化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5206-5217.DOI: 10.11949/0438-1157.20210416

收稿日期:2021-03-24

修回日期:2021-07-08

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

张书平,熊源泉

作者简介:苏银海(1990—),男,博士,讲师,基金资助:

Yinhai SU1( ),Shuping ZHANG2(

),Shuping ZHANG2( ),Lingqin LIU1,Yuanquan XIONG3(

),Lingqin LIU1,Yuanquan XIONG3( )

)

Received:2021-03-24

Revised:2021-07-08

Online:2021-10-05

Published:2021-10-05

Contact:

Shuping ZHANG,Yuanquan XIONG

摘要:

苯酚和合成气均为工业生产中重要的基础化工原料。以自制的活性炭为催化剂,以纤维素为原料实现了催化热解液相产物中苯酚和气相产物中CO的同时富集。实验发现,生物质灰分中的钾、热解过程中催化剂/纤维素质量比和热解温度均对气液相产物的品质有着不同程度的影响。研究表明:钾的存在不利于热解产物品质的提高。钾虽然提高了生物油中苯酚的富集度,但降低了实际产率。而热解气中CO的浓度和产率均下降。对催化热解条件的研究表明热解温度450℃,催化剂比例为1∶1时可获得最佳的热解产物。此时,生物油中酚类物质占可检测有机物相对含量的62.31%,其中苯酚为45.37%,产率为1.78%(质量)。热解气中CO的浓度和产率分别为69.21%(体积)和 169.95 ml/g,热值为12.93 MJ/m3。

中图分类号:

苏银海,张书平,刘凌沁,熊源泉. 活性炭催化热解纤维素协同制备酚类和合成气[J]. 化工学报, 2021, 72(10): 5206-5217.

Yinhai SU,Shuping ZHANG,Lingqin LIU,Yuanquan XIONG. Synergetic production of phenols and syngas from the catalytic pyrolysis of cellulose on activated carbon[J]. CIESC Journal, 2021, 72(10): 5206-5217.

| 样品 | 工业分析/(%(质量), 干燥基) | 元素分析/(%(质量), 干燥无灰基) | 热值/(MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 灰分 | 挥发分 | 固定碳 | C | H | O | N | O/C | H/C | ||

| 纤维素 | 0.03±0.01 | 94.08±0.18 | 5.89±0.19 | 43.07±0.24 | 6.47±0.09 | 50.46±0.33 | — | 0.87±0.001 | 1.80±0.008 | 17.433±0.536 |

| 杨木粉 | 0.38±0.05 | 85.51±0.21 | 14.11±0.26 | 50.98±0.32 | 6.08±0.27 | 42.80±0.64 | 0.14±0.05 | 0.63±0.009 | 1.43±0.038 | 17.811±0.389 |

表1 纤维素和杨木粉的燃料特性分析

Table 1 Fuel characteristics analysis of cellulose and poplar wood

| 样品 | 工业分析/(%(质量), 干燥基) | 元素分析/(%(质量), 干燥无灰基) | 热值/(MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 灰分 | 挥发分 | 固定碳 | C | H | O | N | O/C | H/C | ||

| 纤维素 | 0.03±0.01 | 94.08±0.18 | 5.89±0.19 | 43.07±0.24 | 6.47±0.09 | 50.46±0.33 | — | 0.87±0.001 | 1.80±0.008 | 17.433±0.536 |

| 杨木粉 | 0.38±0.05 | 85.51±0.21 | 14.11±0.26 | 50.98±0.32 | 6.08±0.27 | 42.80±0.64 | 0.14±0.05 | 0.63±0.009 | 1.43±0.038 | 17.811±0.389 |

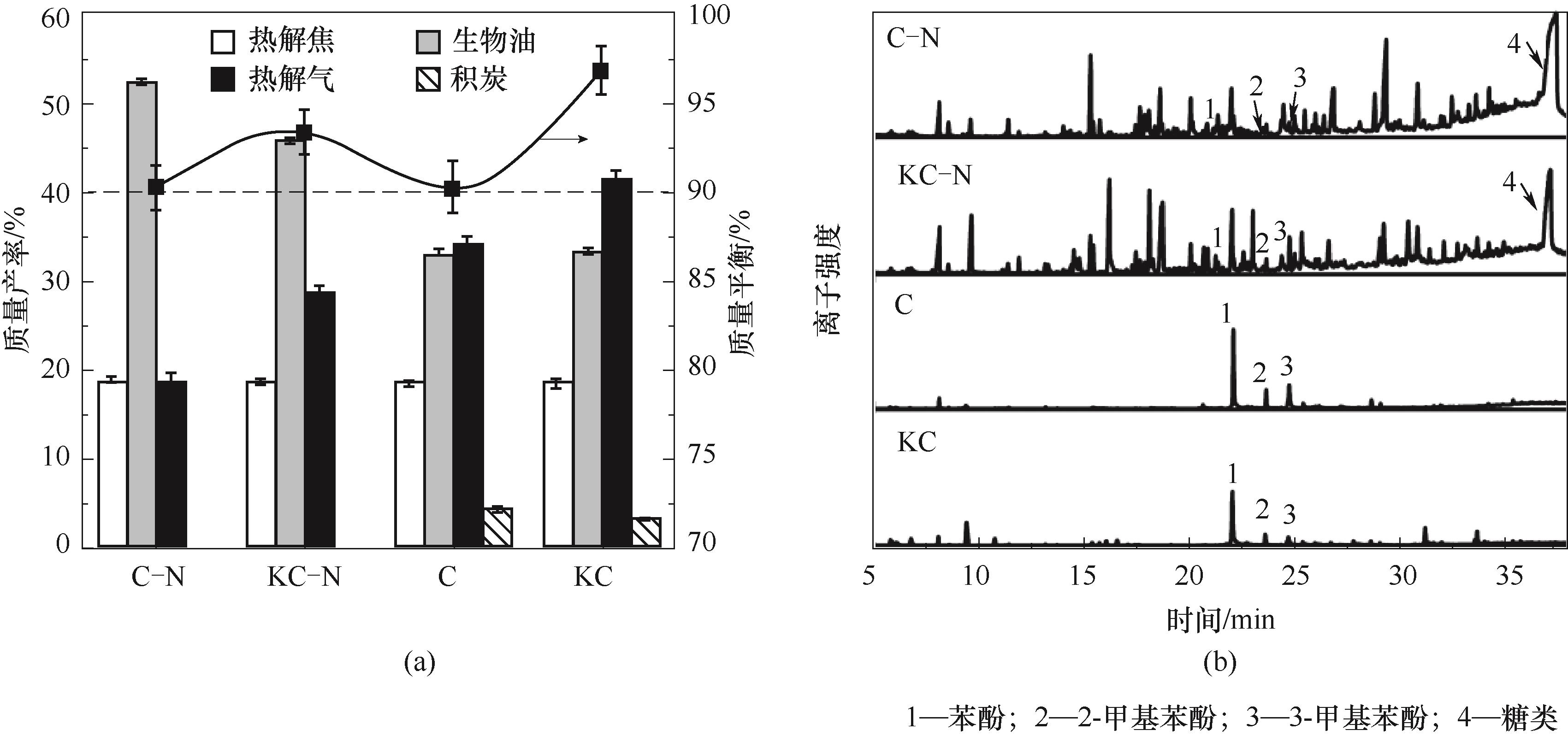

图3 钾对纤维素催化热解产物质量分布的影响(a)及典型离子色谱图(b)

Fig.3 Effects of potassium on mass distribution of catalytic pyrolysis products from cellulose(a) and typical ion chromatograms (b)

| 1 | Schmidt R J. Industrial catalytic processes—phenol production[J]. Applied Catalysis A: General, 2005, 280(1): 89-103. |

| 2 | Zhou Y, Wang Y P, Fan L L, et al. Fast microwave-assisted catalytic co-pyrolysis of straw stalk and soapstock for bio-oil production[J]. Journal of Analytical and Applied Pyrolysis, 2017, 124: 35-41. |

| 3 | 姜小祥. 基于组分分离的松木残渣生物油品质提升与老化预测模型研究[D]. 南京: 东南大学, 2011. |

| Jiang X X. Study on quality improvement and aging prediction model of bio-oil from pine residues based on component separation [D]. Nanjing: Southeast University, 2011. | |

| 4 | 李德彬. 生物质催化热解产酚及其生物油中酚类物质的络合提取与配位反应机理的研究[D]. 厦门: 厦门大学, 2017. |

| Li D B. Catalytic pyrolysis of biomass for the production of phenolic compounds and complexation precipitation extraction of phenols from bio-oil with the study of complexation reaction mechanism [D]. Xiamen: Xiamen University,2017. | |

| 5 | Wang S R, Ru B, Lin H Z, et al. Pyrolysis behaviors of four lignin polymers isolated from the same pine wood[J]. Bioresource Technology, 2015, 182: 120-127. |

| 6 | Duan D L, Lei H W, Wang Y P, et al. Renewable phenol production from lignin with acid pretreatment and ex-situ catalytic pyrolysis[J]. Journal of Cleaner Production, 2019, 231: 331-340. |

| 7 | Zheng A Q, Zhao Z L, Chang S, et al. Maximum synergistic effect in the coupling conversion of bio-derived furans and methanol over ZSM-5 for enhancing aromatic production[J]. Green Chemistry, 2014, 16(5): 2580-2586. |

| 8 | Yi L L, Liu H, Xiao K X, et al. In situ upgrading of bio-oil via CaO catalyst derived from organic precursors[J]. Proceedings of the Combustion Institute, 2019, 37(3): 3119-3126. |

| 9 | Mamaeva A, Tahmasebi A, Yu J L. The effects of mineral salt catalysts on selectivity of phenolic compounds in bio-oil during microwave pyrolysis of peanut shell[J]. Korean Journal of Chemical Engineering, 2017, 34(3): 672-680. |

| 10 | Peng C N, Zhang G Y, Yue J, et al. Pyrolysis of lignin for phenols with alkaline additive[J]. Fuel Processing Technology, 2014, 124: 212-221. |

| 11 | Xu L J, Zhong Q Q, Dong Q, et al. Co-production of phenolic oil and CaO/char deoxidation catalyst via catalytic fast pyrolysis of phenol-formaldehyde resin with Ca(OH)2[J]. Journal of Analytical and Applied Pyrolysis, 2019, 142: 104663. |

| 12 | Lu Q, Zhang Z B, Yang X C, et al. Catalytic fast pyrolysis of biomass impregnated with K3PO4 to produce phenolic compounds: analytical Py-GC/MS study[J]. Journal of Analytical and Applied Pyrolysis, 2013, 104: 139-145. |

| 13 | Lu Q, Zhang Z X, Wang X, et al. Catalytic fast pyrolysis of biomass impregnated with potassium phosphate in a hydrogen atmosphere for the production of phenol and activated carbon[J]. Frontiers in Chemistry, 2018, 6:32. |

| 14 | Bu Q, Lei H W, Wang L, et al. Bio-based phenols and fuel production from catalytic microwave pyrolysis of lignin by activated carbons[J]. Bioresource Technology, 2014, 162: 142-147. |

| 15 | Yang Z X, Lei H W, Qian K Z, et al. Renewable bio-phenols from in situ and ex situ catalytic pyrolysis of Douglas fir pellet over biobased activated carbons[J]. Sustainable Energy & Fuels, 2018, 2(4): 894-904. |

| 16 | Bu Q, Lei H W, Wang L, et al. Renewable phenols production by catalytic microwave pyrolysis of Douglas fir sawdust pellets with activated carbon catalysts[J]. Bioresource Technology, 2013, 142: 546-552. |

| 17 | Su Y H, Xu D, Liu L Q, et al. Simultaneous catalytic conversion of acid-pretreated biomass into high-quality syngas and bio-oil at mild temperature[J]. Energy & Fuels, 2020, 34(7): 8366-8375. |

| 18 | Yang H P, Yan R, Chen H P, et al. Characteristics of hemicellulose, cellulose and lignin pyrolysis[J]. Fuel, 2007, 86(12/13): 1781-1788. |

| 19 | Zhang Y Y, Lei H W, Yang Z X, et al. From glucose-based carbohydrates to phenol-rich bio-oils integrated with syngas production via catalytic pyrolysis over an activated carbon catalyst[J]. Green Chemistry, 2018, 20(14): 3346-3358. |

| 20 | Su Y H, Zhang S P, Liu L Q, et al. Combination of acid washing and torrefaction on co-production of syngas and phenoli-riched bio-oil via low-temperature catalytic pyrolysis[J]. Energy, 2020, 210: 118633. |

| 21 | Liu G C, Liao Y F, Wu Y T, et al. Synthesis gas production from microalgae gasification in the presence of Fe2O3 oxygen carrier and CaO additive[J]. Applied Energy, 2018, 212: 955-965. |

| 22 | Zhang Y Y, Lei H W, Yang Z X, et al. Renewable high-purity mono-phenol production from catalytic microwave-induced pyrolysis of cellulose over biomass-derived activated carbon catalyst[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(4): 5349-5357. |

| 23 | Chen X, Chen Y Q, Chen Z, et al. Catalytic fast pyrolysis of cellulose to produce furan compounds with SAPO type catalysts[J]. Journal of Analytical and Applied Pyrolysis, 2018, 129: 53-60. |

| 24 | Xie Y H, Su Y H, Wang P, et al. In-situ catalytic conversion of tar from biomass gasification over carbon nanofibers- supported Fe-Ni bimetallic catalysts[J]. Fuel Processing Technology, 2018, 182: 77-87. |

| 25 | Gargiulo V, Giudicianni P, Alfè M, et al. About the influence of doping approach on the alkali metal catalyzed slow pyrolysis of xylan[J]. Journal of Chemistry, 2019, 2019: 1-11. |

| 26 | Cen K H, Cao X B, Chen D Y, et al. Leaching of alkali and alkaline earth metallic species (AAEMs) with phenolic substances in bio-oil and its effect on pyrolysis characteristics of moso bamboo[J]. Fuel Processing Technology, 2020, 200: 106332. |

| 27 | Su Y H, Liu L Q, Zhang S P, et al. A green route for pyrolysis poly-generation of typical high ash biomass, rice husk: effects on simultaneous production of carbonic oxide-rich syngas, phenol-abundant bio-oil, high-adsorption porous carbon and amorphous silicon dioxide[J]. Bioresource Technology, 2020, 295: 122243. |

| 28 | Lin Y C, Cho J, Tompsett G A, et al. Kinetics and mechanism of cellulose pyrolysis[J]. The Journal of Physical Chemistry C, 2009, 113(46): 20097-20107. |

| 29 | Wang K G, Kim K H, Brown R C. Catalytic pyrolysis of individual components of lignocellulosic biomass[J]. Green Chemistry, 2014, 16(2): 727-735. |

| 30 | Von Ballmoos R, Meier W M. Oxygen-18 exchange between zeolite ZSM-5 and water[J]. The Journal of Physical Chemistry, 1982, 86(14): 2698-2700. |

| 31 | Mukarakate C, Mcbrayer J D, Evans T J, et al. Catalytic fast pyrolysis of biomass: the reactions of water and aromatic intermediates produces phenols[J]. Green Chemistry, 2015, 17(8): 4217-4227. |

| 32 | Zhang H Y, Ma Y N, Shao S S, et al. The effects of potassium on distributions of bio-oils obtained from fast pyrolysis of agricultural and forest biomass in a fluidized bed[J]. Applied Energy, 2017, 208: 867-877. |

| 33 | Saddawi A, Jones J M, Williams A. Influence of alkali metals on the kinetics of the thermal decomposition of biomass[J]. Fuel Processing Technology, 2012, 104: 189-197. |

| 34 | Mahadevan R, Adhikari S, Shakya R, et al. Effect of alkali and alkaline earth metals on in-situ catalytic fast pyrolysis of lignocellulosic biomass: a microreactor study[J]. Energy & Fuels, 2016, 30(4): 3045-3056. |

| [1] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [2] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [3] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [4] | 吕龙义, 及文博, 韩沐达, 李伟光, 高文芳, 刘晓阳, 孙丽, 王鹏飞, 任芝军, 张光明. 铁基导电材料强化厌氧去除卤代有机污染物:研究进展及未来展望[J]. 化工学报, 2023, 74(8): 3193-3202. |

| [5] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [6] | 屈园浩, 邓文义, 谢晓丹, 苏亚欣. 活性炭/石墨辅助污泥电渗脱水研究[J]. 化工学报, 2023, 74(7): 3038-3050. |

| [7] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [8] | 董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295. |

| [9] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [10] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [11] | 包嘉靖, 别洪飞, 王子威, 肖睿, 刘冬, 吴石亮. 正庚烷对冲扩散火焰中添加长链醚类对碳烟前体生成特性的影响[J]. 化工学报, 2023, 74(4): 1680-1692. |

| [12] | 刘海芹, 李博文, 凌喆, 刘亮, 俞娟, 范一民, 勇强. 羟基-炔点击化学改性半乳甘露聚糖薄膜的制备及性能研究[J]. 化工学报, 2023, 74(3): 1370-1378. |

| [13] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [14] | 祖凌鑫, 胡荣庭, 李鑫, 陈余道, 陈广林. 木质生物质化学组分的碳释放产物特征和反硝化利用程度[J]. 化工学报, 2023, 74(3): 1332-1342. |

| [15] | 郑杰元, 张先伟, 万金涛, 范宏. 丁香酚环氧有机硅树脂的制备及其固化动力学研究[J]. 化工学报, 2023, 74(2): 924-932. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号