化工学报 ›› 2021, Vol. 72 ›› Issue (8): 4030-4038.DOI: 10.11949/0438-1157.20201758

收稿日期:2020-12-07

修回日期:2021-02-27

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

李伯耿

作者简介:赵晶(1991—),女,博士研究生,基金资助:

Jing ZHAO( ),Bogeng LI(

),Bogeng LI( ),Zhiyang BU,Hong FAN

),Zhiyang BU,Hong FAN

Received:2020-12-07

Revised:2021-02-27

Online:2021-08-05

Published:2021-08-05

Contact:

Bogeng LI

摘要:

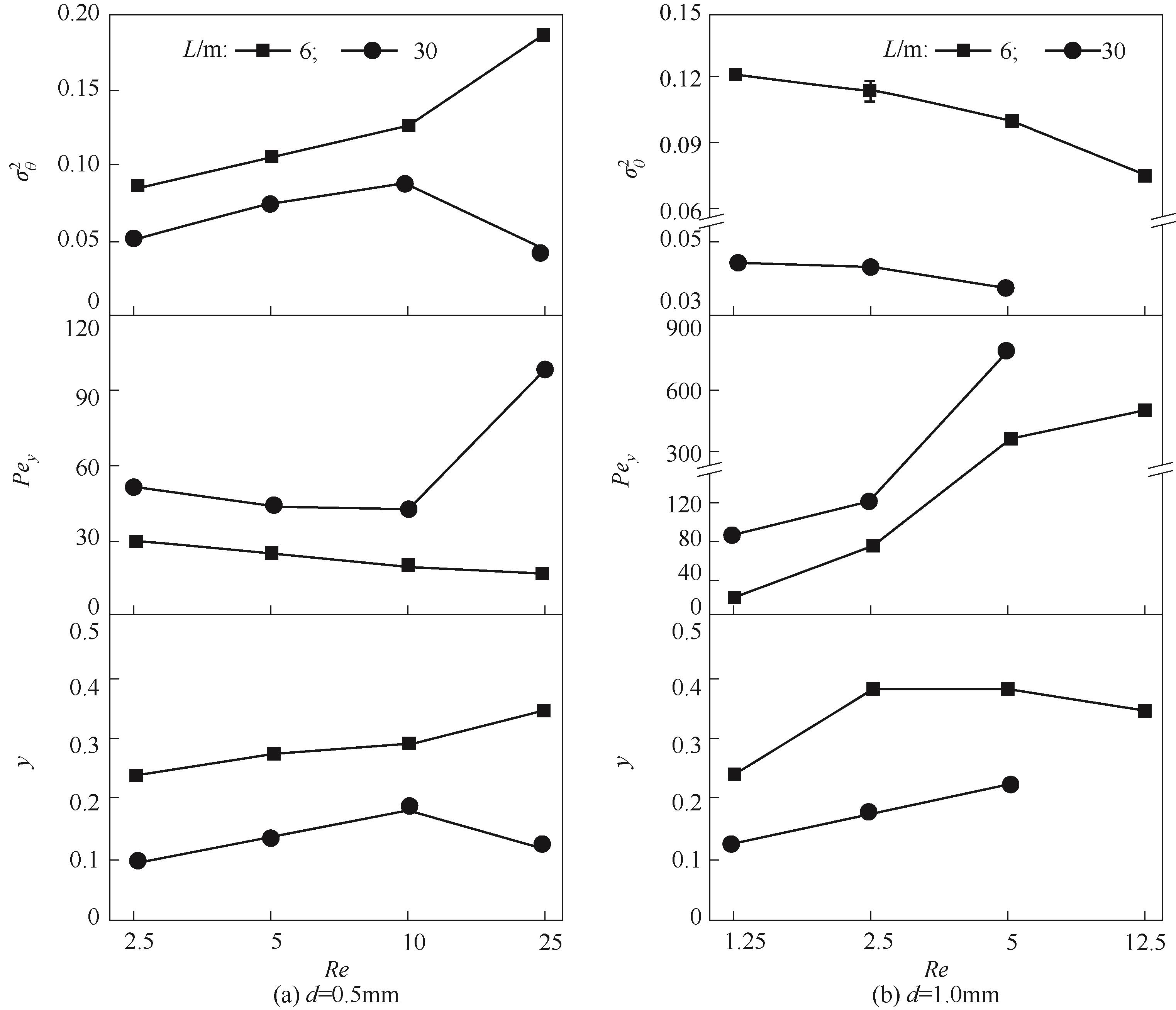

以低分子量的聚丙二醇为流动介质、酸性橙的N,N-二甲基乙酰胺溶液为示踪剂,采用脉冲响应法测定了螺旋型微通道(MC)反应器内的停留时间分布(RTD),验证了平行多釜串联(PTIS)模型与RTD实验数据的匹配性,系统考察了MC长度和Reynolds数(Re)对RTD的影响,并讨论了流体径向速度分布指数y和Peclet数(Pe)的变化规律。结果表明,RTD随MC长度的增加而变窄。当通过降低黏度来增大Re时,RTD随之变窄。当通过增大流速来增大Re时,若管径较大,则RTD随之变窄。但若管径较小且管长不长时,则RTD随Re的增加而变宽;如管长较长,则RTD随Re(或流速)的增加先变宽后变窄,即存在临界Reynolds数(Rec)。RTD的这些变化规律表明,二次流动和径向分子扩散对细小管径的MC的RTD有显著的影响。

中图分类号:

赵晶, 李伯耿, 卜志扬, 范宏. 微通道内低黏聚合物流体的停留时间分布研究[J]. 化工学报, 2021, 72(8): 4030-4038.

Jing ZHAO, Bogeng LI, Zhiyang BU, Hong FAN. Research on residence time distribution of the low-viscous polymer fluid in microchannel[J]. CIESC Journal, 2021, 72(8): 4030-4038.

| 参数 | PTIS-y | PTIS-m |

|---|---|---|

| v | ||

| r | ||

| ?r |

表1 v、vˉ、r以及?r与y(或m)的关系

Table 1 Relationship between v, vˉ, r, ?r and y (or m)

| 参数 | PTIS-y | PTIS-m |

|---|---|---|

| v | ||

| r | ||

| ?r |

| Run | d/mm | L/m | Q/(ml/min) | u/(m/s) | Re | RSSE/% | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| PTIS-y model | PTIS-m model | TIS model | AD model | |||||||

| 1 | 0.5 | 6 | 0.5 | 0.043 | 142 | 2.5 | 1.4 | 3.4 | 3.6 | 7.9 |

| 2 | 0.5 | 6 | 1.0 | 0.085 | 71 | 5 | 2.2 | 2.9 | 6.1 | 11.8 |

| 3 | 0.5 | 6 | 2.0 | 0.170 | 35.5 | 10 | 1.4 | 3.1 | 2.3 | 4.9 |

| 4 | 0.5 | 6 | 5.0 | 0.425 | 14.2 | 25 | 1.2 | 1.9 | 3.7 | 11.1 |

| 5 | 0.5 | 12 | 0.5 | 0.043 | 284 | 2.5 | 0.4 | 6 | 1.1 | 3.7 |

| 6 | 0.5 | 12 | 1.0 | 0.085 | 142 | 5 | 4.2 | 8.3 | 5.8 | 9.9 |

| 7 | 0.5 | 12 | 2.0 | 0.170 | 71 | 10 | 0.8 | 3 | 3.9 | 8.8 |

| 8 | 0.5 | 12 | 5.0 | 0.425 | 28.4 | 25 | 3.6 | 5 | 6.3 | 10 |

| 9 | 0.5 | 30 | 0.5 | 0.043 | 709.4 | 2.5 | 0.3 | 2.7 | 0.8 | 3.2 |

| 10 | 0.5 | 30 | 1.0 | 0.085 | 354.7 | 5 | 1 | 2.3 | 2.1 | 4.9 |

| 11 | 0.5 | 30 | 2.0 | 0.170 | 177.5 | 10 | 2.1 | 4.5 | 4.7 | 7.9 |

| 12 | 0.5 | 30 | 5.0 | 0.425 | 70.9 | 25 | 0.4 | 6.7 | 1.7 | 3.7 |

| 13 | 1.0 | 6 | 0.5 | 0.011 | 567.5 | 1.25 | 0.3 | 5.8 | 0.9 | 2.5 |

| 14 | 1.0 | 6 | 1.0 | 0.021 | 283.7 | 2.5 | 0.8 | 14.7 | 16.1 | 20.5 |

| 15 | 1.0 | 6 | 2.0 | 0.042 | 142 | 5 | 5.7 | 6.8 | 16.2 | 20.2 |

| 16 | 1.0 | 6 | 5.0 | 0.106 | 56.7 | 12.5 | 5.5 | 6.6 | 34.2 | 38.8 |

| 17 | 1.0 | 12 | 0.5 | 0.011 | 1135 | 1.25 | 3.1 | 3.9 | 9.6 | 13.8 |

| 18 | 1.0 | 12 | 1.0 | 0.021 | 567.5 | 2.5 | 2.2 | 3.1 | 11 | 15.6 |

| 19 | 1.0 | 12 | 2.0 | 0.043 | 283.7 | 5 | 3 | 5 | 13.2 | 15.4 |

| 20 | 1.0 | 30 | 0.5 | 0.011 | 2837 | 1.25 | 0.6 | 7.7 | 2.12 | 4.1 |

| 21 | 1.0 | 30 | 1.0 | 0.021 | 1419 | 2.5 | 1.3 | 6.7 | 4.2 | 7.1 |

| 22 | 1.0 | 30 | 2.0 | 0.043 | 709.3 | 5 | 5.4 | 12.6 | 11.7 | 13.3 |

| 23 | 1.0 | 30 | 0.5① | 0.011 | 2837 | 0.5 | 1.4 | 2.6 | 5.7 | 12.6 |

| 24 | 1.0 | 30 | 0.5② | 0.011 | 2837 | 0.21 | 2.4 | 3.3 | 4.8 | 9.1 |

表2 RTD的模型回归结果

Table 2 Comparison of regression results with various RTD models

| Run | d/mm | L/m | Q/(ml/min) | u/(m/s) | Re | RSSE/% | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| PTIS-y model | PTIS-m model | TIS model | AD model | |||||||

| 1 | 0.5 | 6 | 0.5 | 0.043 | 142 | 2.5 | 1.4 | 3.4 | 3.6 | 7.9 |

| 2 | 0.5 | 6 | 1.0 | 0.085 | 71 | 5 | 2.2 | 2.9 | 6.1 | 11.8 |

| 3 | 0.5 | 6 | 2.0 | 0.170 | 35.5 | 10 | 1.4 | 3.1 | 2.3 | 4.9 |

| 4 | 0.5 | 6 | 5.0 | 0.425 | 14.2 | 25 | 1.2 | 1.9 | 3.7 | 11.1 |

| 5 | 0.5 | 12 | 0.5 | 0.043 | 284 | 2.5 | 0.4 | 6 | 1.1 | 3.7 |

| 6 | 0.5 | 12 | 1.0 | 0.085 | 142 | 5 | 4.2 | 8.3 | 5.8 | 9.9 |

| 7 | 0.5 | 12 | 2.0 | 0.170 | 71 | 10 | 0.8 | 3 | 3.9 | 8.8 |

| 8 | 0.5 | 12 | 5.0 | 0.425 | 28.4 | 25 | 3.6 | 5 | 6.3 | 10 |

| 9 | 0.5 | 30 | 0.5 | 0.043 | 709.4 | 2.5 | 0.3 | 2.7 | 0.8 | 3.2 |

| 10 | 0.5 | 30 | 1.0 | 0.085 | 354.7 | 5 | 1 | 2.3 | 2.1 | 4.9 |

| 11 | 0.5 | 30 | 2.0 | 0.170 | 177.5 | 10 | 2.1 | 4.5 | 4.7 | 7.9 |

| 12 | 0.5 | 30 | 5.0 | 0.425 | 70.9 | 25 | 0.4 | 6.7 | 1.7 | 3.7 |

| 13 | 1.0 | 6 | 0.5 | 0.011 | 567.5 | 1.25 | 0.3 | 5.8 | 0.9 | 2.5 |

| 14 | 1.0 | 6 | 1.0 | 0.021 | 283.7 | 2.5 | 0.8 | 14.7 | 16.1 | 20.5 |

| 15 | 1.0 | 6 | 2.0 | 0.042 | 142 | 5 | 5.7 | 6.8 | 16.2 | 20.2 |

| 16 | 1.0 | 6 | 5.0 | 0.106 | 56.7 | 12.5 | 5.5 | 6.6 | 34.2 | 38.8 |

| 17 | 1.0 | 12 | 0.5 | 0.011 | 1135 | 1.25 | 3.1 | 3.9 | 9.6 | 13.8 |

| 18 | 1.0 | 12 | 1.0 | 0.021 | 567.5 | 2.5 | 2.2 | 3.1 | 11 | 15.6 |

| 19 | 1.0 | 12 | 2.0 | 0.043 | 283.7 | 5 | 3 | 5 | 13.2 | 15.4 |

| 20 | 1.0 | 30 | 0.5 | 0.011 | 2837 | 1.25 | 0.6 | 7.7 | 2.12 | 4.1 |

| 21 | 1.0 | 30 | 1.0 | 0.021 | 1419 | 2.5 | 1.3 | 6.7 | 4.2 | 7.1 |

| 22 | 1.0 | 30 | 2.0 | 0.043 | 709.3 | 5 | 5.4 | 12.6 | 11.7 | 13.3 |

| 23 | 1.0 | 30 | 0.5① | 0.011 | 2837 | 0.5 | 1.4 | 2.6 | 5.7 | 12.6 |

| 24 | 1.0 | 30 | 0.5② | 0.011 | 2837 | 0.21 | 2.4 | 3.3 | 4.8 | 9.1 |

图5 流体黏度变化时RTD方差及PTIS-y模型参数随Re变化曲线(T=110℃, d=1 mm, L=30 m, u=0.011 m/s, D=140 mm, μ=8.5~50.3 mPa·s)

Fig.5 Variance of RTD and parameters of PTIS-y model with Re when changing viscosity

图6 流速改变时MC中的RTD方差及PTIS-y模型参数随Re变化曲线(T=110℃, μ=8.5 mPa·s, D=140 mm, u=0.011~0.425 m/s)

Fig.6 Variance of RTD and parameters of PTIS-y model with Re when changing flow rate

| 1 | Biesenberger J A, Sebastian D H. Principles of Polymerization Engineering[M]. New York: Wiley, 1983. |

| 2 | Rojahn P, Hessel V, Nigam K D P, et al. Applicability of the axial dispersion model to coiled flow inverters containing single liquid phase and segmented liquid-liquid flows[J]. Chemical Engineering Science, 2018, 182: 77-92. |

| 3 | Pegoraro P R, Marangoni M, Gut J A W. Residence time distribution models derived from non-ideal laminar velocity profiles in tubes[J]. Chemical Engineering & Technology, 2012, 35(9): 1593-1603. |

| 4 | Fazli-Abukheyli R, Darvishi P. Combination of axial dispersion and velocity profile in parallel tanks-in-series compartment model for prediction of residence time distribution in a wide range of non-ideal laminar flow regimes[J]. Chemical Engineering Science, 2019, 195: 531-540. |

| 5 | Kim I, Byun S H, Ha C S. Ring-opening polymerizations of propylene oxide by double metal cyanide catalysts prepared with ZnX2 (X = F, Cl, Br, or I)[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2005, 43(19): 4393-4404. |

| 6 | Zhao J, Li B G, Bu Z Y, et al. Ring-opening polymerization of propylene oxide by double metal complex in micro-reactor[J]. Macromolecular Reaction Engineering, 2020, 14(1): 1900048. |

| 7 | 赵玉潮, 应盈, 陈光文, 等. T形微混合器内的混合特性[J]. 化工学报, 2006, 57(8): 1884-1890. |

| Zhao Y C, Ying Y, Chen G W, et al. Characterization of micro-mixing in T-shaped micro-mixer[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(8): 1884-1890. | |

| 8 | Adeosun J T, Lawal A. Numerical and experimental studies of mixing characteristics in a T-junction microchannel using residence-time distribution[J]. Chemical Engineering Science, 2009, 64(10): 2422-2432. |

| 9 | Adeosun J T, Lawal A. Residence-time distribution as a measure of mixing in T-junction and multilaminated/elongational flow micromixers[J]. Chemical Engineering Science, 2010, 65(5): 1865-1874. |

| 10 | Rossi D, Gargiulo L, Valitov G, et al. Experimental characterization of axial dispersion in coiled flow inverters[J]. Chemical Engineering Research and Design, 2017, 120: 159-170. |

| 11 | Gobert S R L, Kuhn S, Braeken L, et al. Characterization of milli- and microflow reactors: mixing efficiency and residence time distribution[J]. Organic Process Research & Development, 2017, 21(4): 531-542. |

| 12 | Bošković D, Loebbecke S, Gross G A, et al. Residence time distribution studies in microfluidic mixing structures[J]. Chemical Engineering & Technology, 2011, 34(3): 361-370. |

| 13 | Cantu-Perez A, Barrass S, Gavriilidis A. Residence time distributions in microchannels: comparison between channels with herringbone structures and a rectangular channel[J]. Chemical Engineering Journal, 2010, 160(3): 834-844. |

| 14 | Lohse S, Kohnen B T, Janasek D, et al. A novel method for determining residence time distribution in intricately structured microreactors[J]. Lab on a Chip, 2008, 8(3): 431-438. |

| 15 | Bošković D, Loebbecke S. Modelling of the residence time distribution in micromixers[J]. Chemical Engineering Journal, 2008, 135: S138-S146. |

| 16 | Dong Z Y, Zhao S N, Zhang Y C, et al. Mixing and residence time distribution in ultrasonic microreactors[J]. AIChE Journal, 2017, 63(4): 1404-1418. |

| 17 | Saxena A K, Nigam K D P. Coiled configuration for flow inversion and its effect on residence time distribution[J]. AIChE Journal, 1984, 30(3): 363-368. |

| 18 | Castelain C, Mokrani A, Legentilhomme P, et al. Residence time distribution in twisted pipe flows: helically coiled system and chaotic system[J]. Experiments in Fluids, 1997, 22(5): 359-368. |

| 19 | Castelain C, Berger D, Legentilhomme P, et al. Experimental and numerical characterisation of mixing in a steady spatially chaotic flow by means of residence time distribution measurements[J]. International Journal of Heat and Mass Transfer, 2000, 43(19): 3687-3700. |

| 20 | Zha L, Pu X, Shang M J, et al. A study on the micromixing performance in microreactors for polymer solutions[J]. AIChE Journal, 2018, 64(9): 3479-3490. |

| 21 | Mashelkar R A, Venkatasubramanian C V. Influence of secondary flow on diffusion with reaction[J]. AIChE Journal, 1985, 31(3): 440-449. |

| 22 | Seader J D, Southwick L M. Saponification of ethyl acetate in curved-tube reactors[J]. Chemical Engineering Communications, 1981, 9(1/2/3/4/5/6): 175-183. |

| 23 | Levenspiel O. Chemical Reaction Engineering[M]. New York: Wiley, 1999. |

| 24 | Ham J H, Platzer B. Semi-empirical equations for the residence time distributions in disperse systems (1): Continuous phase[J]. Chemical Engineering & Technology, 2004, 27(11): 1172-1178. |

| 25 | Hessel V. Chemical Micro Process Engineering[M]. Weinheim: Wiley-VCH, 2005. |

| 26 | 朱琳. 微反应器混合特性研究和三水碳酸镁的制备[D]. 大连: 大连理工大学, 2016. |

| Zhu L. Study of mixing characteristics in microreactor and preparation of nesquehonite[D]. Dalian: Dalian University of Technology, 2016. | |

| 27 | Soleymani A, Kolehmainen E, Turunen I. Numerical and experimental investigations of liquid mixing in T-type micromixers[J]. Chemical Engineering Journal, 2008, 135: S219-S228. |

| 28 | Mandal M M, Serra C, Hoarau Y, et al. Numerical modeling of polystyrene synthesis in coiled flow inverter[J]. Microfluidics and Nanofluidics, 2011, 10(2): 415-423. |

| 29 | Trachsel F, Günther A, Khan S, et al. Measurement of residence time distribution in microfluidic systems[J]. Chemical Engineering Science, 2005, 60(21): 5729-5737. |

| 30 | Günther A, Khan S A, Thalmann M, et al. Transport and reaction in microscale segmented gas-liquid flow[J]. Lab on a Chip, 2004, 4(4): 278-286. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [3] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [4] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [5] | 谈莹莹, 刘晓庆, 王林, 黄鲤生, 李修真, 王占伟. R1150/R600a自复叠制冷循环开机动态特性实验研究[J]. 化工学报, 2023, 74(S1): 213-222. |

| [6] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [7] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [8] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [9] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [10] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [11] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [12] | 汪尔奇, 彭书舟, 杨震, 段远源. 含HFO混合体系气液相平衡的理论模型评价[J]. 化工学报, 2023, 74(8): 3216-3225. |

| [13] | 于旭东, 李琪, 陈念粗, 杜理, 任思颖, 曾英. 三元体系KCl + CaCl2 + H2O 298.2、323.2及348.2 K相平衡研究及计算[J]. 化工学报, 2023, 74(8): 3256-3265. |

| [14] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [15] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号