化工学报 ›› 2021, Vol. 72 ›› Issue (1): 452-467.DOI: 10.11949/0438-1157.20201114

收稿日期:2020-08-05

修回日期:2020-09-04

出版日期:2021-01-05

发布日期:2021-01-05

通讯作者:

苏远海

作者简介:李光晓 (1988—),男,博士研究生, 基金资助:

LI Guangxiao( ),LIU Sai'er,SU Yuanhai(

),LIU Sai'er,SU Yuanhai( )

)

Received:2020-08-05

Revised:2020-09-04

Online:2021-01-05

Published:2021-01-05

Contact:

SU Yuanhai

摘要:

微化工技术作为一种高效的过程强化技术获得了广泛应用。本文从流动、传递及反应三者之间的耦合机制出发,系统综述了近十五年以来关于微尺度内液-液两相流动与传质过程特征、强化传质的微反应器、评价标准及其在化学品合成与材料制备中的应用等方面的研究进展,并对其未来发展方向进行了展望。

中图分类号:

李光晓,刘塞尔,苏远海. 微尺度内液-液传质及反应过程强化的研究进展[J]. 化工学报, 2021, 72(1): 452-467.

LI Guangxiao,LIU Sai'er,SU Yuanhai. Research progress on micro-scale internal liquid-liquid mass transfer and reaction process enhancement[J]. CIESC Journal, 2021, 72(1): 452-467.

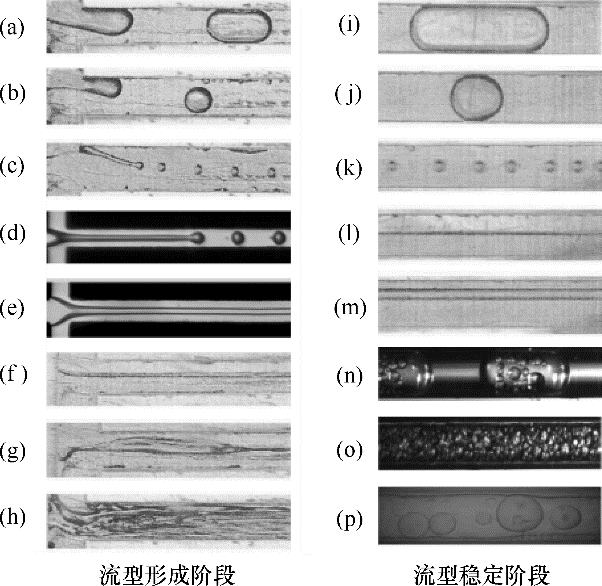

图1 微尺度内液-液两相流型[5-7, 9-10]流型形成阶段:(a) 弹状流,(b) 单分散液滴流,(c) 液滴群流,(d) 射流,(e) 环状流,(f) 具有光滑界面的平行流,(g) 界面处有漩涡存在的平行流,(h) 不规则薄条纹流; 流型稳定阶段:(i) 弹状流,(j) 单分散液滴流,(k) 液滴群流,(l) 平行流,(m) 环状流,(n) 弹状分散流,(o) 液滴分散流,(p) 环状分散流

Fig.1 Flow patterns of liquid-liquid two phases at microscale[5-7, 9-10]Flow pattern formation stage: (a) slug flow, (b) monodispersed droplet flow, (c) droplet populations flow, (d) jetting flow, (e) annular flow, (f) parallel flow with smooth interface, (g) parallel flow with wavy interface, (h) chaotic thin striations flow; Flow patterns in steady stage: (i) slug flow, (j) monodispersed droplet flow, (k) droplet populations flow, (l) parallel flow, (m) annular flow, (n) slug-dispersed flow, (o) droplet-dispersed flow, (p) annular-dispersed flow

图2 典型的微尺度内液-液两相流型分布[5, 9, 22-23](下角标: C,c为连续相;D,d为分散相;ks为油相;ws,aq为水相;org为有机相)

Fig.2 Typical liquid-liquid flow pattern maps at the microscale[5, 9, 22-23]

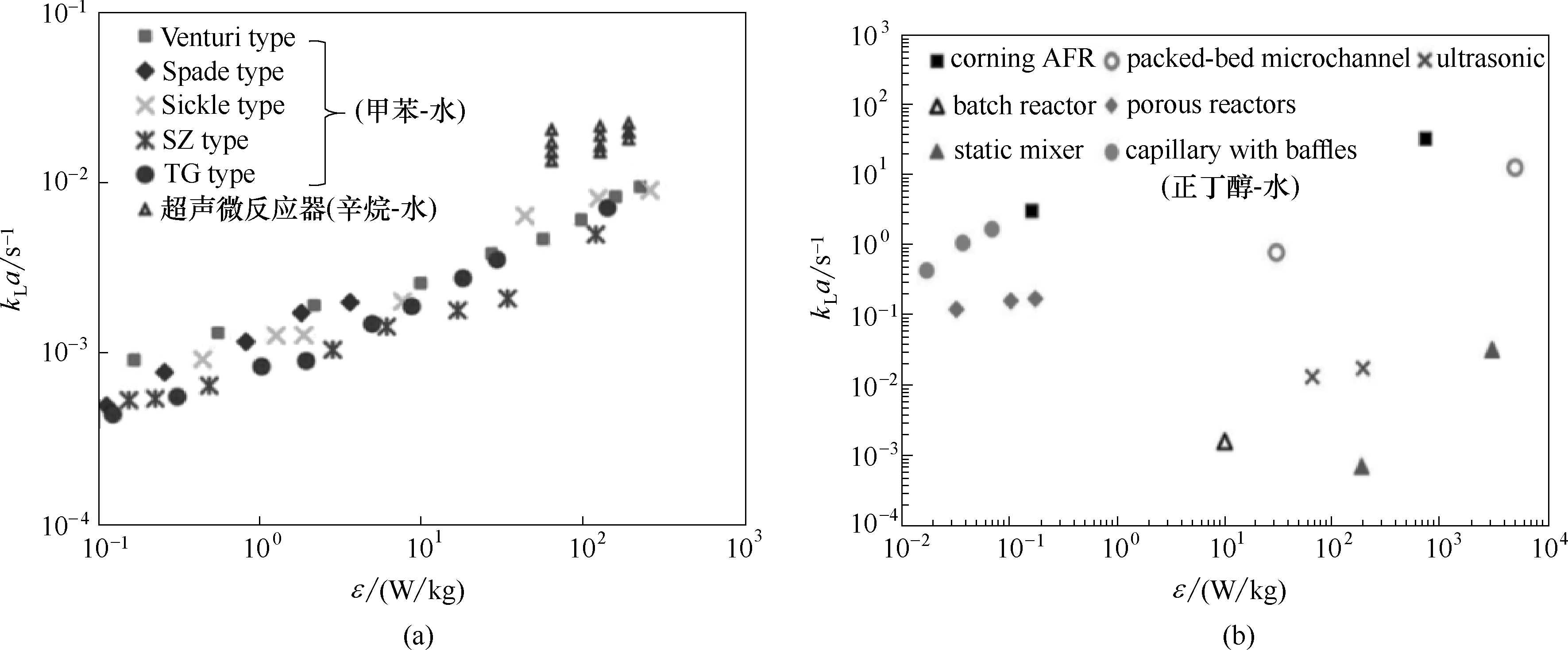

图8 不同传质强化微反应器的总体积传质系数和比能耗[29, 70, 79]

Fig.8 Overall volumetric mass transfer coefficient as a function of the specific energy dissipation for different microreactors with mass transfer intensification[29, 70, 79]

| 1 | 陈光文, 袁权. 微化工技术[J]. 化工学报, 2003, 54(4): 427-439. |

| Chen G W, Yuan Q. Micro-chemical technology[J]. Journal of Chemical Industry and Engineering(China), 2003, 54(4): 427-439. | |

| 2 | Gemoets H P L, Su Y H, Shang M J, et al. Liquid phase oxidation chemistry in continuous-flow microreactors[J]. Chemical Society Reviews, 2016, 45(1): 83-117. |

| 3 | Su Y H, Song Y, Xiang L. Continuous-flow microreactors for molymer synthesis: engineering principles and applications[M]// Noël T, Luque R. Accounts on Sustainable Flow Chemistry. Switzerland: Springer, Cham, 2020: 147-190. |

| 4 | Wang K, Luo G S. Microflow extraction: a review of recent development[J]. Chemical Engineering Science, 2017, 169(SI): 18-33. |

| 5 | Zhao Y C, Chen G W, Yuan Q. Liquid-liquid two-phase flow patterns in a rectangular microchannel[J]. AIChE Journal, 2006, 52(12): 4052-4060. |

| 6 | Cubaud T, Mason T G. Capillary threads and viscous droplets in square microchannels[J]. Physics of Fluids, 2008, 20(5): 53302. |

| 7 | Christopher G F, Anna S L. Microfluidic methods for generating continuous droplet streams[J]. Journal of Physics D: Applied Physics, 2007, 40(19): R319-R336. |

| 8 | Kashid M N, Renken A, Kiwi-Minsker L. Influence of flow regime on mass transfer in different types of microchannels[J]. Industrial & Engineering Chemistry Research, 2011, 50(11): 6906-6914. |

| 9 | Zhang Q, Liu H C, Zhao S N, et al. Hydrodynamics and mass transfer characteristics of liquid-liquid slug flow in microchannels: the effects of temperature, fluid properties and channel size[J]. Chemical Engineering Journal, 2019, 358: 794-805. |

| 10 | Kashid M N, Agar D W. Hydrodynamics of liquid-liquid slug flow capillary microreactor: flow regimes, slug size and pressure drop[J]. Chemical Engineering Journal, 2007, 131(1/2/3): 1-13. |

| 11 | Abiev R, Svetlov S, Haase S. Hydrodynamics and mass transfer of gas-liquid and liquid-liquid taylor flow in micro channels: a review[J]. Chemical Engineering & Technology, 2017, 40(11): 1985-1998 |

| 12 | Dessimoz A, Cavin L, Renken A, et al. Liquid-liquid two-phase flow patterns and mass transfer characteristics in rectangular glass microreactors[J]. Chemical Engineering Science, 2008, 63(16): 4035-4044. |

| 13 | Timung S, Tiwari V, Singh A K, et al. Capillary force mediated flow patterns and non-monotonic pressure drop characteristics of oil-water microflows[J]. The Canadian Journal of Chemical Engineering, 2015, 93(10): 1736-1743. |

| 14 | Gupta A, Kumar R. Flow regime transition at high capillary numbers in a microfluidic T-junction: viscosity contrast and geometry effect[J]. Physics of Fluids, 2010, 22(12): 122001. |

| 15 | Feigl K, Tanner F X, Holzapfel S, et al. Effect of flow type, channel height, and viscosity on drop production from micropores[J]. Chemical Engineering Science, 2014, 116: 372-382. |

| 16 | Wehking J D, Gabany M, Chew L, et al. Effects of viscosity, interfacial tension, and flow geometry on droplet formation in a microfluidic T-junction[J]. Microfluidics and Nanofluidics, 2014, 16(3): 441-453. |

| 17 | Tsaoulidis D, Dore V, Angeli P, et al. Flow patterns and pressure drop of ionic liquid-water two-phase flows in microchannels[J]. International Journal of Multiphase Flow, 2013, 54: 1-10. |

| 18 | Zhao Y C, Su Y H, Chen G W, et al. Effect of surface properties on the flow characteristics and mass transfer performance in microchannels[J]. Chemical Engineering Science, 2010, 65(5): 1563-1570. |

| 19 | Xu J H, Luo G S, Li S W, et al. Shear force induced monodisperse droplet formation in a microfluidic device by controlling wetting properties[J]. Lab Chip, 2006, 6(1): 131-136. |

| 20 | Nunes J K, Tsai S S, Wan J, et al. Dripping and jetting in microfluidic multiphase flows applied to particle and fiber synthesis[J]. Journal of Physics D: Applied Physics, 2013, 46(11). |

| 21 | Fu T T, Wei L J, Zhu C Y, et al. Flow patterns of liquid-liquid two-phase flow in non-Newtonian fluids in rectangular microchannels[J]. Chemical Engineering and Processing, 2015, 91: 114-120. |

| 22 | Cao Z, Wu Z, Sundén B. Dimensionless analysis on liquid-liquid flow patterns and scaling law on slug hydrodynamics in cross-junction microchannels[J]. Chemical Engineering Journal, 2018, 344: 604-615. |

| 23 | Shen C, Zheng Q B, Shang M J, et al. Using deep learning to recognize liquid-liquid flow patterns in microchannels[J]. AIChE Journal, 2020, 66(8): e16260. |

| 24 | 王文坦, 刘喆, 金涌, 等.微通道中液滴内部速度场的LBM模拟[J]. 中国科技论文在线, 2010, 5(12): 911-918. |

| Wang W T, Liu Z, Jin Y, et al. Simulation of velocity field inside the droplet in micro-channels by Lattice Boltzmann Method [J]. Sciencepaper Online, 2010, 5(12): 911-918. | |

| 25 | Ghaini A, Mescher A, Agar D W. Hydrodynamic studies of liquid-liquid slug flows in circular microchannels[J]. Chemical Engineering Science, 2011, 66(6): 1168-1178. |

| 26 | Hartmann D, Meinke M, Schröder W. The constrained reinitialization equation for level set methods[J]. Journal of Computational Physics, 2010, 229(5): 1514-1535. |

| 27 | Su Y H, Chen G W, Zhao Y C, et al. Intensification of liquid-liquid two-phase mass transfer by gas agitation in a microchannel[J]. AIChE Journal, 2009, 55(8): 1948-1958. |

| 28 | Woitalka A, Kuhn S, Jensen K F. Scalability of mass transfer in liquid-liquid flow[J]. Chemical Engineering Science, 2014, 116: 1-8. |

| 29 | Li G X, Pu X, Shang M J, et al. Intensification of liquid-liquid two-phase mass transfer in a capillary microreactor system[J]. AIChE Journal, 2019, 65(1): 334-346. |

| 30 | Zhao Y C, Chen G W, Yuan Q. Liquid-liquid two-phase mass transfer in the T-junction microchannels[J]. AIChE Journal, 2007, 53(12): 3042-3053. |

| 31 | Li G X, Shang M J, Song Y, et al. Characterization of liquid-liquid mass transfer performance in a capillary microreactor system[J]. AIChE Journal, 2018, 64(3): 1106-1116. |

| 32 | 朱春英, 付涛涛, 高习群, 等.微通道内液液两相流流型[J]. 化工进展, 2011, 30(S2): 65-69. |

| Zhu C Y, Fu T T, Gao X Q, et al. Study on the liquid-liquid two-phase flow patterns in microchannels[J]. Chemical Industry and Engineering Progress, 2011, 30(S2): 65-69. | |

| 33 | Yang L, Nieves-Remacha M J, Jensen K F. Simulations and analysis of multiphase transport and reaction in segmented flow microreactors[J]. Chemical Engineering Science, 2017, 169: 106-116. |

| 34 | Shang L R, Cheng Y, Zhao Y J. Emerging droplet microfluidics[J]. Chemical Reviews, 2017, 117 (12): 7964-8040. |

| 35 | Bai L, Zhao S F, Fu Y H, et al. Experimental study of mass transfer in water/ionic liquid microdroplet systems using micro-LIF technique[J]. Chemical Engineering Journal, 2016, 298: 281-290. |

| 36 | Xu J H, Tan J, Li S W, et al. Enhancement of mass transfer performance of liquid-liquid system by droplet flow in microchannels[J]. Chemical Engineering Journal, 2008, 141(1/2/3): 242-249. |

| 37 | Mary P, Studer V, Tabeling P. Microfluidic droplet-based liquid-liquid extraction[J]. Analytical Chemistry, 2008, 80(80): 2680-2687. |

| 38 | Burns J R, Ramshaw C. The intensification of rapid reactions in multiphase systems using slug flow in capillaries[J]. Lab Chip, 2001, 1(1): 10. |

| 39 | Song Y, Song J N, Shang M J, et al. Hydrodynamics and mass transfer performance during the chemical oxidative polymerization of aniline in microreactors[J]. Chemical Engineering Journal, 2018, 353: 769-780. |

| 40 | Kashid M N, Gerlach I, Goetz S, et al. Internal circulation within the liquid slugs of a liquid-liquid slug-flow capillary microreactor[J]. Industrial & Engineering Chemistry Research, 2005, 44(14): 5003-5010. |

| 41 | Bretherton F P. The motion of long bubbles in tubes[J]. Journal of Fluid Mechanics, 1961, 10(2): 166. |

| 42 | Li Q, Angeli P. Experimental and numerical hydrodynamic studies of ionic liquid-aqueous plug flow in small channels[J]. Chemical Engineering Journal, 2017, 328: 717-736. |

| 43 | Xu B J, Cai W F, Liu X L, et al. Mass transfer behavior of liquid-liquid slug flow in circular cross-section microchannel[J]. Chemical Engineering Research and Design, 2013, 91(7): 1203-1211. |

| 44 | Tsaoulidis D, Angeli P. Effect of channel size on liquid-liquid plug flow in small channels[J]. AIChE Journal, 2016, 62(1): 315-324. |

| 45 | Yao C Q, Dong Z Y, Zhao Y C, et al. An online method to measure mass transfer of slug flow in a microchannel[J]. Chemical Engineering Science, 2014, 112: 15-24. |

| 46 | Svetlov S D, Abiev R S. Modeling mass transfer in a Taylor flow regime through microchannels using a three-layer model[J]. Theoretical Foundations of Chemical Engineering, 2016, 50(6): 975-989. |

| 47 | Butler C, Lalanne B, Sandmann K, et al. Mass transfer in Taylor flow: transfer rate modelling from measurements at the slug and film scale[J]. International Journal of Multiphase Flow, 2018, 105: 185-201. |

| 48 | Nirmal G M, Leary T F, Ramachandran A. Mass transfer dynamics in the dissolution of Taylor bubbles[J]. Soft Matter, 2019, 15(13): 2746-2756. |

| 49 | Li G X, Shang M J, Song Y, et al. Characterization of liquid-liquid mass transfer performance in a capillary microreactor system[J]. AIChE Journal, 2018, 64(3): 1106-1116. |

| 50 | Yang L X, Dietrich N, Loubière K, et al. Visualization and characterization of gas-liquid mass transfer around a Taylor bubble right after the formation stage in microreactors[J]. Chemical Engineering Science, 2016, 143: 364-368. |

| 51 | Cygan Z T, Cabral J T, Beers K L, et al. Microfluidic platform for the generation of organic-phase microreactors[J]. Langmuir, 2005, 21(8): 3629-3634. |

| 52 | 陈光文, 赵玉潮, 袁权.微尺度下液-液流动与传质特性的研究进展[J]. 化工学报, 2010, 61(7): 1627-1635. |

| Chen G W, Zhao Y C, Yuan Q. Advances in flow hydrodynamic and mass transfer characteristics of liquid phase in microscale [J]. CIESC Journal, 2010, 61(7): 1627-1635. | |

| 53 | Kashid M N, Harshe Y M, Agar D W. Liquid-liquid slug flow in a capillary: an alternative to suspended drop or film contactors[J]. Industrial & Engineering Chemistry Research, 2007, 46(25): 8420-8430. |

| 54 | Susanti, Winkelman J G M, Schuur B, et al. Lactic acid extraction and mass transfer characteristics in slug flow capillary microreactors[J]. Industrial & Engineering Chemistry Research, 2016, 55(16): 4691-4702. |

| 55 | Gürsel I V, Kurt S K, Aalders J, et al. Utilization of milli-scale coiled flow inverter in combination with phase separator for continuous flow liquid-liquid extraction processes[J]. Chemical Engineering Journal, 2016, 283: 855-868. |

| 56 | Tsaoulidis D, Angeli P. Effect of channel size on mass transfer during liquid-liquid plug flow in small scale extractors[J]. Chemical Engineering Journal, 2015, 262: 785-793. |

| 57 | Raimondi N D M, Prat L, Gourdon C, et al. Direct numerical simulations of mass transfer in square microchannels for liquid-liquid slug flow[J]. Chemical Engineering Science, 2008, 63(22): 5522-5530. |

| 58 | Kashid M N, Agar D W, Turek S. CFD modelling of mass transfer with and without chemical reaction in the liquid-liquid slug flow microreactor[J]. Chemical Engineering Science, 2007, 62(18/19/20): 5102-5109. |

| 59 | Hetsroni G, Mosyak A, Pogrebnyak E, et al. Fluid flow in micro-channels[J]. International Journal of Heat and Mass Transfer, 2005, 48(10): 1982-1998. |

| 60 | Qu W L, Mala G M, Li D Q. Pressure-driven water flows in trapezoidal silicon microchannels[J]. International Journal of Heat and Mass Transfer, 2000, 43(3): 353-364. |

| 61 | Azimi N, Rahimi M, Abdollahi N. Using magnetically excited nanoparticles for liquid-liquid two-phase mass transfer enhancement in a Y-type micromixer[J]. Chemical Engineering and Processing: Process Intensification, 2015, 97: 12-22. |

| 62 | Zhao S N, Yao C Q, Dong Z Y, et al. Intensification of liquid-liquid two-phase mass transfer by oscillating bubbles in ultrasonic microreactor[J]. Chemical Engineering Science, 2018, 186: 122-134. |

| 63 | Deng J C, Feng X, Qiu X H. Extraction of heavy metal from sewage sludge using ultrasound-assisted nitric acid[J]. Chemical Engineering Journal, 2009, 152(1): 177-182. |

| 64 | Comer E, Organ M G. A microreactor for microwave-assisted capillary (continuous flow) organic synthesis[J]. Journal of the American Chemical Society, 2005, 127(22): 8160-8167. |

| 65 | Jafari O, Rahimi M, Hosseini Kakavandi F, et al. Cu (II) removal intensification using Fe3O4 nanoparticles under inert gas and magnetic field in a microchannel[J]. International Journal of Environmental Science and Technology, 2017, 14(8): 1651-1664. |

| 66 | Azimi N, Rahimi M. Magnetic nanoparticles stimulation to enhance liquid-liquid two-phase mass transfer under static and rotating magnetic fields[J]. Journal of Magnetism and Magnetic Materials, 2017, 422: 188-196. |

| 67 | Stankiewicz A. On the applications of alternative energy forms and transfer mechanisms in microprocessing systems[J]. Industrial & Engineering Chemistry Research, 2007, 46(12): 4232-4235. |

| 68 | Zhao S N, Yao C Q, Zhang Q, et al. Acoustic cavitation and ultrasound-assisted nitration process in ultrasonic microreactors: the effects of channel dimension, solvent properties and temperature[J]. Chemical Engineering Journal, 2019, 374: 68-78. |

| 69 | Dong Z Y, Yao C Q, Zhang X L, et al. A high-power ultrasonic microreactor and its application in gas-liquid mass transfer intensification[J]. Lab Chip, 2015, 15(4): 1145-1152. |

| 70 | Zhao S N, Dong Z Y, Yao C Q, et al. Liquid-liquid two-phase flow in ultrasonic microreactors: cavitation, emulsification, and mass transfer enhancement[J]. AIChE Journal, 2018, 64(4): 1412-1423. |

| 71 | John J J, Kuhn S, Braeken L, et al. Effect of fluid properties on ultrasound assisted liquid-liquid extraction in a microchannel[J]. Ultrasonics Sonochemistry, 2018, 42: 68-75. |

| 72 | 徐建鸿, 骆广生, 孙永, 等.膜分散式混合澄清萃取器性能研究[J]. 高校化学工程学报, 2003, (4): 361-364. |

| Xu J H, Luo G S, Sun Y, et al. Extraction performance of a new mixer-settler with membrane dispersion Technique[J]. Journal of Chemical Engineering of Chinese Universities, 2003, (4): 361-364. | |

| 73 | Wang K, Lu Y C, Luo G S. Strategy for scaling-up of a microsieve dispersion reactor[J]. Chemical Engineering & Technology, 2014, 37(12): 2116-2122. |

| 74 | Shao H W, Lu Y C, Wang K, et al. Liquid-liquid flow and mass transfer characteristics in micro-sieve array device with dual-sized pores[J]. Chemical Engineering Journal, 2012, 193/194: 96-101. |

| 75 | Özkan A, Erdem E Y. Numerical analysis of mixing performance in sinusoidal microchannels based on particle motion in droplets[J]. Microfluidics and Nanofluidics, 2015, 19(5): 1101-1108. |

| 76 | Mary P, Studer V, Tabeling P. Microfluidic droplet-based liquid-liquid extraction[J]. Analytical Chemistry, 2008, 80(8): 2680-2687. |

| 77 | Plouffe P, Roberge D M, Sieber J, et al. Liquid-liquid mass transfer in a serpentine micro-reactor using various solvents[J]. Chemical Engineering Journal, 2016, 285: 605-615. |

| 78 | Kurt S K, Gürsel I V, Hessel V, et al. Liquid-liquid extraction system with microstructured coiled flow inverter and other capillary setups for single-stage extraction applications[J]. Chemical Engineering Journal, 2016, 284: 764-777. |

| 79 | Plouffe P, Roberge D M, Macchi A. Liquid-liquid flow regimes and mass transfer in various micro-reactors[J]. Chemical Engineering Journal, 2016, 300: 9-19. |

| 80 | Xie T L, Wang L J, Xu C. Nitric acid removal via mini-extractors[J]. Chemical Engineering and Processing: Process Intensification, 2019, 144: 107637. |

| 81 | Su Y H, Zhao Y C, Chen G W, et al. Liquid-liquid two-phase flow and mass transfer characteristics in packed microchannels[J]. Chemical Engineering Science, 2010, 65(13): 3947-3956. |

| 82 | Du C C, Wang P C, Hu Y P, et al. Liquid-liquid mass transfer enhancement in milliscale packed beds[J]. Industrial & Engineering Chemistry Research, 2020, 59(9): 4048-4057. |

| 83 | Potdar A, Thomassen L C J, Kuhn S. Structured porous millireactors for liquid‐liquid chemical reactions[J]. Chemie Ingenieur Technik, 2019, 91(5): 592-601. |

| 84 | Zhang J S, Wang K, Lin X Y, et al. Intensification of fast exothermic reaction by gas agitation in a microchemical system[J]. AIChE Journal, 2014, 60(7): 2724-2730. |

| 85 | Tan J, Lu Y C, Xu J H, et al. Modeling investigation of mass transfer of gas-liquid-liquid dispersion systems[J]. Separation and Purification Technology, 2013, 108: 111-118. |

| 86 | Feng T F, Tan J, Deng W S, et al. Intensification of high-phase-ratio extraction via microbubble-agitation in gas-liquid-liquid systems[J]. Chemical Engineering Science, 2018, 177: 270-283. |

| 87 | Falk L, Commenge J M. Performance comparison of micromixers[J]. Chemical Engineering Science, 2010, 65(1): 405-411. |

| 88 | Jovanović J, Zhou W, Rebrov E V, et al. Liquid-liquid slug flow: hydrodynamics and pressure drop[J]. Chemical Engineering Science, 2011, 66(1): 42-54. |

| 89 | Eain M M G, Egan V, Howard J, et al. Review and extension of pressure drop models applied to Taylor flow regimes[J]. International Journal of Multiphase Flow, 2015, 68: 1-9. |

| 90 | Qian J Y, Li X J, Wu Z, et al. A comprehensive review on liquid-liquid two-phase flow in microchannel: flow pattern and mass transfer[J]. Microfluidics and Nanofluidics, 2019, 23(10): 116 |

| 91 | Su Y H, Zhao Y C, Jiao F J, et al. The intensification of rapid reactions for multiphase systems in a microchannel reactor by packing microparticles[J]. AIChE Journal, 2011, 57(6): 1409-1418. |

| 92 | Shang M J, Noël T, Wang Q, et al. 2- and 3-Stage temperature ramping for the direct synthesis of adipic acid in micro-flow packed-bed reactors[J]. Chemical Engineering Journal, 2015, 260(Supplement C): 454-462. |

| 93 |

Li G X, Liu S E, Dou X Y, et al. Synthesis of adipic acid through oxidation of K/A oil and its kinetic study in a microreactor system[J]. AIChE Journal, 2020, doi: 10.1002/aic.16289.

DOI |

| 94 | Pu X, Li G X, Song Y, et al. Droplet coalescence phenomena during liquid-liquid heterogeneous reactions in microreactors[J]. Industrial & Engineering Chemistry Research, 2017, 56(43): 12316-12325. |

| 95 | Song Y, Liu S E, Wang B Y, et al. Continuous and controllable preparation of polyaniline with different reaction media in microreactors for supercapacitor applications[J]. Chemical Engineering Science, 2019, 207: 820-828. |

| 96 | Aljbour S, Tagawa T, Yamada H. Ultrasound-assisted capillary microreactor for aqueous-organic multiphase reactions[J]. Journal of Industrial and Engineering Chemistry, 2009, 15(6): 829-834. |

| 97 | John J J, Kuhn S, Braeken L, et al. Ultrasound assisted liquid-liquid extraction in microchannels—a direct contact method[J]. Chemical Engineering and Processing: Process Intensification, 2016, 102(Supplement C): 37-46. |

| 98 | Rahimi M, Jafari O, Mohammdifar A. Intensification of liquid-liquid mass transfer in micromixer assisted by ultrasound irradiation and Fe3O4 nanoparticles[J]. Chemical Engineering and Processing: Process Intensification, 2017, 111: 79-88. |

| 99 | Xia S T, Ding X F, Wang Y J, et al. Large-scale synthesis of dihydrostreptomycin via hydrogenation of streptomycin in a membrane dispersion microreactor[J]. Chemical Engineering Journal, 2018, 334: 2250-2254. |

| 100 | Tan J, Liu Z D, Lu Y C, et al. Process intensification of H2O2 extraction using gas-liquid-liquid microdispersion system[J]. Separation and Purification Technology, 2011, 80(2): 225-234. |

| [1] | 苏伟, 马东旭, 金旭, 刘忠彦, 张小松. 表面润湿性对霜层传递特性影响可视化实验研究[J]. 化工学报, 2023, 74(S1): 122-131. |

| [2] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [3] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [4] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [5] | 葛运通, 王玮, 李楷, 肖帆, 于志鹏, 宫敬. 多相分散体系中微油滴与改性二氧化硅表面间作用力的AFM研究[J]. 化工学报, 2023, 74(4): 1651-1659. |

| [6] | 刘倩, 曹禹, 周琦, 穆景山, 历伟. 孔道结构修饰的Ziegler-Natta催化剂设计与高抗冲低缠结UHMWPE的制备[J]. 化工学报, 2023, 74(3): 1092-1101. |

| [7] | 陈号, 田仪娟, 全学军, 蒋子文, 李纲. 铬铁矿在HCl-HF体系中的分解行为[J]. 化工学报, 2023, 74(3): 1161-1174. |

| [8] | 付家崴, 陈帅帅, 方凯伦, 蒋新. 微反应器共沉淀反应制备铜锰催化剂[J]. 化工学报, 2023, 74(2): 776-783. |

| [9] | 杨星宇, 马优, 朱春英, 付涛涛, 马友光. 梳状并行微通道内液液分布规律研究[J]. 化工学报, 2023, 74(2): 698-706. |

| [10] | 章承浩, 罗京, 张吉松. 微反应器内基于氮氧自由基催化剂连续氧气/空气氧化反应的研究进展[J]. 化工学报, 2023, 74(2): 511-524. |

| [11] | 谢煜, 张民, 胡卫国, 王玉军, 骆广生. 利用膜分散微反应器高效溶解D-7-ACA的研究[J]. 化工学报, 2023, 74(2): 748-755. |

| [12] | 顾仁杰, 张加威, 靳雪阳, 文利雄. 微撞击流反应器制备镍钴复合氢氧化物超级电容器材料及其性能研究[J]. 化工学报, 2022, 73(8): 3749-3757. |

| [13] | 侯跃辉, 刘璇, 廉应江, 韩梅, 尧超群, 陈光文. 超声微反应器内三硝基间苯三酚合成工艺研究[J]. 化工学报, 2022, 73(8): 3597-3607. |

| [14] | 张经纬, 周弋惟, 陈卓, 徐建鸿. 微反应器内的有机合成前沿进展[J]. 化工学报, 2022, 73(8): 3472-3482. |

| [15] | 许非石, 杨丽霞, 陈光文. 超声微反应器内气液传质过程的介尺度强化机制[J]. 化工学报, 2022, 73(6): 2552-2562. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号