化工学报 ›› 2024, Vol. 75 ›› Issue (10): 3579-3587.DOI: 10.11949/0438-1157.20240352

收稿日期:2024-04-01

修回日期:2024-05-12

出版日期:2024-10-25

发布日期:2024-11-04

通讯作者:

刘民

作者简介:张昊(1999—),男,硕士研究生,2196596044@qq.com

基金资助:

Hao ZHANG( ), Min LIU(

), Min LIU( ), Xinwen GUO

), Xinwen GUO

Received:2024-04-01

Revised:2024-05-12

Online:2024-10-25

Published:2024-11-04

Contact:

Min LIU

摘要:

在晶种法合成过程中添加不同比例的十六烷基三甲基溴化铵(CTAB)作为晶体生长抑制剂制备了一系列纳米ZSM-5团聚体分子筛样品。采用XRD、SEM、ICP、氩气物理吸附、NH3-TPD等分析手段表征了催化剂的孔结构和酸性等,并阐述了CTAB对ZSM-5分子筛物化性质的影响:适量CTAB的添加在促进ZSM-5分子筛晶化的同时可抑制晶体的进一步生长,使初级纳米晶粒产生团聚,增加了比表面积,促进了微孔孔道的构筑,增加了酸性位点。采用固定床反应器评价了样品在高空速下的甲醇制丙烯(MTP)催化性能。结果显示,样品Z5-2(合成初始物料中CTAB/SiO2摩尔比为0.02)具有适宜的孔结构和酸量,表现出较好的催化性能,丙烯选择性为47.6%。

中图分类号:

张昊, 刘民, 郭新闻. CTAB辅助晶种法制备ZSM-5催化MTP反应[J]. 化工学报, 2024, 75(10): 3579-3587.

Hao ZHANG, Min LIU, Xinwen GUO. Preparation of ZSM-5 catalysts for MTP reaction by CTAB-assisted seeding method[J]. CIESC Journal, 2024, 75(10): 3579-3587.

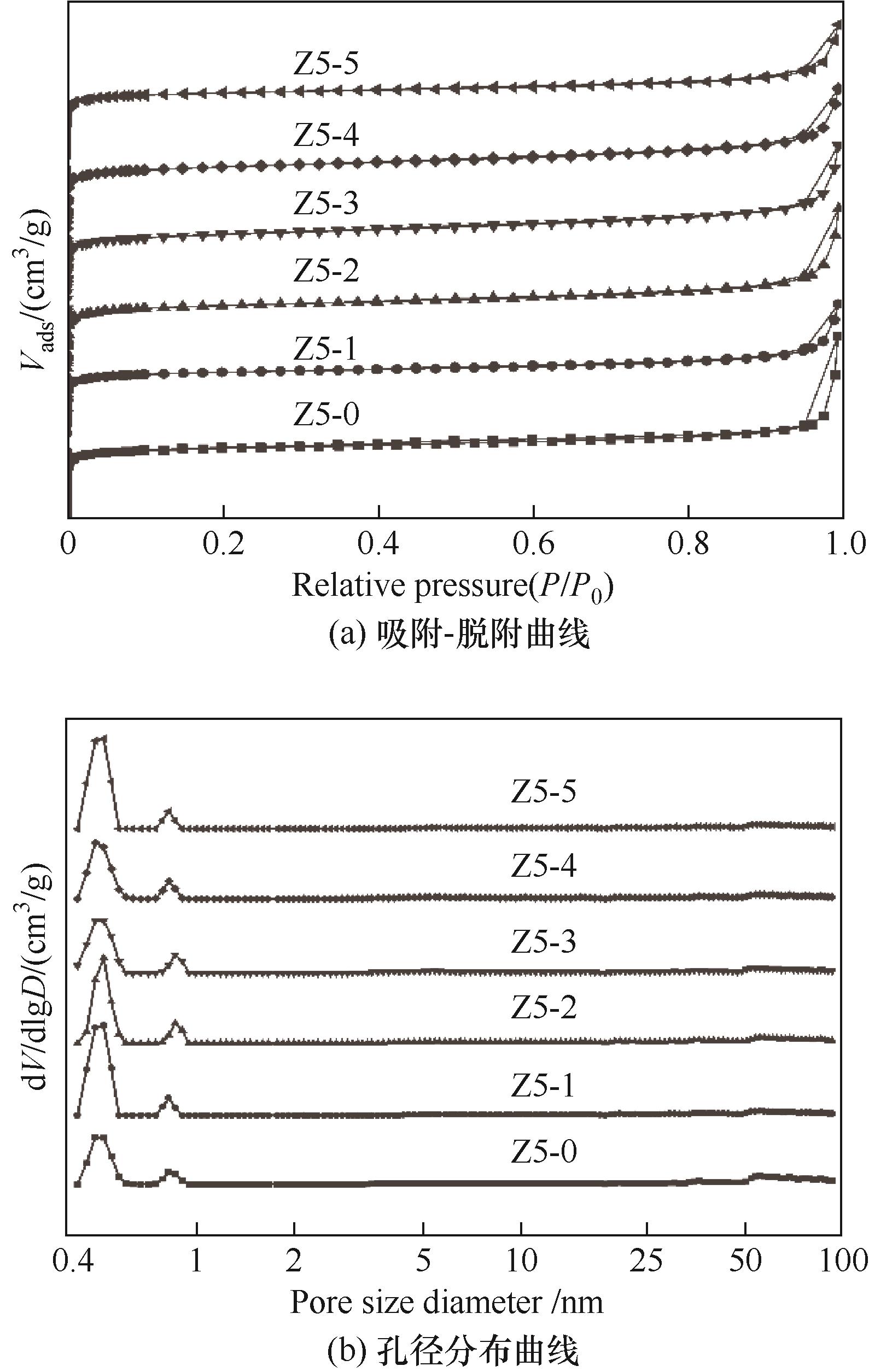

图3 不同CTAB/SiO2摩尔比样品的氩气物理吸脱附曲线和孔径分布曲线

Fig.3 Ar adsorption-desorption isotherms and pore size distribution curves of samples with various CTAB/SiO2 molar ratios

| Sample | Si/Al molar ratio | SBET/(m2/g) | SMicro/ (m2/g) | SMeso/(m2/g) | VTotal/ (cm3/g) | VMicro/ (cm3/g) | VMeso/ (cm3/g) |

|---|---|---|---|---|---|---|---|

| Z5-0 | 291 | 353 | 318 | 35 | 0.32 | 0.13 | 0.19 |

| Z5-1 | 288 | 410 | 375 | 34 | 0.33 | 0.15 | 0.18 |

| Z5-2 | 270 | 478 | 437 | 41 | 0.34 | 0.18 | 0.17 |

| Z5-3 | 290 | 439 | 386 | 53 | 0.32 | 0.16 | 0.15 |

| Z5-4 | 303 | 418 | 370 | 48 | 0.29 | 0.15 | 0.14 |

| Z5-5 | 277 | 395 | 366 | 30 | 0.26 | 0.14 | 0.12 |

表1 不同CTAB/SiO2摩尔比样品的Si/Al和孔结构特性

Table 1 Pore structure and solid yield of samples with various CTAB/SiO2 molar ratios

| Sample | Si/Al molar ratio | SBET/(m2/g) | SMicro/ (m2/g) | SMeso/(m2/g) | VTotal/ (cm3/g) | VMicro/ (cm3/g) | VMeso/ (cm3/g) |

|---|---|---|---|---|---|---|---|

| Z5-0 | 291 | 353 | 318 | 35 | 0.32 | 0.13 | 0.19 |

| Z5-1 | 288 | 410 | 375 | 34 | 0.33 | 0.15 | 0.18 |

| Z5-2 | 270 | 478 | 437 | 41 | 0.34 | 0.18 | 0.17 |

| Z5-3 | 290 | 439 | 386 | 53 | 0.32 | 0.16 | 0.15 |

| Z5-4 | 303 | 418 | 370 | 48 | 0.29 | 0.15 | 0.14 |

| Z5-5 | 277 | 395 | 366 | 30 | 0.26 | 0.14 | 0.12 |

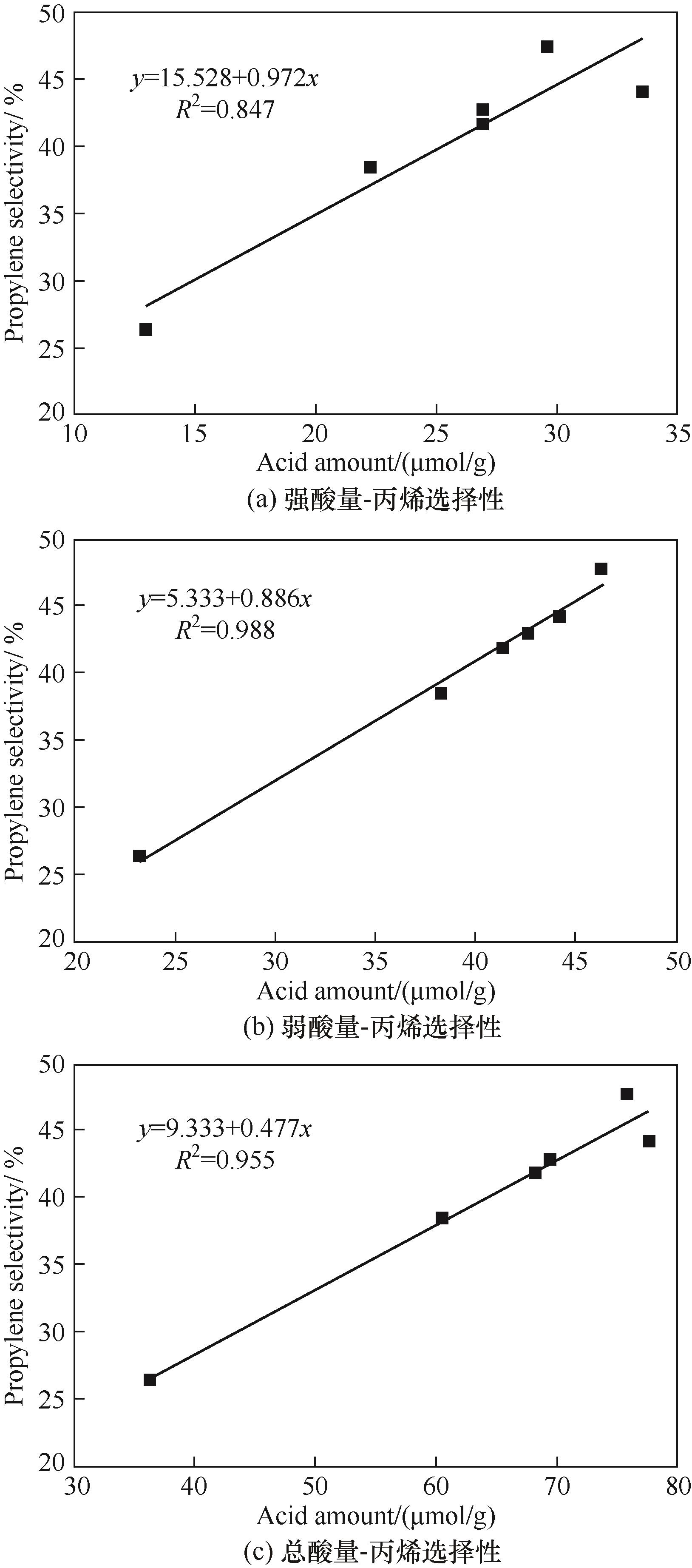

| Sample | Total acidity/(μmol/g) | Weak acidity/(μmol/g) | Strong acidity/(μmol/g) |

|---|---|---|---|

| Z5-0 | 36 | 23 | 13 |

| Z5-1 | 60 | 38 | 22 |

| Z5-2 | 76 | 46 | 30 |

| Z5-3 | 78 | 44 | 34 |

| Z5-4 | 70 | 43 | 27 |

| Z5-5 | 68 | 41 | 27 |

表2 不同CTAB/SiO2摩尔比样品的酸量统计

Table 2 Acid amount of samples with various CTAB/SiO2 molar ratios

| Sample | Total acidity/(μmol/g) | Weak acidity/(μmol/g) | Strong acidity/(μmol/g) |

|---|---|---|---|

| Z5-0 | 36 | 23 | 13 |

| Z5-1 | 60 | 38 | 22 |

| Z5-2 | 76 | 46 | 30 |

| Z5-3 | 78 | 44 | 34 |

| Z5-4 | 70 | 43 | 27 |

| Z5-5 | 68 | 41 | 27 |

| Catalysts | Methanol conversion/% | Selectivity/% | P/E | |||||

|---|---|---|---|---|---|---|---|---|

| CH4 | C2H4 | C3H6 | C2=~C4= | C2 ~C4 | C6+ | |||

| Z5-0 | 62.3 | 1.7 | 1.7 | 26.4 | 34.9 | 15.1 | 17.3 | 15.2 |

| Z5-1 | 95.7 | 0.3 | 1.4 | 38.5 | 55.1 | 10.2 | 17.5 | 27.5 |

| Z5-2 | 99.7 | 0.4 | 3.2 | 47.6 | 69.1 | 7.5 | 9.0 | 14.9 |

| Z5-3 | 97.0 | 0.3 | 2.4 | 44.1 | 60.2 | 6.7 | 14.4 | 18.4 |

| Z5-4 | 97.7 | 0.2 | 2.4 | 42.8 | 60.4 | 7.1 | 14.8 | 17.8 |

| Z5-5 | 95.9 | 0.3 | 2.6 | 41.7 | 59.3 | 6.8 | 15.0 | 16.0 |

表3 不同CTAB/SiO2摩尔比样品的平均甲醇转化率和产物选择性

Table 3 Average methanol conversion and product selectivity of samples with various CTAB/SiO2 molar ratios

| Catalysts | Methanol conversion/% | Selectivity/% | P/E | |||||

|---|---|---|---|---|---|---|---|---|

| CH4 | C2H4 | C3H6 | C2=~C4= | C2 ~C4 | C6+ | |||

| Z5-0 | 62.3 | 1.7 | 1.7 | 26.4 | 34.9 | 15.1 | 17.3 | 15.2 |

| Z5-1 | 95.7 | 0.3 | 1.4 | 38.5 | 55.1 | 10.2 | 17.5 | 27.5 |

| Z5-2 | 99.7 | 0.4 | 3.2 | 47.6 | 69.1 | 7.5 | 9.0 | 14.9 |

| Z5-3 | 97.0 | 0.3 | 2.4 | 44.1 | 60.2 | 6.7 | 14.4 | 18.4 |

| Z5-4 | 97.7 | 0.2 | 2.4 | 42.8 | 60.4 | 7.1 | 14.8 | 17.8 |

| Z5-5 | 95.9 | 0.3 | 2.6 | 41.7 | 59.3 | 6.8 | 15.0 | 16.0 |

图6 丙烯选择性与不同CTAB/SiO2摩尔比样品强酸量、弱酸量及总酸量的关系

Fig.6 Correlation of propylene selectivity with strong acid amount, weak acid amount and total acid amount of samples with various CTAB/SiO2 molar ratios

| 1 | 谭捷. 我国丙烯的供需现状及发展前景[J]. 精细与专用化学品, 2019, 27(11): 13-15. |

| Tan J. Supply and demand situation and development prospect of propylene in China[J]. Fine and Specialty Chemicals, 2019, 27(11): 13-15. | |

| 2 | 林玉霞, 徐德义, 李芳, 等. 甲醇制丙烯过程研究进展[J]. 化学反应工程与工艺, 2021, 37(4): 363-374. |

| Lin Y X, Xu D Y, Li F, et al. Recent advances of the methanol to propylene reaction[J]. Chemical Reaction Engineering and Technology, 2021, 37(4): 363-374. | |

| 3 | 王峰, 张伟, 雍晓静, 等. Lurgi甲醇制丙烯技术的工业应用[J]. 石油炼制与化工, 2014, 45(3): 46-50. |

| Wang F, Zhang W, Yong X J, et al. Commercial application of Lurgi MTP technology[J]. Petroleum Processing and Petrochemicals, 2014, 45(3): 46-50. | |

| 4 | Ahmadpour J, Taghizadeh M. Catalytic conversion of methanol to propylene over high-silica mesoporous ZSM-5 zeolites prepared by different combinations of mesogenous templates[J]. Journal of Natural Gas Science and Engineering, 2015, 23: 184-194. |

| 5 | Mohamed H O, Parsapur R K, Hita I, et al. Stable and reusable hierarchical ZSM-5 zeolite with superior performance for olefin oligomerization when partially coked[J]. Applied Catalysis B: Environmental, 2022, 316: 121582. |

| 6 | Gyungah P, Jeongmee K, Seon-Ju P, et al. Effect of acid modification of ZSM-5 catalyst on performance and coke formation for methanol-to-hydrocarbon reaction[J]. Molecular Catalysis, 2022, 531: 112702. |

| 7 | Chu Y Y, Yi X F, Li C B, et al. Brønsted/Lewis acid sites synergistically promote the initial C—C bond formation in the MTO reaction[J]. Chemical Science, 2018, 9(31): 6470-6479. |

| 8 | Jin R, Ma K, Xu S, et al. Effect of acid distribution and pore structure of ZSM-5 on catalytic performance[J]. Reaction Chemistry & Engineering, 2022, 7(10): 2152-2162. |

| 9 | Zhao Y N, Fan S B, Ma Q X, et al. Methanol converting to propylene on weakly acidic and hierarchical porous MFI zeolite[J]. Journal of Fuel Chemistry and Technology, 2022, 50(2): 210-217. |

| 10 | Zhu Q J, Kondo J N, Setoyama T, et al. Activation of hydrocarbons on acidic zeolites: superior selectivity of methylation of ethene with methanol to propene on weakly acidic catalysts[J]. Chemical Communications, 2008(41): 5164-5166. |

| 11 | Liu M, Cui T, Guo X W, et al. Stable Zn@ZSM-5 catalyst via a dry gel conversion process for methanol-to-aromatics reaction[J]. Microporous and Mesoporous Materials, 2021, 312: 110696. |

| 12 | Chen K, Wu X Q, Zhao J Y, et al. Organic-free modulation of the framework Al distribution in ZSM-5 zeolite by magnesium participated synthesis and its impact on the catalytic cracking reaction of alkanes[J]. Journal of Catalysis, 2022, 413: 735-750. |

| 13 | Tuo J, Fan S B, Yang N W, et al. Direct synthesis of [B, H]ZSM-5 by a solid-phase method: AlF siting and catalytic performance in the MTP reaction[J]. Catalysis Science & Technology, 2020, 10(20): 7034-7045. |

| 14 | Liu J, Zhang C X, Shen Z H, et al. Methanol to propylene: effect of phosphorus on a high silica HZSM-5 catalyst[J]. Catalysis Communications, 2009, 10(11): 1506-1509. |

| 15 | Weissenberger T, Reiprich B, Machoke A G F, et al. Hierarchical MFI type zeolites with intracrystalline macropores: the effect of the macropore size on the deactivation behaviour in the MTO reaction[J]. Catalysis Science & Technology, 2019, 9(12): 3259-3269. |

| 16 | Wang S, Chen Y, Wei Z, et al. Polymethylbenzene or alkene cycle? Theoretical study on their contribution to the process of methanol to olefins over H-ZSM-5 zeolite[J]. The Journal of Physical Chemistry C, 2015, 119(51): 28482-28498. |

| 17 | Liu Z Q, Chu Y Y, Tang X M, et al. Diffusion dependence of the dual-cycle mechanism for MTO reaction inside ZSM-12 and ZSM-22 zeolites[J]. The Journal of Physical Chemistry C, 2017, 121(41): 22872-22882. |

| 18 | Li J J, Liu M, Li S S, et al. Influence of diffusion and acid properties on methane and propane selectivity in methanol-to-olefins reaction[J]. Ind. Eng. Chem. Res., 2019, 58 (5): 1896-1905. |

| 19 | Li W Q, Li Y F, Liu Z Q, et al. Pore-confined and diffusion-dependent olefin catalytic cracking for the production of propylene over SAPO zeolites[J]. Industrial & Engineering Chemistry Research, 2022, 61(23): 7760-7776. |

| 20 | Wu Q M, Luan H M, Xiao F S. Theoretical design for zeolite synthesis[J]. Science China Chemistry, 2022, 65(9): 1683-1690. |

| 21 | Shang Z Y, Chen Y, Zhang L J, et al. Constructing single-crystalline hierarchical plate-like ZSM-5 zeolites with short b-axis length for catalyzing MTO reactions[J]. Inorganic Chemistry Frontiers, 2022, 9(7): 1456-1466. |

| 22 | Hamidzadeh M, Saeidi M, Komeili S. Modified seeding method to produce hierarchical nanocrystalline ZSM-5 zeolite[J]. Materials Today Communications, 2020, 25: 101308. |

| 23 | Chen Z W, Li Z, Zhang Y, et al. A green route for the synthesis of nano-sized hierarchical ZSM-5 zeolite with excellent DTO catalytic performance[J]. Chemical Engineering Journal, 2020, 388: 124322. |

| 24 | Chen L H, Sun M H, Wang Z, et al. Hierarchically structured zeolites: from design to application[J]. Chemical Reviews, 2020, 120(20): 11194-11294. |

| 25 | Li J J, Liu M, Guo X W, et al. Interconnected hierarchical ZSM-5 with tunable acidity prepared by a dealumination-realumination process: a superior MTP catalyst[J]. ACS Applied Materials & Interfaces, 2017, 9(31): 26096-26106. |

| 26 | Chen K, Zhao J Y, Li A H, et al. Realumination of dealuminated HZSM-5 zeolites by acid treatment, the impact of AlF distribution and its catalytic cracking performance of alkanes[J]. Microporous and Mesoporous Materials, 2022, 338: 111969. |

| 27 | Yousef S, Eimontas J, Striūgas N, et al. Catalytic pyrolysis and kinetic study of glass fibre-reinforced epoxy resin over CNTs, graphene and carbon black particles/ZSM-5 zeolite hybrid catalysts[J]. Journal of Thermal Analysis and Calorimetry, 2023, 148(3): 897-912. |

| 28 | Sachse A, García-Martínez J. Surfactant-templating of zeolites: from design to application[J]. Chemistry of Materials, 2017, 29(9): 3827-3853. |

| 29 | Huang L M, Guo W P, Deng P, et al. Investigation of synthesizing MCM-41/ZSM-5 composites[J]. The Journal of Physical Chemistry B, 2000, 104(13): 2817-2823. |

| 30 | Xue T, Liu H P, Zhang Y, et al. Synthesis of ZSM-5 with hierarchical porosity: in-situ conversion of the mesoporous silica-alumina species to hierarchical zeolite[J]. Microporous and Mesoporous Materials, 2017, 242: 190-199. |

| 31 | Zhang Y C, Zhu K K, Duan X Z, et al. Synthesis of hierarchical ZSM-5 zeolite using CTAB interacting with carboxyl-ended organosilane as a mesotemplate[J]. RSC Advances, 2014, 4(28): 14471-14474. |

| 32 | Chen H B, Wang Y Q, Sun C, et al. Aggregates of nano-sized ZSM-5 crystals synthesized with template-free and alkali-treated seeds for improving the catalytic performance in MTP reaction[J]. Catalysis Communications, 2017, 100: 107-111. |

| 33 | Sun L Y, Wang Y Q, Chen H B, et al. Direct synthesis of hierarchical ZnZSM-5 with addition of CTAB in a seeding method and improved catalytic performance in methanol to aromatics reaction[J]. Catalysis Today, 2018, 316: 91-98. |

| 34 | Xu D D, Feng J, Che S N. An insight into the role of the surfactant CTAB in the formation of microporous molecular sieves[J]. Dalton Transactions, 2014, 43(9): 3612-3617. |

| 35 | Zhang W M, Hao W M, Guo Y N, et al. A surfactant-directe sol-gel evolution in the formation of hierarchical zeolite beta[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2024, 689: 133720. |

| 36 | Velaga B, Doley R, Peela N R. Rapid synthesis of hierarchical ZSM-5 zeolites for the reactions involving larger reactant molecules[J]. Advanced Powder Technology, 2021, 32(4): 1033-1046. |

| 37 | Razavian M, Fatemi S. Synthesis and evaluation of seed-directed hierarchical ZSM-5 catalytic supports: inductive influence of various seeds and aluminosilicate gels on the physicochemical properties and catalytic dehydrogenative behavior[J]. Materials Chemistry and Physics, 2015, 165: 55-65. |

| 38 | Jin L J, Liu S B, Xie T, et al. Synthesis of hierarchical ZSM-5 by cetyltrimethylammonium bromide assisted self-assembly of zeolite seeds and its catalytic performances[J]. Reaction Kinetics, Mechanisms and Catalysis, 2014, 113(2): 575-584. |

| 39 | Tjandra W, Yao J, Tam K C. Interaction between silicates and ionic surfactants in dilute solution[J]. Langmuir, 2006, 22(4): 1493-1499. |

| 40 | Liu H, Zhang S, Xie S J, et al. Synthesis, characterization, and catalytic performance of hierarchical ZSM-11 zeolite synthesized via dual-template route[J]. Chinese Journal of Catalysis, 2018, 39(1): 167-180. |

| 41 | Gao S S, Xu S T, Wei Y X, et al. Insight into the deactivation mode of methanol-to-olefins conversion over SAPO-34: coke, diffusion, and acidic site accessibility[J]. Journal of Catalysis, 2018, 367: 306-314. |

| 42 | 郭强胜, 毛东森, 劳嫣萍, 等. 氟改性对纳米HZSM-5分子筛催化甲醇制丙烯的影响[J]. 催化学报, 2009, 30(12): 1248-1254. |

| Guo Q S, Mao D S, Lao Y P, et al. The effect of fluorine modification on catalytic performance of nanosized HZSM-5 zeolite for conversion of methanol to propene[J]. Chinese Journal of Catalysis, 2009, 30(12): 1248-1254. | |

| 43 | Zhang W M, Ming W X, Hu S F, et al. A feasible one-step synthesis of hierarchical zeolite beta with uniform nanocrystals via CTAB[J]. Materials, 2018, 11(5): 651. |

| 44 | Huang H W, Zhu H, Zhang S H, et al. Effect of silicon to aluminum ratio on the selectivity to propene in methanol conversion over H-ZSM-5 zeolites[J]. Journal of Fuel Chemistry and Technology, 2019, 47(1): 74-82. |

| [1] | 王树振, 王玉婷, 马梦茜, 张巍, 向江南, 鲁海莹, 王琰, 范彬彬, 郑家军, 代卫炯, 李瑞丰. 两步晶化合成ZSM-22分子筛及其临氢异构反应性能[J]. 化工学报, 2024, 75(9): 3176-3187. |

| [2] | 刘亚超, 谭晓杰, 李旭东, 王瑞, 王慧, 韩璇, 赵青山. DES合成高活性CoCO3纳米片及析氧反应性能研究[J]. 化工学报, 2024, 75(9): 3320-3328. |

| [3] | 张梦婷, 王书林, 桑熙, 元兴昊, 徐刚. 人工Cu-TM1459金属酶催化不对称迈克尔加成反应[J]. 化工学报, 2024, 75(9): 3255-3265. |

| [4] | 王冉, 王焕, 熊晓云, 关慧敏, 郑云锋, 陈彩琳, 秦玉才, 宋丽娟. FCC催化剂传质强化活性位利用效率的可视化分析[J]. 化工学报, 2024, 75(9): 3198-3209. |

| [5] | 王靖宇, 刘佳, 徐继香, 王磊. 薄片状PtZn@Silicalite-1分子筛的合成及催化丙烷脱氢性能研究[J]. 化工学报, 2024, 75(9): 3188-3197. |

| [6] | 刘旭升, 李泽洋, 杨宇森, 卫敏. 电催化二氧化碳还原制备气态产物的研究进展[J]. 化工学报, 2024, 75(7): 2385-2408. |

| [7] | 罗莉, 陈文尧, 张晶, 钱刚, 周兴贵, 段学志. 氧化铝结构与表面性质调控及其催化甲醇脱水制二甲醚性能研究[J]. 化工学报, 2024, 75(7): 2522-2532. |

| [8] | 王寅, 初鹏飞, 刘虎, 吕静, 黄守莹, 王胜平, 马新宾. 不同pH铝溶胶对二甲醚羰基化成型丝光沸石催化剂性能的影响[J]. 化工学报, 2024, 75(7): 2533-2543. |

| [9] | 杨露, 刘聪聪, 孟彤彤, 张博远, 杨腾飞, 邓文安, 王晓斌. 分散型催化剂在煤/重油共炼体系中的加氢抑焦作用[J]. 化工学报, 2024, 75(7): 2556-2564. |

| [10] | 黄静茹, 陈佳轩, 张群锋, 阮晋, 朱来, 叶光华, 周兴贵. ZSM-5分子筛结构对苯烷基化反应性能影响的数值模拟研究[J]. 化工学报, 2024, 75(7): 2544-2555. |

| [11] | 冀钟, 赵彦玲, 陈雨濛, 高林霞, 王翼鹏, 刘欢. ZSM-5分子筛对典型涂装VOCs的吸附性能及机理研究[J]. 化工学报, 2024, 75(6): 2332-2343. |

| [12] | 王天闻, 闫肃, 赵梦园, 杨天让, 刘建国. 固体氧化物电池空气电极铬中毒机理及抗铬性能研究进展[J]. 化工学报, 2024, 75(6): 2091-2108. |

| [13] | 丁禹, 杨昌泽, 李军, 孙会东, 商辉. 原子尺度钼系加氢脱硫催化剂的研究进展与展望[J]. 化工学报, 2024, 75(5): 1735-1749. |

| [14] | 赵亭亭, 鄢立祥, 唐福利, 肖敏之, 谭烨, 宋刘斌, 肖忠良, 李灵均. 光辅助锂-二氧化碳电池催化剂的设计策略与反应机理研究进展[J]. 化工学报, 2024, 75(5): 1750-1764. |

| [15] | 莫锦洪, 韩雪, 朱毅翔, 李菁, 王旭裕, 纪红兵. Pt-Ga/CeO2-ZrO2-Al2O3脱氢裂解双功能催化剂用于正丁烷催化制烯烃研究[J]. 化工学报, 2024, 75(5): 1855-1869. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号