Energy, 2015, 155: 660-670. |

| 32 | Ding L, Wei J T, Dai Z H, et al. Study on rapid pyrolysis and in-situ char gasification characteristics of coal and petroleum coke[J]. International Journal of Hydrogen Energy, 2016, 41(38): 16823-16834. |

| 33 | Zhang Y, Han Z N, Wu H, et al. Interactive matching between the temperature profile and secondary reactions of oil shale pyrolysis[J]. Energy & Fuels, 2016, 30(4): 2865-2873. |

| 34 | 周剑林, 张书, 王永刚, 等. 褐煤碳结构与含氧官能团分析方法研究[J]. 煤炭科学技术, 2012, 40(10): 116-119. |

| Zhou J L, Zhang S, Wang Y G, et al. Study on analysis method of lignite carbon structure and oxygen functional groups[J]. Coal Science and Technology, 2012, 40(10): 116-119. | |

| 35 | Niu Z Y, Liu G J, Yin H, et al. Effect of pyridine extraction on the pyrolysis of a perhydrous coal based on in-situ FTIR analysis[J]. Journal of the Energy Institute, 2019, 92(3): 428-437. |

| [1] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [2] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [3] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [4] | 盛冰纯, 于建国, 林森. 铝基锂吸附剂分离高钠型地下卤水锂资源过程研究[J]. 化工学报, 2023, 74(8): 3375-3385. |

| [5] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [6] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [7] | 朱风, 陈凯琳, 黄小凤, 鲍银珠, 李文斌, 刘嘉鑫, 吴玮强, 高王伟. KOH改性电石渣脱除羰基硫的性能研究[J]. 化工学报, 2023, 74(6): 2668-2679. |

| [8] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [9] | 罗来明, 张劲, 郭志斌, 王海宁, 卢善富, 相艳. 1~5 kW高温聚合物电解质膜燃料电池堆的理论模拟与组装测试[J]. 化工学报, 2023, 74(4): 1724-1734. |

| [10] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [11] | 吴选军, 王超, 曹子健, 蔡卫权. 数据与物理信息混合驱动的固定床吸附穿透深度学习模型[J]. 化工学报, 2023, 74(3): 1145-1160. |

| [12] | 钱志广, 樊越, 王世学, 岳利可, 王金山, 朱禹. 吹扫条件对PEMFC阻抗弛豫现象和低温启动的影响[J]. 化工学报, 2023, 74(3): 1286-1293. |

| [13] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [14] | 张家庆, 蒋榕培, 史伟康, 武博翔, 杨超, 刘朝晖. 煤基/石油基火箭煤油高参数黏温特性与组分特性研究[J]. 化工学报, 2023, 74(2): 653-665. |

| [15] | 张娜, 潘鹤林, 牛波, 张亚运, 龙东辉. 酚醛树脂热裂解反应机理的密度泛函理论研究[J]. 化工学报, 2023, 74(2): 843-860. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号