化工学报 ›› 2020, Vol. 71 ›› Issue (12): 5599-5609.DOI: 10.11949/0438-1157.20200416

收稿日期:2020-04-21

修回日期:2020-06-08

出版日期:2020-12-05

发布日期:2020-12-05

通讯作者:

李平

作者简介:曲冬蕾(1992—),女,博士研究生,基金资助:

QU Donglei( ),YANG Ying,QIAN Zhiling,LI Ping(

),YANG Ying,QIAN Zhiling,LI Ping( ),YU Jianguo

),YU Jianguo

Received:2020-04-21

Revised:2020-06-08

Online:2020-12-05

Published:2020-12-05

Contact:

LI Ping

摘要:

针对CO2置换吸附分离CH4/N2过程中CO2再生困难的问题,采用少量产品气CH4真空吹扫以提高CO2的解吸效果,并以解吸得到的CH4/CO2混合气为置换步骤的置换气,通过置换来强化含氮低品质甲烷的浓缩过程。以自制椰壳活性炭为吸附剂,对CH4/CO2混合气置换强化吸附回收含氮低品质甲烷工艺过程进行了实验与模拟研究。在gPROMS软件中建立并求解固定床吸附分离模型方程,预测了CH4、N2 和CO2在自制椰壳活性炭上的竞争吸附穿透曲线,通过预测结果和实验的对比,验证了数学模型方程的准确性。对比了不同置换气强化吸附分离低品质甲烷的效果,结果表明CH4/CO2混合气置换强化相对于CO2置换强化可获得更高纯度产品。进行了CH4/CO2混合气置换强化真空变压吸附循环实验,可以将14%的CH4/N2和53%的CH4/CO2联合富集到98.8%,同时获得77.8%的回收率。

中图分类号:

曲冬蕾,杨颖,钱智玲,李平,于建国. CH4/CO2混合气置换强化含氮低品质甲烷的浓缩[J]. 化工学报, 2020, 71(12): 5599-5609.

QU Donglei,YANG Ying,QIAN Zhiling,LI Ping,YU Jianguo. Intensification of low-grade methane enrichment in nitrogen mixture by CH4/CO2 displacement[J]. CIESC Journal, 2020, 71(12): 5599-5609.

| 步骤 | 时间/s | 进料流率/(L·min-1) | ||

|---|---|---|---|---|

| CH4 | N2 | CO2 | ||

| 充压 | 150 | 0.2 | 0.8 | — |

| 进料 | 400 | 0.2 | 0.8 | — |

| 置换 | 1400 | 0.5 | — | 0.5 |

| 抽真空 | 1300 | — | — | — |

| 吹扫1 | 3000 | 0.1 | — | — |

| 吹扫2 | 300 | — | 0.3 | — |

表1 CH4/CO2置换强化真空变压吸附实验操作条件

Table 1 Operating parameter of vacuum pressure swing adsorption with CH4/CO2 displacement intensification

| 步骤 | 时间/s | 进料流率/(L·min-1) | ||

|---|---|---|---|---|

| CH4 | N2 | CO2 | ||

| 充压 | 150 | 0.2 | 0.8 | — |

| 进料 | 400 | 0.2 | 0.8 | — |

| 置换 | 1400 | 0.5 | — | 0.5 |

| 抽真空 | 1300 | — | — | — |

| 吹扫1 | 3000 | 0.1 | — | — |

| 吹扫2 | 300 | — | 0.3 | — |

| mass balance of column |

|---|

| mass balance of pellet |

| mass balance of micropore |

| energy balance of gas phase |

| energy balance of solid phase |

| energy balance of column wall |

| momentum balance in the column |

| initial conditions |

| boundary conditions |

| pressurization step |

| feed and displacement step |

| blowdown step |

表2 固定床数学模型、边界条件和初始条件

Table 2 Mathematical model, boundary conditions, initial conditions for fixed bed experiment

| mass balance of column |

|---|

| mass balance of pellet |

| mass balance of micropore |

| energy balance of gas phase |

| energy balance of solid phase |

| energy balance of column wall |

| momentum balance in the column |

| initial conditions |

| boundary conditions |

| pressurization step |

| feed and displacement step |

| blowdown step |

| purge step |

|---|

adsorption equilibrium isotherms IAST-Sips model |

续表2

| purge step |

|---|

adsorption equilibrium isotherms IAST-Sips model |

| Diffusion coefficient | CH4 | N2 | CO2 |

|---|---|---|---|

| Dax /(m2·s-1) | 1.57×10-5 | 1.57×10-5 | 1.54×10-5 |

| Dp /(m2·s-1) | 5.74×10-6 | 5.65×10-6 | 4.05×10-6 |

| kf /(m2·s-1) | 3.77×10-2 | 3.77×10-2 | 2.82×10-2 |

| Dμ0 /(m2·s-1) | 23.54 | 5.57 | 6.86 |

| Ea /(J·mol-1) | 13062 | 7162 | 4280 |

| Thermal conductivity | Gas properties | ||

| Parameter | Value | Parameter | Value |

| hf /(W·m-2·K-1) | 91.13 | μg /(Pa·s) | 1.61×10-5 |

| hw /(W·m-2·K-1) | 60 | cp/(J·mol-1·K-1) | 30.44 |

| λ /(W·m-2·K-1) | 0.20 | cv/(J·mol-1·K-1) | 22.13 |

| U /(W·m-2·K-1) | 180 | ||

表3 传递系数和气体性质参数

Table 3 Transport parameters and gas phase properties

| Diffusion coefficient | CH4 | N2 | CO2 |

|---|---|---|---|

| Dax /(m2·s-1) | 1.57×10-5 | 1.57×10-5 | 1.54×10-5 |

| Dp /(m2·s-1) | 5.74×10-6 | 5.65×10-6 | 4.05×10-6 |

| kf /(m2·s-1) | 3.77×10-2 | 3.77×10-2 | 2.82×10-2 |

| Dμ0 /(m2·s-1) | 23.54 | 5.57 | 6.86 |

| Ea /(J·mol-1) | 13062 | 7162 | 4280 |

| Thermal conductivity | Gas properties | ||

| Parameter | Value | Parameter | Value |

| hf /(W·m-2·K-1) | 91.13 | μg /(Pa·s) | 1.61×10-5 |

| hw /(W·m-2·K-1) | 60 | cp/(J·mol-1·K-1) | 30.44 |

| λ /(W·m-2·K-1) | 0.20 | cv/(J·mol-1·K-1) | 22.13 |

| U /(W·m-2·K-1) | 180 | ||

| Gas | qm,i/(mol·kg-1) | K0,i/kPa-1 | -ΔHi/(kJ·mol-1) | ni |

|---|---|---|---|---|

| CH4 | 6.466 | 1.10×10-6 | 19.556 | 1.112 |

| N2 | 3.834 | 2.02×10-6 | 16.381 | 1.011 |

| CO2 | 15.459 | 1.52×10-7 | 23.698 | 1.344 |

表4 CH4,N2和CO2在GAC上吸附平衡的Sips模型拟合参数

Table 4 Fitting parameters of Sips model for adsorption equilibrium isotherms of pure CH4, N2 and CO2 on GAC

| Gas | qm,i/(mol·kg-1) | K0,i/kPa-1 | -ΔHi/(kJ·mol-1) | ni |

|---|---|---|---|---|

| CH4 | 6.466 | 1.10×10-6 | 19.556 | 1.112 |

| N2 | 3.834 | 2.02×10-6 | 16.381 | 1.011 |

| CO2 | 15.459 | 1.52×10-7 | 23.698 | 1.344 |

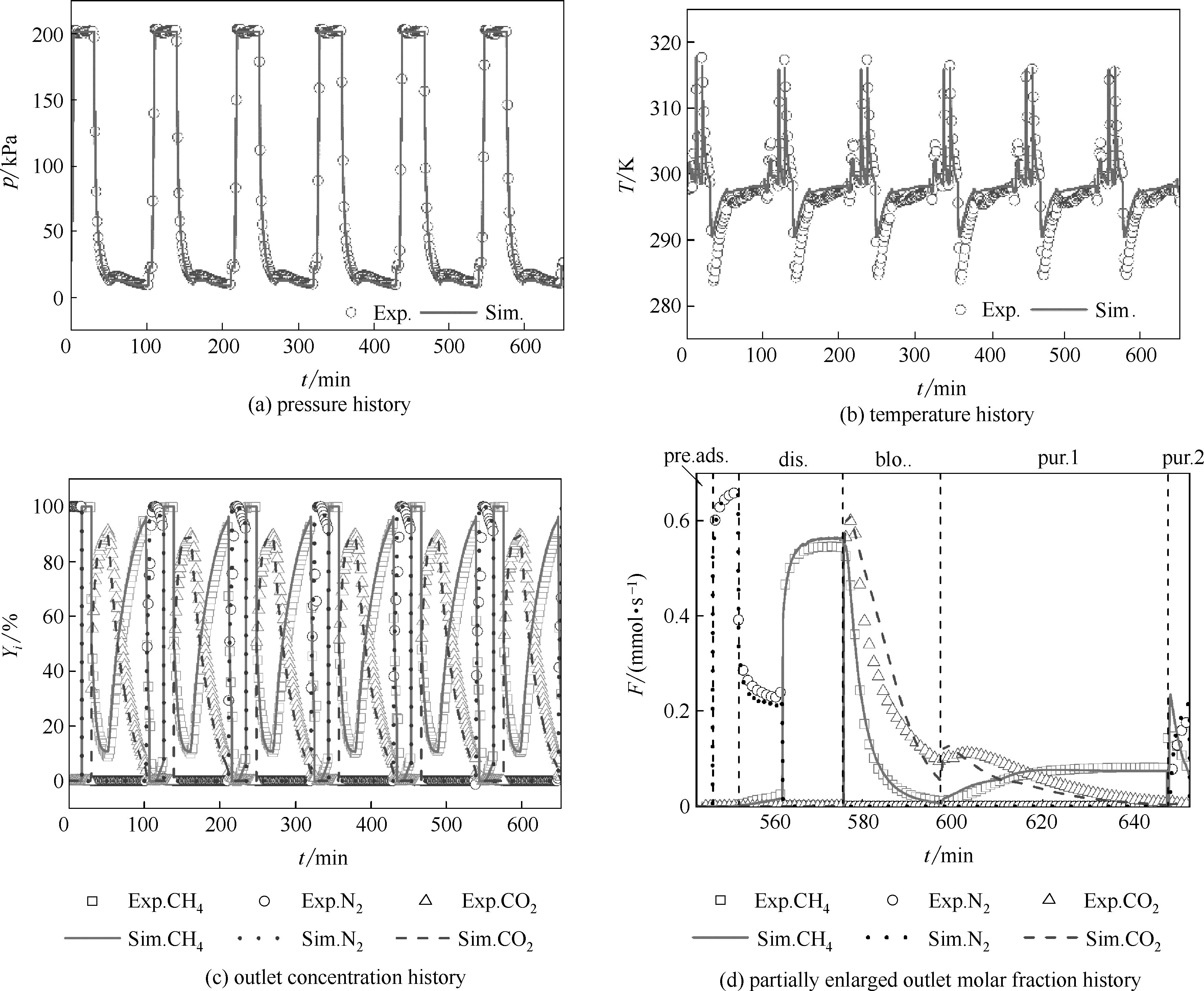

图6 固定床CH4/CO2置换强化变压吸附分离CH4/N2实验的中压力、温度、出口浓度以及流率变化曲线

Fig.6 Pressure, temperature, outlet concentration and flowrate histories in VPSA-CH4/CO2 DIS process

| 1 | 政府间气候变化专门委员会. 气候变化2014: 综合报告[R].日内瓦, 2013. |

| Intergovernmental Panel on Climate Change. Synthesis Report: Climate Change 2014[R]. Geneva, 2013. | |

| 2 | Effendy S, Xu C, Farooq S. Optimization of a pressure swing adsorption process for nitrogen rejection from natural gas[J]. Industrial & Engineering Chemistry Research, 2017, 56: 5417-5431. |

| 3 | Yousef A M, El-Maghlany W M, Eldrainy Y A, et al. Upgrading biogas to biomethane and liquid CO2: a novel cryogenic process[J]. Fuel, 2019, 251: 611-628. |

| 4 | 高婷, 林文胜, 顾安忠, 等. 利用吸附余压预冷的煤层气氮膨胀液化流程[J]. 天然气工业, 2009, 29(2): 117-147. |

| Gao T, Lin W S, Gu A Z, et al. Integrated process of nitrogen expansion and liquefaction for precooling CBM by adsorbing residue pressure[J]. Natural Gas Industry, 2009, 29(2): 117-147. | |

| 5 | 李雯, 王志, 李潘源, 等. 用于甲烷-氮气体系分离的膜技术研究进展[J]. 化工学报, 2016, 67(2): 404-415. |

| Li W, Wang Z, Li P Y, et al. Progress in membrane technology for CH4-N2 separation[J]. CIESC Journal, 2016, 67(2): 404-415. | |

| 6 | Wu T, Diaz M C, Zheng Y, et al. Influence of propane on CO2/CH4 and N2/CH4 separations in CHA zeolite membranes[J]. Journal of Membrane Science, 2015, 473: 201-209. |

| 7 | Zong Z, Carreon M A. Thin SAPO-34 membranes synthesized in stainless steel autoclaves for N2/CH4 separation[J]. Journal of Membrane Science, 2017, 524: 117-123. |

| 8 | Wang S, Guo Q, Liang S, et al. Preparation of Ni-MOF-74/SBS mixed matrix membranes and its application of CH4/N2 separation[J]. Separation and Purification Technology, 2018, 199: 206-213. |

| 9 | Zhang Y Y , Xie Y J, Zhu Y, et al. Energy consumption analysis for CO2 separation from gas mixtures with liquid absorbents[J]. Energy Procedia, 2014, 61: 2695-2698. |

| 10 | Matsui H, Jia J, Tsuji T, et al. Microsecond simulation study on the replacement of methane in methane hydrate by carbon dioxide, nitrogen, and carbon dioxide-nitrogen mixtures[J]. Fuel, 2020, 263: 116640. |

| 11 | Yang X, Li Z, Zhang C Z , et al. Practical separation performance evaluation of coal mine methane upgrading with carbon molecular sieves[J]. Chemical Engineering Journal, 2019, 367: 295-303. |

| 12 | Yang H W , Yin C B, Jiang B, et al. Optimization and analysis of a VPSA process for N2/CH4 separation[J]. Separation and Purification Technology, 2014, 134: 232-240. |

| 13 | Yin C, Sun W, Yang H W, et al. Optimization of three-bed VPSA system for biogas upgrading[J]. Chemical Engineering Science, 2015, 135: 100-108. |

| 14 | 刘海庆, 吴一江, 杨颖, 等. 沸石ZSM-5吸附回收低浓度煤层气中CH4[J]. 化工学报, 2016, 67(5): 1931-1941. |

| Liu H Q, Wu Y J, Yang Y, et al. Adsorption and recovery of low concentration coal-bed methane by zeolite ZSM-5[J]. CIESC Journal, 2016, 67(5): 1931-1941. | |

| 15 | Gu M, Zhang B, Qi Z D , et al. Effects of pore structure of granular activated carbons on CH4 enrichment from CH4/N2 by vacuum pressure swing adsorption[J]. Separation and Purification Technology, 2015, 146: 213-218. |

| 16 | Guo Y, Hu J L, Liu X W, et al. Scalable solvent-free preparation of [Ni3(HCOO)6] frameworks for highly efficient separation of CH4 from N2[J]. Chemical Engineering Journal, 2017, 327: 564-572. |

| 17 | Tang R L, Dai Q B, Liang W W, et al. Synthesis of novel particle rice-based carbon materials and its excellent CH4/N2 adsorption selectivity for methane enrichment from low-rank natural gas[J]. Chemical Engineering Journal, 2020, 384: 123388. |

| 18 | Xiao G, Saleman T L, Zou Y, et al. Nitrogen rejection from methane using dual-reflux pressure swing adsorption with a kinetically-selective adsorbent[J]. Chemical Engineering Journal, 2019, 372: 1038-1046. |

| 19 | 杨颖, 曲冬蕾, 李平, 等. 低浓度煤层气吸附浓缩技术研究与发展[J]. 化工学报, 2018, 69(11): 4518-4529. |

| Yang Y, Qu D L, Li P, et al. Research and development on enrichment of low concentration coal mine methane by adsorption technology[J]. CIESC Journal, 2018, 69(11): 4518-4529. | |

| 20 | Yang J F, Bai H H, Shang H, et al. Experimental and simulation study on efficient CH4/N2 separation by pressure swing adsorption on silicalite-1 pellets[J]. Chemical Engineering Journal, 2020, 388: 124222. |

| 21 | Saleman T L, Li G, Ruffor T E, et al. Capture of low grade methane from nitrogen gas using dual-reflux pressure swing adsorption[J]. Chemical Engineering Journal, 2015, 281: 739-748. |

| 22 | 韩治洋, 丁兆阳, 韩旸湲, 等. 真空变压吸附分离氮气甲烷的模拟与控制[J]. 化工学报, 2018, 69(2): 750-758. |

| Han Z Y, Ding Z Y, Han Y Y, et al. Simulation and control of vacuum pressure swing adsorption for N2/CH4 separation[J]. CIESC Journal, 2018, 69(2): 750-758. | |

| 23 | Sun W N, Shen Y H, Zhang D H, et al. A systematic simulation and proposed optimization of the pressure swing adsorption process for N2/CH4 separation under external disturbances[J]. Industrial & Engineering Chemistry Research, 2015, 54(30): 7489-7501. |

| 24 | Han Z Y, Xing R, Zhang D H, et al. Vacuum pressure swing adsorption system for N2/CH4 separation under uncertainty[J]. Chemical Engineering Research and Design, 2019, 142: 245-256. |

| 25 | Yang X, Liu Y S, Li Z Y, et al. Vacuum exhaust process in pilot-scale vacuum pressure swing adsorption for coal mine ventilation air methane enrichment[J]. Energies, 2018, 11: 1030. |

| 26 | Liu C M, Zhou Y P, Sun Y, et al. Enrichment of coal-bed methane by PSA complemented with CO2 displacement[J]. AIChE J., 2011, 57(3): 645-654. |

| 27 | Yang Y, Wu Y J, Liu H Q, et al. Enrichment of ventilation air methane by adsorption with displacement chromatography technology: experiment and numerical simulation[J]. Chemical Engineering Science, 2016, 149: 215-228. |

| 28 | Qu D L, Yang Y, Qian Z L, et al. Enrichment of low-grade methane gas from nitrogen mixture by VPSA with CO2 displacement process: modeling and experiment[J]. Chemical Engineering Journal, 2020, 380: 122509. |

| 29 | Qu D L, Yang Y, Lu K, et al. Microstructure effect of carbon materials on the low-concentration methane adsorption separation from its mixture with nitrogen[J]. Adsorption, 2018, 24(4): 357-369. |

| 30 | Farooq S, Ruthven D M, Boniface H A. Numerical simulation of a pressure swing adsorption oxygen unit[J]. Chemical Engineering Science, 1989, 44(12): 2809-2816. |

| 31 | Glueckauf E, Coates J I. Theory of chromatography(Ⅳ): The influence of incomplete equilibrium on the front boundary of chromatograms and on the effectiveness of separation[J]. Journal of the Chemical Society (Resumed), 1947: 1315-1321. |

| 32 | Sips R. On the Structure of a catalyst surface [J]. Journal of Chemiacal Physics, 1948, 16: 490-495. |

| 33 | Edwards M F, Richardson J F. Gas dispersion in packed beds[J]. Chemical Engineering Science, 1968, 23(2): 109-123. |

| 34 | Do D D. Adsorption Analysis: Equilibria and Kinetics [M]. London: Imperial College Press, 1998. |

| [1] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [4] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [5] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [6] | 吕龙义, 及文博, 韩沐达, 李伟光, 高文芳, 刘晓阳, 孙丽, 王鹏飞, 任芝军, 张光明. 铁基导电材料强化厌氧去除卤代有机污染物:研究进展及未来展望[J]. 化工学报, 2023, 74(8): 3193-3202. |

| [7] | 刘晓洋, 喻健良, 侯玉洁, 闫兴清, 张振华, 吕先舒. 螺旋微通道对掺氢甲烷爆轰传播的影响[J]. 化工学报, 2023, 74(7): 3139-3148. |

| [8] | 屈园浩, 邓文义, 谢晓丹, 苏亚欣. 活性炭/石墨辅助污泥电渗脱水研究[J]. 化工学报, 2023, 74(7): 3038-3050. |

| [9] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [10] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [11] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [12] | 周小文, 杜杰, 张战国, 许光文. 基于甲烷脉冲法的Fe2O3-Al2O3载氧体还原特性研究[J]. 化工学报, 2023, 74(6): 2611-2623. |

| [13] | 李晨曦, 刘永峰, 张璐, 刘海峰, 宋金瓯, 何旭. O2/CO2氛围下正庚烷的燃烧机理研究[J]. 化工学报, 2023, 74(5): 2157-2169. |

| [14] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| [15] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号