化工学报 ›› 2022, Vol. 73 ›› Issue (11): 5230-5239.DOI: 10.11949/0438-1157.20220816

刘立1,2( ), 蒋鹏1, 王伟2, 张同桓1, 穆立文1, 陆小华1, 朱家华1(

), 蒋鹏1, 王伟2, 张同桓1, 穆立文1, 陆小华1, 朱家华1( )

)

收稿日期:2022-06-11

修回日期:2022-07-24

出版日期:2022-11-05

发布日期:2022-12-06

通讯作者:

朱家华

作者简介:刘立(1991—),女,博士,助理研究员,Liuli1226137@163.com

基金资助:

Li LIU1,2( ), Peng JIANG1, Wei WANG2, Tonghuan ZHANG1, Liwen MU1, Xiaohua LU1, Jiahua ZHU1(

), Peng JIANG1, Wei WANG2, Tonghuan ZHANG1, Liwen MU1, Xiaohua LU1, Jiahua ZHU1( )

)

Received:2022-06-11

Revised:2022-07-24

Online:2022-11-05

Published:2022-12-06

Contact:

Jiahua ZHU

摘要:

生物质可以替代化石燃料,减少温室气体排放,是一种有前途的可再生能源。生物质通过化学链气化制备氢气,碳化活化制备活性炭,两条工艺路线耦合可以联产绿色能源氢气和具有高附加值的活性炭,但是原材料选择和工艺参数优化成为规模化生产的主要障碍。在生物质联产氢气和活性炭工艺模型的基础上,建立高性能的随机森林预测模型,并探究生物质组分、工艺参数和过程产物对联产工艺的相对重要性。结果表明:生物质组分中的灰分、碳元素、氢元素的含量以及气体重整温度和水蒸气用量是准确预测氢气浓度和产量的重要影响因素。其中,重整温度、合成气中氢气浓度、水蒸气用量三个影响因素对氢气浓度的影响高达61%,活化剂用量、水蒸气用量两个因素对氢气产量的影响高达63%。此外,基于随机森林模型对生物质制氢过程中的因素进行分析和优化,可以实现氢气浓度达到96.8%(体积)。

中图分类号:

刘立, 蒋鹏, 王伟, 张同桓, 穆立文, 陆小华, 朱家华. 基于过程模拟和随机森林模型的生物质制氢过程因素分析与预测[J]. 化工学报, 2022, 73(11): 5230-5239.

Li LIU, Peng JIANG, Wei WANG, Tonghuan ZHANG, Liwen MU, Xiaohua LU, Jiahua ZHU. Coupling process simulation and random forest model for analyzing and predicting biomass-to-hydrogen conversion[J]. CIESC Journal, 2022, 73(11): 5230-5239.

| 工业分析/%(mass) | 元素分析/%(mass) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Moi(水分) | Vol(挥发分) | FC(固定碳) | Ash(灰分) | C | H | O | N | ||

| 2.1~50.0 | 32.5~83.0 | 2.1~30.2 | 0.1~20.6 | 29.2~53.7 | 2.1~8.3 | 9.2~58.8 | 0~1.2 | ||

| 裂解温度/℃ | 裂解产物/%(mass) | ||||||||

| Char | H2 | CH4 | CO | CO2 | |||||

| 400~800 | 14.1~49.2 | 0.1~16.9 | 0.1~13.3 | 11.0~52.3 | 17.7~62.0 | ||||

表1 输入生物质组成变量、热解产物产率的范围

Table 1 The range of input variables, pyrolysis products yield

| 工业分析/%(mass) | 元素分析/%(mass) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Moi(水分) | Vol(挥发分) | FC(固定碳) | Ash(灰分) | C | H | O | N | ||

| 2.1~50.0 | 32.5~83.0 | 2.1~30.2 | 0.1~20.6 | 29.2~53.7 | 2.1~8.3 | 9.2~58.8 | 0~1.2 | ||

| 裂解温度/℃ | 裂解产物/%(mass) | ||||||||

| Char | H2 | CH4 | CO | CO2 | |||||

| 400~800 | 14.1~49.2 | 0.1~16.9 | 0.1~13.3 | 11.0~52.3 | 17.7~62.0 | ||||

| 工艺参数 | 产品 | ||||

|---|---|---|---|---|---|

| 重整温度/℃ | 水蒸气量/(kg/h) | 活性炭产率/%(mass) | 氢气浓度/%(vol) | 氢气流量/(kmol/h) | |

| 630~790 | 100~11950 | 0~20 | 44.58~96.77 | 142.35~615.98 | |

表2 Aspen Plus模拟得到的过程条件、产物组分及含量

Table 2 The range of input variables, pyrolysis products yield, and process conditions in Aspen Plus

| 工艺参数 | 产品 | ||||

|---|---|---|---|---|---|

| 重整温度/℃ | 水蒸气量/(kg/h) | 活性炭产率/%(mass) | 氢气浓度/%(vol) | 氢气流量/(kmol/h) | |

| 630~790 | 100~11950 | 0~20 | 44.58~96.77 | 142.35~615.98 | |

图5 氢气浓度和氢气产量相关的单变量PDP分析(x轴上的刻度表示目标特征值的分位数,反映数据密度)

Fig.5 Univariate PDP analysis of the correlation between hydrogen concentration and hydrogen yield (the ticks on the x-axis represent the quantiles of the target feature values, reflecting the data density)

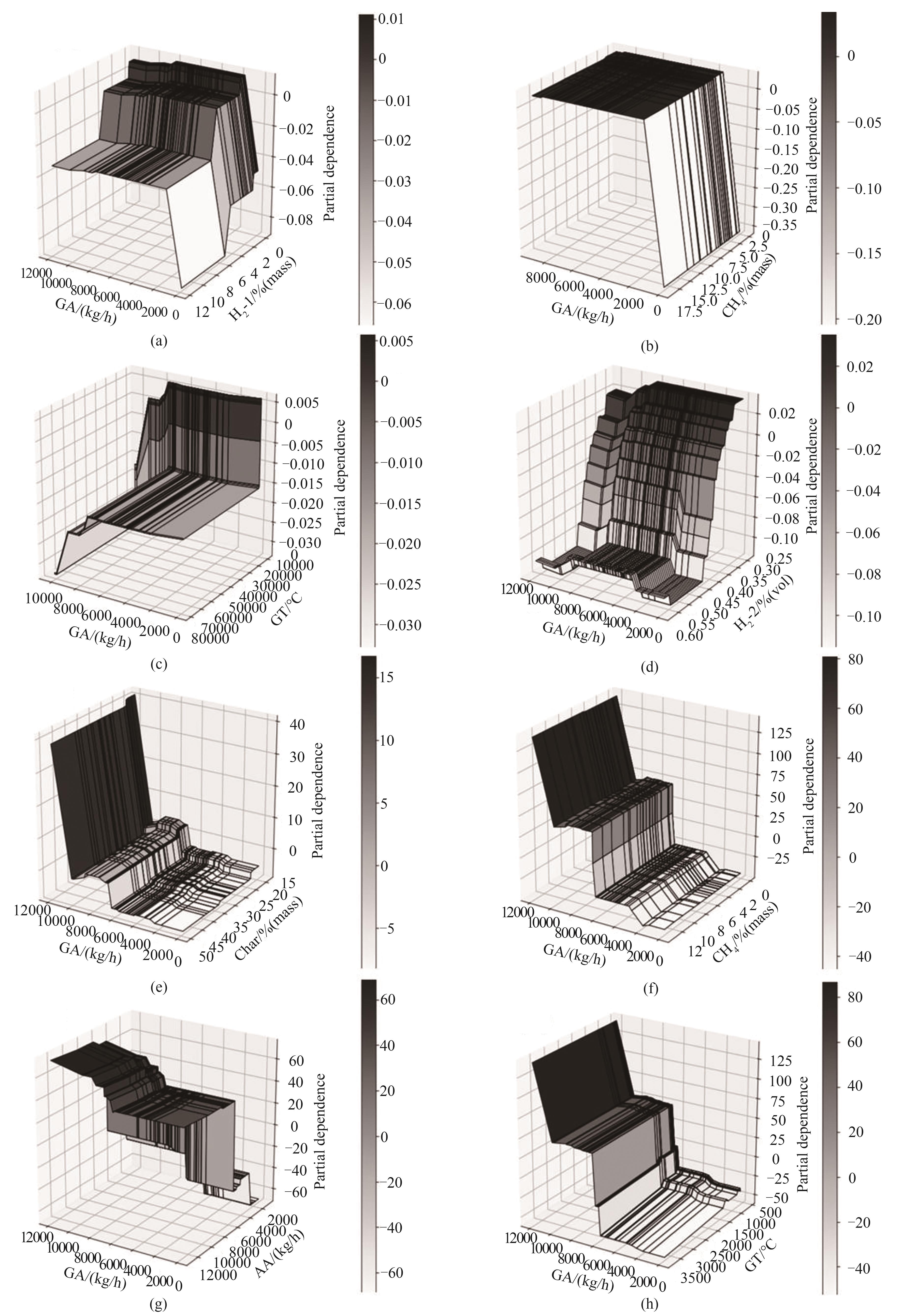

图6 氢气浓度[(a)~(d)]和产量[(e)~(h)]对任意两个输入变量的部分依赖图以及两个输入变量之间的相互作用

Fig.6 The PDP of the H2 concentration [(a)—(d)] and H2 yield [(e)—(h)] on any two input variables and the interactions between two input variables

| 1 | Sheldon R A. Green and sustainable manufacture of chemicals from biomass: state of the art[J]. Green Chem., 2014, 16(3): 950-963. |

| 2 | Detchusananard T, Sharma S, Maréchal F, et al. Multi-objective optimization of sorption enhanced steam biomass gasification with solid oxide fuel cell[J]. Energy Conversion and Management, 2019, 182: 412-429. |

| 3 | Suopajärvi H, Umeki K, Mousa E, et al. Use of biomass in integrated steelmaking—status quo, future needs and comparison to other low-CO2 steel production technologies[J]. Applied Energy, 2018, 213: 384-407. |

| 4 | Nwachukwu C M, Wang C, Wetterlund E. Exploring the role of forest biomass in abating fossil CO2 emissions in the iron and steel industry—the case of Sweden[J]. Applied Energy, 2021, 288: 116558. |

| 5 | 方向晨. 生物质在能源资源替代中的途径及前景展望[J]. 化工进展, 2011, 30(11): 2333-2339. |

| Fang X C. Routes and prospects in the energy resources replacing by biomasses[J]. Chemical Industry and Engineering Progress, 2011, 30(11): 2333-2339. | |

| 6 | Liu L, Jiang P, Qian H L, et al. CO2-negative biomass conversion: an economic route with co-production of green hydrogen and highly porous carbon[J]. Applied Energy, 2022, 311: 118685. |

| 7 | Zhu X Z, Li Y N, Wang X N. Machine learning prediction of biochar yield and carbon contents in biochar based on biomass characteristics and pyrolysis conditions[J]. Bioresource Technology, 2019, 288: 121527. |

| 8 | Jiang G C, Liu L, Xiong J J, et al. Advanced material-oriented biomass precise reconstruction: a review on porous carbon with inherited natural structure and created artificial structure by post-treatment[J]. Macromolecular Bioscience, 2022, 22(6): 2100479. |

| 9 | Wang Z T, Gong Z Q, Yusan T, et al. Renewable hydrogen production from biogas using iron-based chemical looping technology[J]. Chemical Engineering Journal, 2022, 429: 132192. |

| 10 | Zhuang R, Wang X, Guo M, et al. Waste-to-hydrogen: recycling HCl to produce H2 and Cl2 [J]. Applied Energy, 2020, 259: 114184. |

| 11 | Xu D K, Zhang Y T, Hsieh T L, et al. A novel chemical looping partial oxidation process for thermochemical conversion of biomass to syngas[J]. Applied Energy, 2018, 222: 119-131. |

| 12 | Chuayboon S, Abanades S. An overview of solar decarbonization processes, reacting oxide materials, and thermochemical reactors for hydrogen and syngas production[J]. International Journal of Hydrogen Energy, 2020, 45(48): 25783-25810. |

| 13 | Peters J F, Banks S W, Bridgwater A V, et al. A kinetic reaction model for biomass pyrolysis processes in Aspen Plus[J]. Applied Energy, 2017, 188: 595-603. |

| 14 | Tang Q H, Chen Y Q, Yang H P, et al. Prediction of bio-oil yield and hydrogen contents based on machine learning method: effect of biomass compositions and pyrolysis conditions[J]. Energy & Fuels, 2020, 34(9): 11050-11060. |

| 15 | Li J, Zhu X Z, Li Y N, et al. Multi-task prediction and optimization of hydrochar properties from high-moisture municipal solid waste: application of machine learning on waste-to-resource[J]. Journal of Cleaner Production, 2021, 278: 123928. |

| 16 | Chee E W, Wong W C, Wang X N. An integrated approach for machine-learning-based system identification of dynamical systems under control: application towards the model predictive control of a highly nonlinear reactor system[J]. Frontiers of Chemical Science and Engineering, 2022, 16(2): 237-250. |

| 17 | Han X, Wang X N, Zhou K. Develop machine learning-based regression predictive models for engineering protein solubility[J]. Bioinformatics, 2019, 35(22): 4640-4646. |

| 18 | Wang H H, Wang X, Cui Y S, et al. Slow pyrolysis polygeneration of bamboo (phyllostachys pubescens): product yield prediction and biochar formation mechanism[J]. Bioresource Technology, 2018, 263: 444-449. |

| 19 | Lee X J, Lee L Y, Gan S Y, et al. Biochar potential evaluation of palm oil wastes through slow pyrolysis: thermochemical characterization and pyrolytic kinetic studies[J]. Bioresource Technology, 2017, 236: 155-163. |

| 20 | Moralı U, Şensöz S. Pyrolysis of hornbeam shell (Carpinus betulus L.) in a fixed bed reactor: characterization of bio-oil and bio-char[J]. Fuel, 2015, 150: 672-678. |

| 21 | Luo L, Xu C, Chen Z E, et al. Properties of biomass-derived biochars: combined effects of operating conditions and biomass types[J]. Bioresource Technology, 2015, 192: 83-89. |

| 22 | Chen D Y, Liu D, Zhang H R, et al. Bamboo pyrolysis using TG-FTIR and a lab-scale reactor: analysis of pyrolysis behavior, product properties, and carbon and energy yields[J]. Fuel, 2015, 148: 79-86. |

| 23 | Chen D Y, Zhou J B, Zhang Q S. Effects of heating rate on slow pyrolysis behavior, kinetic parameters and products properties of moso bamboo[J]. Bioresource Technology, 2014, 169: 313-319. |

| 24 | Lee Y, Eum P R B, Ryu C, et al. Characteristics of biochar produced from slow pyrolysis of Geodae-Uksae 1[J]. Bioresource Technology, 2013, 130: 345-350. |

| 25 | Angın D. Effect of pyrolysis temperature and heating rate on biochar obtained from pyrolysis of safflower seed press cake[J]. Bioresource Technology, 2013, 128: 593-597. |

| 26 | Abnisa F, Arami-Niya A, Wan Daud W M A, et al. Utilization of oil palm tree residues to produce bio-oil and bio-char via pyrolysis[J]. Energy Conversion and Management, 2013, 76: 1073-1082. |

| 27 | Abnisa F, Arami-Niya A, Daud W M A W, et al. Characterization of bio-oil and bio-char from pyrolysis of palm oil wastes[J]. BioEnergy Research, 2013, 6(2): 830-840. |

| 28 | Mani T, Murugan P, Mahinpey N. Pyrolysis of oat straw and the comparison of the product yield to wheat and flax straw pyrolysis[J]. Energy & Fuels, 2011, 25(7): 2803-2807. |

| 29 | Cagnon B, Py X, Guillot A, et al. Contributions of hemicellulose, cellulose and lignin to the mass and the porous properties of chars and steam activated carbons from various lignocellulosic precursors[J]. Bioresource Technology, 2009, 100(1): 292-298. |

| 30 | Şensöz S, Angın D. Pyrolysis of safflower (Charthamus tinctorius L.) seed press cake (part 1): The effects of pyrolysis parameters on the product yields[J]. Bioresource Technology, 2008, 99(13): 5492-5497. |

| 31 | Demirbas A. Production and characterization of bio-chars from biomass via pyrolysis[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2006, 28(5): 413-422. |

| 32 | Demirbas A. Effects of temperature and particle size on bio-char yield from pyrolysis of agricultural residues[J]. Journal of Analytical and Applied Pyrolysis, 2004, 72(2): 243-248. |

| 33 | Windeatt J H, Ross A B, Williams P T, et al. Characteristics of biochars from crop residues: potential for carbon sequestration and soil amendment[J]. Journal of Environmental Management, 2014, 146: 189-197. |

| 34 | Oginni O, Singh K, Zondlo J W. Pyrolysis of dedicated bioenergy crops grown on reclaimed mine land in West Virginia[J]. Journal of Analytical and Applied Pyrolysis, 2017, 123: 319-329. |

| 35 | Cao D Y, Ji Y X, Liu L, et al. A facile and green strategy to synthesize N/P co-doped bio-char as VOCs adsorbent: through efficient biogas slurry treatment and struvite transform[J]. Fuel, 2022, 322: 124156. |

| 36 | Tan D, Suvarna M, Shee Tan Y, et al. A three-step machine learning framework for energy profiling, activity state prediction and production estimation in smart process manufacturing[J]. Applied Energy, 2021, 291: 116808. |

| 37 | Li J, Suvarna M, Pan L J, et al. A hybrid data-driven and mechanistic modelling approach for hydrothermal gasification[J]. Applied Energy, 2021, 304: 117674. |

| 38 | Xiong J J, Jiang G C, Qian Y, et al. Cycling pressure-switching process enriches micropores in activated carbon by accelerating reactive gas internal diffusion in porous channels[J]. Sustainable Materials and Technologies, 2021, 28: e00248. |

| 39 | Li L Y, Yao Z Y, You S M, et al. Optimal design of negative emission hybrid renewable energy systems with biochar production[J]. Applied Energy, 2019, 243: 233-249. |

| 40 | Ascher S, Watson I, Wang X N, et al. Township-based bioenergy systems for distributed energy supply and efficient household waste re-utilisation: techno-economic and environmental feasibility[J]. Energy, 2019, 181: 455-467. |

| 41 | Kathe M V, Empfield A, Na J, et al. Hydrogen production from natural gas using an iron-based chemical looping technology: thermodynamic simulations and process system analysis[J]. Applied Energy, 2016, 165: 183-201. |

| [1] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [2] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [3] | 吕龙义, 及文博, 韩沐达, 李伟光, 高文芳, 刘晓阳, 孙丽, 王鹏飞, 任芝军, 张光明. 铁基导电材料强化厌氧去除卤代有机污染物:研究进展及未来展望[J]. 化工学报, 2023, 74(8): 3193-3202. |

| [4] | 尹刚, 李伊惠, 何飞, 曹文琦, 王民, 颜非亚, 向禹, 卢剑, 罗斌, 卢润廷. 基于KPCA和SVM的铝电解槽漏槽事故预警方法[J]. 化工学报, 2023, 74(8): 3419-3428. |

| [5] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [6] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [7] | 郭雨莹, 敬加强, 黄婉妮, 张平, 孙杰, 朱宇, 冯君炫, 陆洪江. 稠油管道水润滑减阻及压降预测模型修正[J]. 化工学报, 2023, 74(7): 2898-2907. |

| [8] | 屈园浩, 邓文义, 谢晓丹, 苏亚欣. 活性炭/石墨辅助污泥电渗脱水研究[J]. 化工学报, 2023, 74(7): 3038-3050. |

| [9] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [10] | 李艳辉, 丁邵明, 白周央, 张一楠, 于智红, 邢利梅, 高鹏飞, 王永贞. 非常规服役超临界锅炉的微纳尺度腐蚀动力学模型建立及应用[J]. 化工学报, 2023, 74(6): 2436-2446. |

| [11] | 董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295. |

| [12] | 于源, 陈薇薇, 付俊杰, 刘家祥, 焦志伟. 几何相似涡流空气分级机环形区流场变化规律研究及预测[J]. 化工学报, 2023, 74(6): 2363-2373. |

| [13] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [14] | 刘海芹, 李博文, 凌喆, 刘亮, 俞娟, 范一民, 勇强. 羟基-炔点击化学改性半乳甘露聚糖薄膜的制备及性能研究[J]. 化工学报, 2023, 74(3): 1370-1378. |

| [15] | 吴心远, 刘奇磊, 曹博渊, 张磊, 都健. Group2vec:基于无监督机器学习的基团向量表示及其物性预测应用[J]. 化工学报, 2023, 74(3): 1187-1194. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号