化工学报 ›› 2020, Vol. 71 ›› Issue (1): 265-273.DOI: 10.11949/0438-1157.20191214

收稿日期:2019-10-23

修回日期:2019-10-31

出版日期:2020-01-05

发布日期:2020-01-05

通讯作者:

骆广生

作者简介:陈宇超(1994—),男,博士研究生,基金资助:

Yuchao CHEN( ),Yongjin CUI,Kai WANG,Guangsheng LUO(

),Yongjin CUI,Kai WANG,Guangsheng LUO( )

)

Received:2019-10-23

Revised:2019-10-31

Online:2020-01-05

Published:2020-01-05

Contact:

Guangsheng LUO

摘要:

采用高速摄像仪对嵌入毛细管的阶梯式T型微通道内液滴和气泡的分散规律进行研究。考察了两相流量、黏度、表面活性剂浓度等因素对分散流型及分散尺寸的影响规律。结果表明,对于液滴分散过程,表面活性剂的浓度和连续相流量决定了分散流型,随二者增大,流型从dripping流向jetting流转变。对于气泡分散过程,实验范围内仅存在squeezing、dripping流型,表面活性剂的加入对气泡分散过程影响可忽略。嵌入毛细管的阶梯式T型微通道内获得的液滴、气泡直径小于微通道直径,根据实验结果基于两相流量和毛细管数分别建立了计算液滴、气泡分散尺寸的半经验模型,模型与实验结果符合良好。

中图分类号:

陈宇超, 崔永晋, 王凯, 骆广生. 阶梯式T型微通道内液滴、气泡分散规律[J]. 化工学报, 2020, 71(1): 265-273.

Yuchao CHEN, Yongjin CUI, Kai WANG, Guangsheng LUO. Droplet and bubble dispersion in step T-junction microchannel[J]. CIESC Journal, 2020, 71(1): 265-273.

| 丙三醇质量分数/%(mass) | 表面活性剂浓度/%(mass) | 黏度/(mPa·s) | 界面张力/ (mN/m) |

|---|---|---|---|

| 50 | 0.01 | 6.92 | 17.7 |

| 50 | 0.05 | 6.92 | 11.1 |

| 50 | 0.1 | 6.92 | 8.15 |

| 50 | 0.2 | 6.92 | 6.1 |

| 50 | 0.5 | 6.92 | 4.95 |

| 50 | 1 | 6.92 | 4.4 |

表1 液滴分散体系的黏度及界面张力

Table 1 Viscosity and interfacial tension of liquid-liquid systems

| 丙三醇质量分数/%(mass) | 表面活性剂浓度/%(mass) | 黏度/(mPa·s) | 界面张力/ (mN/m) |

|---|---|---|---|

| 50 | 0.01 | 6.92 | 17.7 |

| 50 | 0.05 | 6.92 | 11.1 |

| 50 | 0.1 | 6.92 | 8.15 |

| 50 | 0.2 | 6.92 | 6.1 |

| 50 | 0.5 | 6.92 | 4.95 |

| 50 | 1 | 6.92 | 4.4 |

| 二甘醇质量分数/%(mass) | 表面活性剂浓度/%(mass) | 黏度/(mPa·s) | 界面张力/ (mN/m) |

|---|---|---|---|

| 20 | — | 2.20 | 62.23 |

| 30 | — | 2.80 | 60.81 |

| 40 | — | 3.82 | 58.26 |

| 50 | — | 5.24 | 55.91 |

| 60 | — | 7.44 | 53.33 |

| 60 | 0.5 | 7.44 | 31.15 |

| 60 | 0.5 | 7.44 | 33.26 |

表2 气泡分散体系的黏度及界面张力

Table 2 Viscosity and interfacial tension of gas-liquid systems

| 二甘醇质量分数/%(mass) | 表面活性剂浓度/%(mass) | 黏度/(mPa·s) | 界面张力/ (mN/m) |

|---|---|---|---|

| 20 | — | 2.20 | 62.23 |

| 30 | — | 2.80 | 60.81 |

| 40 | — | 3.82 | 58.26 |

| 50 | — | 5.24 | 55.91 |

| 60 | — | 7.44 | 53.33 |

| 60 | 0.5 | 7.44 | 31.15 |

| 60 | 0.5 | 7.44 | 33.26 |

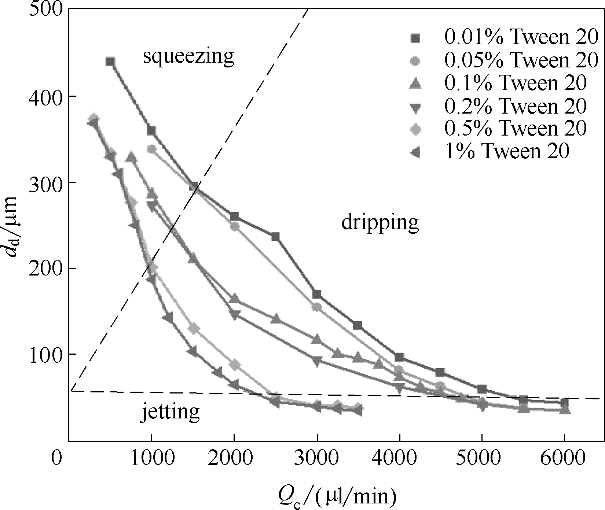

图3 液滴直径随连续相流量和表面活性剂浓度的变化趋势(分散相流量Q d=5 μl/min)

Fig.3 Variation of droplet size with continuous phase flow rate and surfactant concentration (Q d=5 μl/min)

| 参数 | 液滴分散 | 气泡分散 |

|---|---|---|

| 主通道尺寸 | 750 μm × 750 μm | 365 μm × 365 μm |

| 最小分散尺寸 | 20 μm | 60 μm |

| 稳定条件下最大相比(连续/分散) | 1000 | 30 |

| 流型 | Squeezing, dripping, jetting | Squeezing, dripping |

| 表面活性剂影响 | 影响流型及液滴尺寸 | 几乎无影响 |

| 分散尺寸数学模型 | (jetting) | (squeezing, dripping) |

表3 阶梯式T型微通道中液滴、气泡分散规律对比

Table 3 Comparison of droplet and bubble preparation in step T-junction microchannels

| 参数 | 液滴分散 | 气泡分散 |

|---|---|---|

| 主通道尺寸 | 750 μm × 750 μm | 365 μm × 365 μm |

| 最小分散尺寸 | 20 μm | 60 μm |

| 稳定条件下最大相比(连续/分散) | 1000 | 30 |

| 流型 | Squeezing, dripping, jetting | Squeezing, dripping |

| 表面活性剂影响 | 影响流型及液滴尺寸 | 几乎无影响 |

| 分散尺寸数学模型 | (jetting) | (squeezing, dripping) |

| 1 | Calabrese G S , Pissavini S . From batch to continuous flow processing in chemicals manufacturing[J]. AIChE Journal, 2011, 57(4): 828-834. |

| 2 | Kashid M N , Kiwi-Minsker L . Microstructured reactors for multiphase reactions: state of the art[J]. Industrial & Engineering Chemistry Research, 2009, 48(14): 6465-6485. |

| 3 | Hartman R L , Jensen K F . Microchemical systems for continuous-flow synthesis[J]. Lab Chip, 2009, 9(17): 2495-507. |

| 4 | Tostado C P , Xu J , Luo G . The effects of hydrophilic surfactant concentration and flow ratio on dynamic wetting in a T-junction microfluidic device[J]. Chemical Engineering Journal, 2011, 171(3): 1340-1347. |

| 5 | Utada A S , Fernandez-Nieves A , Stone H A , et al . Dripping to jetting transitions in coflowing liquid streams[J]. Phys. Rev. Lett., 2007, 99(9): 094502. |

| 6 | Xu J H , Li S W , Tan J , et al . Preparation of highly monodisperse droplet in a T-junction microfluidic device[J]. AIChE Journal, 2006, 52(9): 3005-3010. |

| 7 | Guillot P , Colin A , Utada A S , et al . Stability of a jet in confined pressure-driven biphasic flows at low Reynolds numbers[J]. Phys. Rev. Lett., 2007, 99(10): 104502. |

| 8 | Anna S L , Bontoux N , Stone H A . Formation of dispersions using “flow focusing” in microchannels[J]. Applied Physics Letters, 2003, 82(3): 364-366. |

| 9 | Xu J H , Li S W , Chen G G , et al . Formation of monodisperse microbubbles in a microfluidic device[J]. AIChE Journal, 2006, 52(6): 2254-2259. |

| 10 | Cramer C , Fischer P , Windhab E J . Drop formation in a co-flowing ambient fluid[J]. Chemical Engineering Science, 2004, 59(15): 3045-3058. |

| 11 | Xiong R , Chung J N . Bubble generation and transport in a microfluidic device with high aspect ratio[J]. Experimental Thermal and Fluid Science, 2009, 33(8): 1156-1162. |

| 12 | Ganan-Calvo A M , Gordillo J M . Perfectly monodisperse microbubbling by capillary flow focusing[J]. Phys. Rev. Lett., 2001, 87(27 Pt 1): 274501. |

| 13 | De Menech M , Garstecki P , Jousse F , et al . Transition from squeezing to dripping in a microfluidic T-shaped junction[J]. Journal of Fluid Mechanics, 2008, 595: 141-161. |

| 14 | Fu T , Ma Y . Bubble formation and breakup dynamics in microfluidic devices: a review[J]. Chemical Engineering Science, 2015, 135: 343-372. |

| 15 | Salman W , Gavriilidis A , Angeli P . On the formation of Taylor bubbles in small tubes[J]. Chemical Engineering Science, 2006, 61(20): 6653-6666. |

| 16 | Tan J , Li S W , Wang K , et al . Gas-liquid flow in T-junction microfluidic devices with a new perpendicular rupturing flow route[J]. Chemical Engineering Journal, 2009, 146(3): 428-433. |

| 17 | Vansteene A , Jasmin J P , Cavadias S , et al . Towards chip prototyping: a model for droplet formation at both T and X-junctions in dripping regime[J]. Microfluidics and Nanofluidics, 2018, 22(6): 61. |

| 18 | Yoon D H , Tanaka D , Sekiguchi T , et al . Structural formation of oil-in-water (O/W) and water-in-oil-in-water (W/O/W) droplets in PDMS device using protrusion channel without hydrophilic surface treatment[J]. Micromachines (Basel), 2018, 9(9): 468. |

| 19 | Gordillo J M , Cheng Z D , Ganan-Calvo A M , et al . A new device for the generation of microbubbles[J]. Physics of Fluids, 2004, 16(8): 2828-2834. |

| 20 | Li Y , Wang K , Luo G . Microdroplet generation with dilute surfactant concentration in a modified T-junction device[J]. Industrial & Engineering Chemistry Research, 2017, 56(42): 12131-12138. |

| 21 | 兰文杰, 李少伟, 徐建鸿, 等 . 同轴环管微流控设备内液-液两相黏性流体的流动规律[J]. 化工学报, 2013, 64(2): 476-483. |

| Lan W J , Li S W , Xu J H , et al . Liquid-liquid two-phase viscous flow in coaxial microfluidic device[J]. CIESC Journal, 2013, 64(2): 476-483. | |

| 22 | Li Y K , Liu G T , Xu J H , et al . A microdevice for producing monodispersed droplets under a jetting flow[J]. RSC Advances, 2015, 5(35): 27356-27364. |

| 23 | Castro-Hernández E , Gundabala V , Fernández-Nieves A , et al . Scaling the drop size in coflow experiments[J]. New Journal of Physics, 2009, 11(7), 075021. |

| 24 | Li Y K , Wang K , Xu J H , et al . A capillary-assembled micro-device for monodispersed small bubble and droplet generation[J]. Chemical Engineering Journal, 2016, 293: 182-188. |

| 25 | Castro-Hernandez E , van Hoeve W , Lohse D , et al . Microbubble generation in a co-flow device operated in a new regime[J]. Lab Chip, 2011, 11(12): 2023. |

| 26 | Shih R , Bardin D , Martz T D , et al . Flow-focusing regimes for accelerated production of monodisperse drug-loadable microbubbles toward clinical-scale applications[J]. Lab Chip, 2013, 13(24): 4816. |

| 27 | Xu J H , Li S W , Wang Y J , et al . Controllable gas-liquid phase flow patterns and monodisperse microbubbles in a microfluidic T-junction device[J]. Applied Physics Letters, 2006, 88(13): 133506. |

| 28 | Qin K , Wang K , Luo R , et al . Dispersion of supercritical carbon dioxide to [Emim][BF4] with a T-junction tubing connector[J]. Chemical Engineering and Processing - Process Intensification, 2018, 127: 58-64. |

| 29 | Garstecki P , Fuerstman M J , Stone H A , et al . Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up[J]. Lab Chip, 2006, 6(3): 437. |

| 30 | Garstecki P , Stone H A , Whitesides G M . Mechanism for flow-rate controlled breakup in confined geometries: a route to monodisperse emulsions[J]. Phys. Rev. Lett., 2005, 94(16): 164501. |

| 31 | Herrada M A , Ganan-Calvo A M , Montanero J M . Theoretical investigation of a technique to produce microbubbles by a microfluidic T junction[J]. Phys. Rev. E Stat. Nonlin. Soft Matter Phys., 2013, 88(3): 033027. |

| [1] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [2] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [3] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [4] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [5] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [6] | 郭雨莹, 敬加强, 黄婉妮, 张平, 孙杰, 朱宇, 冯君炫, 陆洪江. 稠油管道水润滑减阻及压降预测模型修正[J]. 化工学报, 2023, 74(7): 2898-2907. |

| [7] | 董明, 徐进良, 刘广林. 超临界水非均质特性分子动力学研究[J]. 化工学报, 2023, 74(7): 2836-2847. |

| [8] | 郑志航, 马郡男, 闫子涵, 卢春喜. 提升管射流影响区内压力脉动特性研究[J]. 化工学报, 2023, 74(6): 2335-2350. |

| [9] | 邓璐, 巨晓洁, 张文杰, 谢锐, 汪伟, 刘壮, 潘大伟, 褚良银. 微流控法可控制备放射性壳聚糖栓塞微球[J]. 化工学报, 2023, 74(4): 1781-1794. |

| [10] | 贾露凡, 王艺颖, 董钰漫, 李沁园, 谢鑫, 苑昊, 孟涛. 微流控双水相贴壁液滴流动强化酶促反应研究[J]. 化工学报, 2023, 74(3): 1239-1246. |

| [11] | 张雪婷, 胡激江, 赵晶, 李伯耿. 高分子量聚丙二醇在微通道反应器中的制备[J]. 化工学报, 2023, 74(3): 1343-1351. |

| [12] | 李新亚, 邢雷, 蒋明虎, 赵立新. 倒锥注气强化井下油水分离水力旋流器性能研究[J]. 化工学报, 2023, 74(3): 1134-1144. |

| [13] | 颜少航, 赖天伟, 王彦武, 侯予, 陈双涛. 微间隙内R134a空化可视化实验研究[J]. 化工学报, 2023, 74(3): 1054-1061. |

| [14] | 章承浩, 罗京, 张吉松. 微反应器内基于氮氧自由基催化剂连续氧气/空气氧化反应的研究进展[J]. 化工学报, 2023, 74(2): 511-524. |

| [15] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号