化工学报 ›› 2023, Vol. 74 ›› Issue (12): 4988-4996.DOI: 10.11949/0438-1157.20230769

丁奇胜1( ), 谭晶1,2(

), 谭晶1,2( ), 程礼盛1,2, 张政和3, 宋立健1, 杨卫民1,2

), 程礼盛1,2, 张政和3, 宋立健1, 杨卫民1,2

收稿日期:2023-07-24

修回日期:2023-10-20

出版日期:2023-12-25

发布日期:2024-02-19

通讯作者:

谭晶

作者简介:丁奇胜(1998—),男,硕士研究生,2021210347@mail.buct.edu.cn

Qisheng DING1( ), Jing TAN1,2(

), Jing TAN1,2( ), Lisheng CHENG1,2, Zhenghe ZHANG3, Lijian SONG1, Weimin YANG1,2

), Lisheng CHENG1,2, Zhenghe ZHANG3, Lijian SONG1, Weimin YANG1,2

Received:2023-07-24

Revised:2023-10-20

Online:2023-12-25

Published:2024-02-19

Contact:

Jing TAN

摘要:

在氩气压力0~0.3 MPa下对聚丙烯腈基碳纤维进行高功率激光快速辐照热传导制备了石墨纤维,研究了氩气压力对碳纤维石墨化性能的影响。结果表明,当气场压力为0 MPa时,高功率激光快速辐照下碳纤维发生了气胀现象:碳纤维中非碳元素以气体形式大量快速逸出、碳纤维直径增加,同时伴随着部分表层脱落。进一步增加高功率激光辐照时的气场环境压力,当气场压力为0.2~0.3 MPa时,碳纤维直径减小并逐渐稳定、表层脱落消失,碳纤维的石墨化程度和石墨微晶尺寸进一步增加,同时加压激光辐照后石墨纤维拉伸强度损失减小,杨氏模量增加。因此,施加0.2~0.3 MPa氩气压力是改善高功率激光辐照制备石墨纤维性能的一种有效方法。

中图分类号:

丁奇胜, 谭晶, 程礼盛, 张政和, 宋立健, 杨卫民. 气场压力对激光辐照制备石墨纤维微观结构与力学性能影响[J]. 化工学报, 2023, 74(12): 4988-4996.

Qisheng DING, Jing TAN, Lisheng CHENG, Zhenghe ZHANG, Lijian SONG, Weimin YANG. Effect of gas field pressure on the microstructure and mechanical properties of graphite fibers prepared by laser irradiation[J]. CIESC Journal, 2023, 74(12): 4988-4996.

| 去浆碳纤维 | 直径/µm | 拉伸强度/MPa | 杨氏模量/GPa |

|---|---|---|---|

| CF-0-0 | 7~7.5 | 3100 | 225 |

表1 样品CF-0-0性能参数

Table 1 Performance parameters of CF-0-0 sample

| 去浆碳纤维 | 直径/µm | 拉伸强度/MPa | 杨氏模量/GPa |

|---|---|---|---|

| CF-0-0 | 7~7.5 | 3100 | 225 |

| 样品 | C/% | N/% | H/% | S/% |

|---|---|---|---|---|

| CF-0-0 | 92.68 | 5.28 | 1.286 | 0.862 |

| CF-200-0 | 95.20 | 1.85 | 0.198 | 0.226 |

| CF-200-0.1 | 94.60 | 1.75 | 0.21 | 0.265 |

| CF-200-0.2 | 95.12 | 1.76 | 0.385 | 0.412 |

| CF-200-0.3 | 94.40 | 2.02 | 0.769 | 0.621 |

| CF-260-0 | 96.37 | 1.34 | 0.163 | 0.223 |

| CF-260-0.1 | 95.70 | 1.42 | 0.122 | 0.322 |

| CF-260-0.2 | 95.85 | 1.45 | 0.65 | 0.452 |

| CF-260-0.3 | 95.53 | 1.98 | 0.82 | 0.763 |

表2 CF-P-S系列样品元素含量

Table 2 Element content of CF-P-S series samples

| 样品 | C/% | N/% | H/% | S/% |

|---|---|---|---|---|

| CF-0-0 | 92.68 | 5.28 | 1.286 | 0.862 |

| CF-200-0 | 95.20 | 1.85 | 0.198 | 0.226 |

| CF-200-0.1 | 94.60 | 1.75 | 0.21 | 0.265 |

| CF-200-0.2 | 95.12 | 1.76 | 0.385 | 0.412 |

| CF-200-0.3 | 94.40 | 2.02 | 0.769 | 0.621 |

| CF-260-0 | 96.37 | 1.34 | 0.163 | 0.223 |

| CF-260-0.1 | 95.70 | 1.42 | 0.122 | 0.322 |

| CF-260-0.2 | 95.85 | 1.45 | 0.65 | 0.452 |

| CF-260-0.3 | 95.53 | 1.98 | 0.82 | 0.763 |

| 样品 | D峰 | G峰 | ID | IG | R | ||

|---|---|---|---|---|---|---|---|

| 峰位值/cm-1 | FWHM | 峰位值/cm-1 | FWHM | ||||

| CF-200-0 | 1356.13 | 44.37 | 1591.77 | 48.18 | 9068.05 | 13335.36 | 0.68 |

| CF-200-0.1 | 1356.21 | 39.30 | 1589.13 | 39.21 | 7047.10 | 12812.90 | 0.55 |

| CF-200-0.2 | 1353.33 | 38.25 | 1587.90 | 26.35 | 5271.12 | 14514.88 | 0.36 |

| CF-200-0.3 | 1354.25 | 39.10 | 1588.78 | 28.07 | 3697.69 | 10829.36 | 0.34 |

| CF-260-0 | 1346.57 | 42.37 | 1581.34 | 32.85 | 1410.91 | 7506.16 | 0.19 |

| CF-260-0.1 | 1351.52 | 38.43 | 1586.13 | 25.76 | 1320.99 | 13293.37 | 0.10 |

| CF-260-0.2 | 1351.94 | 36.13 | 1587.22 | 23.92 | 989.19 | 21982.01 | 0.04 |

| CF-260-0.3 | 1357.43 | 34.46 | 1585.07 | 22.80 | 1039.34 | 18868.15 | 0.05 |

表3 CF-P-S系列样品Raman光谱拟合参数

Table 3 Raman spectrum fitting parameters of CF-P-S series samples

| 样品 | D峰 | G峰 | ID | IG | R | ||

|---|---|---|---|---|---|---|---|

| 峰位值/cm-1 | FWHM | 峰位值/cm-1 | FWHM | ||||

| CF-200-0 | 1356.13 | 44.37 | 1591.77 | 48.18 | 9068.05 | 13335.36 | 0.68 |

| CF-200-0.1 | 1356.21 | 39.30 | 1589.13 | 39.21 | 7047.10 | 12812.90 | 0.55 |

| CF-200-0.2 | 1353.33 | 38.25 | 1587.90 | 26.35 | 5271.12 | 14514.88 | 0.36 |

| CF-200-0.3 | 1354.25 | 39.10 | 1588.78 | 28.07 | 3697.69 | 10829.36 | 0.34 |

| CF-260-0 | 1346.57 | 42.37 | 1581.34 | 32.85 | 1410.91 | 7506.16 | 0.19 |

| CF-260-0.1 | 1351.52 | 38.43 | 1586.13 | 25.76 | 1320.99 | 13293.37 | 0.10 |

| CF-260-0.2 | 1351.94 | 36.13 | 1587.22 | 23.92 | 989.19 | 21982.01 | 0.04 |

| CF-260-0.3 | 1357.43 | 34.46 | 1585.07 | 22.80 | 1039.34 | 18868.15 | 0.05 |

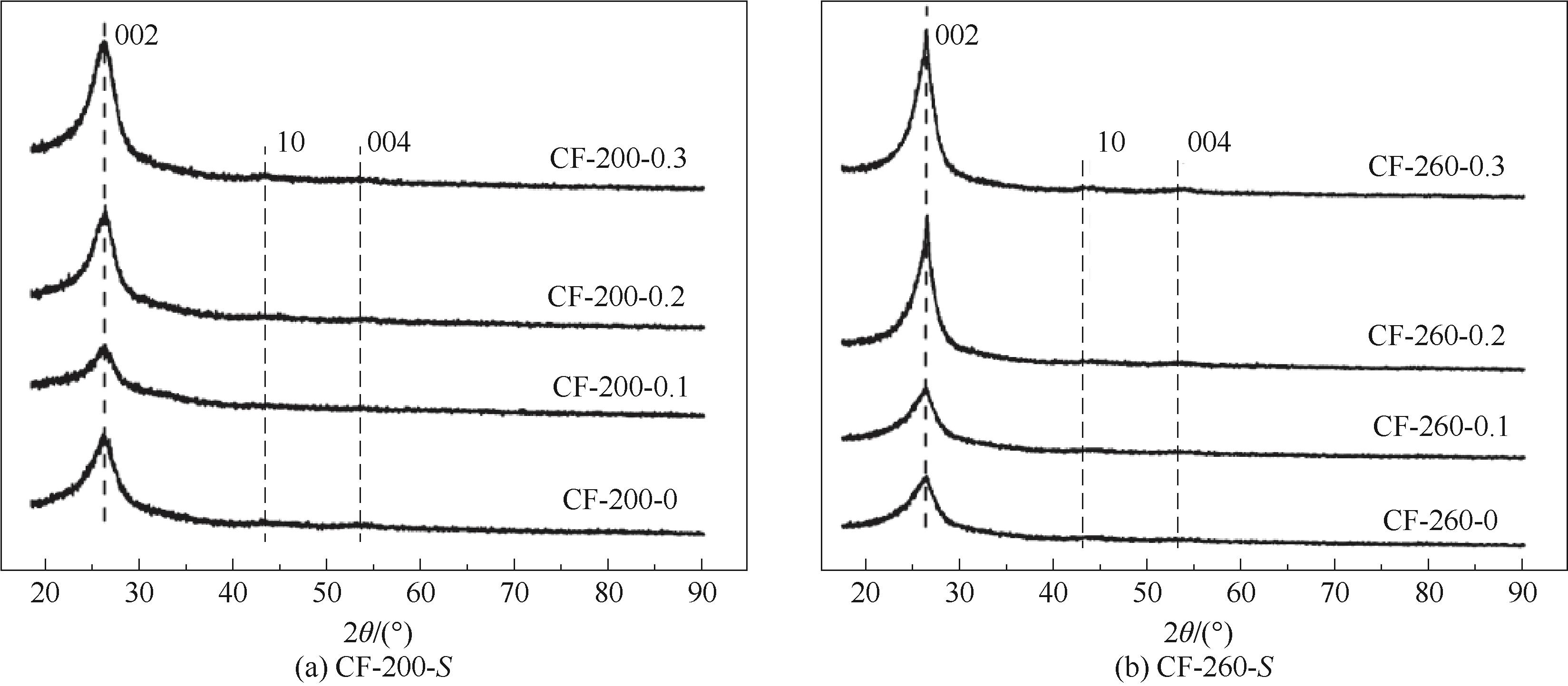

图5 不同气场压力下200 W和260 W激光辐照后碳纤维XRD赤道扫描谱图

Fig.5 XRD equatorial scanning spectra of carbon fibers after 200 W and 260 W laser irradiation under different gas field pressures

图6 不同气场压力下200 W和260 W激光辐照后碳纤维类石墨微晶尺寸变化

Fig.6 Size changes of carbon fiber like graphite microcrystals after 200 W and 260 W laser irradiation under different gas field pressures

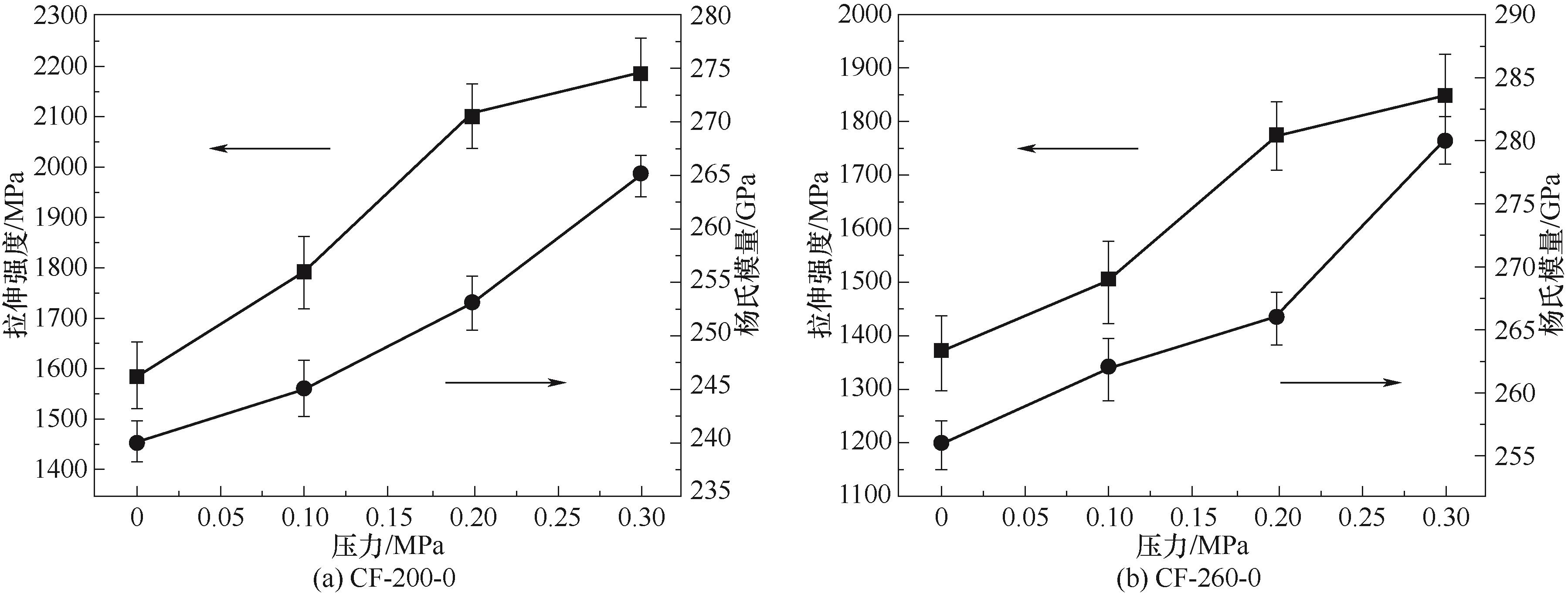

图7 不同气场压力下200 W和260 W激光辐照后碳纤维力学性能变化

Fig.7 Changes in mechanical properties of carbon fibers after 200 W and 260 W laser irradiation under different gas field pressures

| 1 | Zhou H H, Yu Q, Peng Q L, et al. Catalytic graphitization of carbon fibers with electrodeposited Ni-B alloy coating[J]. Materials Chemistry and Physics, 2008, 110(2/3): 434-439. |

| 2 | Zhang Z H, Song L J, Cheng L S, et al. Accelerated graphitization of PAN-based carbon fibers: K+-effected graphitization via laser irradiation[J]. ACS Sustainable Chemistry and Engineering, 2022, 10(24): 8086-8093. |

| 3 | Wang H T, Wang Y, Li T, et al. Gradient distribution of radial structure of PAN-based carbon fiber treated by high temperature[J]. Progress in Natural Science: Materials International, 2014, 24(1): 31-34. |

| 4 | He D M, Yao Y H, Xu S H, et al. Effect of anodization on the graphitization of PAN-based carbon fibers of PAN-based carbon fibers[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2011, 26(5): 926-930. |

| 5 | Greene M L, Schwartz R W, Treleaven J W. Short residence time graphitization of mesophase pitch-based carbon fibers[J]. Carbon, 2002, 40(8): 1217-1226. |

| 6 | Xiao P, Gong Y J, Li D F, et al. In-situ SAXS study on pore structure change of PAN-based carbon fiber during graphitization[J]. Microporous and Mesoporous Materials, 2021, 323: 111201. |

| 7 | Wei X Y, Zhang W J, Chen L W, et al. Evaluation of graphitization and tensile property in microwave plasma treated carbon fiber[J]. Diamond and Related Materials, 2022, 126: 109094. |

| 8 | Zhou H H, Peng Q L, Huang Z H, et al. Catalytic graphitization of PAN-based carbon fibers with electrodeposited Ni-Fe alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 581-587. |

| 9 | 陈力, 吕春祥, 蒋俊祺, 等. 聚丙烯腈凝胶纤维渗硼对炭纤维的石墨化过程的影响[J]. 新型炭材料, 2019, 34(1): 95-104. |

| Chen L, Lu C X, Jiang J Q, et al. Influence of boron on the graphitization of carbon fibers prepared by boron-modified polyacrylonitrile gel fibers[J]. New Carbon Materials, 2019, 34(1): 95-104. | |

| 10 | Barton B E, Behr M J, Patton J T, et al. High-modulus low-cost carbon fibers from polyethylene enabled by boron catalyzed graphitization[J]. Small, 2017, 13(36): 1701926. |

| 11 | Ming X, Wei A, Liu Y, et al. 2D-topology-seeded graphitization for highly thermally conductive carbon fibers[J]. Advanced Materials, 2022, 34(28): 2201867. |

| 12 | Yang Y, Chen J, Shi Y P. Recent developments in modifying polypropylene hollow fibers for sample preparation[J]. TRAC-Trends in Analytical Chemistry, 2015, 64: 109-117. |

| 13 | Wang H D, Liu J H, Zhang X, et al. Raman measurements of optical absorption and heat transfer coefficients of a single carbon fiber in atmosphere environment[J]. International Journal of Heat and Mass Transfer, 2014, 70: 40-45. |

| 14 | Lott P, Stollenwerk J, Wissenbach K. Laser-based production of carbon fibers[J]. Journal of Laser Applications, 2015, 27(S2): S29106. |

| 15 | Zhang Z H, Yang W M, Cheng L S, et al. Carbon fibers with high electrical conductivity: laser irradiation of mesophase pitch filaments obtains high graphitization degree[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(48): 17629-17638. |

| 16 | Janićijević M, Srećković M, Kaluđerović B, et al. Characterization of laser beam interaction with carbon materials[J]. Laser Physics, 2013, 23(5): 056002. |

| 17 | Yao L B, Yang W M, Li S L, et al. Graphitization of PAN-based carbon fibers by CO2 laser irradiation[J]. Carbon letters, 2017, 24: 97-102. |

| 18 | 钱鑫, 张永刚, 王雪飞. 高温石墨化对碳纤维结构的影响[J]. 高科技纤维与应用, 2016, 41(2): 24-27. |

| Qian X, Zhang Y G, Wang X F. Effect of high temperature graphitization on the structure of carbon fibers[J]. Hi-Tech Fiber & Application, 2016, 41(2): 24-27. | |

| 19 | Sha Y, Yang W M, Li S, et al. Laser induced graphitization of PAN-based carbon fibers[J]. RSC Advances, 2018, 8(21): 11543-11550. |

| 20 | 刘福杰, 王浩静, 范立东. PAN碳纤维在高温石墨化过程中密度的变化规律[J]. 化工新型材料, 2007, 35(1): 43-45. |

| Liu F J, Wang H J, Fan L D. The change of density under high temperature heat treatment in PAN-based carbon fibers[J]. New Chemical Materials, 2007, 35(1): 43-45. | |

| 21 | Voisey K T, Fouquet S, Roy D, et al. Fibre swelling during laser drilling of carbon fibre composites[J]. Optics and Lasers in Engineering, 2006, 44(11): 1185-1197. |

| 22 | 高爱君, 靳玉伟, 刘钟铃, 等. 碳纤维石墨化过程中的气胀[C]//复合材料: 创新与可持续发展(上册). 长沙, 2010: 286-290. |

| Gao A J, Jin Y W, Liu Z L, et al. Inflation during the graphitization process of carbon fibers[C]//Composite Materials: Innovation and Sustainable Development (Volume 1. Changsha, 2010: 286-290. | |

| 23 | 徐樑华, 曹维宇, 胡良全. 聚丙烯腈基碳纤维[M]. 北京: 国防工业出版社, 2018: 156-162. |

| Xu L H, Cao W Y, Hu L Q. Polyacrylonitrile Based Carbon Fiber[M]. Beijing: National DefenseIndustry Press, 2018: 156-162. | |

| 24 | Baba S, Goto T, Cho S H, et al. Effect of nitrogen gas pressure during heat treatment on the morphology of silicon nitride fibers synthesized by carbothermal nitridation[J]. Journal of Asian Ceramic Societies, 2018, 6(4): 401-408. |

| 25 | 刘杰, 牛鹏飞, 薛岩, 等. 炭化气场压力对PAN基碳纤维聚集态结构和力学性能的关联性研究[J]. 复合材料学报, 2013, 30(S1): 7-14. |

| Liu J, Niu P F, Xue Y, et al. Study on the correlation between the pressure of carbonization gas field and the aggregate structure and mechanical properties of PAN-based carbon fibers[J]. Acta Materiae Compositae Sinica, 2013, 30(S1): 7-14. | |

| 26 | Li D F, Wang H J, Wang X K. Raman spectra of PAN-based carbon fibers during graphitization[J]. Spectroscopy and Spectral Analysis, 2007, 27(11): 2249-2253. |

| 27 | Ye C, Wu H, Zhu S P, et al. Microstructure of high thermal conductivity mesophase pitch-based carbon fibers[J]. New Carbon Materials, 2021, 36(5): 980-985. |

| 28 | 葛曷一, 陈娟, 柳华实, 等. 聚丙烯腈预氧化纤维碳化中的结构演变与碳纤维微观结构[J]. 化工学报, 2009, 60(1): 238-243. |

| Ge H Y, Chen J, Liu H S, et al. Structural evolvement of PAN oxidized fiber during carbonization and microstructure of carbon fiber[J]. CIESC Journal, 2009, 60(1): 238-243. | |

| 29 | Gao A J, Su C J, Luo S, et al. Densification mechanism of polyacrylonitrile-based carbon fiber during heat treatment[J]. Journal of Physics and Chemistry of Solids, 2011, 72(10): 1159-1164. |

| 30 | 黎三洋. PAN基碳纤维高温激光石墨化工艺及连续化生产设备的研究[D]. 北京: 北京化工大学, 2018. |

| Li S Y. Study on high temperature laser graphitization process and continuous production equipment of PAN-based carbon fiber[D]. Beijing: Beijing University of Chemical Technology, 2018. | |

| 31 | Qin X Y, Lu Y G, Xiao H, et al. A comparison of the effect of graphitization on microstructures and properties of polyacrylonitrile and mesophase pitch-based carbon fibers[J]. Carbon, 2012, 50(12): 4459-4469. |

| 32 | Ramos A, Cameán I, García A B. Graphitization thermal treatment of carbon nanofibers[J]. Carbon, 2013, 59: 2-32. |

| 33 | 钱鑫, 王雪飞, 郑凯杰, 等. PAN基高模量碳纤维成型过程中的结构性能关联性[J]. 化工进展, 2019, 38(5): 2276-2283. |

| Qian X, Wang X F, Zheng K J, et al. Relationship between micro-structure and macro-properties during the formation of PAN-based high modulus carbon fibers[J]. Chemical Industry and Engineering Progress, 2019, 38(5): 2276-2283. | |

| 34 | Wang H, Wang H, Li D, et al. The effect of graphitization temperature on the microstructure and mechanical properties of carbon fibers[J]. New Carbon Materials, 2005, 20(2): 157-163. |

| 35 | Li D H, Lu C X, Hao J J, et al. A comparative analysis of polyacrylonitrile-based carbon fibers(Ⅰ): Microstructures[J]. New Carbon Materials, 2020, 35(6): 793-801. |

| 36 | Bao C G, Zeng Q, Li F J, et al. Effect of boron doping on the interlayer spacing of graphite[J]. Materials, 2022, 15(12): 4203. |

| 37 | Stankiewicz R, Badowski M. Influence of heaf treatment of carbon fibers on their microcrystalline structure and thermal stability[J]. Przemysl Chemiczny, 2001, 80(4): 145-149. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [3] | 金伟其, 吴月荣, 王霞, 李力, 裘溯, 袁盼, 王铭赫. 化工园区工业气体泄漏气云红外成像检测技术与国产化装备进展[J]. 化工学报, 2023, 74(S1): 32-44. |

| [4] | 刘远超, 关斌, 钟建斌, 徐一帆, 蒋旭浩, 李耑. 单层XSe2(X=Zr/Hf)的热电输运特性研究[J]. 化工学报, 2023, 74(9): 3968-3978. |

| [5] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [6] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [7] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [8] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [9] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [10] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [11] | 龙臻, 王谨航, 任俊杰, 何勇, 周雪冰, 梁德青. 离子液体协同PVCap抑制天然气水合物生成实验研究[J]. 化工学报, 2023, 74(6): 2639-2646. |

| [12] | 李靖, 沈聪浩, 郭大亮, 李静, 沙力争, 童欣. 木质素基碳纤维复合材料在储能元件中的应用研究进展[J]. 化工学报, 2023, 74(6): 2322-2334. |

| [13] | 刘远超, 蒋旭浩, 邵钶, 徐一帆, 钟建斌, 李耑. 几何尺寸及缺陷对石墨炔纳米带热输运特性的影响[J]. 化工学报, 2023, 74(6): 2708-2716. |

| [14] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| [15] | 徐文超, 孙志高, 李翠敏, 李娟, 黄海峰. 静态条件下表面活性剂E-1310对HCFC-141b水合物生成的影响[J]. 化工学报, 2023, 74(5): 2179-2185. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号