化工学报 ›› 2019, Vol. 70 ›› Issue (3): 1227-1235.DOI: 10.11949/j.issn.0438-1157.20181072

收稿日期:2018-09-22

修回日期:2018-12-19

出版日期:2019-03-05

发布日期:2019-03-05

通讯作者:

喻健良

作者简介:喻健良(1963—),男,博士,教授,<email>yujianliang@dlut.edu.cn</email>

基金资助:

Jianliang YU( ),Yujie HOU,Xingqing YAN,Wentao JI,Xiaozhe YU,Yibo WANG

),Yujie HOU,Xingqing YAN,Wentao JI,Xiaozhe YU,Yibo WANG

Received:2018-09-22

Revised:2018-12-19

Online:2019-03-05

Published:2019-03-05

Contact:

Jianliang YU

摘要:

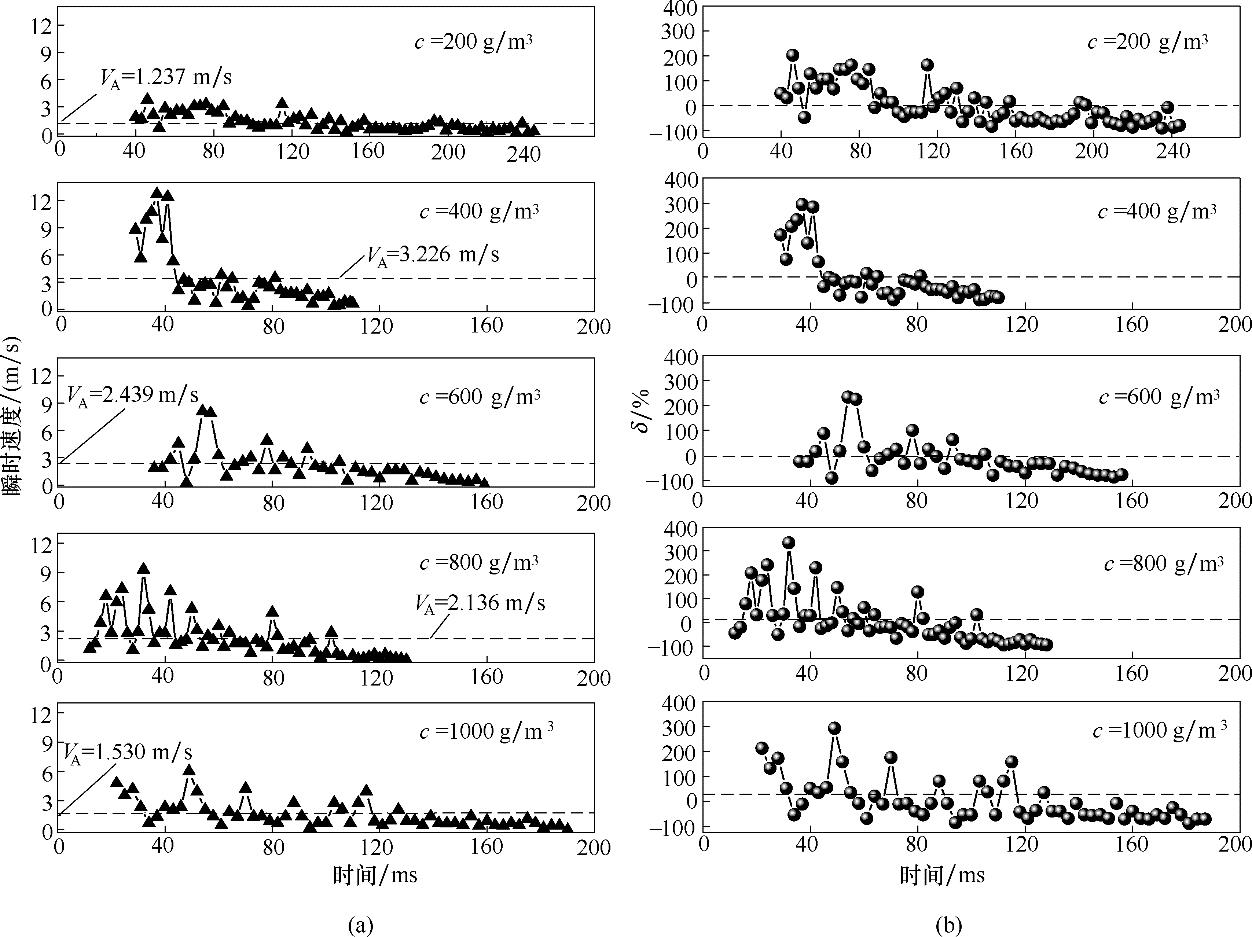

采用竖直、可视粉尘爆炸火焰传播实验平台,结合粒子图像测速PIV技术测得喷粉的冷态流场分布,研究聚乙烯粉尘在密闭容器内的爆炸火焰传播特性,探讨火焰结构与锋面位置的动态变化、火焰传播速度等参数的变化规律。结果表明,在200~1000 g/m3浓度范围内,低浓度聚乙烯粉尘爆炸火焰呈不连续片羽状结构,火焰锋面呈离散的星点状。粉尘浓度增加,火焰连续性及亮度增强,锋面呈齿状,并在400 g/m3火焰最明亮,火焰平均传播速度均随粉尘浓度的增加先增大后减小。采用均方根湍流速度量化体系整体脉动幅度,浓度接近最佳爆炸浓度400 g/m3时,均方根湍流速度为3.21 m/s。

中图分类号:

喻健良, 侯玉洁, 闫兴清, 纪文涛, 于小哲, 王祎博. 密闭空间内聚乙烯粉尘爆炸火焰传播特性的实验研究[J]. 化工学报, 2019, 70(3): 1227-1235.

Jianliang YU, Yujie HOU, Xingqing YAN, Wentao JI, Xiaozhe YU, Yibo WANG. Experimental study on flame propagation characteristic of polyethylene dust explosion under confined chamber[J]. CIESC Journal, 2019, 70(3): 1227-1235.

图12 不同浓度的聚乙烯粉尘爆炸火焰传播瞬时速度(a)及脉动程度(b)随时间的变化

Fig.12 Flame propagation velocities (a) and fluctuant deviation (b) of polyethylene dust explosion along with time at different dust concentrations

| 1 | 刘义, 赵东风, 路帅, 等. 聚乙烯粉体粒径对静电放电点火的影响[J]. 河北大学学报(自然科学版), 2007, 27(6): 625-629. |

| LiuY, ZhaoD F, LuS, et al. Effects of polyethylene size on ignition of electrostatics discharge[J]. Journal of Hebei University (Natural Science Edition), 2007, 27(6): 625-629. | |

| 2 | 由衷. 聚乙烯工厂爆炸原因分析[J]. 化工科技动态, 1991, (3): 34-35. |

| YouZ. Cause analysis of polyethylene plant explosion[J]. Chemical Technology Trends, 1991, (3): 34-35. | |

| 3 | YanX Q, YuJ L. Dust explosion incidents in China[J]. Process Safety Progress, 2012, 31(2): 187-189. |

| 4 | 冯文萍. 高密度聚乙烯生产火灾爆炸危险性分析及评价[D]. 天津: 天津大学, 2005. |

| FengW P. Risk analysis and assessment of fire explosion for high-density polyethylene production[D]. Tianjin: Tianjin University, 2005. | |

| 5 | GaoW, MogiT, SunJ H, et al. Effects of particle size distributions on flame propagation mechanism during octadecanol dust explosions[J]. Powder Technology, 2013, 249: 168-174. |

| 6 | GaoW, DobashiR, MogiT, et al. Effects of particle characteristics on flame propagation behavior during organic dust explosions in a half-closed chamber [J]. Journal of Loss Prevention in the Process Industries, 2012, 25(6): 993-999. |

| 7 | 孙金华. PMMA 微粒子云中传播火焰的基本结构[J]. 热科学与技术, 2004, 3(1): 76-80. |

| SunJ H. Structure of flame propagating through PMMA particle cloud[J]. Journal of Thermal Science and Technology, 2004, 3(1): 76-80. | |

| 8 | ChenJ L, DobashiR, HiranoT. Mechanisms of flame propagation through combustible particle clouds[J]. Journal of Loss Prevention in the Process Industries, 1996, 9(3): 225-229. |

| 9 | YuJ L, ZhangX Y, ZhangQ, et al. Combustion behaviors and flame microstructures of micro- and nano-titanium dust explosions[J]. Fuel, 2016, 181: 785-792. |

| 10 | SunJ H, DobashiR, HiranoT. Structure of flames propagating through aluminum particles cloud and combustion process of particles[J]. Journal of Loss Prevention in the Process Industries, 2006, 19(6): 769-773. |

| 11 | SunJ H, DobashiR, HiranoT. Temperature profile across the combustion zone propagating through an iron particle cloud [J]. Journal of Loss Prevention in the Process Industries, 2001, 14(6): 463-467. |

| 12 | 孙金华, 卢平, 刘义. 空气中悬浮金属微粒子的燃烧特性[J]. 南京理工大学学报, 2005, 29(5): 582-588. |

| SunJ H, LuP, LiuY. Combustion behavior of metal particles suspended in air[J]. Journal of Nanjing University of Science and Technology, 2005, 29(5): 582-588. | |

| 13 | 潘峰, 马超, 曹卫国, 等. 玉米淀粉粉尘爆炸危险性研究[J]. 中国安全科学学报, 2011, 21(7): 46-51. |

| PangF, MaC, CaoW G, et al. Research on explosion risk of corn starch dust[J]. China Safety Science Journal, 2011, 21(7): 46-51. | |

| 14 | 高聪, 李化, 苏丹, 等. 密闭空间煤粉的爆炸特性[J]. 爆炸与冲击, 2010, 30(2): 164-168. |

| GaoC, LiH, SuD, et al. Explosion characteristics of coal dust in a sealed vessel[J]. Explosion and Shock Waves, 2010, 30(2): 164-168. | |

| 15 | 黄丽媛. 石松子粉粉尘爆炸特性研究[D]. 南京: 南京理工大学, 2014. |

| HuangL Y. Research on dust explosion characteristics of lycopodium[D]. Nanjing: Nanjing University of Science and Technology, 2014. | |

| 16 | 尹同山. 乙烯氛围下的聚乙烯热解动力学研究[D]. 青岛: 中国石油大学(华东), 2014. |

| YinT S. Study on pyrolysis kinetics of polyethylene in the ethylene[D]. Qingdao: China University of Petroleum, 2014. | |

| 17 | HanO, LeeJ S. Pyrolysis characteristic and ignition energy of high-density polyethylene powder[J]. Journal of the Korean Institute of Gas, 2014, 18(3): 31-37. |

| 18 | MittalM, GuhaB K. Minimum ignition temperature of polyethylene dust: a theoretical model[J]. Fire & Materials, 2015, 21(4): 169-177. |

| 19 | 马小明, 周可. 不饱和聚酯树脂钮扣粉尘静电爆炸敏感性研究[J]. 中国安全生产科学技术, 2016, 12(3): 149-154. |

| MaX M, ZhouK. Study on sensitivity of electrostatic explosion for dust of unsaturated polyester resin button[J]. Journal of Safety Science and Technology, 2016, 12(3): 149-154. | |

| 20 | BenedettoA D, RussoP. Thermo-kinetic modelling of dust explosions[J]. Journal of Loss Prevention in the Process Industries, 2007, 20(4/5/6): 303-309. |

| 21 | GanB, GaoW, JiangH, et al. Flame propagation behaviors and temperature characteristics in polyethylene dust explosions[J]. Powder Technology, 2018, 328: 345-357. |

| 22 | GanB, LiB, JiangH, et al. Ethylene/polyethylene hybrid explosions(Ι): Effects of ethylene concentrations on flame propagations[J]. Journal of Loss Prevention in the Process Industries, 2018, 54: 93-102. |

| 23 | TraoréM, DufaudO, PerrinL, et al. Dust explosions: how should the influence of humidity be taken into account[J]. Process Safety and Environment Protection, 2009, 87(1): 14-20. |

| 24 | 罗宏昌. 粉尘爆炸及“杂混合物”对其特性的影响[J]. 交通部上海船舶运输科学研究所学报, 2000, 23(1): 21-26. |

| LuoH C .Explosion of powder dust and effect of scramble compound on its characteristics[J]. Journal of Shanghai Ship and Shipping Research Institute, 2000, 23(1): 21-26. | |

| 25 | 葛毅钧. 聚乙烯装置料仓闪爆原因分析及预防措施[J]. 安全、健康和环境, 2017, 17(1): 5-8. |

| GeY J. Cause analysis and preventive measures of flash explosion in silo of polyethylene units[J]. Safety Environment Health, 2017, 17(1): 5-8. | |

| 26 | 马冉, 高建村, 杨凯, 等. 聚乙烯粉尘爆炸研究进展[J]. 中国粉体技术, 2017, 23(6): 59-63. |

| MaR, GaoJ C, YangK, et al. Progress research on polyethylene dust explosion[J]. China Powder Science and Technology, 2017, 23(6): 59-63. | |

| 27 | 喻健良, 纪文涛, 孙会利, 等. 乙烯/聚乙烯两相体系爆炸特性[J]. 化工学报, 2017, 68(12): 4841-4847. |

| YuJ L, JiW T, SunH L, et al. Explosibility of hybrid mixtures of ethylene and polyethylene dust[J]. CIESC Journal, 2017, 68(12): 4841-4847. | |

| 28 | 곽민철, 김기홍, 여재익. The change of deflagration to detonation transition by wall cooling effect in ethylene-air mixture[C]//한국추진공학회 2011년도 제회 춘계학술대회 논문집,2011. |

| 29 | JiW T, YanX Q, SunH L, et al. Explosibility of hybrid mixtures of lycopodium dust and methane [C]//11th International Symposium on Hazards, Prevention, and Mitigation of Industrial Explosions. Dalian, 2016. |

| 30 | 李新光, RadandtS, 赫冀成, 等. 哈特曼装置上均方根湍流速度的测量及研究[J]. 中国粉体技术, 1999, 5(4): 11-14. |

| LiX G, RadandtS, HeJ C, et al. Measurement and research of root-mean-square turbulence velocity on Hartmann bomb[J]. China Power Science and Science and Technology, 1999, 5(4): 11-14. |

| [1] | 杨克, 贾岳, 纪虹, 邢志祥, 蒋军成. 垃圾焚烧飞灰对瓦斯爆炸压力及火焰传播的抑制作用及机理研究[J]. 化工学报, 2023, 74(8): 3597-3607. |

| [2] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [3] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [4] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [5] | 何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247. |

| [6] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [7] | 朱兵国, 何吉祥, 徐进良, 彭斌. 冷却条件下渐扩/渐缩管内超临界压力二氧化碳的传热特性[J]. 化工学报, 2023, 74(3): 1062-1072. |

| [8] | 张伟政, 赵吉军, 马学忠, 张琦璇, 庞益祥, 张俊涛. 湍流效应对高速机械密封端面型槽冷却性能影响分析[J]. 化工学报, 2023, 74(3): 1228-1238. |

| [9] | 武子超, 汪志雷, 李荣业, 李可昕, 华敏, 潘旭海, 王三明, 蒋军成. 点火方式对欠膨胀氢气射流爆炸超压影响规律研究[J]. 化工学报, 2023, 74(3): 1409-1418. |

| [10] | 杨克, 王辰升, 纪虹, 郑凯, 邢志祥, 毕海普, 蒋军成. 聚多巴胺包覆混合粉体抑制甲烷爆炸的实验研究[J]. 化工学报, 2022, 73(9): 4245-4254. |

| [11] | 王燕, 何佳, 杨晶晶, 林晨迪, 纪文涛. 草酸盐和碳酸氢盐抑制聚乙烯粉尘爆炸特性[J]. 化工学报, 2022, 73(9): 4207-4216. |

| [12] | 王永倩, 王平, 程康, 毛晨林, 刘文锋, 尹智成, Ferrante Antonio. 氨气/甲烷贫预混旋转湍流火焰稳定性及NO生成[J]. 化工学报, 2022, 73(9): 4087-4094. |

| [13] | 张建伟, 高伟峰, 董鑫, 冯颖. 浸没式撞击流反应器流场涡特性的数值研究[J]. 化工学报, 2022, 73(8): 3553-3564. |

| [14] | 王利民, 郭舒宇, 向星, 付少童. 湍流系统的能量最小多尺度模型研究进展[J]. 化工学报, 2022, 73(6): 2415-2426. |

| [15] | 施炜斌, 龙姗姗, 杨晓钢, 蔡心悦. 计及气泡诱导与剪切湍流的气泡破碎、湍流相间扩散及传质模型[J]. 化工学报, 2022, 73(6): 2573-2588. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号