化工学报 ›› 2022, Vol. 73 ›› Issue (9): 4173-4186.DOI: 10.11949/0438-1157.20220689

收稿日期:2022-05-13

修回日期:2022-06-20

出版日期:2022-09-05

发布日期:2022-10-09

通讯作者:

张军营,程珏

作者简介:刘佳宁(1996—),女,硕士研究生,Jianing_liu96@163.com

Jianing LIU( ), Jiahao MA, Junying ZHANG(

), Jiahao MA, Junying ZHANG( ), Jue CHENG(

), Jue CHENG( )

)

Received:2022-05-13

Revised:2022-06-20

Online:2022-09-05

Published:2022-10-09

Contact:

Junying ZHANG, Jue CHENG

摘要:

在常温下,叔胺催化的巯基-丙烯酸酯和巯基-环氧反应活性的差异明显,具有可控顺序固化特征。以四(3-巯基丙酸)季戊四醇酯(SH4)、对苯二甲醇二缩水甘油醚(BOB)或2,5-呋喃二甲醇二缩水甘油醚(BOF)、1,4-环己烷二甲醇二丙烯酸酯(CHDMDA)构建了硫醇-丙烯酸酯-环氧顺序双重热固化体系,并研究氢键对体系固化过程及性能的影响。采用FTIR、流变分析、DSC、DMA、万能材料试验机和硬度仪表征了一重固化后的中间态材料和二重固化后的终态材料的热性能、流变性能、力学性能及常温适用期。结果表明,氢键的存在会延缓双重固化反应的进行,提高终态材料的力学性能。此外,此顺序双重热固化体系所产生的两阶段材料流变性能、热性能和力学性能可调控,中间态材料可在室温24 h保持性能稳定。可控顺序双重固化赋予热固性聚合物方便的复杂形状加工成型、高性能于一身,以及更广泛的应用范围,如形状记忆致动器和压敏胶膜,突破了热固性塑料在形状设计与加工上的局限性。

中图分类号:

刘佳宁, 马嘉浩, 张军营, 程珏. 顺序双重热固化的硫醇-丙烯酸酯-环氧树脂三维网络的构建及性能[J]. 化工学报, 2022, 73(9): 4173-4186.

Jianing LIU, Jiahao MA, Junying ZHANG, Jue CHENG. Construction and properties of sequential dual thermal curing thiol-acrylate-epoxy 3D network[J]. CIESC Journal, 2022, 73(9): 4173-4186.

| Sample | racrylate | SH4/% | Epoxy/% | Acrylate/% |

|---|---|---|---|---|

| S4BOB-A00 | 0 | 47.80 | 52.20 | 0 |

| S4BOB-A02 | 0.2 | 48.07 | 42.00 | 9.93 |

| S4BOB-A04 | 0.4 | 48.35 | 31.68 | 19.97 |

| S4BOB-A06 | 0.6 | 48.63 | 21.24 | 25.03 |

| S4BOB-A08 | 0.8 | 48.91 | 10.68 | 30.13 |

| S4BOF-A00 | 0 | 47.61 | 52.39 | 40.41 |

| S4BOF-A02 | 0.2 | 47.92 | 42.19 | 0 |

| S4BOF-A04 | 0.4 | 48.23 | 31.85 | 9.90 |

| S4BOF-A06 | 0.6 | 48.55 | 21.37 | 19.92 |

| S4BOF-A08 | 0.8 | 48.87 | 10.76 | 30.08 |

| S4A10 | 1 | 49.20 | 0 | 40.37 |

表1 硫醇-丙烯酸酯-环氧树脂三维网络的配方组成

Table 1 Formulations of thiol-acrylate-epoxy 3D networks

| Sample | racrylate | SH4/% | Epoxy/% | Acrylate/% |

|---|---|---|---|---|

| S4BOB-A00 | 0 | 47.80 | 52.20 | 0 |

| S4BOB-A02 | 0.2 | 48.07 | 42.00 | 9.93 |

| S4BOB-A04 | 0.4 | 48.35 | 31.68 | 19.97 |

| S4BOB-A06 | 0.6 | 48.63 | 21.24 | 25.03 |

| S4BOB-A08 | 0.8 | 48.91 | 10.68 | 30.13 |

| S4BOF-A00 | 0 | 47.61 | 52.39 | 40.41 |

| S4BOF-A02 | 0.2 | 47.92 | 42.19 | 0 |

| S4BOF-A04 | 0.4 | 48.23 | 31.85 | 9.90 |

| S4BOF-A06 | 0.6 | 48.55 | 21.37 | 19.92 |

| S4BOF-A08 | 0.8 | 48.87 | 10.76 | 30.08 |

| S4A10 | 1 | 49.20 | 0 | 40.37 |

| Sample | racrylate | G'/Pa | G"/Pa | Gel point/min |

|---|---|---|---|---|

| S4BOB-A02 | 0.2 | 1.40×10-3 | 3.00 | >150.0 |

| S4BOB-A04 | 0.4 | 2.21×105 | 7.19×102 | 25.5 |

| S4BOB-A06 | 0.6 | 1.18×106 | 6.68×103 | 16.0 |

| S4BOB-A08 | 0.8 | 1.76×106 | 1.99×104 | 13.0 |

| S4BOF-A02 | 0.2 | 2.94×10-4 | 6.00 | >150.0 |

| S4BOF-A04 | 0.4 | 6.10×104 | 9.81×103 | 29.0 |

| S4BOF-A06 | 0.6 | 7.70×105 | 7.95×103 | 19.0 |

| S4BOF-A08 | 0.8 | 1.54×106 | 5.05×104 | 17.0 |

表2 S4BOB和S4BOF体系第一固化阶段的流变性能

Table 2 Rheological properties of S4BOB and S4BOF systems in the first curing stage

| Sample | racrylate | G'/Pa | G"/Pa | Gel point/min |

|---|---|---|---|---|

| S4BOB-A02 | 0.2 | 1.40×10-3 | 3.00 | >150.0 |

| S4BOB-A04 | 0.4 | 2.21×105 | 7.19×102 | 25.5 |

| S4BOB-A06 | 0.6 | 1.18×106 | 6.68×103 | 16.0 |

| S4BOB-A08 | 0.8 | 1.76×106 | 1.99×104 | 13.0 |

| S4BOF-A02 | 0.2 | 2.94×10-4 | 6.00 | >150.0 |

| S4BOF-A04 | 0.4 | 6.10×104 | 9.81×103 | 29.0 |

| S4BOF-A06 | 0.6 | 7.70×105 | 7.95×103 | 19.0 |

| S4BOF-A08 | 0.8 | 1.54×106 | 5.05×104 | 17.0 |

图10 中间态(int)与终态(fin)材料的DSC曲线和中间态与终态材料的Tg随racrylate的函数关系

Fig.10 DSC curves of intermediate (int) and final (fin) materials and function diagram of Tg and racrylate of intermediate and final materials

| Sample | E′ at | Tensile strength/MPa | Elongation at break/% | Young’s modulus/MPa | |

|---|---|---|---|---|---|

| S4BOB-A00 | 9.65 | 6.38 | 0.76 | 17.05 | 5.17 |

| S4BOB-A02 | 12.45 | 9.29 | 1.39 | 20.04 | 7.53 |

| S4BOB-A04 | 13.77 | 10.59 | 4.22 | 44.14 | 14.79 |

| S4BOB-A06 | 17.06 | 11.95 | 6.00 | 60.57 | 9.03 |

| S4BOB-A08 | 22.16 | 12.29 | 8.00 | 66.26 | 118.55 |

| S4BOF-A00 | 10.97 | 10.23 | 3.02 | 44.15 | 8.01 |

| S4BOF-A02 | 14.07 | 10.89 | 4.59 | 52.94 | 9.51 |

| S4BOF-A04 | 16.44 | 12.28 | 9.82 | 66.25 | 14.77 |

| S4BOF-A06 | 15.73 | 12.14 | 11.51 | 106.92 | 8.22 |

| S4BOF-A08 | 20.03 | 13.22 | 15.98 | 86.97 | 277.34 |

| S4A10 | 44.21 | 18.63 | 14.19 | 12.06 | 722.26 |

表3 终态材料的热机械性能和力学性能

Table 3 Thermomechanical properties and mechanical properties of final materials

| Sample | E′ at | Tensile strength/MPa | Elongation at break/% | Young’s modulus/MPa | |

|---|---|---|---|---|---|

| S4BOB-A00 | 9.65 | 6.38 | 0.76 | 17.05 | 5.17 |

| S4BOB-A02 | 12.45 | 9.29 | 1.39 | 20.04 | 7.53 |

| S4BOB-A04 | 13.77 | 10.59 | 4.22 | 44.14 | 14.79 |

| S4BOB-A06 | 17.06 | 11.95 | 6.00 | 60.57 | 9.03 |

| S4BOB-A08 | 22.16 | 12.29 | 8.00 | 66.26 | 118.55 |

| S4BOF-A00 | 10.97 | 10.23 | 3.02 | 44.15 | 8.01 |

| S4BOF-A02 | 14.07 | 10.89 | 4.59 | 52.94 | 9.51 |

| S4BOF-A04 | 16.44 | 12.28 | 9.82 | 66.25 | 14.77 |

| S4BOF-A06 | 15.73 | 12.14 | 11.51 | 106.92 | 8.22 |

| S4BOF-A08 | 20.03 | 13.22 | 15.98 | 86.97 | 277.34 |

| S4A10 | 44.21 | 18.63 | 14.19 | 12.06 | 722.26 |

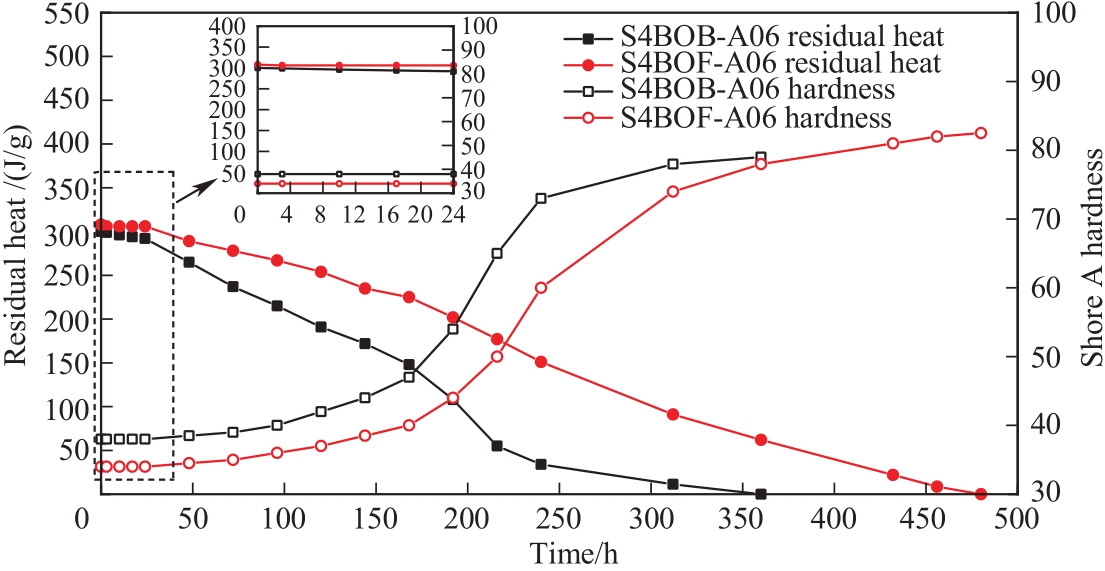

图12 S4BOB-A04和S4BOF-A04中间态材料在室温下的剩余反应热和硬度随时间的变化规律

Fig.12 The time dependence of residual heat and hardness of S4BOB-A04 and S4BOF-A04 intermediate materials at room temperature

| Sample | Shear strength/MPa | |||

|---|---|---|---|---|

| Aluminum substrate | Glass substrate | |||

| int-materials | fin-materials | int-materials | fin-materials | |

| S4BOB-A02 | 0.42 | 6.72 | 1.18 | 2.38 |

| S4BOF-A08 | 0.33 | 8.26 | 1.68 | 2.75 |

表4 S4BOB和S4BOF体系的黏接性能

Table 4 Bonding properties of S4BOB and S4BOF systems

| Sample | Shear strength/MPa | |||

|---|---|---|---|---|

| Aluminum substrate | Glass substrate | |||

| int-materials | fin-materials | int-materials | fin-materials | |

| S4BOB-A02 | 0.42 | 6.72 | 1.18 | 2.38 |

| S4BOF-A08 | 0.33 | 8.26 | 1.68 | 2.75 |

| 1 | Konuray O, Fernández-Francos X, Ramis X, et al. State of the art in dual-curing acrylate systems[J]. Polymers, 2018, 10(2): 178. |

| 2 | Muñoz B K, Bosque A D, Sánchez M, et al. Epoxy resin systems modified with ionic liquids and ceramic nanoparticles as structural composites for multifunctional applications[J]. Polymer, 2021, 214: 123233. |

| 3 | Wang X Q, Ma B, Chen S S, et al. Properties of epoxy-resin binders and feasibility of their application in pavement mixtures[J]. Construction and Building Materials, 2021, 295: 123531. |

| 4 | Karak N. Overview of epoxies and their thermosets[M]//Sustainable Epoxy Thermosets and Nanocomposites. New York: American Chemical Society, 2021: 1-36. |

| 5 | Raetzke K, Shaikh M Q, Faupel F, et al. Shelf stability of reactive adhesive formulations: a case study for dicyandiamide-cured epoxy systems[J]. International Journal of Adhesion and Adhesives, 2010, 30(2): 105-110. |

| 6 | Yu J H, Huang X Y, Wang L C, et al. Preparation of hyperbranched aromatic polyamide grafted nanoparticles for thermal properties reinforcement of epoxy composites[J]. Polymer Chemistry, 2011, 2(6): 1380. |

| 7 | Fan M J, Liu J L, Li X Y, et al. Curing behaviors and properties of an extrinsic toughened epoxy/anhydride system and an intrinsic toughened epoxy/anhydride system[J]. Thermochimica Acta, 2013, 554: 39-47. |

| 8 | 尹顺禹, 许艺, 岑诺, 等. 软体智能机器人的系统设计与力学建模[J]. 力学进展, 2020, 50(1): 202006. |

| Yin S Y, Xu Y, Cen N, et al. System design and mechanical modeling of soft smart robots[J]. Advances in Mechanics, 2020, 50(1): 202006. | |

| 9 | Nair D P, Cramer N B, Caipa J C, et al. Two-stage reactive polymer network forming systems[J]. Advanced functional materials. 2012, 22(7): 1502-1510. |

| 10 | Belmonte A, Russo C, Ambrogi V, et al. Epoxy-based shape-memory actuators obtained via dual-curing of off-stoichiometric "thiol-epoxy" mixtures[J]. Polymers, 2017, 9(3): 113. |

| 11 | Ramis X, Fernández-Francos X, De-La-Flor S, et al. Click-based dual-curing thermosets and their applications[M]//Guo Q P. Thermosets Structure, Properties, and Applications. Amsterdam: Elsevier, 2017: 511-541. |

| 12 | Konuray A O, Fernández-Francos X, Ramis X. Curing kinetics and characterization of dual-curable thiol-acrylate-epoxy thermosets with latent reactivity[J]. Reactive and Functional Polymers, 2018, 122: 60-67. |

| 13 | Jin K L, Wilmot N, Heath W H, et al. Phase-separated thiol-epoxy-acrylate hybrid polymer networks with controlled cross-link density synthesized by simultaneous thiol-acrylate and thiol-epoxy click reactions[J]. Macromolecules, 2016, 49(11): 4115-4123. |

| 14 | 孙鹤. 具有二阶段固化特征形状记忆环氧固化动力学及性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. |

| Sun H. Study on curing kinetics and properties of shape memory epoxy resin with two-stage curing characteristic[D]. Harbin: Harbin Institute of Technology, 2014. | |

| 15 | Santín D, Konuray O, Fernàndez-Francos X, et al. Kinetics analysis and simulation of sequential epoxy dual-curing systems with independent thermal activation[J]. Thermochimica Acta, 2019, 673: 158-168. |

| 16 | Belmonte A, Fernàndez-Francos X, Serra A . et al. Phenomenological characterization of sequential dual-curing of off-stoichiometric "thiol-epoxy" systems: towards applicability[J]. Materials & Design, 2017, 113: 116-127. |

| 17 | Russo C, Serra A, Fernández-Francos X, et al. Characterization of sequential dual-curing of thiol-acrylate-epoxy systems with controlled thermal properties[J]. European Polymer Journal, 2019, 112: 376-388. |

| 18 | Fernàndez-Francos X, Konuray A O, Belmonte A, et al. Sequential curing of off-stoichiometric thiol-epoxy thermosets with a custom-tailored structure[J]. Polymer Chemistry, 2016, 7: 2280-2290. |

| 19 | 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 增塑剂环氧值的测定: [S]. 北京: 中国标准出版社, 2009. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Determinating the epoxy value of plasticizers: [S]. Beijing: Standards Press of China, 2009. | |

| 20 | Hu F S, La Scala J J, Sadler J M, et al. Synthesis and characterization of thermosetting furan-based epoxy systems[J]. Macromolecules, 2014, 47(10): 3332-3342. |

| 21 | Hoyle C E, Lowe A B, Bowman C N. Thiol-click chemistry: a multifaceted toolbox for small molecule and polymer synthesis[J]. Chemical Society Reviews, 2010, 39(4): 1355-1387. |

| 22 | Rozenberg B A. Kinetics, thermodynamics and mechanism of reactions of epoxy oligomers with amines[J]. Advances in Polymer Science, 1986, 75: 113-165. |

| 23 | Fernàndez-Francos X. Theoretical modeling of the effect of proton donors and regeneration reactions in the network build-up of epoxy thermosets using tertiary amines as initiators[J]. European Polymer Journal, 2014, 55: 35-47. |

| 24 | Jin K L, Heath W H, Torkelson J M. Kinetics of multifunctional thiol-epoxy click reactions studied by differential scanning calorimetry: effects of catalysis and functionality[J]. Polymer, 2015, 81: 70-78. |

| 25 | Carioscia J A, Stansbury J W, Bowman C N. Evaluation and control of thiol-ene/thiol-epoxy hybrid networks[J]. Polymer, 2007, 48(6): 1526-1532. |

| 26 | Konuray A O, Fernández-Francos X, Ramis X. Analysis of the reaction mechanism of the thiol-epoxy addition initiated by nucleophilic tertiary amines[J]. Polymer Chemistry, 2017, 8(38): 5934-5947. |

| 27 | 翁诗甫, 徐怡庄. 傅里叶变换红外光谱分析[M]. 3版. 北京: 化学工业出版社, 2016: 41-42. |

| Weng S F, Xu Y Z. Fourier Transform Infrared Spectroscopy Analysis[M]. 3rd ed. Beijing: Chemical Industry Press, 2016: 41-42. | |

| 28 | Shen X B, Liu X Q, Dai J Y, et al. How does the hydrogen bonding interaction influence the properties of furan-based epoxy resins[J]. Industrial & Engineering Chemistry Research, 2017, 56(38): 10929-10938. |

| 29 | Li W Y, Ma J H, Wu S N, et al. The effect of hydrogen bond on the thermal and mechanical properties of furan epoxy resins: molecular dynamics simulation study[J]. Polymer Testing, 2021, 101: 107275. |

| 30 | Russo C, Fernández-Francos X, de la Flor S. Rheological and mechanical characterization of dual-curing thiol-acrylate-epoxy thermosets for advanced applications[J]. Polymers, 2019, 11(6): 997. |

| [1] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [2] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [3] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [4] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| [5] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [6] | 赵婧, 顾程文, 蹇锡高, 翁志焕. 厚朴酚基环氧树脂防腐涂层的制备及性能评价[J]. 化工学报, 2023, 74(7): 3010-3017. |

| [7] | 刘杰, 吴立盛, 李锦锦, 罗正鸿, 周寅宁. 含乙烯基胺酯键聚醚类可逆交联聚合物的制备及性能研究[J]. 化工学报, 2023, 74(7): 3051-3057. |

| [8] | 朱风, 陈凯琳, 黄小凤, 鲍银珠, 李文斌, 刘嘉鑫, 吴玮强, 高王伟. KOH改性电石渣脱除羰基硫的性能研究[J]. 化工学报, 2023, 74(6): 2668-2679. |

| [9] | 龙臻, 王谨航, 任俊杰, 何勇, 周雪冰, 梁德青. 离子液体协同PVCap抑制天然气水合物生成实验研究[J]. 化工学报, 2023, 74(6): 2639-2646. |

| [10] | 杨琴, 秦传鉴, 李明梓, 杨文晶, 赵卫杰, 刘虎. 用于柔性传感的双形状记忆MXene基水凝胶的制备及性能研究[J]. 化工学报, 2023, 74(6): 2699-2707. |

| [11] | 陈韶云, 徐东, 陈龙, 张禹, 张远方, 尤庆亮, 胡成龙, 陈建. 单层聚苯胺微球阵列结构的制备及其吸附性能[J]. 化工学报, 2023, 74(5): 2228-2238. |

| [12] | 张建华, 陈萌萌, 孙雅雯, 彭永臻. 部分短程硝化同步除磷耦合Anammox实现生活污水高效脱氮除磷[J]. 化工学报, 2023, 74(5): 2147-2156. |

| [13] | 李木金, 胡松, 施德磐, 赵鹏, 高瑞, 李进龙. 环氧丁烷尾气溶剂吸收及精制工艺[J]. 化工学报, 2023, 74(4): 1607-1618. |

| [14] | 龙臻, 王谨航, 何勇, 梁德青. 离子液体与动力学抑制剂作用下混合气体水合物生成特性研究[J]. 化工学报, 2023, 74(4): 1703-1711. |

| [15] | 吴学红, 栾林林, 陈亚南, 赵敏, 吕财, 刘勇. 可降解柔性相变薄膜的制备及其热性能[J]. 化工学报, 2023, 74(4): 1818-1826. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号