化工学报 ›› 2022, Vol. 73 ›› Issue (5): 2270-2278.DOI: 10.11949/0438-1157.20211800

李梦雨1( ),王冬祥2,郑晓阳3,徐桂转2,杜朝军4,常春1(

),王冬祥2,郑晓阳3,徐桂转2,杜朝军4,常春1( )

)

收稿日期:2021-12-22

修回日期:2022-02-16

出版日期:2022-05-05

发布日期:2022-05-24

通讯作者:

常春

作者简介:李梦雨(1996—),女,硕士研究生,基金资助:

Mengyu LI1( ),Dongxiang WANG2,Xiaoyang ZHENG3,Guizhuan XU2,Chaojun DU4,Chun CHANG1(

),Dongxiang WANG2,Xiaoyang ZHENG3,Guizhuan XU2,Chaojun DU4,Chun CHANG1( )

)

Received:2021-12-22

Revised:2022-02-16

Online:2022-05-05

Published:2022-05-24

Contact:

Chun CHANG

摘要:

以生物质基粗甘油为主要原料,采用一锅法合成粗甘油基多元醇,进一步发泡制备了聚氨酯泡沫材料。在此基础上,利用甲基三氯硅烷对泡沫材料进行疏水改性,制备出改性聚氨酯吸油材料。采用傅里叶红外光谱仪、扫描电镜和热重分析对改性前后泡沫的结构形貌、热稳定性和接触角进行表征,测试了改性聚氨酯吸油材料吸油性能。结果表明:经疏水改性后在泡沫表面合成了聚硅氧烷,水接触角由130°增大至140°,提高了吸油材料疏水性能。改性聚氨酯吸油材料对乙醇、甲醇、氯仿等8种有机物的吸附量范围为16.7~45.2 g/g。经循环使用50次后,吸油材料对柴油和大豆油的吸附量分别为最高吸附量的95.8%和97.6%,表现出优异的吸油性能。

中图分类号:

李梦雨, 王冬祥, 郑晓阳, 徐桂转, 杜朝军, 常春. 粗甘油生物基聚氨酯材料的制备及吸附性能研究[J]. 化工学报, 2022, 73(5): 2270-2278.

Mengyu LI, Dongxiang WANG, Xiaoyang ZHENG, Guizhuan XU, Chaojun DU, Chun CHANG. Preparation and adsorption properties of crude glycerol bio-based polyurethane material[J]. CIESC Journal, 2022, 73(5): 2270-2278.

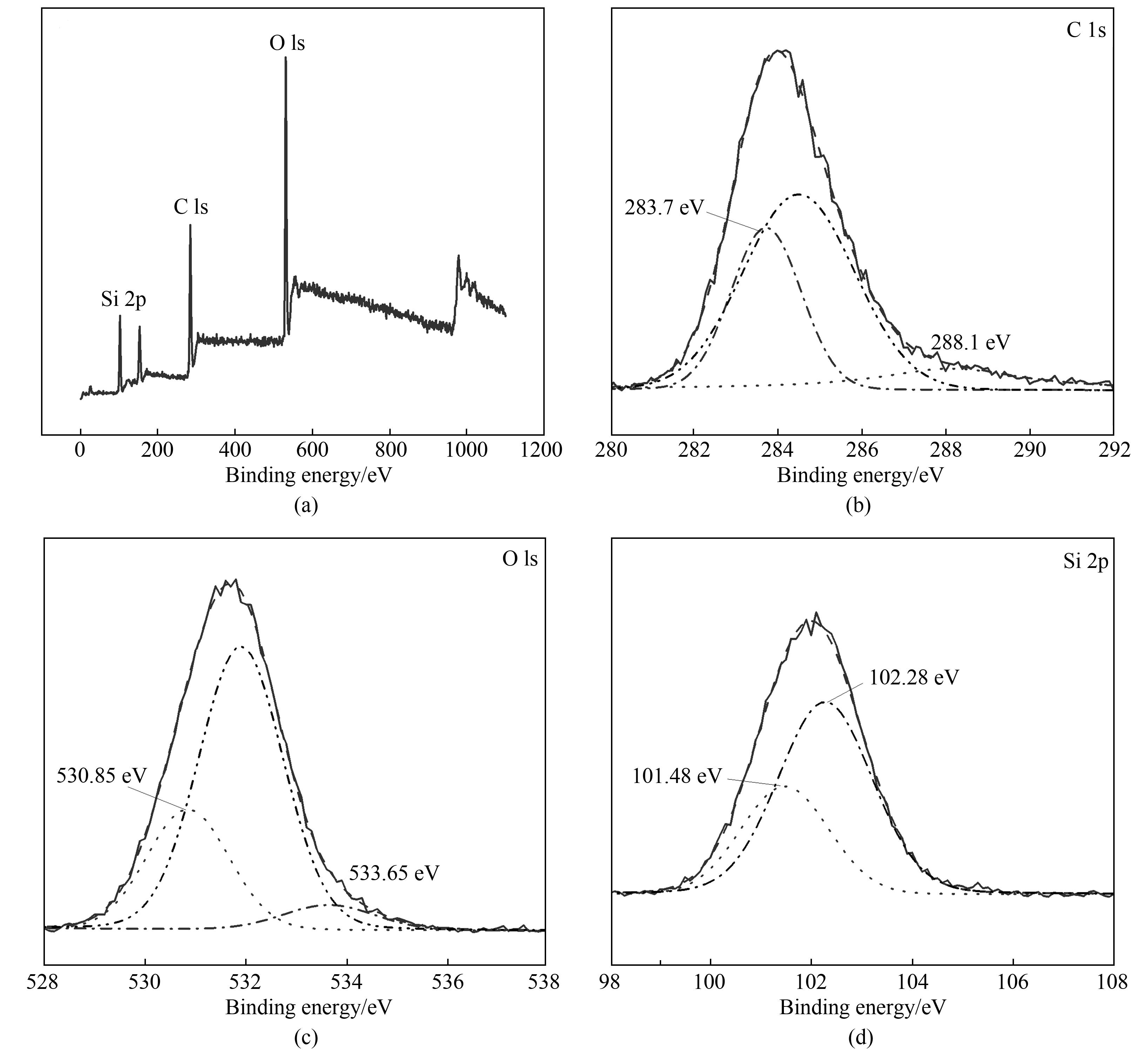

图4 PU-MTS表面的XPS谱图:(a) 全谱图;(b) C 1s谱图;(c) O 1s谱图;(d) Si 2p谱图

Fig.4 XPS spectra for the surface of PU-MTS: (a) survey spectrum;(b) C1s spectra;(c) O1s spectra;(d) Si 2p spectra

| 样品 | T5%/℃ | T50%/℃ | Tmax/℃ | 残炭率/% |

|---|---|---|---|---|

| PU-25 | 265 | 399 | 389 | 7.03 |

| PU-MTS | 260 | 400 | 403 | 9.06 |

表1 PU-25和PU-MTS的TG分析

Table 1 TG analysis of PU-25 and PU-MTS

| 样品 | T5%/℃ | T50%/℃ | Tmax/℃ | 残炭率/% |

|---|---|---|---|---|

| PU-25 | 265 | 399 | 389 | 7.03 |

| PU-MTS | 260 | 400 | 403 | 9.06 |

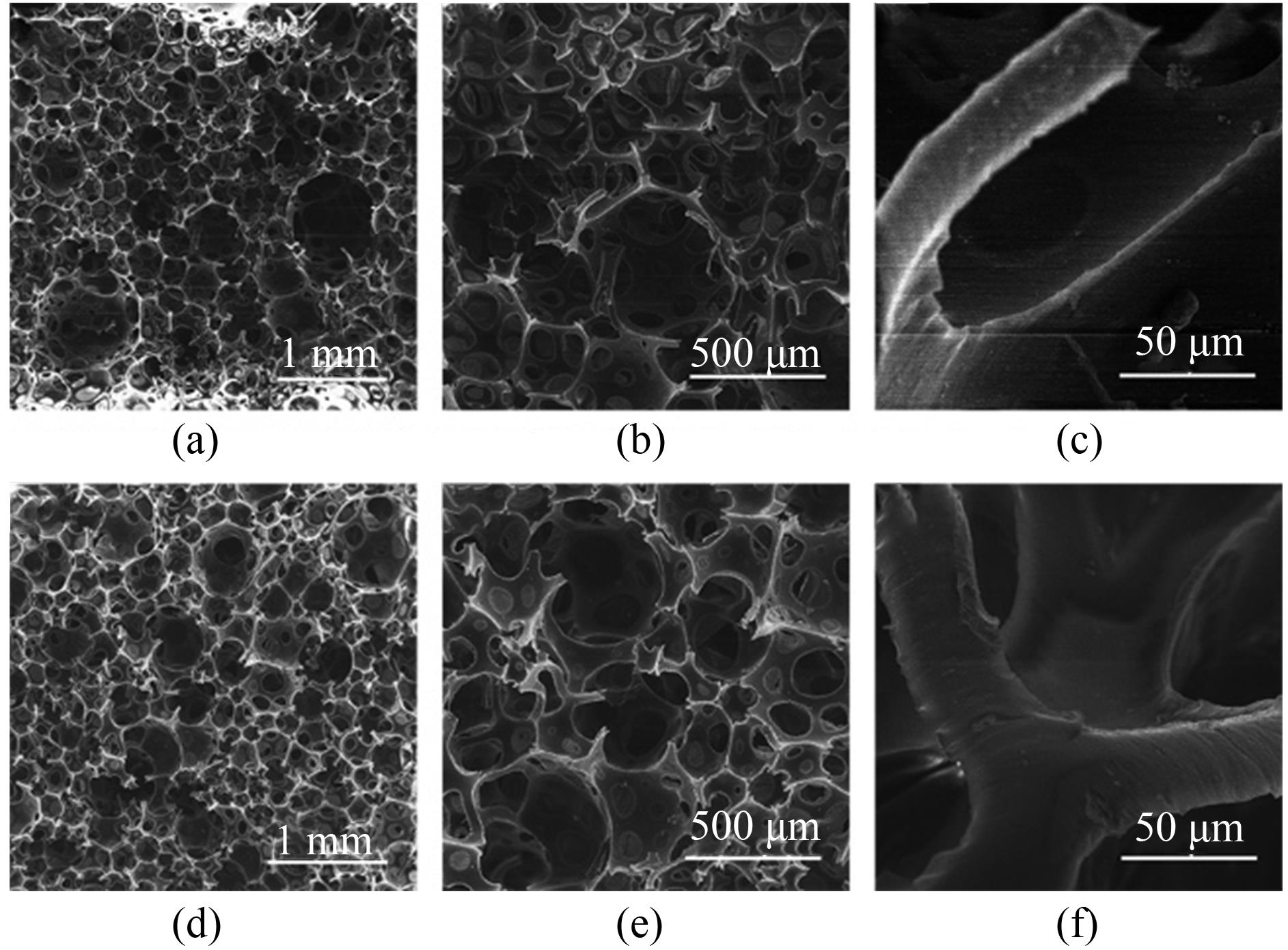

图6 PU-25和PU-MTS扫描电镜图:(a)~(c) PU-25在不同放大倍数下的SEM图;(d)~(f) PU-MTS在不同放大倍数下的SEM图(d)—(f) SEM images of PU-MTS at different magnifications

Fig.6 SEM images of PU-25 and PU-MTS: (a)—(c) SEM images of PU-25 at different magnification;

| 溶剂 | PU-25吸附量/ (g/g) | PU-MTS吸附量/ (g/g) | 提高比例/% |

|---|---|---|---|

| 乙醇 | 15.1 | 16.7 | 10.60 |

| 甲醇 | 14.7 | 18.7 | 27.21 |

| 氯仿 | 40.9 | 45.2 | 10.51 |

| 二氯甲烷 | 43.7 | 44.9 | 2.75 |

| 丙酮 | 18.0 | 23.7 | 31.67 |

| 甲苯 | 19.2 | 24.3 | 26.56 |

| 大豆油 | 9.0 | 16.9 | 87.78 |

| 柴油 | 11.2 | 18.1 | 61.61 |

| 煤油 | 12.0 | 19.1 | 59.17 |

表2 PU-25和PU-MTS的吸附性能对比

Table 2 Comparison of adsorption properties between PU-25 and PU-MTS

| 溶剂 | PU-25吸附量/ (g/g) | PU-MTS吸附量/ (g/g) | 提高比例/% |

|---|---|---|---|

| 乙醇 | 15.1 | 16.7 | 10.60 |

| 甲醇 | 14.7 | 18.7 | 27.21 |

| 氯仿 | 40.9 | 45.2 | 10.51 |

| 二氯甲烷 | 43.7 | 44.9 | 2.75 |

| 丙酮 | 18.0 | 23.7 | 31.67 |

| 甲苯 | 19.2 | 24.3 | 26.56 |

| 大豆油 | 9.0 | 16.9 | 87.78 |

| 柴油 | 11.2 | 18.1 | 61.61 |

| 煤油 | 12.0 | 19.1 | 59.17 |

图8 PU-MTS吸附去除水中有机物(苏丹红Ⅲ染色):(a)~(c)氯仿;(d)~(f)甲苯

Fig.8 Adsorptive removal of organics (dyed by Sudan Ⅲ) from water by PU-MTS: (a)—(c) chloroform; (d)—(f) toluene

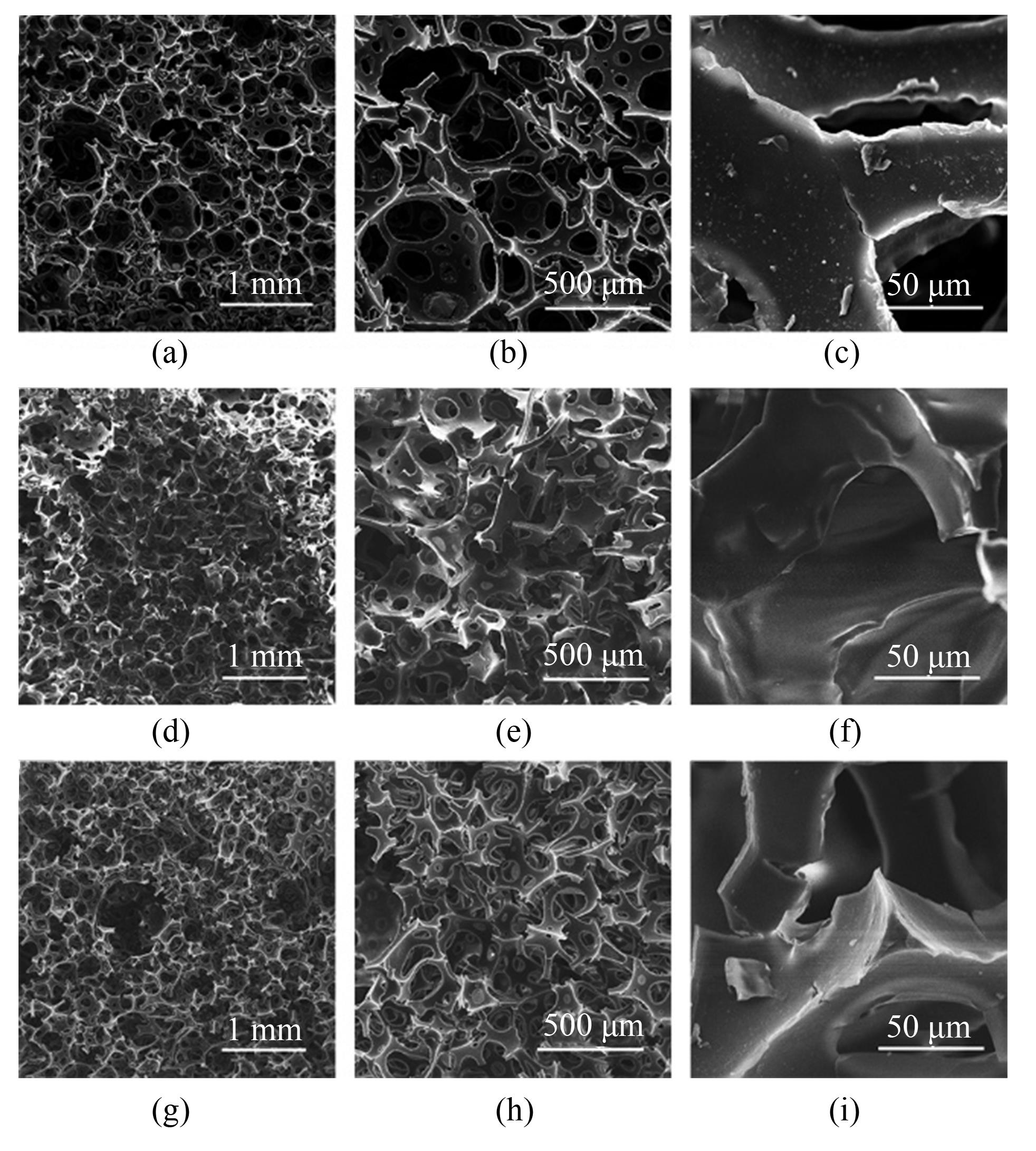

图11 PU-MTS循环吸附后扫描电镜图:(a)~(c)循环10次后PU-MTS在不同放大倍数下的SEM图;(d)~(f)循环30次后PU-MTS在不同放大倍数下的SEM图;(g)~(i)循环50次后PU-MTS在不同放大倍数下的SEM图

Fig.11 SEM images of PU-MTS after cyclic adsorption: (a)—(c) SEM images of PU-MTS at different magnification after 10 cycles; (d)—(f) SEM images of PU-MTS at different magnifications after 30 cycles; (g)—(i) SEM images of PU-MTS at different magnifications after 50 cycles

| 改性试剂 | 水接触角/(°) | 吸附溶剂 | 吸附性能/ (g/g) | 文献 |

|---|---|---|---|---|

| KH-570处理过的氧化石墨烯分散液 | 161 | 大豆油、柴油、泵油 | 35~39 | [ |

| 甲基三氯硅烷-正己烷 | 157 | 润滑油、豆油、汽油、原油、正辛烷、十二烷、癸烷 | 15~25 | [ |

| 纤维素纳米晶须的石墨烯悬浮液 | 152 | 丙酮、乙醇、乙二醇、橄榄油、大豆油、润滑油、甲苯 | 28~47 | [ |

| 凹凸棒石和十八烷基三氯硅烷 | 160 | 氯仿、正己烷、石油醚、柴油、甲苯、煤油、菜籽油 | 17~45 | [ |

| 碳纳米纤维的乙醇分散液 | 146 | 正己烷、庚烷、甲苯、二甲苯、汽油 | 26~50 | [ |

| 甲基三氯硅烷-正己烷 | 140 | 乙醇、甲醇、 丙酮、氯仿、二氯甲烷、甲苯、柴油、煤油、大豆油 | 16.67~45.15 | 本研究 |

表3 不同改性泡沫吸附性能对比

Table.3 Comparison of adsorption properties of different modified foams

| 改性试剂 | 水接触角/(°) | 吸附溶剂 | 吸附性能/ (g/g) | 文献 |

|---|---|---|---|---|

| KH-570处理过的氧化石墨烯分散液 | 161 | 大豆油、柴油、泵油 | 35~39 | [ |

| 甲基三氯硅烷-正己烷 | 157 | 润滑油、豆油、汽油、原油、正辛烷、十二烷、癸烷 | 15~25 | [ |

| 纤维素纳米晶须的石墨烯悬浮液 | 152 | 丙酮、乙醇、乙二醇、橄榄油、大豆油、润滑油、甲苯 | 28~47 | [ |

| 凹凸棒石和十八烷基三氯硅烷 | 160 | 氯仿、正己烷、石油醚、柴油、甲苯、煤油、菜籽油 | 17~45 | [ |

| 碳纳米纤维的乙醇分散液 | 146 | 正己烷、庚烷、甲苯、二甲苯、汽油 | 26~50 | [ |

| 甲基三氯硅烷-正己烷 | 140 | 乙醇、甲醇、 丙酮、氯仿、二氯甲烷、甲苯、柴油、煤油、大豆油 | 16.67~45.15 | 本研究 |

| 1 | Hadji E M, Fu B, Abebe A, et al. Sponge-based materials for oil spill cleanups: a review[J]. Frontiers of Chemical Science and Engineering, 2020, 14(5): 749-762. |

| 2 | Zhang T, Li Z D, Lü Y F, et al. Recent progress and future prospects of oil-absorbing materials[J]. Chinese Journal of Chemical Engineering, 2019, 27(6): 1282-1295. |

| 3 | Wang X X, Peng G T, Chen M M, et al. Reduced graphene oxide composites and its real-life application potential for in-situ crude oil removal[J]. Chemosphere, 2020, 249: 126141. |

| 4 | Kong D P, He X, Khan F, et al. Small scale experiment study on burning characteristics for in-situ burning of crude oil on open water[J]. Journal of Loss Prevention in the Process Industries, 2019, 60: 46-52. |

| 5 | Hohl L, Knossalla M, Kraume M. Influence of dispersion conditions on phase separation in liquid multiphase systems[J]. Chemical Engineering Science, 2017, 171: 76-87. |

| 6 | Pourrezaei P, Drzewicz P, Wang Y N, et al. The impact of metallic coagulants on the removal of organic compounds from oil sands process-affected water[J]. Environmental Science & Technology, 2011, 45(19): 8452-8459. |

| 7 | Shi Y, Li S W, Zhang H Q, et al. Experimental studies on performances of flexible floating oil booms in coupled wave-current flow[J]. Applied Ocean Research, 2017, 69: 38-52. |

| 8 | Vieira A F, José R P R, Maria V G, et al. Development of hydrophobic polyurethane/castor oil biocomposites with agroindustrial residues for sorption of oils and organic solvents[J]. Journal of Colloid and Interface Science, 2021, 581: 442-454. |

| 9 | Luo Q, Hou D Y, Jiang D W, et al. Bioremediation of marine oil spills by immobilized oil-degrading bacteria and nutrition emulsion[J]. Biodegradation, 2021, 32(2): 165-177. |

| 10 | 孔令通. 聚丙烯酸酯类吸油树脂的合成及其在含油废水处理中的应用[D]. 北京: 北京化工大学, 2019. |

| Kong L T. Synthesis of polyacrylate oil-absorption resin and its application in the treatment process of oily wastewater[D]. Beijing: Beijing University of Chemical Technology, 2019. | |

| 11 | 张书美. 新型三维多孔吸油材料的制备及其在油水分离中的应用[D]. 济南: 山东大学, 2020. |

| Zhang S M. Preparation of a novel three-dimensional porous oil-absorbing material and its application in oil-water separation[D]. Jinan: Shandong University, 2020. | |

| 12 | Anonymous. US chemical profile: glycerine[J]. ICIS Chemical Business, 2020, 298(2): 97. |

| 13 | Qi X G, Zhang Y S, Chang C, et al. Thermal, mechanical, and morphological properties of rigid crude glycerol-based polyurethane foams reinforced with nanoclay and microcrystalline cellulose[J]. European Journal of Lipid Science and Technology, 2018, 120(5): 1700413. |

| 14 | Kosmela P, Hejna A, Formela K, et al. The study on application of biopolyols obtained by cellulose biomass liquefaction performed with crude glycerol for the synthesis of rigid polyurethane foams[J]. Journal of Polymers and the Environment, 2018, 26(6): 2546-2554. |

| 15 | Chang C, Liu L W, Li P, et al. Preparation of flame retardant polyurethane foam from crude glycerol based liquefaction of wheat straw[J]. Industrial Crops and Products, 2021, 160: 113098. |

| 16 | 戚小各, 何玉远, 常春, 等. 基于生物柴油副产物粗甘油的聚氨酯硬泡的制备[J]. 聚氨酯工业, 2018, 33(1): 27-30. |

| Qi X G, He Y Y, Chang C, et al. Preparation of bio-based polyurethane foam based on crude glycerol from biodiesel[J]. Polyurethane Industry, 2018, 33(1): 27-30. | |

| 17 | 刘利威, 常春, 戚小各, 等. 粗甘油生物基聚氨酯泡沫的改性研究[J]. 高校化学工程学报, 2019, 33(2): 469-474. |

| Liu L W, Chang C, Qi X G, et al. Modification of crude glycerol bio-based polyurethane foams[J]. Journal of Chemical Engineering of Chinese Universities, 2019, 33(2): 469-474. | |

| 18 | Zhao S J, Yin L, Zhou Q Q, et al. In situ self-assembly of zeolitic imidazolate frameworks on the surface of flexible polyurethane foam: towards for highly efficient oil spill cleanup and fire safety[J]. Applied Surface Science, 2020, 506: 144700. |

| 19 | 余若冰, 江莹. 超疏水泡沫吸油材料的制备及性能研究[J]. 信阳师范学院学报(自然科学版), 2019, 32(4): 621-625. |

| Yu R B, Jiang Y. The preparation and property of superhydrophobic foam for oil absorption[J]. Journal of Xinyang Normal University(Natural Science Edition), 2019, 32(4): 621-625. | |

| 20 | Sun R Y, Yu N K, Zhao J, et al. Chemically stable superhydrophobic polyurethane sponge coated with ZnO/epoxy resin coating for effective oil/water separation[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 611: 125850. |

| 21 | 吴文浩, 张海军, 贾全利. 疏水亲油材料研究进展[J]. 稀有金属材料与工程, 2021, 50(4): 1471-1481. |

| Wu W H, Zhang H J, Jia Q L. Progress in hydrophobic-oleophilic materials[J]. Rare Metal Materials and Engineering, 2021, 50(4): 1471-1481. | |

| 22 | Baig N, Alghunaimi F I, Dossary H S, et al. Superhydrophobic and superoleophilic carbon nanofiber grafted polyurethane for oil-water separation[J]. Process Safety and Environmental Protection, 2019, 123: 327-334. |

| 23 | Xiong S, Zhong Z X, Wang Y. Direct silanization of polyurethane foams for efficient selective absorption of oil from water[J]. AIChE Journal, 2017, 63(6): 2232-2240. |

| 24 | Pan Y, Zhan J, Pan H F, et al. A facile method to fabricate superoleophilic and hydrophobic polyurethane foam for oil-water separation[J]. Materials Letters, 2015, 159: 345-348. |

| 25 | Verdolotti L, Lavorgna M, Lamanna R, et al. Polyurethane-silica hybrid foam by sol-gel approach: chemical and functional properties[J]. Polymer, 2015, 56: 20-28. |

| 26 | 程千会, 刘长松, 刘盛友. 超疏水聚硅氧烷/聚氨酯海绵的制备及其油水分离特性的研究[J]. 材料研究与应用, 2017, 11(4): 230-235. |

| Cheng Q H, Liu C S, Liu S Y. Fabrication of superhydrophobic polysiloxane/polyurethane sponge and its oil-water separation[J]. Materials Research and Application, 2017, 11(4): 230-235. | |

| 27 | Shirgholami M A, Shateri-Khalilabad M, Yazdanshenas M E. Effect of reaction duration in the formation of superhydrophobic polymethylsilsesquioxane nanostructures on cotton fabric[J]. Textile Research Journal, 2013, 83(1): 100-110. |

| 28 | 祝青. 超疏水聚氨酯(PU)海绵的制备及油水分离特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. |

| Zhu Q. Fabrication and oil-water separation performance of superhydrophobic polyurethane (PU) sponges[D]. Harbin: Harbin Institute of Technology, 2014. | |

| 29 | Zhang B, Liu H, Han J. RETRACTED: aluminum phosphate microcapsule flame retardants for flexible polyurethane foams[J]. Journal of Physics and Chemistry of Solids, 2018, 115: 199-207. |

| 30 | Fang Z, Qiu C H, Ji D, et al. Development of high-performance biodegradable rigid polyurethane foams using full modified soy-based polyols[J]. Journal of Agricultural and Food Chemistry, 2019, 67(8): 2220-2226. |

| 31 | Zhu Q, Chu Y, Wang Z K, et al. Robust superhydrophobic polyurethane sponge as a highly reusable oil-absorption material[J]. Journal of Materials Chemistry A, 2013, 1(17): 5386-5393. |

| 32 | Li B B, Liu X Y, Zhang X Y, et al. Oil-absorbent polyurethane sponge coated with KH-570-modified graphene[J]. Journal of Applied Polymer Science, 2015, 132(16): 41821. |

| 33 | Zhang X T, Liu D Y, Ma Y L, et al. Super-hydrophobic graphene coated polyurethane (GN@PU) sponge with great oil-water separation performance[J]. Applied Surface Science, 2017, 422: 116-124. |

| 34 | Li J, Xu C C, Zhang Y, et al. Robust superhydrophobic attapulgite coated polyurethane sponge for efficient immiscible oil/water mixture and emulsion separation[J]. Journal of Materials Chemistry A, 2016, 4(40): 15546-15553. |

| [1] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [2] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [3] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [4] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| [5] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [6] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [7] | 邢美波, 张中天, 景栋梁, 张洪发. 磁调控水基碳纳米管协同多孔材料强化相变储/释能特性[J]. 化工学报, 2023, 74(7): 3093-3102. |

| [8] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [9] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [10] | 董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295. |

| [11] | 崔张宁, 胡紫璇, 吴雷, 周军, 叶干, 刘田田, 张秋利, 宋永辉. 可降解纤维素基材料的耐水性能研究进展[J]. 化工学报, 2023, 74(6): 2296-2307. |

| [12] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| [13] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [14] | 陈韶云, 徐东, 陈龙, 张禹, 张远方, 尤庆亮, 胡成龙, 陈建. 单层聚苯胺微球阵列结构的制备及其吸附性能[J]. 化工学报, 2023, 74(5): 2228-2238. |

| [15] | 代佳琳, 毕唯东, 雍玉梅, 陈文强, 莫晗旸, 孙兵, 杨超. 热物性对混合型CPCMs固液相变特性影响模拟研究[J]. 化工学报, 2023, 74(5): 1914-1927. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号