化工学报 ›› 2022, Vol. 73 ›› Issue (10): 4311-4323.DOI: 10.11949/0438-1157.20220838

王欣慧1,2,3( ), 王颖1,2, 姚明东1,2,3(

), 王颖1,2, 姚明东1,2,3( ), 肖文海1,2

), 肖文海1,2

收稿日期:2022-06-15

修回日期:2022-07-27

出版日期:2022-10-05

发布日期:2022-11-02

通讯作者:

姚明东

作者简介:王欣慧(1998—),女,硕士研究生,1575799416@qq.com

基金资助:

Xinhui WANG1,2,3( ), Ying WANG1,2, Mingdong YAO1,2,3(

), Ying WANG1,2, Mingdong YAO1,2,3( ), Wenhai XIAO1,2

), Wenhai XIAO1,2

Received:2022-06-15

Revised:2022-07-27

Online:2022-10-05

Published:2022-11-02

Contact:

Mingdong YAO

摘要:

维生素A是维持人体代谢的必需维生素,在食品、药品及护肤品等多个领域占有重要地位,是三大维生素支柱产品之一,应用前景广阔。市场上的维生素A主要来源于化学合成和天然提取。近年来,随着绿色生物制造的发展,维生素A的生物合成研究取得了重大的进展。总结了维生素A生物合成的研究现状,并对维生素A生物合成的优化改造方案进行了分析归纳,概述了维生素A发酵生产以及产品组分调控和储存策略,最后对生物合成维生素A的现状进行总结与展望。

中图分类号:

王欣慧, 王颖, 姚明东, 肖文海. 维生素A生物合成的研究进展[J]. 化工学报, 2022, 73(10): 4311-4323.

Xinhui WANG, Ying WANG, Mingdong YAO, Wenhai XIAO. Research progress of vitamin A biosynthesis[J]. CIESC Journal, 2022, 73(10): 4311-4323.

| 公司 | 产地 | 上游中间体 | 生产工艺 | 产能/(t/a) |

|---|---|---|---|---|

| 新和成 | 中国 | 自配 | Roche[ | 10000 |

| 帝斯曼 | 荷兰等 | 外购 | Roche | 7500 |

| 巴斯夫 | 德国等 | 自配 | BASF[ | 6000 |

| 浙江医药 | 中国 | 外购 | BASF | 5600 |

| 安迪苏 | 法国等 | 外购 | BASF | 5000 |

| 金达威 | 中国 | 外购 | Roche | 2900 |

表1 全球维生素A主要厂商

Table 1 Global major manufacturers of vitamin A

| 公司 | 产地 | 上游中间体 | 生产工艺 | 产能/(t/a) |

|---|---|---|---|---|

| 新和成 | 中国 | 自配 | Roche[ | 10000 |

| 帝斯曼 | 荷兰等 | 外购 | Roche | 7500 |

| 巴斯夫 | 德国等 | 自配 | BASF[ | 6000 |

| 浙江医药 | 中国 | 外购 | BASF | 5600 |

| 安迪苏 | 法国等 | 外购 | BASF | 5000 |

| 金达威 | 中国 | 外购 | Roche | 2900 |

图2 维生素A生物合成路径Erg10—乙酰辅酶a C-乙酰转移酶;Erg13—羟甲基戊二酰辅酶a合酶;MVA—真核微生物和古细菌甲羟戊酸途径;MEP—原核微生物2-C-甲基-D-赤藓糖醇-4-磷酸途径;Bts1—法尼基转移酶;CrtE—GGPP合成酶;CrtB—八氢番茄红素合成酶;CrtI—八氢番茄红素脱氢酶;CrtY—番茄红素β-环化酶;实线箭头表示直接催化生成;虚线箭头表示部分路径信息省略;灰色标注表示维生素A合成基因

Fig.2 Vitamin A biosynthetic pathway

| 底盘细胞 | 工程化手段 | 产量 | 文献 |

|---|---|---|---|

| 大肠杆菌 | 表达家鼠来源的β-胡萝卜素15,15′-氧化酶; 优化最佳反应条件:pH、温度、底物浓度和表面活性剂 | 视黄醛产量:72 mg/L | [ |

| 大肠杆菌 | 选择密码子优化后的β-胡萝卜素15,15′-氧化酶; 上调dxs,优化内源MEP途径; 引入外源性MVA途径,提供IPP和DMAPP; 筛选大肠菌株:MG1655、DH5a、X11-BLUE、S17-1和BL21; 发酵条件优化:氧浓度、碳源和温度 | 视黄醛产量:136 mg/L | [ |

| 大肠杆菌 | 引入两个异源基因blhSR和RALDH2; 删除内源编码醛还原酶的ybbO基因; 采用mRNA稳定区工程方法; 优化维生素A产生菌的培养条件:温度、pH和氧浓度 | 5 L生物反应器分批发酵;维甲酸产量: (8.20±0.05) mg/L | [ |

| 大肠杆菌 | 筛选了编码β-胡萝卜素裂解酶的基因:blh、brp和bcox; 采用mRNA稳定区工程提高blh催化效率; 共同表达合成视黄基棕榈酸酯路径基因LRAT和CRBP | 分批补料发酵培养;视黄基棕榈酸酯产量为(69.96±2.64) mg/L | [ |

| 大肠杆菌 | 优化发酵条件:温度、pH、搅拌速度; 筛选最佳表面活性剂 | 视黄醛产量:600 mg/L | [ |

| 大肠杆菌 | 过表达内源基因ybbO,增强醛→醇转化; 敲除编码O-乙酰转移酶的基因cat | 视黄醛、视黄醇、视黄醇醋酸酯产量的比例为6%、88%、6% | [ |

| 酿酒酵母 | 采用以木糖为碳源的酵母菌株; 采用十二烷和橄榄油两相原位萃取 | 3 L生物反应器分批补料;视黄醇、视黄醛产量为1256、2094 mg/L | [ |

| 酿酒酵母 | 引入人来源RDH12和乳球菌noxE; 优化发酵条件,以木糖为碳源,十二烷为萃取剂; 筛选最适培养和储存条件,包括温度、光照和抗氧化剂 | 250 ml摇瓶发酵;视黄醇产量:123.1 mg/L | [ |

| 酿酒酵母 | 过表达酵母内源ENV9和截短的Hmg1; 发酵添加1.44 mmol/L Fe2+以维持blh酶活性 | 视黄醇产量:443.43 mg/L | [ |

表2 维生素A相关的代谢工程改造进展

Table 2 Progress in metabolic engineering transformation related to vitamin A

| 底盘细胞 | 工程化手段 | 产量 | 文献 |

|---|---|---|---|

| 大肠杆菌 | 表达家鼠来源的β-胡萝卜素15,15′-氧化酶; 优化最佳反应条件:pH、温度、底物浓度和表面活性剂 | 视黄醛产量:72 mg/L | [ |

| 大肠杆菌 | 选择密码子优化后的β-胡萝卜素15,15′-氧化酶; 上调dxs,优化内源MEP途径; 引入外源性MVA途径,提供IPP和DMAPP; 筛选大肠菌株:MG1655、DH5a、X11-BLUE、S17-1和BL21; 发酵条件优化:氧浓度、碳源和温度 | 视黄醛产量:136 mg/L | [ |

| 大肠杆菌 | 引入两个异源基因blhSR和RALDH2; 删除内源编码醛还原酶的ybbO基因; 采用mRNA稳定区工程方法; 优化维生素A产生菌的培养条件:温度、pH和氧浓度 | 5 L生物反应器分批发酵;维甲酸产量: (8.20±0.05) mg/L | [ |

| 大肠杆菌 | 筛选了编码β-胡萝卜素裂解酶的基因:blh、brp和bcox; 采用mRNA稳定区工程提高blh催化效率; 共同表达合成视黄基棕榈酸酯路径基因LRAT和CRBP | 分批补料发酵培养;视黄基棕榈酸酯产量为(69.96±2.64) mg/L | [ |

| 大肠杆菌 | 优化发酵条件:温度、pH、搅拌速度; 筛选最佳表面活性剂 | 视黄醛产量:600 mg/L | [ |

| 大肠杆菌 | 过表达内源基因ybbO,增强醛→醇转化; 敲除编码O-乙酰转移酶的基因cat | 视黄醛、视黄醇、视黄醇醋酸酯产量的比例为6%、88%、6% | [ |

| 酿酒酵母 | 采用以木糖为碳源的酵母菌株; 采用十二烷和橄榄油两相原位萃取 | 3 L生物反应器分批补料;视黄醇、视黄醛产量为1256、2094 mg/L | [ |

| 酿酒酵母 | 引入人来源RDH12和乳球菌noxE; 优化发酵条件,以木糖为碳源,十二烷为萃取剂; 筛选最适培养和储存条件,包括温度、光照和抗氧化剂 | 250 ml摇瓶发酵;视黄醇产量:123.1 mg/L | [ |

| 酿酒酵母 | 过表达酵母内源ENV9和截短的Hmg1; 发酵添加1.44 mmol/L Fe2+以维持blh酶活性 | 视黄醇产量:443.43 mg/L | [ |

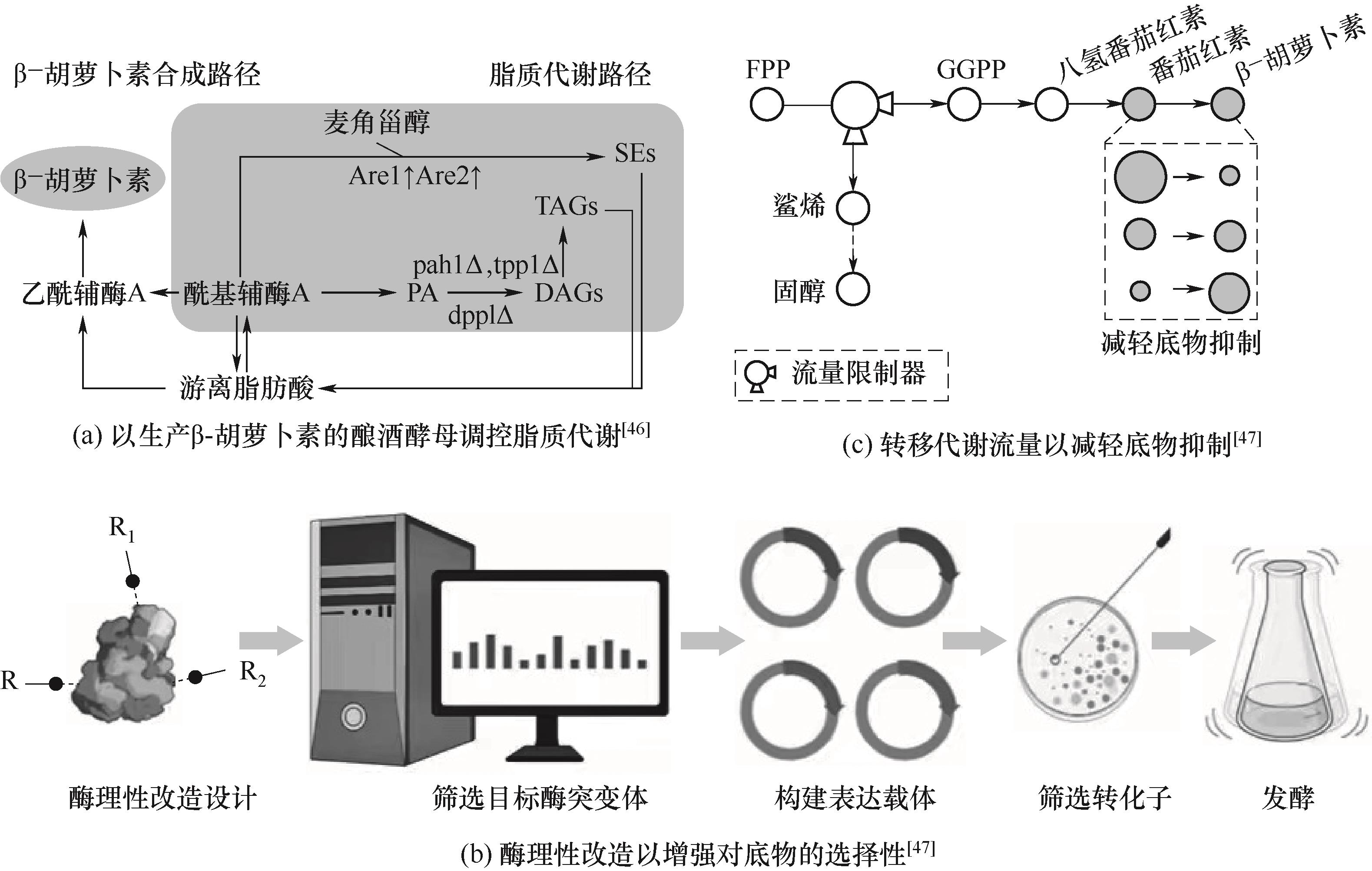

图3 维生素A前体β-胡萝卜素生物合成策略Are1,Are2—甾醇酰基转移酶;pah1,lpp1,dpp1—磷脂酸磷酸酶;PA—磷脂酸;DAG—二酰基甘油;TAG—三酰基甘油;SE—甾醇酯;FPP—法呢基焦磷酸;GGPP—牻牛儿基牻牛儿基焦磷酸;R—酶结构域

Fig.3 Biosynthesis strategy of vitamin A precursor β-carotene

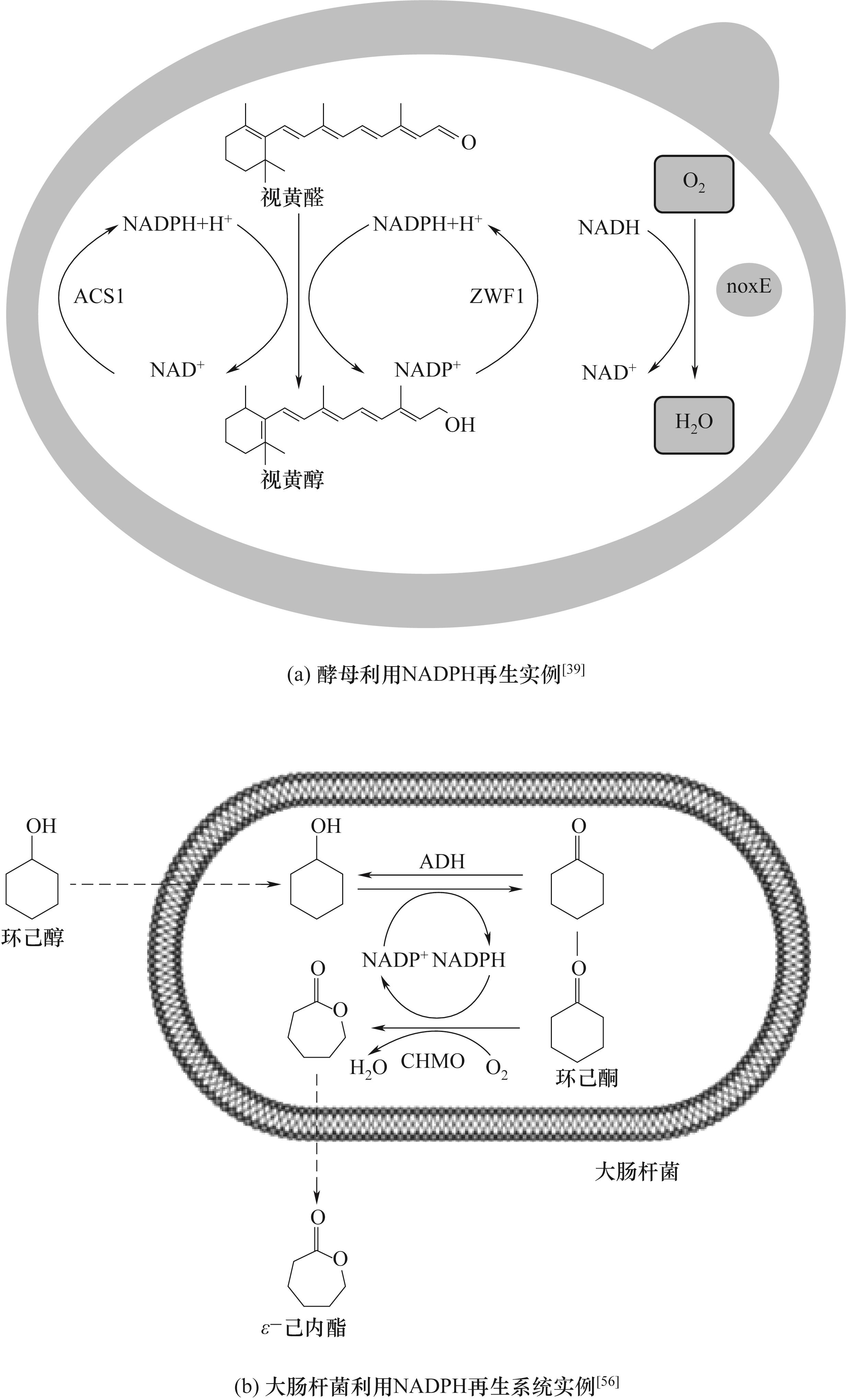

图4 维生素A辅因子改造优化策略ADH—乙醇脱氢酶;CHMO—环己酮氧化酶;ACS1—乙酰辅酶连接酶1;ZWF1—葡萄糖-6-磷酸脱氢酶;noxE—NADH氧化酶;NADH—烟酰胺腺嘌呤二核苷酸;NADPH—烟酰胺腺嘌呤二核苷酸磷酸

Fig.4 Optimization strategy of vitamin A cofactor transformation

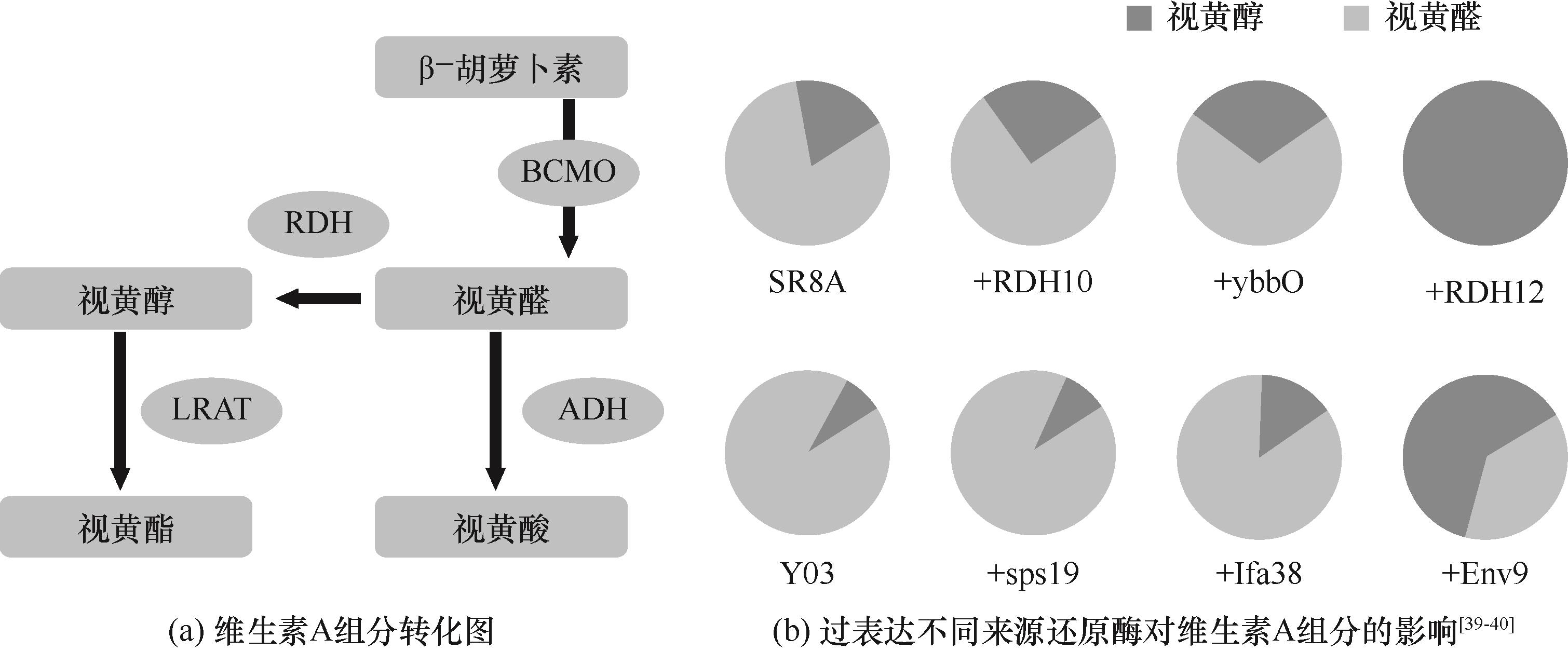

图5 维生素A组分调控优化策略RDH—视黄醇脱氢酶;ADH—乙醇脱氢酶;BCMO—β-胡萝卜素15,15′-氧化酶;LRAT—卵磷脂视黄醇酰基转移酶;SR8A—维生素A酵母生产出发菌株1;RDH10—人来源视黄醇脱氢酶10;ybbO—NADP+依赖型醛还原酶;RDH12—人来源视黄醇脱氢酶12;Y03—维生素A酵母生产出发菌株2;sps19—2,4-二烯酰辅酶a还原酶;Ifa38—极长链3-氧代酰基辅酶a还原酶;Env9—短链乙醇脱氢酶

Fig.5 Optimization strategy of vitamin A component regulation

| 改造策略 | 具体改造信息 | 结果 | 文献 |

|---|---|---|---|

| 碳源 | 葡萄糖、木糖 | 20.74 mg/L维生素A(44 g/L木糖) | [ |

| 温度、pH | 温度:24~33℃ pH:5.5~8.0 | 视黄醛产量最大(pH 7.0,30℃), 细胞量达到最大(27℃) | [ |

| 表面活性剂 | Span20、Span40、Span60、Span80、 Tween20、Tween40、Tween80、Brij58、Triton X-100 | 细胞量最大, 细胞积累量为15.2 g/L(10 g/L Span80) | [ |

| 搅拌速率 | 400、500、600、700、800 r/min | 视黄醛产量最大为600 mg/L(600 r/min) | [ |

| 萃取剂 | 十二烷、大豆油和橄榄油 | 十二烷效果最佳 | [ |

| 光 | 光照条件、黑暗条件 | 视黄醇浓度最高为124.6 mg/L(黑暗) | [ |

表3 维生素A生产下游改造策略

Table 3 The downstream transformation strategy of vitamin A production

| 改造策略 | 具体改造信息 | 结果 | 文献 |

|---|---|---|---|

| 碳源 | 葡萄糖、木糖 | 20.74 mg/L维生素A(44 g/L木糖) | [ |

| 温度、pH | 温度:24~33℃ pH:5.5~8.0 | 视黄醛产量最大(pH 7.0,30℃), 细胞量达到最大(27℃) | [ |

| 表面活性剂 | Span20、Span40、Span60、Span80、 Tween20、Tween40、Tween80、Brij58、Triton X-100 | 细胞量最大, 细胞积累量为15.2 g/L(10 g/L Span80) | [ |

| 搅拌速率 | 400、500、600、700、800 r/min | 视黄醛产量最大为600 mg/L(600 r/min) | [ |

| 萃取剂 | 十二烷、大豆油和橄榄油 | 十二烷效果最佳 | [ |

| 光 | 光照条件、黑暗条件 | 视黄醇浓度最高为124.6 mg/L(黑暗) | [ |

| 1 | Blomhoff R, Blomhoff H K. Overview of retinoid metabolism and function[J]. Journal of Neurobiology, 2006, 66(7): 606-630. |

| 2 | Tanumihardjo S A. Vitamin A: biomarkers of nutrition for development[J]. The American Journal of Clinical Nutrition, 2011, 94(2): 658S-665S. |

| 3 | Wirth J P, Petry N, Tanumihardjo S A, et al. Vitamin A supplementation programs and country-level evidence of vitamin A deficiency[J]. Nutrients, 2017, 9(3): 190. |

| 4 | Srinivasan K, Buys E M. Insights into the role of bacteria in vitamin A biosynthesis: future research opportunities[J]. Critical Reviews in Food Science and Nutrition, 2019, 59(19): 3211-3226. |

| 5 | Khalil S, Bardawil T, Stephan C, et al. Retinoids: a journey from the molecular structures and mechanisms of action to clinical uses in dermatology and adverse effects[J]. Journal of Dermatological Treatment, 2017, 28(8): 684-696. |

| 6 | Eggersdorfer M, Laudert D, Létinois U, et al. One hundred years of vitamins—a success story of the natural sciences[J]. Angewandte Chemie International Edition, 2012, 51(52): 12960-12990. |

| 7 | Parker G L, Smith L K, Baxendale I R. Development of the industrial synthesis of vitamin A[J]. Tetrahedron, 2016, 72(13): 1645-1652. |

| 8 | Steinle A, Bergander K, Steinbüchel A. Metabolic engineering of Saccharomyces cerevisiae for production of novel cyanophycins with an extended range of constituent amino acids[J]. Appl. Environ. Microbiol., 2009, 75(11): 3437-3446. |

| 9 | Chen Y, Nielsen J. Biobased organic acids production by metabolically engineered microorganisms[J]. Current Opinion in Biotechnology, 2016, 37: 165-172. |

| 10 | Karunanandaa B, Qi Q G, Hao M, et al. Metabolically engineered oilseed crops with enhanced seed tocopherol[J]. Metabolic Engineering, 2005, 7(5/6): 384-400. |

| 11 | Zhang C Y, Cahoon R E, Hunter S C, et al. Genetic and biochemical basis for alternative routes of tocotrienol biosynthesis for enhanced vitamin E antioxidant production[J]. The Plant Journal, 2013, 73(4): 628-639. |

| 12 | Chapman M S. Vitamin A: history, current uses, and controversies[J]. Seminars in Cutaneous Medicine and Surgery, 2012, 31(1): 11-16. |

| 13 | Kim Y S, Oh D K. Biotransformation of carotenoids to retinal by carotenoid 15, 15'-oxygenase[J]. Applied Microbiology and Biotechnology, 2010, 88(4): 807-816. |

| 14 | Goodman D S, Huang H S, Shiratori T. Mechanism of the biosynthesis of vitamin A from beta-carotene[J]. The Journal of Biological Chemistry, 1966, 241(9): 1929-1932. |

| 15 | Goodman D S, Huang H S, Kanai M, et al. The enzymatic conversion of all-trans β-carotene into retinal[J]. Journal of Biological Chemistry, 1967, 242(15): 3543-3554. |

| 16 | Wang X D, Krinsky N I. Fat-soluble vitamins [M]//Quinn P J, Kagan V E. Subcellular Biochemistry: Volume 30. New York: Plenum Press, 1998: 159-177. |

| 17 | Olson J A, Hayaishi O. The enzymatic cleavage of beta-carotene into vitamin A by soluble enzymes of rat liver and intestine[J]. PLoS One, 1965, 54(5): 1364-1370. |

| 18 | Lakshman M R, Mychkovsky I, Attlesey M. Enzymatic conversion of all-trans-beta-carotene to retinal by a cytosolic enzyme from rabbit and rat intestinal mucosa[J]. The Journal of General and Applied Microbiology, 1989, 86(23): 9124-9128. |

| 19 | Helden Y G J, Heil S G, Schooten F J, et al. Knockout of the Bcmo1 gene results in an inflammatory response in female lung, which is suppressed by dietary beta-carotene[J]. Cellular and Molecular Life Sciences, 2010, 67(12): 2039-2056. |

| 20 | von Lintig J, Hessel S, Isken A, et al. Towards a better understanding of carotenoid metabolism in animals[J]. Biochimica et Biophysica Acta (BBA) - Molecular Basis of Disease, 2005, 1740(2): 122-131. |

| 21 | Lampert J M, Holzschuh J, Hessel S, et al. Provitamin A conversion to retinal via the beta, beta-carotene-15, 15'-oxygenase (bcox) is essential for pattern formation and differentiation during zebrafish embryogenesis[J]. Development (Cambridge, England), 2003, 130(10): 2173-2186. |

| 22 | Paik J, During A, Harrison E H, et al. Expression and characterization of a murine enzyme able to cleave β-carotene: the formation of retinoids[J]. Journal of Biological Chemistry, 2001, 276(34): 32160-32168. |

| 23 | von Lintig J, Vogt K. Filling the gap in vitamin A research: molecular identification of an enzyme cleaving β-carotene to retinal[J]. Journal of Biological Chemistry, 2000, 275(16): 11915-11920. |

| 24 | Lindqvist A, Andersson S. Biochemical properties of purified recombinant human β-carotene 15, 15'-monooxygenase[J]. Journal of Biological Chemistry, 2002, 277(26): 23942-23948. |

| 25 | Höög J O, Östberg L J. Mammalian alcohol dehydrogenases — a comparative investigation at gene and protein levels[J]. Chemico-Biological Interactions, 2011, 191(1/2/3): 2-7. |

| 26 | O'Byrne S M, Blaner W S. Retinol and retinyl esters: biochemistry and physiology[J]. Journal of Lipid Research, 2013, 54(7): 1731-1743. |

| 27 | Menozzi I, Vallese F, Polverini E, et al. Structural and molecular determinants affecting the interaction of retinol with human CRBP1[J]. Journal of Structural Biology, 2017, 197(3): 330-339. |

| 28 | Devery J, Milborrow B V. β-Carotene-15,15′-dioxygenase (EC 1.13.11.21) isolation reaction mechanism and an improved assay procedure[J]. British Journal of Nutrition, 1994, 72(3): 397-414. |

| 29 | Nagao A, During A, Hoshino C, et al. Stoichiometric conversion of all trans-beta-carotene to retinal by pig intestinal extract[J]. Archives of Biochemistry and Biophysics, 1996, 328(1): 57-63. |

| 30 | Kim Y S, Oh D K. Substrate specificity of a recombinant chicken β-carotene 15, 15'-monooxygenase that converts β-carotene into retinal[J]. Biotechnology Letters, 2009, 31(3): 403-408. |

| 31 | Peck R F, Echavarri-Erasun C, Johnson E A, et al. Brp and blh are required for synthesis of the retinal cofactor of bacteriorhodopsin in Halobacterium salinarum [J]. Journal of Biological Chemistry, 2001, 276(8): 5739-5744. |

| 32 | Kim Y S, Kim N H, Kim H J, et al. Effective production of retinal from beta-carotene using recombinant mouse beta-carotene 15, 15'-monooxygenase[J]. Applied Microbiology and Biotechnology, 2007, 76(6): 1339-1345. |

| 33 | Jang H J, Yoon S H, Ryu H K, et al. Retinoid production using metabolically engineered Escherichia coli with a two-phase culture system[J]. Microbial Cell Factories, 2011, 10: 59. |

| 34 | Han M, Lee P C. Microbial production of bioactive retinoic acid using metabolically engineered Escherichia coli [J]. Microorganisms, 2021, 9(7): 1520. |

| 35 | Choi B H, Hwang H J, Lee J E, et al. Microbial production of retinyl palmitate and its application as a cosmeceutical[J]. Antioxidants (Basel, Switzerland), 2020, 9(11): 1130. |

| 36 | Lee J H, Choi J G, Kim Y S, et al. Enhancement of retinal production by supplementing the surfactant Span 80 using metabolically engineered Escherichia coli [J]. Journal of Bioscience and Bioengineering, 2012, 113(4): 461-466. |

| 37 | Jang H J, Ha B K, Zhou J, et al. Selective retinol production by modulating the composition of retinoids from metabolically engineered E. coli [J]. Biotechnology and Bioengineering, 2015, 112(8): 1604-1612. |

| 38 | Sun L, Kwak S, Jin Y S. Vitamin A production by engineered Saccharomyces cerevisiae from xylose via two-phase in situ extraction[J]. ACS Synthetic Biology, 2019, 8(9): 2131-2140. |

| 39 | Lee Y G, Kim C, Sun L, et al. Selective production of retinol by engineered Saccharomyces cerevisiae through the expression of retinol dehydrogenase[J]. Biotechnology and Bioengineering, 2022, 119(2): 399-410. |

| 40 | Hu Q Y, Zhang T L, Yu H W, et al. Selective biosynthesis of retinol in S. cerevisiae [J]. Bioresources and Bioprocessing, 2022, 9: 22. |

| 41 | 汪之顼. 维生素A[J]. 营养学报, 2014, 36(1): 8-12. |

| Wang Z X. Vitamin A[J]. Journal of Nutrition, 2014, 36(1): 8-12. | |

| 42 | Chen Y, Xiao W H, Wang Y, et al. Lycopene overproduction in Saccharomyces cerevisiae through combining pathway engineering with host engineering[J]. Microbial Cell Factories, 2016, 15(1): 113. |

| 43 | Yamada R, Yamauchi A, Ando Y, et al. Modulation of gene expression by cocktail δ-integration to improve carotenoid production in Saccharomyces cerevisiae [J]. Bioresource Technology, 2018, 268: 616-621. |

| 44 | Larroude M, Celinska E, Back A, et al. A synthetic biology approach to transform Yarrowia lipolytica into a competitive biotechnological producer of β-carotene[J]. Biotechnology and Bioengineering, 2018, 115(2): 464-472. |

| 45 | Wang M, Liu G N, Liu H, et al. Engineering global transcription to tune lipophilic properties in Yarrowia lipolytica [J]. Biotechnology for Biofuels, 2018, 11: 115. |

| 46 | Zhao Y J, Zhang Y P, Nielsen J, et al. Production of β-carotene in Saccharomyces cerevisiae through altering yeast lipid metabolism[J]. Biotechnology and Bioengineering, 2021, 118(5): 2043-2052. |

| 47 | Ma Y S, Liu N, Greisen P, et al. Removal of lycopene substrate inhibition enables high carotenoid productivity in Yarrowia lipolytica [J]. Nature Communications, 2022, 13: 572. |

| 48 | Duetz W A, van Beilen J B, Witholt B. Using proteins in their natural environment: potential and limitations of microbial whole-cell hydroxylations in applied biocatalysis[J]. Current Opinion in Biotechnology, 2001, 12(4): 419-425. |

| 49 | Lee W H, Kim J W, Park E H, et al. Effects of NADH kinase on NADPH-dependent biotransformation processes in Escherichia coli [J]. Applied Microbiology and Biotechnology, 2013, 97(4): 1561-1569. |

| 50 | Zhao J, Li Q Y, Sun T, et al. Engineering central metabolic modules of Escherichia coli for improving β-carotene production[J]. Metabolic Engineering, 2013, 17: 42-50. |

| 51 | Bruinenberg P M. The NADP(H) redox couple in yeast metabolism[J]. Antonie Van Leeuwenhoek, 1986, 52(5): 411-429. |

| 52 | Lim S J, Jung Y M, Shin H D, et al. Amplification of the NADPH-related genes zwf and gnd for the oddball biosynthesis of PHB in an E. coli transformant harboring a cloned phbCAB operon[J]. Journal of Bioscience and Bioengineering, 2002, 93(6): 543-549. |

| 53 | Wang M, Chen B Q, Fang Y M, et al. Cofactor engineering for more efficient production of chemicals and biofuels[J]. Biotechnology Advances, 2017, 35(8): 1032-1039. |

| 54 | Liu J H, Li H L, Zhao G R, et al. Redox cofactor engineering in industrial microorganisms: strategies, recent applications and future directions[J]. Journal of Industrial Microbiology and Biotechnology, 2018, 45(5): 313-327. |

| 55 | Satowa D, Fujiwara R, Uchio S, et al. Metabolic engineering of E. coli for improving mevalonate production to promote NADPH regeneration and enhance acetyl-CoA supply[J]. Biotechnology and Bioengineering, 2020, 117(7): 2153-2164. |

| 56 | Xiong J H, Chen H F, Liu R, et al. Tuning a bi-enzymatic cascade reaction in Escherichia coli to facilitate NADPH regeneration for ε-caprolactone production[J]. Bioresources and Bioprocessing, 2021, 8: 32. |

| 57 | Du H J, Luo W, Appiah B, et al. Promotion of the asymmetric reduction of prochiral ketone with recombinant E. coli through strengthening intracellular NADPH supply by modifying EMP and introducing NAD kinase[J]. Catalysis Letters, 2021, 151(9): 2527-2536. |

| 58 | Barua A B, Furr H C. Properties of retinoids. structure, handling, and preparation[J]. Molecular Biotechnology, 1998, 10(2): 167-182. |

| 59 | Hong S H, Kim K R, Oh D K. Biochemical properties of retinoid-converting enzymes and biotechnological production of retinoids[J]. Applied Microbiology and Biotechnology, 2015, 99(19): 7813-7826. |

| 60 | Yang J, Wang W, Ooi J, et al. Signalling through retinoic acid receptors is required for reprogramming of both mouse embryonic fibroblast cells and epiblast stem cells to induced pluripotent stem cells[J]. Stem Cells, 2015, 33(5): 1390-1404. |

| 61 | Ro J, Kim Y, Kim H, et al. Anti-oxidative activity of pectin and its stabilizing effect on retinyl palmitate[J]. The Korean Journal of Physiology & Pharmacology, 2013, 17(3): 197-201. |

| 62 | Parente E, Ricciardi A. Production, recovery and purification of bacteriocins from lactic acid bacteria[J]. Applied Microbiology and Biotechnology, 1999, 52(5): 628-638. |

| 63 | Laouar L, Lowe K C, Mulligan B J. Yeast responses to nonionic surfactants[J]. Enzyme and Microbial Technology, 1996, 18(6): 433-438. |

| 64 | Kim Y S, Kim N H, Yeom S J, et al. In vitro characterization of a recombinant blh protein from an uncultured marine bacterium as a β-carotene 15,15'-dioxygenase[J]. Journal of Biological Chemistry, 2009, 284(23): 15781-15793. |

| 65 | Abbasiliasi S, Tan J S, Kadkhodaei S, et al. Enhancement of BLIS production by Pediococcus acidilactici kp10 in optimized fermentation conditions using an artificial neural network[J]. RSC Advances, 2016, 6(8): 6342-6349. |

| 66 | Puri S, Beg Q K, Gupta R. Optimization of alkaline protease production from Bacillus sp. by response surface methodology[J]. Current Microbiology, 2002, 44(4): 286-290. |

| 67 | Sauvant P, Cansell M, Hadj Sassi A, et al. Vitamin A enrichment: caution with encapsulation strategies used for food applications[J]. Food Research International, 2012, 46(2): 469-479. |

| 68 | Carlotti M E, Rossatto V, Gallarate M. Vitamin A and vitamin A palmitate stability over time and under UVA and UVB radiation[J]. International Journal of Pharmaceutics, 2002, 240(1/2): 85-94. |

| 69 | Loveday S M, Singh H. Recent advances in technologies for vitamin A protection in foods[J]. Trends in Food Science & Technology, 2008, 19(12): 657-668. |

| 70 | Chmykh Y G, Nadeau J L. Characterization of retinol stabilized in phosphatidylcholine vesicles with and without antioxidants[J]. ACS Omega, 2020, 5(29): 18367-18375. |

| 71 | Crank G, Pardijanto M S. Photo-oxidations and photosensitized oxidations of vitamin A and its palmitate ester[J]. Journal of Photochemistry and Photobiology A: Chemistry, 1995, 85(1/2): 93-100. |

| 72 | Liew S L, Ariff A B, Raha A R, et al. Optimization of medium composition for the production of a probiotic microorganism, Lactobacillus rhamnosus, using response surface methodology[J]. International Journal of Food Microbiology, 2005, 102(2): 137-142. |

| [1] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [2] | 陈雅鑫, 袁航, 刘冠章, 毛磊, 杨纯, 张瑞芳, 张光亚. 蛋白质纳米笼介导的酶自固定化研究进展[J]. 化工学报, 2023, 74(7): 2773-2782. |

| [3] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [4] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [5] | 张兰河, 赖青燚, 王铁铮, 关潇卓, 张明爽, 程欣, 徐小惠, 贾艳萍. H2O2对SBR脱氮效率和污泥性能的影响[J]. 化工学报, 2023, 74(5): 2186-2196. |

| [6] | 赵春雷, 郭亮, 高聪, 宋伟, 吴静, 刘佳, 刘立明, 陈修来. 代谢工程改造大肠杆菌生产软骨素[J]. 化工学报, 2023, 74(5): 2111-2122. |

| [7] | 贾露凡, 王艺颖, 董钰漫, 李沁园, 谢鑫, 苑昊, 孟涛. 微流控双水相贴壁液滴流动强化酶促反应研究[J]. 化工学报, 2023, 74(3): 1239-1246. |

| [8] | 刘瑞琪, 周栖桐, 张悦, 贺莹, 高静, 马丽. 基于金纳米颗粒修饰二氧化硅纳米花的生物传感器构建及应用[J]. 化工学报, 2023, 74(3): 1247-1259. |

| [9] | 苏伟怡, 丁佳慧, 李春利, 王洪海, 姜艳军. 酶促反应结晶研究进展[J]. 化工学报, 2023, 74(2): 617-629. |

| [10] | 毕浩然, 张洋, 王凯, 徐晨晨, 霍奕影, 陈必强, 谭天伟. 微生物制造绿色化学品研究进展[J]. 化工学报, 2023, 74(1): 1-13. |

| [11] | 刘昕, 戈钧, 李春. 光驱动微生物杂合系统提高生物制造水平[J]. 化工学报, 2023, 74(1): 330-341. |

| [12] | 胡阳, 孙彦. 酶分子的自驱动及其介导的微纳马达[J]. 化工学报, 2023, 74(1): 116-132. |

| [13] | 谭卓涛, 齐思雨, 许梦蛟, 戴杰, 朱晨杰, 应汉杰. 辅酶自循环的氧化还原级联体系在生物催化过程中的应用:机遇与挑战[J]. 化工学报, 2023, 74(1): 45-59. |

| [14] | 刘雪, 张莉娟, 赵广荣. 大肠杆菌偏利共培养系统合成大豆苷元[J]. 化工学报, 2022, 73(9): 4015-4024. |

| [15] | 安绍杰, 许洪峰, 李思, 许远航, 李佳锡. 利用分子机器的组装与分解构建pH敏感性谷胱甘肽过氧化物人工酶[J]. 化工学报, 2022, 73(8): 3669-3678. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号