化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5273-5283.DOI: 10.11949/0438-1157.20210574

收稿日期:2021-04-22

修回日期:2021-05-21

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

罗雄麟

作者简介:任超(1998—),男,硕士研究生,基金资助:

Chao REN( ),Lin SUN,Xionglin LUO(

),Lin SUN,Xionglin LUO( )

)

Received:2021-04-22

Revised:2021-05-21

Online:2021-10-05

Published:2021-10-05

Contact:

Xionglin LUO

摘要:

换热器作为化工过程中重要的热量传递设备,一般需要持续运行较长时间,期间由于结垢热阻的不断累积,换热器的换热效率将随时间逐渐下降,直至无法满足工艺要求。在实际的工业换热过程中,工艺人员通常会对换热器进行裕量设计,然而,当换热器需要运行的时间增长或者裕量设计不足时,面对不可避免的结垢增长,常用的流量控制策略在换热器运行末期的调节效果逐渐变差,旁路控制的方案无法实现全周期的持续控制。因此,本文首先在渐近增长模型的基础上建立了换热器结垢累积的积分渐近模型,该模型考虑了过程参数对结垢速率的影响;其次,以一个用于水循环的小面积换热器为例,分析了考虑结垢增长的条件下流量控制和旁路控制的调节效果;最后,针对结垢过程的慢时变和持续性等特点,设计了基于流量与旁路开度的控制系统重构方案。示例的运行结果表明,对于同样面积裕量有限的换热器,这一控制方案能延长其使用寿命,实现其全周期持续可控的目标。

中图分类号:

任超,孙琳,罗雄麟. 换热器因应结垢慢时变的控制系统重构分析[J]. 化工学报, 2021, 72(10): 5273-5283.

Chao REN,Lin SUN,Xionglin LUO. Analysis on the reconfiguration of the control system of the heat exchanger in response to the slow and time-varying fouling[J]. CIESC Journal, 2021, 72(10): 5273-5283.

| 项目 | 壳程(热流) | 管程(冷流) |

|---|---|---|

| 物流名称 | 水 | 水 |

| 流量/(kg·s | 90 | 90 |

| 进口温度/K | 366.49 | 283.15 |

| 出口温度/K | 338.2 | 310.5 |

| 进口压力/kPa | 551.59 | 551.59 |

| 密度/(kg·m | 965.3 | 999.7 |

| 比热容/(J·kg | 4177 | 4187 |

| 黏度/(mPa·s) | 0.355 | 0.9 |

表1 换热器物流数据

Table 1 Flow data of heat exchanger

| 项目 | 壳程(热流) | 管程(冷流) |

|---|---|---|

| 物流名称 | 水 | 水 |

| 流量/(kg·s | 90 | 90 |

| 进口温度/K | 366.49 | 283.15 |

| 出口温度/K | 338.2 | 310.5 |

| 进口压力/kPa | 551.59 | 551.59 |

| 密度/(kg·m | 965.3 | 999.7 |

| 比热容/(J·kg | 4177 | 4187 |

| 黏度/(mPa·s) | 0.355 | 0.9 |

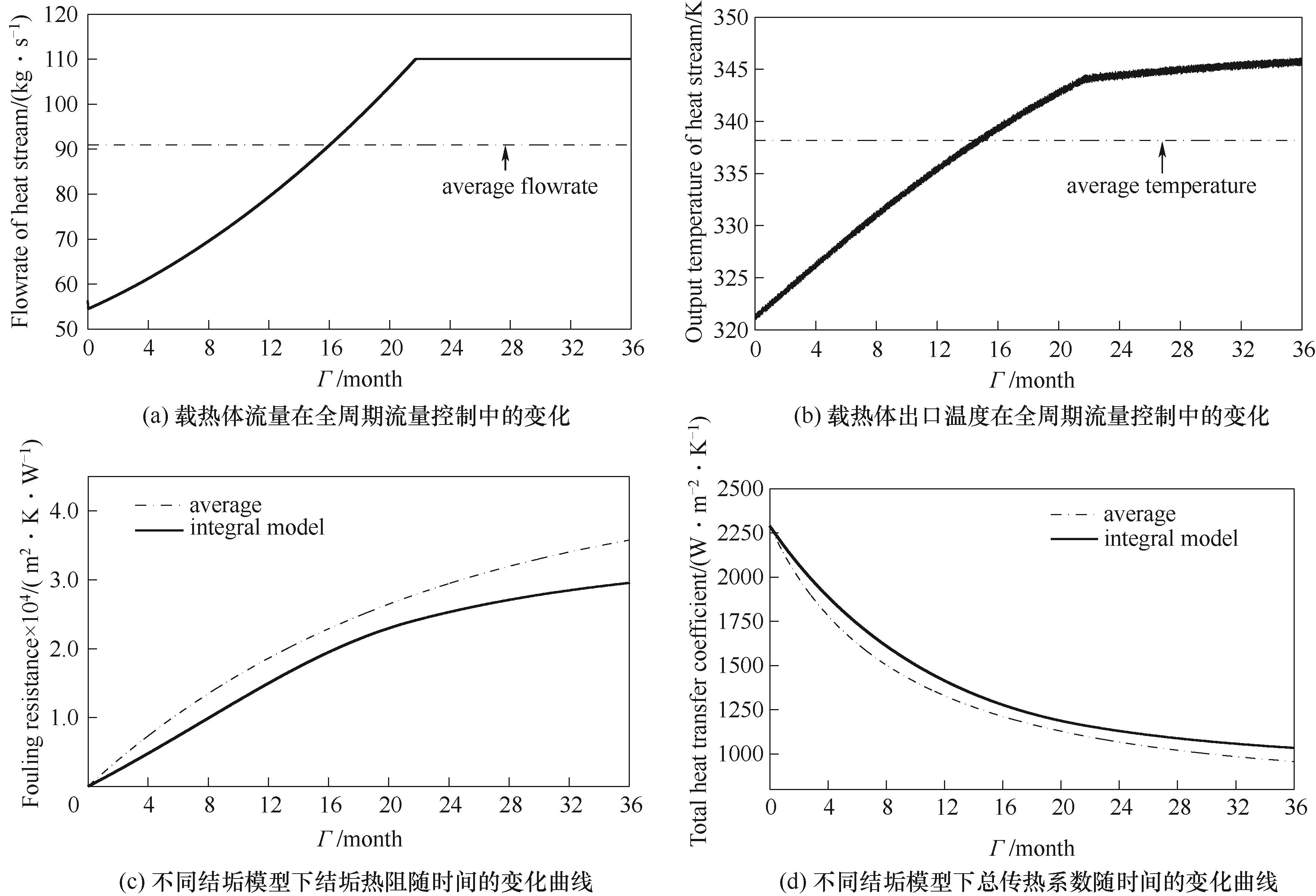

图4 流量控制中不同计算模型下结垢参数的选取及其影响(全周期控制目标为保持冷端出口温度的设定值在310.5 K不变)

Fig.4 Selection and influence of fouling parameters under different calculation models in flow control

| 项目 | 计算值 |

|---|---|

| 壳程传热系数/(W·(m2·K) | 7363.6 |

| 管程传热系数/(W·(m2·K) | 5089.8 |

| 不考虑结垢热阻时的换热器传热系数/(W·(m2·K) | 2288.6 |

| 不考虑结垢热阻和旁路设计时所需的换热面积/ m2 | 80.48 |

| 旁路设计中不考虑结垢热阻时所需的换热面积/ m2 | 96.15 |

| 旁路设计中考虑结垢热阻时所需的换热面积/ m2 | 144.4 |

| 本文选取的换热面积/ m2 | 125 |

| 旁路设计中结垢裕量计算值/% | 50.16 |

| 本文中结垢裕量取值/% | 30 |

表2 换热器面积设计裕量求解结果

Table 2 Results of overdesign area of heat exchanger

| 项目 | 计算值 |

|---|---|

| 壳程传热系数/(W·(m2·K) | 7363.6 |

| 管程传热系数/(W·(m2·K) | 5089.8 |

| 不考虑结垢热阻时的换热器传热系数/(W·(m2·K) | 2288.6 |

| 不考虑结垢热阻和旁路设计时所需的换热面积/ m2 | 80.48 |

| 旁路设计中不考虑结垢热阻时所需的换热面积/ m2 | 96.15 |

| 旁路设计中考虑结垢热阻时所需的换热面积/ m2 | 144.4 |

| 本文选取的换热面积/ m2 | 125 |

| 旁路设计中结垢裕量计算值/% | 50.16 |

| 本文中结垢裕量取值/% | 30 |

| 方案 | 旁路开度剩余量/% |

|---|---|

| 控制方案 1 | 10.8 |

| 控制方案 2 | 0.0 |

| 控制方案 3 | 17.0 |

表3 三种控制方案中旁路开度的剩余量

Table 3 The residual value of the bypass opening in the three control schemes

| 方案 | 旁路开度剩余量/% |

|---|---|

| 控制方案 1 | 10.8 |

| 控制方案 2 | 0.0 |

| 控制方案 3 | 17.0 |

| 14 | 罗雄麟, 孙琳, 张俊峰. 换热网络旁路优化设计[J]. 化工学报, 2008, 59(3): 646-652. |

| Luo X L, Sun L, Zhang J F. Optimal design of bypass location on heat exchanger networks[J]. Journal of Chemical Industry and Engineering(China), 2008, 59(3): 646-652. | |

| 15 | Xu F, Luo X L, Wang R. Design margin and control performance analysis of a fluid catalytic cracking unit regenerator under model predictive control[J]. Industrial & Engineering Chemistry Research, 2014, 53(37): 14339-14350. |

| 16 | 朱真, 孙琳, 罗雄麟. 基于持续节能的多周期换热网络优化设计[J]. 化工学报, 2016, 67(12): 5176-5182. |

| Zhu Z, Sun L, Luo X L. Design optimization of multi-period heat exchanger networks based on continuous energy saving[J]. CIESC Journal, 2016, 67(12): 5176-5182. | |

| 17 | Sun L, Zha X L, Luo X L. Coordination between bypass control and economic optimization for heat exchanger network[J]. Energy, 2018, 160: 318-329. |

| 18 | Mhaskar P, Gani A, Christofides P D. Fault-tolerant control of nonlinear processes: performance-based reconfiguration and robustness[J]. International Journal of Robust and Nonlinear Control, 2006, 16(3): 91-111. |

| 19 | Lakshminarayanan S, Emoto G, Ebara S, et al. Closed loop identification and control loop reconfiguration: an industrial case study[J]. Journal of Process Control, 2001, 11(5): 587-599. |

| 20 | Gopinathan M, Mehra R K, Runkle J C. Hot isostatic pressing furnaces[J]. IEEE Control Systems Magazine, 2000, 20(6): 67-82. |

| 21 | Luo X L, Xia C K, Sun L. Margin design, online optimization, and control approach of a heat exchanger network with bypasses[J]. Computers & Chemical Engineering, 2013, 53: 102-121. |

| 22 | 孙琳, 杨明达, 罗雄麟. 基于持续节能的换热网络缓释优化[J]. 化工进展, 2020, 39(10): 3941-3948. |

| Sun L, Yang M D, Luo X L. Slow-release optimization of heat exchange networks based on sustainable energy saving[J]. Chemical Industry and Engineering Progress, 2020, 39(10): 3941-3948. | |

| 23 | Hasson D, Avriel M, Resnick W, et al. Mechanism of calcium carbonate scale deposition on heat-transfer surfaces[J]. Industrial& Engineering Chemistry Fundamentals, 1968, 7(1): 59-65. |

| 24 | Abuhalima O, Sun L, Chang R X, et al. Synthesis of a multipass heat exchanger network based on life cycle energy saving[J]. Applied Thermal Engineering, 2016, 100: 1189-1197. |

| 1 | Chen Q, Wang M R, Pan N, et al. Optimization principles for convective heat transfer[J]. Energy, 2009, 34(9): 1199-1206. |

| 2 | 蒋立本, 冯霄, 丁生华, 等. 受网络夹点控制的装置的改造分析[J]. 高校化学工程学报, 2001, 15(2): 161-166. |

| 25 | Zubair S M, Sheikh A K, Shaik M N. A probabilistic approach to the maintenance of heat-transfer equipment subject to fouling[J]. Energy, 1992, 17(8): 769-776. |

| 26 | 石油化学工业部石油化工规划设计院. 冷换设备工艺计算[M]. 北京: 石油工业出版社, 1979: 21-25. |

| Petrochemical Planning & Design Institute. Heat Exchanger Technical Calculation[M]. Beijing: Petroleum Industry Press, 1979: 21-25. | |

| 27 | Lugo-Granados H, Picon N M. Modelling scaling growth in heat transfer surfaces and its application on the design of heat exchangers[J]. Energy, 2018, 160: 845-854. |

| 2 | Jiang L B, Feng X, Ding S H, et al. Analysis of retrofitting the process controlled by network pinch[J]. Journal of Chemical Engineering of Chinese Universities, 2001, 15(2): 161-166. |

| 3 | Zheng K, Lou H H, Wang J, et al. A method for flexible heat exchanger network design under severe operation uncertainty[J]. Chemical Engineering & Technology, 2013, 36(5): 757-765. |

| 28 | 高明, 孙奉仲, 黄新元, 等. 换热器结垢工况下换热系数变化的分析研究[J]. 能源工程, 2003(4): 9-13. |

| Gao M, Shun F Z, Huang X Y, et al. Variation of heat transfer coefficient and its mathematic model for heat exchangers in conditions of fouling[J]. Energy Engineering, 2003(4): 9-13. | |

| 4 | 王传芳, 罗雄麟. 控制裕量及其在管壳式换热器设计中的应用[J]. 炼油技术与工程, 2004, 34(2): 21-25. |

| Wang C F, Luo X L. Overdesign for control and its application in tube-shell heat exchanger design[J]. Petroleum Refinery Engineering, 2004, 34(2): 21-25. | |

| 29 | 刘公召, 臧淑艳, 陈尔霆. 渣油换热器结垢热阻的预测模型研究[J]. 化学工程, 2002, 30(5): 25-28, 2. |

| Liu G Z, Zang S Y, Chen E T. Study on prediction model of fouling resistance in residuum heat exchangers[J]. Chemical Engineering (China), 2002, 30(5): 25-28, 2. | |

| 5 | Wang L K, Sundén B. Detailed simulation of heat exchanger networks for flexibility consideration[J]. Applied Thermal Engineering, 2001, 21(12): 1175-1184. |

| 6 | 俞巧心, 崔国民, 张佳仁. 基于一阶滞后传递函数的换热器模型预测控制[J]. 化学工程, 2012, 40(5): 66-69. |

| 30 | Uztürk D, Akman U. Centralized and decentralized control of retrofit heat-exchanger networks[J]. Computers & Chemical Engineering, 1997, 21: S373-S378. |

| 6 | Yu Q X, Cui G M, Zhang J R. Model predictive control of heat exchanger based on first order lag transfer function[J]. Chemical Engineering (China), 2012, 40(5): 66-69. |

| 7 | Bakošová M, Oravec J. Robust model predictive control for heat exchanger network[J]. Applied Thermal Engineering, 2014, 73(1): 924-930. |

| 8 | Mathisen K W, Skogestad S, Wolff E A. Bypass selection for control of heat exchanger networks[J]. Computers & Chemical Engineering, 1992, 16: S263-S272. |

| 9 | Glemmestad B, Mathisen K W, Gundersen T. Optimal operation of heat exchanger networks based on structural information[J]. Computers& Chemical Engineering, 1996, 20: S823-S828. |

| 10 | 侯本权, 孙琳, 罗雄麟. 基于结构可控性分析的换热网络旁路优化设计[J]. 化工学报, 2011, 62(5): 1326-1338. |

| Hou B Q, Sun L, Luo X L. Optimal design of bypass location on heat exchanger networks based on structural controllability[J]. CIESC Journal, 2011, 62(5): 1326-1338. | |

| 11 | Luyben W L. Heat-exchanger bypass control[J]. Industrial & Engineering Chemistry Research, 2011, 50(2): 965-973. |

| 12 | Delatore F, Novazzi L F, Leonardi F, et al. Multivariable optimal control of a heat exchanger network with bypasses[J]. Brazilian Journal of Chemical Engineering, 2016, 33(1): 133-143. |

| 13 | 孙琳, 迟进浩, 罗雄麟. 换热器设计裕量与旁路设计分析[J]. 计算机与应用化学, 2008, 25(11): 1369-1373. |

| Sun L, Chi J H, Luo X L. The analysis of the overdesign and the bypass design for the heat exchanger[J]. Computers and Applied Chemistry, 2008, 25(11): 1369-1373. |

| [1] | 张龙, 宋孟杰, 邵苛苛, 张旋, 沈俊, 高润淼, 甄泽康, 江正勇. 管翅式换热器迎风侧翅片末端霜层生长模拟研究[J]. 化工学报, 2023, 74(S1): 179-182. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 邹启宏, 李乾, 葛天舒. 基于多目标下的两级并联除湿热泵系统实验研究[J]. 化工学报, 2023, 74(S1): 265-271. |

| [4] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [5] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [6] | 康飞, 吕伟光, 巨锋, 孙峙. 废锂离子电池放电路径与评价研究[J]. 化工学报, 2023, 74(9): 3903-3911. |

| [7] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [8] | 李贵贤, 曹阿波, 孟文亮, 王东亮, 杨勇, 周怀荣. 耦合固体氧化物电解槽的CO2制甲醇过程设计与评价研究[J]. 化工学报, 2023, 74(7): 2999-3009. |

| [9] | 邵远哲, 赵忠盖, 刘飞. 基于共同趋势模型的非平稳过程质量相关故障检测方法[J]. 化工学报, 2023, 74(6): 2522-2537. |

| [10] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| [11] | 贠程, 王倩琳, 陈锋, 张鑫, 窦站, 颜廷俊. 基于社团结构的化工过程风险演化路径深度挖掘[J]. 化工学报, 2023, 74(4): 1639-1650. |

| [12] | 张中秋, 李宏光, 石逸林. 基于人工预测调控策略的复杂化工过程多任务学习方法[J]. 化工学报, 2023, 74(3): 1195-1204. |

| [13] | 张江淮, 赵众. 碳三加氢装置鲁棒最小协方差约束控制及应用[J]. 化工学报, 2023, 74(3): 1216-1227. |

| [14] | 王子宗, 索寒生, 赵学良. 数字孪生智能乙烯工厂研究与构建[J]. 化工学报, 2023, 74(3): 1175-1186. |

| [15] | 潘煜, 王子航, 王佳韵, 王如竹, 张华. 基于可得然-氯化锂复合吸附剂的除湿换热器热湿性能研究[J]. 化工学报, 2023, 74(3): 1352-1359. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号