化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2296-2307.DOI: 10.11949/0438-1157.20230316

崔张宁1( ), 胡紫璇1, 吴雷1,2(

), 胡紫璇1, 吴雷1,2( ), 周军1,2(

), 周军1,2( ), 叶干1, 刘田田1, 张秋利1,2, 宋永辉2,3

), 叶干1, 刘田田1, 张秋利1,2, 宋永辉2,3

收稿日期:2023-03-30

修回日期:2023-05-25

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

吴雷,周军

作者简介:崔张宁(1998—),女,硕士研究生,cui@xauat.edu.cn

基金资助:

Zhangning CUI1( ), Zixuan HU1, Lei WU1,2(

), Zixuan HU1, Lei WU1,2( ), Jun ZHOU1,2(

), Jun ZHOU1,2( ), Gan YE1, Tiantian LIU1, Qiuli ZHANG1,2, Yonghui SONG2,3

), Gan YE1, Tiantian LIU1, Qiuli ZHANG1,2, Yonghui SONG2,3

Received:2023-03-30

Revised:2023-05-25

Online:2023-06-05

Published:2023-07-27

Contact:

Lei WU, Jun ZHOU

摘要:

生物质资源制备塑料替代品成为当前最具吸引力的研究课题之一。纤维素是生物质中广泛存在的聚合物,因其具有可降解性、可持续性和良好力学性能等特点而被作为高价值材料的前体。然而,纤维素中丰富的羟基结构增强了亲水性,导致纤维素基材料吸水后变软,严重地影响了其力学性能。在保留纤维素环境友好特性的前提下,改善纤维素基材料的耐水性能以提高其在高湿环境下的水稳定性和力学性能,从而拓宽纤维素基材料的实际应用范围,使其成为石油基或煤基塑料的优良替代品。先通过对纤维素结构与性质的分析,引出纤维素基材料所面临的耐水性能差的问题,再介绍了纤维素基材料的耐水性能指标和行业要求,重点阐述了改善纤维素基材料耐水性能的三种优化方法,即涂覆疏水涂层、制备复合材料和施加添加剂。最后对纤维素基材料的耐水性能进行了总结和展望,提出了其在实际优化过程中存在的阻碍和挑战。

中图分类号:

崔张宁, 胡紫璇, 吴雷, 周军, 叶干, 刘田田, 张秋利, 宋永辉. 可降解纤维素基材料的耐水性能研究进展[J]. 化工学报, 2023, 74(6): 2296-2307.

Zhangning CUI, Zixuan HU, Lei WU, Jun ZHOU, Gan YE, Tiantian LIU, Qiuli ZHANG, Yonghui SONG. Research progress on the water resistance of degradable cellulose-based materials[J]. CIESC Journal, 2023, 74(6): 2296-2307.

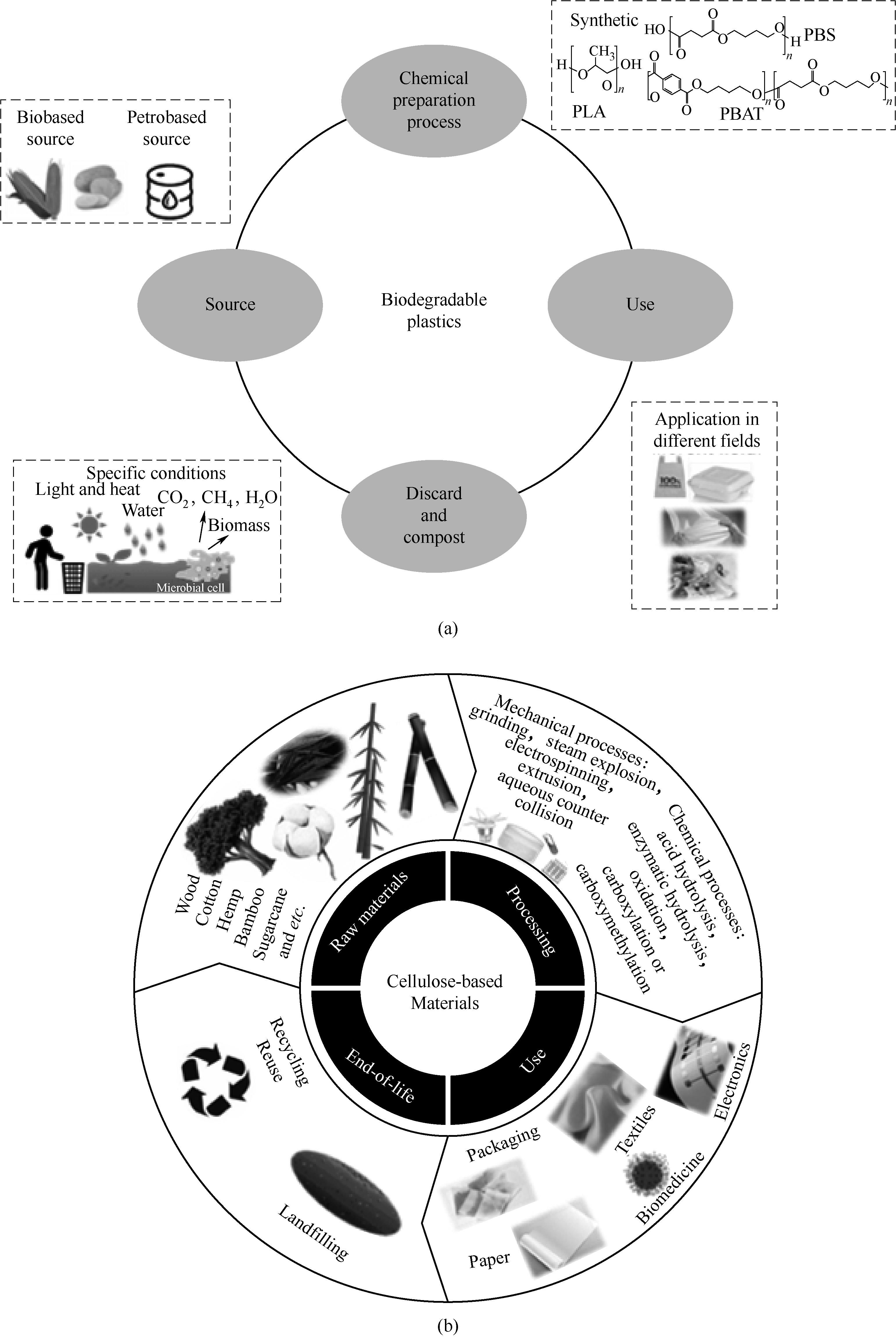

图1 (a)可降解塑料在环境中的降解和循环[5];(b)纤维素材料的生命周期

Fig.1 (a) Degradation and recycling of degradable plastics in the environment[5]; (b) Life cycle of cellulose-based materials

| 标准名称及标准号 | 类型 | 要求/技术指标 | 文献 |

|---|---|---|---|

| 纸浆模塑餐具 (GB/T 36787—2018) | 国家标准 | 注满(23±1)℃的水,静置30 min后,无渗出水印;注满(95±5)℃的水,静置30 min后,无变形,无阴渗、渗漏 | [ |

纸餐盒 (GB/T 27589—2011) | 国家标准 | 注入(95±5)℃的水静置30 min后无变形、开裂、起皮、起皱,无渗漏 | [ |

纸碗 (GB/T 27591—2011) | 国家标准 | (95±5)℃的水加入纸碗内静置30 min后无渗漏的水印 | [ |

| 固体食品包装用纸板 (GB/T 31123—2014) | 国家标准 | 表面吸水性:正面≤40.0 g/m2;反面≤60.0 g/m2 | [ |

医用包装纸 (GB/T 35594—2017) | 国家标准 | Cobb 60≤20.0 g/m2 | [ |

食品包装纸 (QB/T 1014—2010) | 行业标准 | Cobb 60≤30.0 g/m2 | [ |

一次性纸质饮用吸管标准 (T/ZZB 1494—2019) | 团体标准 | 在模拟接触水性食物、酸性食物、含酒精类食物中浸泡2 h,纸张端口不得出现分层开口、软化现象 | [ |

食品接触用一次性纸吸管标 (T/CNFIA 201—2020) | 团体标准 | 预热至45℃的蒸馏水100 ml,加入至100 ml的比色管中,按照卷绕和非卷绕两个方向分别插入2根纸吸管,于45℃烘箱内静置3 h,无纸张分离起翘、弯折、破裂 | [ |

降解型纸吸管 (T/JMES 001—2020) | 团体标准 | 将吸管放入浸泡液后,常温环境下静置2 h,不散开,允许轻微翘边 | [ |

纸基托盘 (T/ZZB 2524—2021) | 团体标准 | 托盘面板表面吸水性应满足测试时间为60 s,吸水性≤40 g/m2 | [ |

表1 纤维素基材料耐水性能的行业要求

Table 1 Industry requirement for water resistance of cellulose-based materials

| 标准名称及标准号 | 类型 | 要求/技术指标 | 文献 |

|---|---|---|---|

| 纸浆模塑餐具 (GB/T 36787—2018) | 国家标准 | 注满(23±1)℃的水,静置30 min后,无渗出水印;注满(95±5)℃的水,静置30 min后,无变形,无阴渗、渗漏 | [ |

纸餐盒 (GB/T 27589—2011) | 国家标准 | 注入(95±5)℃的水静置30 min后无变形、开裂、起皮、起皱,无渗漏 | [ |

纸碗 (GB/T 27591—2011) | 国家标准 | (95±5)℃的水加入纸碗内静置30 min后无渗漏的水印 | [ |

| 固体食品包装用纸板 (GB/T 31123—2014) | 国家标准 | 表面吸水性:正面≤40.0 g/m2;反面≤60.0 g/m2 | [ |

医用包装纸 (GB/T 35594—2017) | 国家标准 | Cobb 60≤20.0 g/m2 | [ |

食品包装纸 (QB/T 1014—2010) | 行业标准 | Cobb 60≤30.0 g/m2 | [ |

一次性纸质饮用吸管标准 (T/ZZB 1494—2019) | 团体标准 | 在模拟接触水性食物、酸性食物、含酒精类食物中浸泡2 h,纸张端口不得出现分层开口、软化现象 | [ |

食品接触用一次性纸吸管标 (T/CNFIA 201—2020) | 团体标准 | 预热至45℃的蒸馏水100 ml,加入至100 ml的比色管中,按照卷绕和非卷绕两个方向分别插入2根纸吸管,于45℃烘箱内静置3 h,无纸张分离起翘、弯折、破裂 | [ |

降解型纸吸管 (T/JMES 001—2020) | 团体标准 | 将吸管放入浸泡液后,常温环境下静置2 h,不散开,允许轻微翘边 | [ |

纸基托盘 (T/ZZB 2524—2021) | 团体标准 | 托盘面板表面吸水性应满足测试时间为60 s,吸水性≤40 g/m2 | [ |

| 涂层 | 涂布方式 | 最大水接触角(WCA)/(°) | Cobb 值/吸水率 | 文献 |

|---|---|---|---|---|

| 壳聚糖接枝聚二甲基硅氧烷 | 涂布机 | 120.53±0.96 | (9.89±0.32) g/m2(Cobb 60) | [ |

| 壳聚糖-玉米醇溶蛋白 | 涂布机 | 96.1±5.8 | 4.88 g/m2(Cobb 60) | [ |

| 生物基聚乳酸 | 棒涂机 | 79.5 | 3.17 g/m2(Cobb 30) | [ |

| 纳米SiO2改性硬脂酸的聚乳酸-肉桂醛 | 喷涂 | 156.3 | 0(Cobb 60) 0(Cobb 300) (1.2±1.0) g/m2(Cobb 600) (9.6±1.0) g/m2(Cobb 1800) | [ |

| 硅烷改性的超疏水纳米原纤化纤维素 | 喷涂 | 160±4 | 7.5 g/m2(Cobb 120) | [ |

| SiO2-乙基纤维素 | 浸渍/喷涂 | 166 | 36.3%(吸水率,3 h) | [ |

| 阳离子淀粉/巴西棕榈蜡 | 浸渍/喷涂 | 122 | 57%(吸水率,48 h) | [ |

| SiO2-有机改性硅酸盐 | 浸渍 | 158.2 | 24.1%(吸水率,24 h) | [ |

表2 文献已报道的涂层及其耐水性能

Table 2 Coatings and its water resistance reported in literatures

| 涂层 | 涂布方式 | 最大水接触角(WCA)/(°) | Cobb 值/吸水率 | 文献 |

|---|---|---|---|---|

| 壳聚糖接枝聚二甲基硅氧烷 | 涂布机 | 120.53±0.96 | (9.89±0.32) g/m2(Cobb 60) | [ |

| 壳聚糖-玉米醇溶蛋白 | 涂布机 | 96.1±5.8 | 4.88 g/m2(Cobb 60) | [ |

| 生物基聚乳酸 | 棒涂机 | 79.5 | 3.17 g/m2(Cobb 30) | [ |

| 纳米SiO2改性硬脂酸的聚乳酸-肉桂醛 | 喷涂 | 156.3 | 0(Cobb 60) 0(Cobb 300) (1.2±1.0) g/m2(Cobb 600) (9.6±1.0) g/m2(Cobb 1800) | [ |

| 硅烷改性的超疏水纳米原纤化纤维素 | 喷涂 | 160±4 | 7.5 g/m2(Cobb 120) | [ |

| SiO2-乙基纤维素 | 浸渍/喷涂 | 166 | 36.3%(吸水率,3 h) | [ |

| 阳离子淀粉/巴西棕榈蜡 | 浸渍/喷涂 | 122 | 57%(吸水率,48 h) | [ |

| SiO2-有机改性硅酸盐 | 浸渍 | 158.2 | 24.1%(吸水率,24 h) | [ |

| 添加剂 | 结构式 | 优点 | 缺点 | 文献 |

|---|---|---|---|---|

| 烷基烯酮二聚体(AKD) |  | 低成本、低毒性,应用中用量少,pH应用范围宽 | 易水解,储存期短 | [ |

| 烯基琥珀酸酐(ASA) |  | 成本低,施胶速度快、适用pH范围宽 | 化学反应活性高 | [ |

| 松香 |  | 来源天然、低黏度、高稳定性 | 耐水性维持时间有限 | [ |

| 聚丙烯酸酯 (ACM) |  | 优异的光稳定性和耐候性,良好的耐水、耐碱、耐化学品性能和黏接性能 | 低温变脆、高温黏度变大、失强 | [ |

表3 文献已报道的防水添加剂的优缺点

Table 3 Advantages and disadvantages of waterproof additives reported in literatures

| 添加剂 | 结构式 | 优点 | 缺点 | 文献 |

|---|---|---|---|---|

| 烷基烯酮二聚体(AKD) |  | 低成本、低毒性,应用中用量少,pH应用范围宽 | 易水解,储存期短 | [ |

| 烯基琥珀酸酐(ASA) |  | 成本低,施胶速度快、适用pH范围宽 | 化学反应活性高 | [ |

| 松香 |  | 来源天然、低黏度、高稳定性 | 耐水性维持时间有限 | [ |

| 聚丙烯酸酯 (ACM) |  | 优异的光稳定性和耐候性,良好的耐水、耐碱、耐化学品性能和黏接性能 | 低温变脆、高温黏度变大、失强 | [ |

| 1 | Chen Y, Awasthi A K, Wei F, et al. Single-use plastics: production, usage, disposal, and adverse impacts[J]. Science of the Total Environment, 2021, 752: 141772. |

| 2 | Chamas A, Moon H, Zheng J J, et al. Degradation rates of plastics in the environment[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(9): 3494-3511. |

| 3 | Bartnikowski M, Dargaville T R, Ivanovski S, et al. Degradation mechanisms of polycaprolactone in the context of chemistry, geometry and environment[J]. Progress in Polymer Science, 2019, 96: 1-20. |

| 4 | Wu F, Misra M, Mohanty A K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging[J]. Progress in Polymer Science, 2021, 117: 101395. |

| 5 | Haider T P, Völker C, Kramm J, et al. Plastics of the future? The impact of biodegradable polymers on the environment and on society[J]. Angewandte Chemie (International Ed. in English), 2019, 58(1): 50-62. |

| 6 | Elsawy M A, Kim K H, Park J W, et al. Hydrolytic degradation of polylactic acid (PLA) and its composites[J]. Renewable and Sustainable Energy Reviews, 2017, 79: 1346-1352. |

| 7 | Ratajczak K, Stobiecka M. High-performance modified cellulose paper-based biosensors for medical diagnostics and early cancer screening: a concise review[J]. Carbohydrate Polymers, 2020, 229: 115463. |

| 8 | Shi L J, Kang L, Gong J, et al. Cellulose nanofibrils reinforced films without chemical modification, hydrophobic, high elongation, and foldability[J]. Industrial Crops and Products, 2022, 180: 114742. |

| 9 | Ray U, Pang Z Q, Li T. Mechanics of cellulose nanopaper using a scalable coarse-grained modeling scheme[J]. Cellulose, 2021, 28(6): 3359-3372. |

| 10 | Jia D M, Xie J Y, Dirican M, et al. Highly smooth, robust, degradable and cost-effective modified lignin-nanocellulose green composite substrates for flexible and green electronics[J]. Composites Part B: Engineering, 2022, 236: 109803. |

| 11 | Herrera M A, Mathew A P, Oksman K. Barrier and mechanical properties of plasticized and cross-linked nanocellulose coatings for paper packaging applications[J]. Cellulose, 2017, 24(9): 3969-3980. |

| 12 | Balu B, Breedveld V, Hess D W. Fabrication of "roll-off" and "sticky" superhydrophobic cellulose surfaces via plasma processing[J]. Langmuir, 2008, 24(9): 4785-4790. |

| 13 | Lafraya A, Prieto C, Pardo-Figuerez M, et al. Super-repellent paper coated with electrospun biopolymers and electrosprayed silica of interest in food packaging applications[J]. Nanomaterials, 2021, 11(12): 3354. |

| 14 | Li T. EML webinar overview: advanced materials toward a sustainable future-mechanics design[J]. Extreme Mechanics Letters, 2021, 42: 101107. |

| 15 | Siqueira G, Bras J, Dufresne A. Cellulosic bionanocomposites: a review of preparation, properties and applications[J]. Polymers, 2010, 2(4): 728-765. |

| 16 | Bao Y, Qian H J, Lu Z Y, et al. Revealing the hydrophobicity of natural cellulose by single-molecule experiments[J]. Macromolecules, 2015, 48(11): 3685-3690. |

| 17 | Lindman B, Medronho B, Alves L, et al. Hydrophobic interactions control the self-assembly of DNA and cellulose[J]. Quarterly Reviews of Biophysics, 2021, 54: e3. |

| 18 | Qian L, Cai W H, Xu D, et al. Single-molecule studies reveal that water is a special solvent for amylose and natural cellulose[J]. Macromolecules, 2019, 52(13): 5006-5013. |

| 19 | Huang Y Y, Chen G W, Liang Q M, et al. Multifunctional cellulose nanocrystal structural colored film with good flexibility and water-resistance[J]. International Journal of Biological Macromolecules, 2020, 149: 819-825. |

| 20 | Wohlert M, Benselfelt T, Wågberg L, et al. Cellulose and the role of hydrogen bonds: not in charge of everything[J]. Cellulose, 2022, 29(1): 1-23. |

| 21 | Bao Y, Xu D, Qian L, et al. Hydrophilicities of amylose and natural cellulose are regulated by the linkage between sugar rings[J]. Nanoscale, 2017, 9(10): 3382-3385. |

| 22 | Zhang W, Lu P, Qian L Y, et al. Fabrication of superhydrophobic paper surface via wax mixture coating[J]. Chemical Engineering Journal, 2014, 250: 431-436. |

| 23 | Wang X Z, Pang Z Q, Chen C J, et al. All-natural, degradable, rolled-up straws based on cellulose micro- and nano-hybrid fibers[J]. Advanced Functional Materials, 2020, 30(22): 1910417. |

| 24 | Wang H Q, Wang J L, Si S R, et al. Residual-lignin-endowed molded pulp lunchbox with a sustained wet support strength[J]. Industrial Crops and Products, 2021, 170: 113756. |

| 25 | Huhtamäki T, Tian X L, Korhonen J T, et al. Surface-wetting characterization using contact-angle measurements[J]. Nature Protocols, 2018, 13(7): 1521-1538. |

| 26 | Feng L, Li S, Li Y, et al. Super-hydrophobic surfaces: from natural to artificial[J]. Advanced Materials, 2002, 14(24): 1857-1860. |

| 27 | Wen Q Y, Guo F, Yang F C, et al. Green fabrication of coloured superhydrophobic paper from native cotton cellulose[J]. Journal of Colloid and Interface Science, 2017, 497: 284-289. |

| 28 | Yi C F, Yuan T Z, Ren H, et al. Fabrication of food-safe, degradable and high-barrier air frying paper by chitosan, zein and LCNF coatings[J]. Cellulose, 2023, 30(4): 2441-2452. |

| 29 | 浙江省品牌建设联合会. 一次性纸质饮用吸管: T/ZZB 1494—2019 [S]. 2019. |

| Zhejiang Brand Building Association. Disposable paper drinking straw: T/ZZB 1494—2019 [S]. 2019. | |

| 30 | 中国食品工业协会. 食品接触用一次性纸吸管: T/C [S]. 北京: 中国标准出版社, 2020. |

| China National Food Industry Association. Disposable paper straw for food contact: T/C [S]. Beijing: Standards Press of China, 2020 | |

| 31 | 国家市场监督管理总局, 中国国家标准化管理委员会. 纸浆模塑餐具: [S]. 北京: 中国标准出版社, 2018. |

| State Administration for Market Regulation, Standardization Administration of the People's Republic of China. Pulp molding tableware: [S]. Beijing: Standards Press of China, 2018. | |

| 32 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 纸餐盒: [S]. 北京: 中国标准出版社, 2012. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Paper container set for food: [S]. Beijing: Standards Press of China, 2012. | |

| 33 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 纸碗: [S]. 北京: 中国标准出版社, 2012. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Paper bowl: [S]. Beijing: Standards Press of China, 2012. | |

| 34 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 固体食品包装用纸板: [S]. 北京: 中国标准出版社, 2015. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Paperboard for solid food packaging: [S]. Beijing: Standards Press of China, 2015. | |

| 35 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 医用包装纸: [S]. 北京: 中国标准出版社, 2017. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Medical packaging paper: [S]. Beijing: Standards Press of China, 2017. | |

| 36 | 中华人民共和国工业和信息化部. 食品包装纸: [S]. 北京: 中国轻工业出版社, 2010. |

| Ministry of Industry and Information of the People's Republic of China. Food packaging paper: [S]. Beijing: China Light Industry Press, 2010. | |

| 37 | 江苏省轻工协会, 江苏省机械工程学会. 降解型纸吸管: T/JMES 001—2020 [S]. 2020. |

| Jiangsu Light Industry Association, Jiangsu Mechanical Engineering Society. Degradable paper straw: T/JMES 001—2020 [S]. 2020. | |

| 38 | 浙江省品牌建设联合会. 纸基托盘: T/ZZB 2524—2021 [S]. 2021. |

| Zhejiang Brand Building Association. Paper pallets: T/ZZB 2524—2021 [S]. 2021. | |

| 39 | Tian X L, Verho T, Ras R H A. Moving superhydrophobic surfaces toward real-world applications[J]. Science, 2016, 352(6282): 142-143. |

| 40 | Li Z, Rabnawaz M, Sarwar M G, et al. A closed-loop and sustainable approach for the fabrication of plastic-free oil-and water-resistant paper products[J]. Green Chemistry, 2019, 21(20): 5691-5700. |

| 41 | Kansal D, Hamdani S S, Ping R Q, et al. Food-safe chitosan-zein dual-layer coating for water-and oil-repellent paper substrates[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(17): 6887-6897. |

| 42 | Sundar N, Kumar S A, Pavithra A, et al. Studies on semi-crystalline poly lactic acid (PLA) as a hydrophobic coating material on kraft paper for imparting barrier properties in coated abrasive applications[J]. Progress in Organic Coatings, 2020, 145: 105682. |

| 43 | Jiang X F, Li Q, Li X T, et al. Preparation and characterization of degradable cellulose-based paper with superhydrophobic, antibacterial, and barrier properties for food packaging[J]. International Journal of Molecular Sciences, 2022, 23(19): 11158. |

| 44 | Ye M T, Tian Z J, Wang S D, et al. Simple preparation of environmentally friendly and durable superhydrophobic antibacterial paper[J]. Cellulose, 2023, 30(4): 2427-2440. |

| 45 | Liu J F, Wang C, Ewulonu C M, et al. Fabrication of superhydrophobic and degradable cellulose paper materials for straw application[J]. Cellulose, 2022, 29(1): 527-540. |

| 46 | Korhonen O, Forsman N, Österberg M, et al. Eco-friendly surface hydrophobization of all-cellulose composites using layer-by-layer deposition[J]. Express Polymer Letters, 2020, 14(10): 896-907. |

| 47 | Zhang X X, Xiao F C, Feng Q F, et al. Preparation of SiO2 nanoparticles with adjustable size for fabrication of SiO2/PMHS ORMOSIL superhydrophobic surface on cellulose-based substrates[J]. Progress in Organic Coatings, 2020, 138: 105384. |

| 48 | Wolf M P, Salieb-Beugelaar G B, Hunziker P. PDMS with designer functionalities—properties, modifications strategies, and applications[J]. Progress in Polymer Science, 2018, 83: 97-134. |

| 49 | Cao C Y, Ge M Z, Huang J Y, et al. Robust fluorine-free superhydrophobic PDMS-ormosil@fabrics for highly effective self-cleaning and efficient oil-water separation[J]. Journal of Materials Chemistry A, 2016, 4(31): 12179-12187. |

| 50 | Saadat-Bakhsh M, Ahadian H R, Nouri N M. Facile, robust and large-scale fabrication method of mechanically durable superhydrophobic PDMS/aerogel coating on fibrous substrates[J]. Cellulose, 2017, 24(8): 3453-3467. |

| 51 | Jing X, Li X, Jiang Y F, et al. Excellent coating of collagen fiber/chitosan-based materials that is water- and oil-resistant and fluorine-free[J]. Carbohydrate Polymers, 2021, 266: 118173. |

| 52 | Hamdani S S, Li Z, Rabnawaz M, et al. Chitosan-graft-poly(dimethylsiloxane)/zein coatings for the fabrication of environmentally friendly oil- and water-resistant paper[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(13): 5147-5155. |

| 53 | Wu X N, Zhao B, Wang L, et al. Superhydrophobic PVDF membrane induced by hydrophobic SiO2 nanoparticles and its use for CO2 absorption[J]. Separation and Purification Technology, 2018, 190: 108-116. |

| 54 | Li H, Yang J, Li P, et al. A facile method for preparation superhydrophobic paper with enhanced physical strength and moisture-proofing property[J]. Carbohydrate Polymers, 2017, 160: 9-17. |

| 55 | Khwaldia K, Arab-Tehrany E, Desobry S. Biopolymer coatings on paper packaging materials[J]. Comprehensive Reviews in Food Science and Food Safety, 2010, 9(1): 82-91. |

| 56 | Zhang Y W, Bi J R, Wang S Q, et al. Functional food packaging for reducing residual liquid food: thermo-resistant edible super-hydrophobic coating from coffee and beeswax[J]. Journal of Colloid and Interface Science, 2019, 533: 742-749. |

| 57 | Wang J L, Chen W, Dong T T, et al. Enabled cellulose nanopaper with outstanding water stability and wet strength via activated residual lignin as a reinforcement[J]. Green Chemistry, 2021, 23(24): 10062-10070. |

| 58 | Jiang B, Chen C J, Liang Z Q, et al. Lignin as a wood-inspired binder enabled strong, water stable, and biodegradable paper for plastic replacement[J]. Advanced Functional Materials, 2020, 30(4): 1906307. |

| 59 | Zhang C W, Nair S S, Chen H Y, et al. Thermally stable, enhanced water barrier, high strength starch bio-composite reinforced with lignin containing cellulose nanofibrils[J]. Carbohydrate Polymers, 2020, 230: 115626. |

| 60 | Wang X Z, Xia Q Q, Jing S S, et al. Strong, hydrostable, and degradable straws based on cellulose-lignin reinforced composites[J]. Small, 2021, 17(18): 2008011. |

| 61 | Saepoo T, Sarak S, Mayakun J, et al. Thermoplastic starch composite with oil palm mesocarp fiber waste and its application as biodegradable seeding pot[J]. Carbohydrate Polymers, 2023, 299: 120221. |

| 62 | Soni R, Hsu Y I, Asoh T A, et al. Synergistic effect of hemiacetal crosslinking and crystallinity on wet strength of cellulose nanofiber-reinforced starch films[J]. Food Hydrocolloids, 2021, 120: 106956. |

| 63 | Xie Y J, Pan Y F, Cai P X. Hydroxyl crosslinking reinforced bagasse cellulose/polyvinyl alcohol composite films as biodegradable packaging[J]. Industrial Crops and Products, 2022, 176: 114381. |

| 64 | Kriechbaum K, Bergström L. Antioxidant and UV-blocking leather-inspired nanocellulose-based films with high wet strength[J]. Biomacromolecules, 2020, 21(5): 1720-1728. |

| 65 | Kumar A, Bhardwaj N K, Singh S P. Polyacrylamide stabilized alkenyl succinic anhydride emulsion as sizing agent for various cellulosic pulps and fillers[J]. Carbohydrate Polymers, 2020, 236: 116069. |

| 66 | Oh Y, Park S Y, Yook S, et al. A waterproof cellulose nanofibril sheet prepared by the deposition of an alkyl ketene dimer on a controlled porous structure[J]. Cellulose, 2022, 29(12): 6645-6657. |

| 67 | Sun P H, Wang S H, Huang Z, et al. Water-resistant, strong, degradable and recyclable rosin-grafted cellulose composite paper[J]. Green Chemistry, 2022, 24(19): 7519-7530. |

| 68 | Li H, Zhou J H, Zhao J J. Fabrication of dual-functional cellulose nanocrystals/fluorinated polyacrylate containing coumarin derivatives by RAFT-assisted Pickering emulsion polymerization for self-healing application[J]. Applied Surface Science, 2023, 614: 156180. |

| 69 | Liu C, Luan P C, Li Q, et al. Biodegradable, hygienic, and compostable tableware from hybrid sugarcane and bamboo fibers as plastic alternative[J]. Matter, 2020, 3(6): 2066-2079. |

| 70 | Yan Y T, Amer H, Rosenau T, et al. Dry, hydrophobic microfibrillated cellulose powder obtained in a simple procedure using alkyl ketene dimer[J]. Cellulose, 2016, 23(2): 1189-1197. |

| 71 | Yang L M, Lu S, Li J J, et al. Nanocrystalline cellulose-dispersed AKD emulsion for enhancing the mechanical and multiple barrier properties of surface-sized paper[J]. Carbohydrate Polymers, 2016, 136: 1035-1040. |

| 72 | Sato A, Kabusaki D, Okumura H, et al. Surface modification of cellulose nanofibers with alkenyl succinic anhydride for high-density polyethylene reinforcement[J]. Composites Part A: Applied Science and Manufacturing, 2016, 83: 72-79. |

| 73 | Ashish K, Bhardwaj N K, Singh S P. Cationic starch and polyacrylamides for alkenyl succinic anhydride (ASA) emulsification for sizing of cellulosic fibers[J]. Cellulose, 2019, 26(18): 9901-9915. |

| 74 | Niu X, Liu Y T, Song Y, et al. Rosin modified cellulose nanofiber as a reinforcing and co-antimicrobial agents in polylactic acid/chitosan composite film for food packaging[J]. Carbohydrate Polymers, 2018, 183: 102-109. |

| [1] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [2] | 林典, 江国梅, 徐秀彬, 赵波, 刘冬梅, 吴旭. 硅基类液防原油黏附涂层的研制及其减阻性能研究[J]. 化工学报, 2023, 74(8): 3438-3445. |

| [3] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [4] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| [5] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [6] | 赵婧, 顾程文, 蹇锡高, 翁志焕. 厚朴酚基环氧树脂防腐涂层的制备及性能评价[J]. 化工学报, 2023, 74(7): 3010-3017. |

| [7] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [8] | 董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295. |

| [9] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| [10] | 陈韶云, 徐东, 陈龙, 张禹, 张远方, 尤庆亮, 胡成龙, 陈建. 单层聚苯胺微球阵列结构的制备及其吸附性能[J]. 化工学报, 2023, 74(5): 2228-2238. |

| [11] | 代佳琳, 毕唯东, 雍玉梅, 陈文强, 莫晗旸, 孙兵, 杨超. 热物性对混合型CPCMs固液相变特性影响模拟研究[J]. 化工学报, 2023, 74(5): 1914-1927. |

| [12] | 包嘉靖, 别洪飞, 王子威, 肖睿, 刘冬, 吴石亮. 正庚烷对冲扩散火焰中添加长链醚类对碳烟前体生成特性的影响[J]. 化工学报, 2023, 74(4): 1680-1692. |

| [13] | 刘瑞琪, 周栖桐, 张悦, 贺莹, 高静, 马丽. 基于金纳米颗粒修饰二氧化硅纳米花的生物传感器构建及应用[J]. 化工学报, 2023, 74(3): 1247-1259. |

| [14] | 徐东, 田杜, 陈龙, 张禹, 尤庆亮, 胡成龙, 陈韶云, 陈建. 聚苯胺/二氧化锰/聚吡咯复合纳米球的制备及其电化学储能性[J]. 化工学报, 2023, 74(3): 1379-1389. |

| [15] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号