化工学报 ›› 2019, Vol. 70 ›› Issue (12): 4777-4786.DOI: 10.11949/0438-1157.20190901

收稿日期:2019-08-06

修回日期:2019-09-05

出版日期:2019-12-05

发布日期:2019-12-05

通讯作者:

孟涛

作者简介:王伟浩(1993—),男,硕士研究生,基金资助:

Weihao WANG( ),Xin YANG,Fei LI,Mengmeng SUN,Yaolei WANG,Tao MENG(

),Xin YANG,Fei LI,Mengmeng SUN,Yaolei WANG,Tao MENG( )

)

Received:2019-08-06

Revised:2019-09-05

Online:2019-12-05

Published:2019-12-05

Contact:

Tao MENG

摘要:

以疏水改性二氧化钛修饰的载酶海藻酸钙微球(E@Alg@s-TiO2微球)稳定水包油(O/W)型Pickering乳液用于两相界面酶催化反应。与传统的两相游离酶体系相比,此体系以绿色、温和的方式将酶固定在乳液界面上,并强化了两相界面酶催化反应。研究成果归纳如下:油水比为1∶1.2时,Pickering乳液为O/W型;E@Alg@s-TiO2微球浓度为3%(质量)时稳定效果最好,脂肪酶的负载量为15.8 mg·g-1。以三丁酸甘油酯的水解反应为研究对象,该体系对油水体系的界面酶催化反应有很好的强化效果,具有96%转化率并提高酶活力7.8倍。重复使用5个批次能保留80%的酶活力。本研究进一步拓展了载酶海藻酸盐微球稳定的Pickering乳液体系的应用范围,有望为O/W体系的界面生物催化过程提供绿色平台。

中图分类号:

王伟浩, 杨鑫, 李飞, 孙梦梦, 王垚磊, 孟涛. 载酶海藻酸钙复合微球稳定水包油型Pickering乳液及其强化界面酶催化反应[J]. 化工学报, 2019, 70(12): 4777-4786.

Weihao WANG, Xin YANG, Fei LI, Mengmeng SUN, Yaolei WANG, Tao MENG. E@Alg@s-TiO2 microsphere stabilized O/W Pickering emulsion and the enhancement of interfacial enzymatic catalysis[J]. CIESC Journal, 2019, 70(12): 4777-4786.

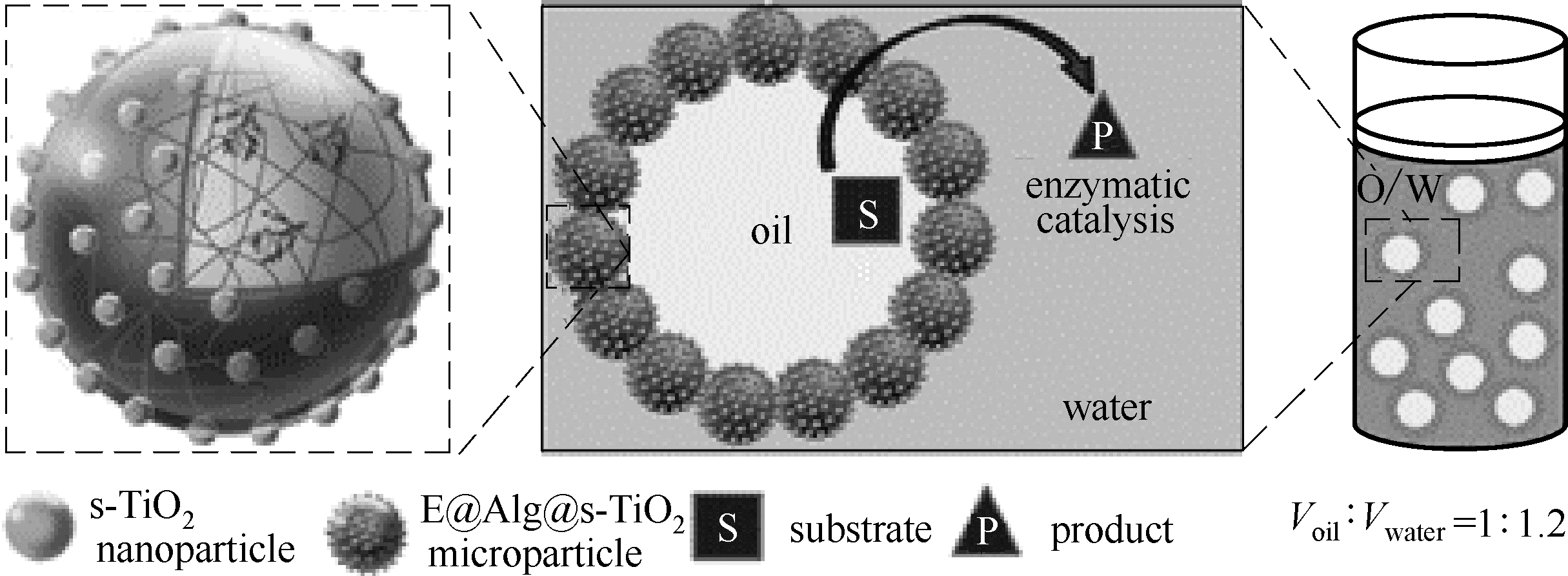

图1 E@Alg@s-TiO2微球稳定O/W型Pickering乳液体系及界面酶催化的机理

Fig.1 Mechanism of O/W Pickering emulsion stabilized by E@Alg@s-TiO2 microsphere and interfacial enzyme catalysis

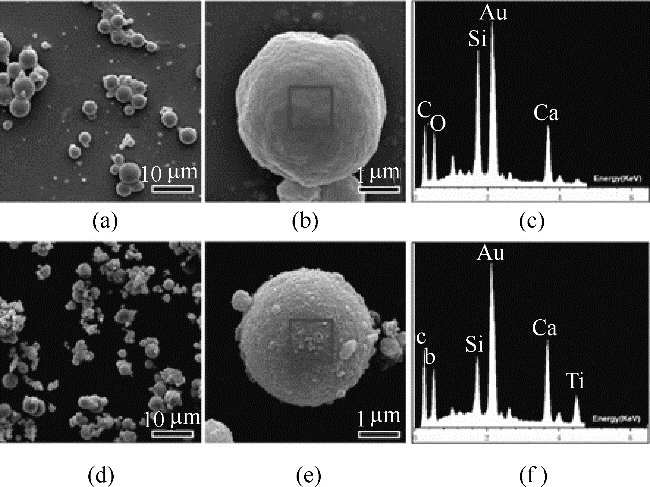

图2 E@Alg[(a)~(c)]和E@Alg@C6-TiO2微球[(d)~(f)]的SEM照片及EDS元素分析

Fig.2 SEM photographs and EDS elemental analysis of E@Alg[(a)—(c)] and E@Alg@C6-TiO2 microspheres[(d)—(f)]

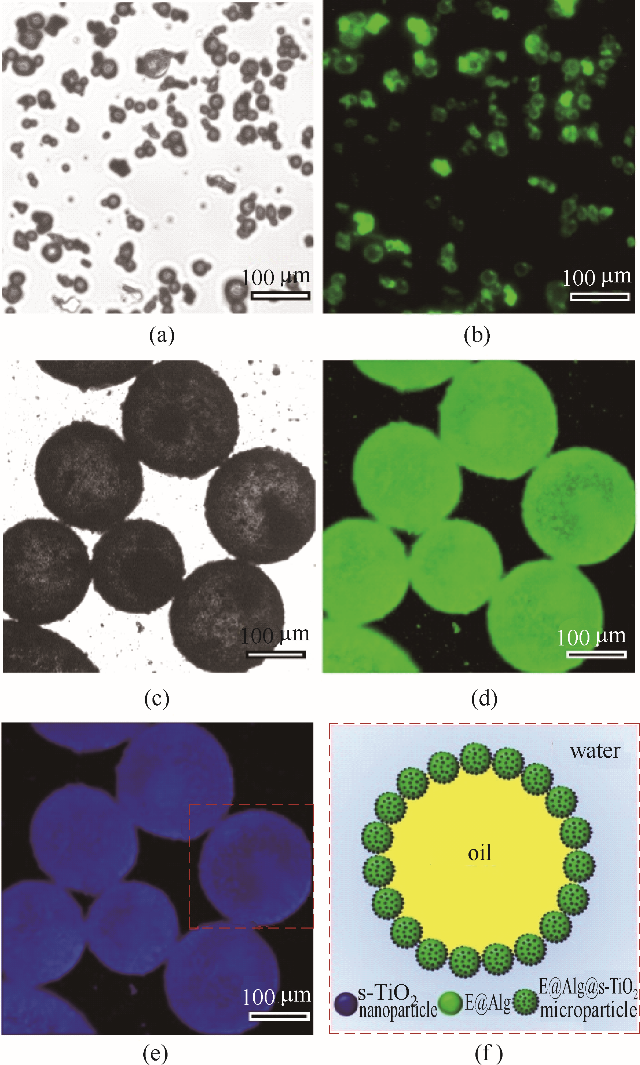

图3 E@Alg@C6-TiO2微球光学显微镜照片(a)和荧光显微镜照片(b),E@Alg@C6-TiO2微球(2%(质量))稳定的水中液体石蜡的Pickering乳液光学显微镜照片(c),(c)在不同波长下的荧光显微镜照片,绿色荧光是由FITC激发(d),蓝色荧光是由C6-TiO2激发(e),E@Alg@C6-TiO2微球稳定的Pickering乳液产生的荧光机理示意图(f)(油水比1∶1.2,乳液制备1 h后观察)

Fig.3 Photomicrographs of E@Alg@C6-TiO2 microspheres (a) and fluorescence micrographs (b), optical microscopy of paraffin-in-water Pickering emulsion stabilized by E@Alg@C6-TiO2 microspheres (2%(mass)) (c), fluorescence micrographs at different wavelengths, green fluorescence is excited by FITC (d), blue fluorescence is excited by C6-TiO2 (e), and schematic diagram of Pickering emulsion stabilized by E@Alg@C6-TiO2 microspheres (f)(oil-water ratio 1∶1.2, observed after 1 h of emulsion preparation)

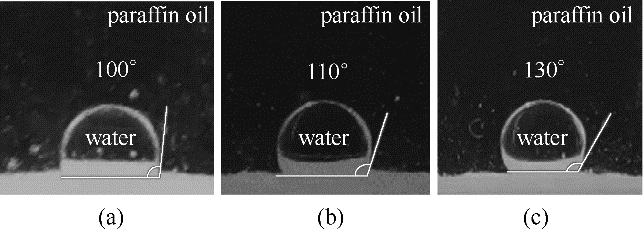

图4 液体石蜡-水体系中E@Alg@C6-TiO2(a),E@Alg@C8-TiO2(b)和E@Alg@C10-TiO2(c)的三相接触角

Fig.4 Three-phase contact angle of E@Alg@C6-TiO2(a), E@Alg@C8-TiO2(b) and E@Alg@C10-TiO2(c) in paraffin oil-water system

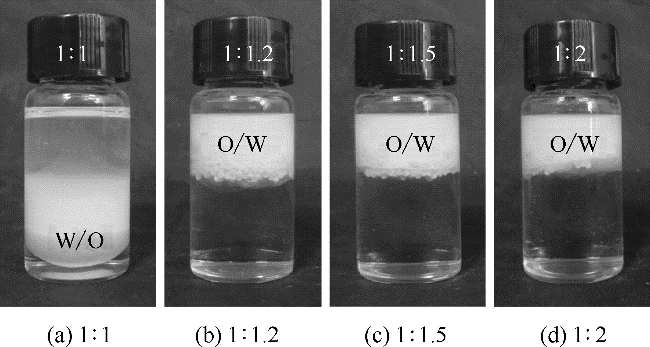

图5 E@Alg@C6-TiO2微球在不同油水比下对液体石蜡/水Pickering乳液稳定情况(微球浓度3%(质量),乳液制备1 h后观察)

Fig.5 E@Alg@C6-TiO2 microspheres stabilized paraffin oil-water Pickering emulsion with different oil-water ratios(concentration of microspheres is 3%(mass), and emulsion is observed after 1 h)

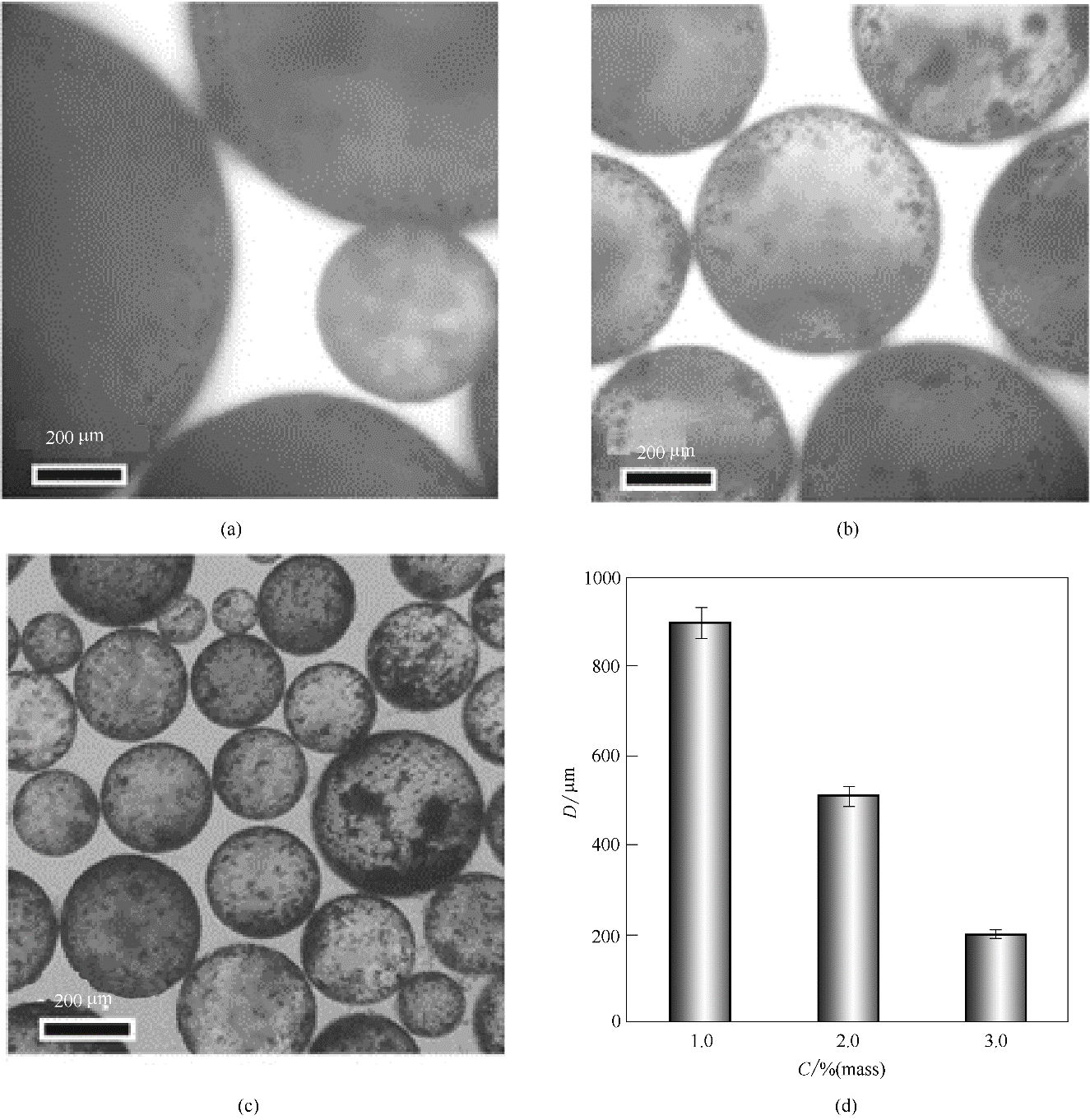

图6 E@Alg@6C-TiO2浓度为1%(质量)(a),2%(质量)(b),3%(质量)(c)时的液体石蜡/水Pickering乳液的液滴光学显微镜照片及其对应的液滴粒径分布(d)(油水比1∶1.2,乳液制备1 h后观察)

Fig.6 Droplet optical micrograph of paraffin oil/water Pickering emulsion with E@Alg@6C-TiO2 concentration of 1%(mass) (a), 2%(mass) (b), 3%(mass) (c) and its corresponding droplets diameter distribution (d)(oil-water ratio 1∶1.2, observed after 1 h preparation of emulsion)

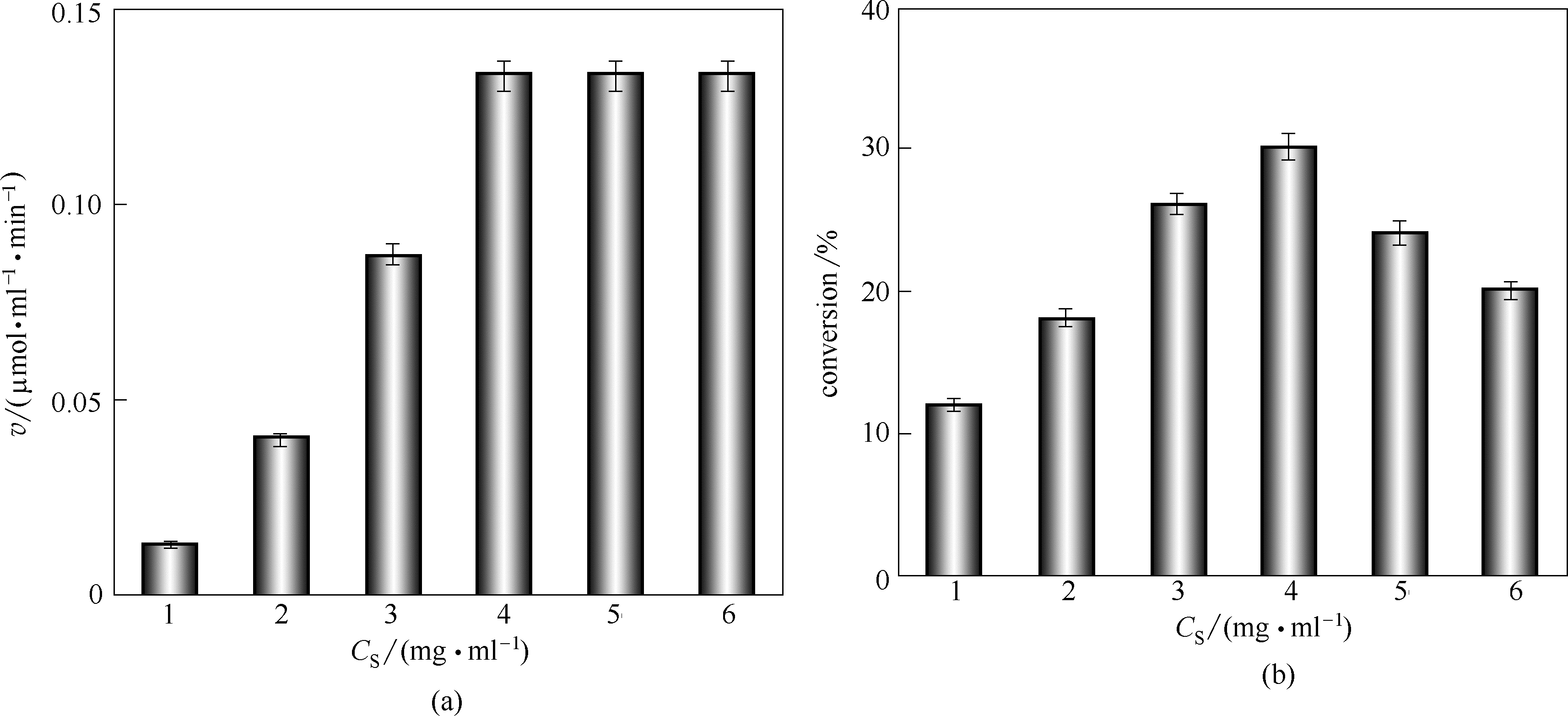

图7 不同底物浓度对反应速率(a)和转化率(b)的影响(所有测量重复3次)

Fig.7 Effect of different substrate concentrations on v (a) and conversion (b)(all measurements were repeated 3 times)

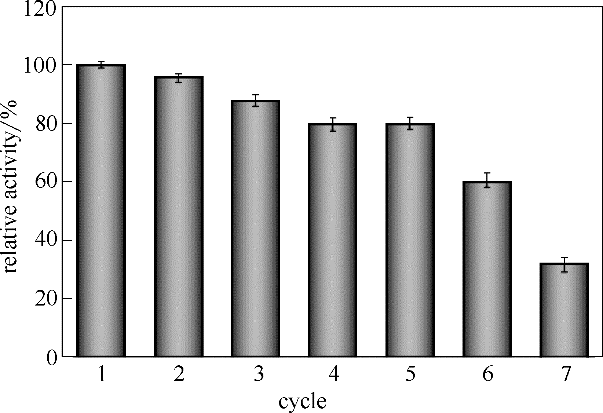

图9 E@Alg@s-TiO2微球稳定的O/W型Pickering乳液在7次反应循环里脂肪酶的相对酶活力比较(每次10 h)

Fig.9 Comparison of relative enzyme activities of lipase in E@Alg@s-TiO2 microsphere-stabilized O/W Pickering emulsion in 7 reaction cycles (10 h per cycle)

| 1 | Klibanov A M. Improving enzymes by using them in organic solvents[J]. Nature, 2001, 409(6817): 241-246. |

| 2 | Schmid A, Dordick J S, Hauer B, et al. Industrial biocatalysis today and tomorrow[J]. Nature, 2001, 409: 258-268. |

| 3 | 戈钧, 卢滇楠, 刘铮, 等. 纳米酶催化剂制备方法研究进展[J]. 化工学报, 2014, 65(7): 2668-2675. |

| Ge J, Lu D N, Liu Z, et al. Advances in preparation of nanostructured enzyme catalysts[J]. CIESC Journal, 2014, 65(7): 2668-2675. | |

| 4 | Klibanov A M. Why are enzymes less active in organic solvents than in water[J]. Trends Biotechnol., 1997, 15: 97-101. |

| 5 | 孙建华, 戴荣继, 邓玉林. 酶固定化技术研究进展[J]. 化工进展, 2010, 29(4): 715-721. |

| Sun J H, Dai R J, Deng Y L. Progress in enzyme immobilization technique[J]. Chemical Industry and Engineering Progress, 2010, 29(4): 715-721. | |

| 6 | Pickerig S U. Emulsions[J]. J. Chem. Soc., Trans., 1907, 91: 2001-2021. |

| 7 | Wang Z P, van Oers M C M, Rutjes F P J T, et al. Polymersome colloidosomes for enzyme catalysis in a biphasic system[J]. Angewandte Chemie-International Edition, 2012, 51(43): 10746-10750. |

| 8 | Wu C Z, Bai S, Ansorge-Schumacher M B, et al. Nanoparticle cages for enzyme catalysis in organic media[J]. Advanced Materials, 2011, 23(47): 5694-5699. |

| 9 | Yang X, Wang Y L, Meng T, et al. Pickering emulsion-enhanced interfacial biocatalysis: tailored alginate microparticles act as particulate emulsifier and enzyme carrier[J]. Green Chemistry, 2019, 21: 2229-2233. |

| 10 | Aschenbrenner E M, Weiss C K, Landfester K. Enzymatic esterification in aqueous miniemulsions[J]. Chemistry-A European Journal, 2009, 15(10): 2434-2444. |

| 11 | Malberg S, Finne-Wistrand A, Albertsson A C. The environmental influence in enzymatic polymerization of aliphatic polyesters in bulk and aqueous mini-emulsion[J]. Polymer, 2010, 51(23): 5318-5322. |

| 12 | de Lima A P D, Aschenbrenner E M, Oliveira S D, et al. Towards regioselective enzymatic hydrolysis and glycerolysis of tricaprylin in miniemulsion and the direct preparation of polyurethane from the hydrolysis products[J]. Journal of Molecular Catalysis B-Enzymatic, 2013, 98: 127-137. |

| 13 | Liu L, Jiang L L, Yang S, et al. Amphiphilic carbonaceous microsphere-stabilized oil-in-water Pickering emulsions and their applications in enzyme catalysis[J]. ChemPlusChem, 2016, 81(7): 629-636. |

| 14 | Shi J F, Wang X L, Jiang Z Y, et al. Enzyme-conjugated ZIF-8 particles as efficient and stable Pickering interfacial biocatalysts for biphasic biocatalysis[J]. Journal of Materials Chemistry B, 2016, 4(15): 2654-2661. |

| 15 | Gao J, Li D, Jiang Y J, et al. Pickering emulsion stabilized by immobilized bienzyme nanoparticles: a novel and robust system for enzymatic purification of isomaltooligosaccharide[J]. Industrial & Engineering Chemistry Research, 2014, 53(47): 18163-18169. |

| 16 | Sun Z Y, Glebe U, Wu C Z, et al. Enzyme-polymer conjugates as robust Pickering interfacial biocatalysts for efficient biotrans for mations and one-pot cascade reactions[J]. Angewandte Chemie-International Edition, 2018, 57(42): 13810-13814. |

| 17 | Villeneuve P, Muderhwa J M, Graille J, et al. Customizing lipases for biocatalysis: a survey of chemical, physical and molecular biological approaches[J]. Journal of Molecular Catalysis B: Enzymatic, 2000, 9(4/5/6): 113-148. |

| 18 | Feng X D, Patterson D A, Emanuelsson E A C, et al. Characterization of tributyrin hydrolysis by immobilized lipase on woolen cloth using conventional batch and novel spinning cloth disc reactors[J]. Chemical Engineering Research & Design, 2013, 9(9): 1684-1692. |

| 19 | 何帆, 谢锐, 褚良银, 等. 超薄壁结构海藻酸钙胶囊膜制备及其功能化研究新进展[J]. 化工学报, 2015, 66(8): 2817-2823. |

| He F, Xie R, Chu L Y, et al. Recent progress in fabrication and functionalization of Ca-alginate capsules with ultrathin membranes[J]. CIESC Journal, 2015, 66(8): 2817-2823. | |

| 20 | Lee K Y, Mooney D J. Alginate: properties and biomedical applications[J]. Prog. Polym. Sci., 2012, 37: 106-126. |

| 21 | Gombotz W R, Wee S F. Protein release from alginate matrices[J]. Advanced Drug Delivery Reviews, 1998, 31(3): 267-285. |

| 22 | Kierstan M, Bucke C. The immobilization of microbial cells, subcellular organelles, and enzymes in calcium alginate gels[J]. Biotechnology and Bioengineering, 1977, 19: 387-397. |

| 23 | Nan F F, Wu J, Ma G H, et al. Uniform chitosan-coated alginate particles as emulsifiers for preparation of stable Pickering emulsions with stimulus dependence[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2014, 456: 246-252. |

| 24 | Zhang W J, Sun X, He G H, et al. Pickering emulsions stabilized by hydrophobically modified alginate nanoparticles: preparation and pH-responsive performance in vitro[J]. Journal of Dispersion Science and Technology, 2018, 39(3): 367-374. |

| 25 | Zhang X J, Yin W J, He G H, et al. Microencapsulation of astaxanthin in alginate using modified emulsion technology: preparation, characterization, and cytostatic activity[J]. Canadian Journal of Chemical Engineering, 2017, 95(3): 412-419. |

| 26 | Xie C Y, Meng S X, Meng T, et al. Light and magnetic dual-responsive Pickering emulsion micro reactors[J]. Langmuir, 2017, 33(49): 14139-14148. |

| 27 | 张方, 史铁钧, 周讯, 等. 二氧化钛纳米管稳定Pickering乳液制备PS/TiO2纳米管复合微球[J]. 化工学报, 2014, 65(3): 1526-1530. |

| Zhang F, Shi T J, Zhou X, et al. Polystyrene /TiO2 nanotubes composite microspheres fabricated via Pickering emulsion polymerization stabilized by TiO2 nanotubes [J]. CIESC Journal, 2014, 65(3): 1526-1530. | |

| 28 | Arditty S, Whitby C P, Binks B P, et al. Some general features of limited coalescence in solid-stabilized emulsions[J]. European Physical Journal E, 2003, 11(3): 273-281. |

| 29 | Jiang Y J, Liu X L, Gao J, et al. Pickering emulsion stabilized by lipase-containing periodic mesoporous organosilica particles: a robust biocatalyst system for biodiesel production[J]. Bioresource Technology, 2014, 153: 278-283. |

| 30 | 杨基础, 董燊, 杨小民. 海藻糖对固定化酶的保护作用[J]. 化工学报, 2000, 51(2): 193-197. |

| Yang J C, Dong S, Yang X M. Protective effect of trehalose on immobilized enzyme[J]. Journal of Chemical Industry and Engineering(China), 2000, 51(2): 193-197. | |

| 31 | 辛嘉英, 李树本, 徐毅, 等. 脂肪酶的固定化及其在有机酶促反应中稳定性研究[J]. 分子催化, 1999, 13(2): 103-108. |

| Xin J Y, Li S B, Xu Y, et al. Studies on the immobilization and stability of lipase in organic media [J]. Journal of Molecular Catalysis, 1999, 13(2): 103-108. | |

| 32 | Liu J, Lan G J, Li C, et al. Enzyme confined in silica-based nanocages for biocatalysis in a Pickering emulsion[J]. Chemical Communications, 2013, 49(83): 9558-9560. |

| 33 | Leroux G, Wang L, Su B L, et al. Hybrid alginate@TiO2 porous microcapsules as a reservoir of animal cells for cell therapy[J]. ACS Applied Materials & Interfaces, 2018, 10: 37865-37877. |

| [1] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [2] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [3] | 陈雅鑫, 袁航, 刘冠章, 毛磊, 杨纯, 张瑞芳, 张光亚. 蛋白质纳米笼介导的酶自固定化研究进展[J]. 化工学报, 2023, 74(7): 2773-2782. |

| [4] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [5] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [6] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [7] | 张兰河, 赖青燚, 王铁铮, 关潇卓, 张明爽, 程欣, 徐小惠, 贾艳萍. H2O2对SBR脱氮效率和污泥性能的影响[J]. 化工学报, 2023, 74(5): 2186-2196. |

| [8] | 刘倩, 曹禹, 周琦, 穆景山, 历伟. 孔道结构修饰的Ziegler-Natta催化剂设计与高抗冲低缠结UHMWPE的制备[J]. 化工学报, 2023, 74(3): 1092-1101. |

| [9] | 贾露凡, 王艺颖, 董钰漫, 李沁园, 谢鑫, 苑昊, 孟涛. 微流控双水相贴壁液滴流动强化酶促反应研究[J]. 化工学报, 2023, 74(3): 1239-1246. |

| [10] | 刘瑞琪, 周栖桐, 张悦, 贺莹, 高静, 马丽. 基于金纳米颗粒修饰二氧化硅纳米花的生物传感器构建及应用[J]. 化工学报, 2023, 74(3): 1247-1259. |

| [11] | 陈号, 田仪娟, 全学军, 蒋子文, 李纲. 铬铁矿在HCl-HF体系中的分解行为[J]. 化工学报, 2023, 74(3): 1161-1174. |

| [12] | 苏伟怡, 丁佳慧, 李春利, 王洪海, 姜艳军. 酶促反应结晶研究进展[J]. 化工学报, 2023, 74(2): 617-629. |

| [13] | 刘昕, 戈钧, 李春. 光驱动微生物杂合系统提高生物制造水平[J]. 化工学报, 2023, 74(1): 330-341. |

| [14] | 谭卓涛, 齐思雨, 许梦蛟, 戴杰, 朱晨杰, 应汉杰. 辅酶自循环的氧化还原级联体系在生物催化过程中的应用:机遇与挑战[J]. 化工学报, 2023, 74(1): 45-59. |

| [15] | 胡阳, 孙彦. 酶分子的自驱动及其介导的微纳马达[J]. 化工学报, 2023, 74(1): 116-132. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号