化工学报 ›› 2024, Vol. 75 ›› Issue (6): 2222-2232.DOI: 10.11949/0438-1157.20231309

收稿日期:2023-12-07

修回日期:2024-02-12

出版日期:2024-06-25

发布日期:2024-07-03

通讯作者:

杜文静

作者简介:李新泽(2000—),男,硕士研究生,lxz2023@mail.sdu.edu.cn

基金资助:

Xinze LI1( ), Shuangxing ZHANG1, Honghai YANG2, Wenjing DU1(

), Shuangxing ZHANG1, Honghai YANG2, Wenjing DU1( )

)

Received:2023-12-07

Revised:2024-02-12

Online:2024-06-25

Published:2024-07-03

Contact:

Wenjing DU

摘要:

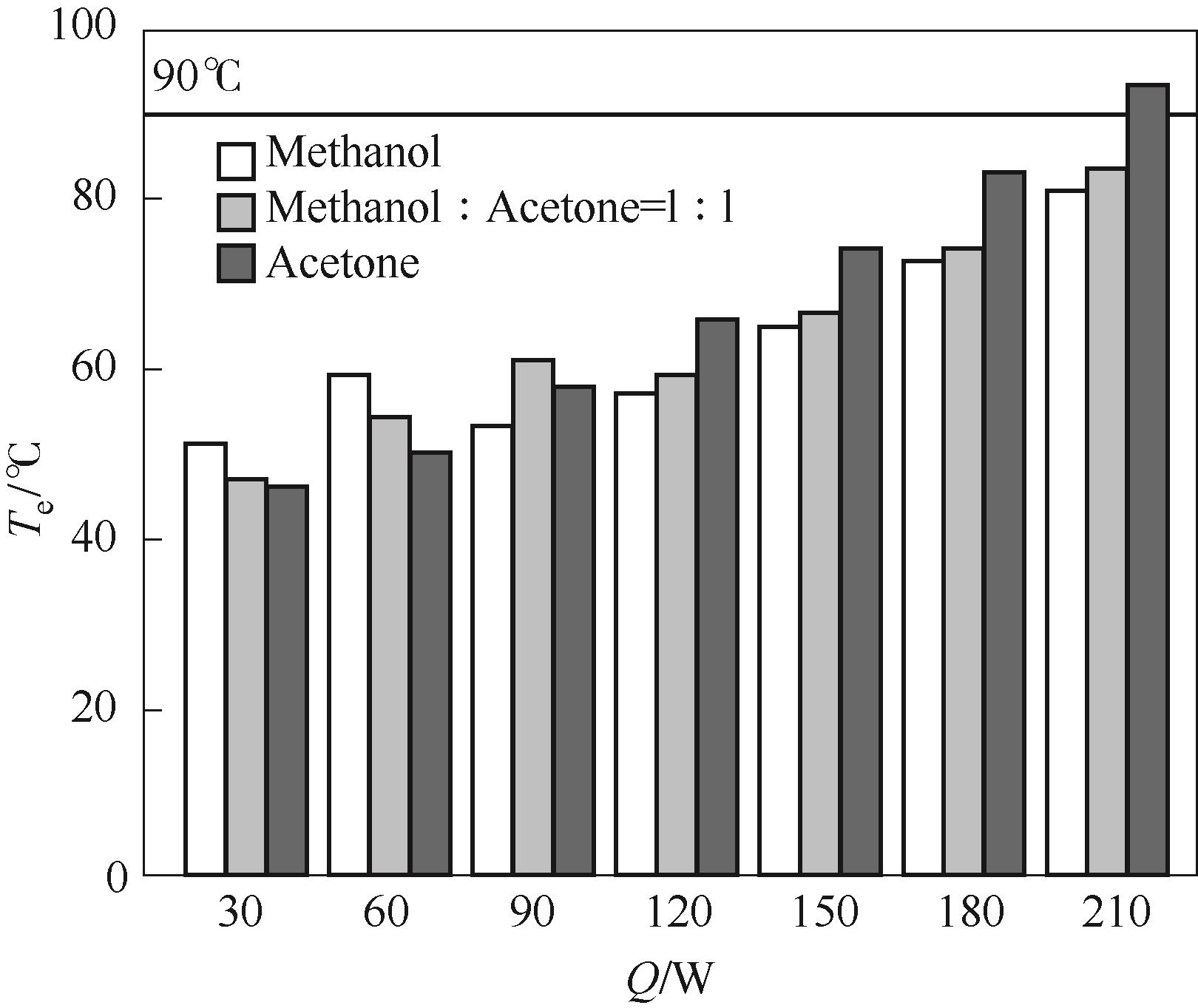

提出一种电池冷却用C形脉动热管(pulsating heat pipe,PHP),具有较好的散热性和包裹特性。选择甲醇、丙酮、去离子水、乙醇和甲醇-丙酮混合物为PHP工质,实验研究了不同加热功率和充液率(filling rate,FR)工况下PHP的性能。结果表明,FR过高或过低均不利于C形PHP稳定运行,实际应用中需综合考虑热阻、传热极限等指标,选取合适的FR。实验研究范围内,C形PHP最佳FR在45%左右。综合考虑蒸发温度与热阻,甲醇-丙酮混合物C形PHP具备更好的性能,能够满足第二代Mirai电池冷却需求,可将其表面温度控制在84℃以下,允许的电池最大体积功率密度为6 kW/L。依据应用场合选择工质和布置方式后,PHP能保证受控对象的安全运行。相关结论为电池热控制系统设计提供了重要的参考和借鉴。

中图分类号:

李新泽, 张双星, 杨洪海, 杜文静. 基于电池冷却用新型脉动热管性能的实验研究[J]. 化工学报, 2024, 75(6): 2222-2232.

Xinze LI, Shuangxing ZHANG, Honghai YANG, Wenjing DU. Experimental study on performance of new type of pulsating heat pipe for battery cooling[J]. CIESC Journal, 2024, 75(6): 2222-2232.

| 设备名称 | 设备参数 |

|---|---|

| 无纸记录仪 | 厂家:YOKOGAWA;型号:GX20;精度:± 0.1℃ |

| 交流电源 | 厂家:国电亚光电源有限公司;型号:HYB1760-0.5 KVA;精度:± 0.1 A,± 0.1 V |

| T型热电偶 | 测温范围:-200~350℃;精度:± 0.5℃ |

表1 相关设备的详细参数

Table 1 Detailed parameters of related devices

| 设备名称 | 设备参数 |

|---|---|

| 无纸记录仪 | 厂家:YOKOGAWA;型号:GX20;精度:± 0.1℃ |

| 交流电源 | 厂家:国电亚光电源有限公司;型号:HYB1760-0.5 KVA;精度:± 0.1 A,± 0.1 V |

| T型热电偶 | 测温范围:-200~350℃;精度:± 0.5℃ |

| 参数 | 最大不确定度/% |

|---|---|

| Tc | ± 1.85 |

| Te | ± 1.85 |

| Q | ± 0.14 |

| R | ± 3.49 |

表2 主要实验参数的最大不确定度

Table 2 Maximum uncertainty of main experimental parameters

| 参数 | 最大不确定度/% |

|---|---|

| Tc | ± 1.85 |

| Te | ± 1.85 |

| Q | ± 0.14 |

| R | ± 3.49 |

图13 甲醇、丙酮及其混合工质C形PHP稳态平均蒸发温度

Fig.13 Average evaporation temperature of methanol, acetone and their mixed working medium C-shaped PHP after steady state

| 1 | Xiong S S, Wu Z K, Li W, et al. Improvement of temperature and humidity control of proton exchange membrane fuel cells[J]. Sustainability, 2021, 13(19): 10578. |

| 2 | Song Y X, Zhang C Z, Deshpande A, et al. Fixed air flow-rate selection by considering the self-regulating function of low power air-cooled PEMFC stack[J]. International Journal of Heat and Mass Transfer, 2020, 158: 119771. |

| 3 | Sasmito A P, Birgersson E, Lum K W, et al. Fan selection and stack design for open-cathode polymer electrolyte fuel cell stacks[J]. Renewable Energy, 2012, 37(1): 325-332. |

| 4 | Sasmito A P, Lum K W, Birgersson E, et al. Computational study of forced air-convection in open-cathode polymer electrolyte fuel cell stacks[J]. Journal of Power Sources, 2010, 195(17): 5550-5563. |

| 5 | Yu S H, Sohn S, Nam J H, et al. Numerical study to examine the performance of multi-pass serpentine flow-fields for cooling plates in polymer electrolyte membrane fuel cells[J]. Journal of Power Sources, 2009, 194(2): 697-703. |

| 6 | Lakshminarayanan V, Karthikeyan P. Performance enhancement of interdigitated flow channel of PEMFC by scaling up study[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020, 42(14): 1785-1796. |

| 7 | Tong G Y, Xu X M, Yuan Q Q, et al. Research on influencing factors of heat transfer enhancement fins in fuel cell cooling channel[J]. Ionics, 2021, 27(2): 743-757. |

| 8 | Fly A, Thring R H. A comparison of evaporative and liquid cooling methods for fuel cell vehicles[J]. International Journal of Hydrogen Energy, 2016, 41(32): 14217-14229. |

| 9 | Garrity P T, Klausner J F, Mei R W. A flow boiling microchannel evaporator plate for fuel cell thermal management[J]. Heat Transfer Engineering, 2007, 28(10): 877-884. |

| 10 | Shirzadi N, Roshandel R, Shafii M B. Integration of miniature heat pipes into a proton exchange membrane fuel cell for cooling applications[J]. Heat Transfer Engineering, 2017, 38(18): 1595-1605. |

| 11 | Leu T S, Wu C H. Experimental studies of surface modified oscillating heat pipes[J]. Heat and Mass Transfer, 2017, 53(11): 3329-3340. |

| 12 | Vasiliev L L. Heat pipes in modern heat exchangers[J]. Applied Thermal Engineering, 2005, 25(1): 1-19. |

| 13 | Min C H, Gao X M, Li F, et al. Thermal performance analyses of pulsating heat pipe for application in proton exchange member fuel cell[J]. Energy Conversion and Management, 2022, 259: 115566. |

| 14 | Bastakoti D, Zhang H N, Li D, et al. An overview on the developing trend of pulsating heat pipe and its performance[J]. Applied Thermal Engineering, 2018, 141: 305-332. |

| 15 | Yang H H, Khandekar S, Groll M. Operational limit of closed loop pulsating heat pipes[J]. Applied Thermal Engineering, 2008, 28(1): 49-59. |

| 16 | Qian N, Fu Y C, Zhang Y W, et al. Experimental investigation of thermal performance of the oscillating heat pipe for the grinding wheel[J]. International Journal of Heat and Mass Transfer, 2019, 136: 911-923. |

| 17 | Saha N D, Das P K, Sharma P K. Influence of process variables on the hydrodynamics and performance of a single loop pulsating heat pipe[J]. International Journal of Heat and Mass Transfer, 2014, 74: 238-250. |

| 18 | Babu E R, Reddappa H N, Gnanendra Reddy G V. Effect of filling ratio on thermal performance of closed loop pulsating heat pipe[J]. Materials Today: Proceedings, 2018, 5(10): 22229-22236. |

| 19 | Xu R J, Zhang C, Chen H, et al. Heat transfer performance of pulsating heat pipe with zeotropic immiscible binary mixtures[J]. International Journal of Heat and Mass Transfer, 2019, 137: 31-41. |

| 20 | Clement J, Wang X. Experimental investigation of pulsating heat pipe performance with regard to fuel cell cooling application[J]. Applied Thermal Engineering, 2013, 50(1): 268-274. |

| 21 | Cattani L, Malavasi M, Bozzoli F, et al. Experimental analysis of an innovative electrical battery thermal management system[J]. Energies, 2023, 16(13): 5071. |

| 22 | Manno V, Filippeschi S, Mameli M, et al. Thermal-hydraulic characterization of a flat plate pulsating heat pipe for automotive applications[J]. Interfacial Phenomena and Heat Transfer, 2015, 3(4): 413-425. |

| 23 | Burban G, Ayel V, Alexandre A, et al. Experimental investigation of a pulsating heat pipe for hybrid vehicle applications[J]. Applied Thermal Engineering, 2013, 50(1): 94-103. |

| 24 | 周智程, 魏爱博, 屈健, 等. 管板结构脉动热管冷却动力电池的传热特性[J]. 化工进展, 2020, 39(10): 3916-3925. |

| Zhou Z C, Wei A B, Qu J, et al. Heat transfer characteristics of oscillating heat pipe and its application in power battery cooling[J]. Chemical Industry and Engineering Progress, 2020, 39(10): 3916-3925. | |

| 25 | 郭子瑞, 池日光. 工质对顶部加热/底部冷却型脉动热管的影响[J]. 建筑热能通风空调, 2022, 41(5): 18-23. |

| Guo Z R, Chi R G. Effect of working fluid on top heating/bottom cooling type oscillating heat pipe[J]. Building Energy & Environment, 2022, 41(5): 18-23. | |

| 26 | 池日光, 郭子瑞, 公绪金. L形脉动热管启动和传热特性的研究[J]. 制冷学报, 2022, 43(5): 99-105. |

| Chi R G, Guo Z R, Gong X J. Start-up and heat transfer characteristics of L-shaped pulsating heat pipe[J]. Journal of Refrigeration, 2022, 43(5): 99-105. | |

| 27 | Zhou Y, Cui X Y, Weng J H, et al. Experimental investigation of the heat transfer performance of an oscillating heat pipe with graphene nanofluids[J]. Powder Technology, 2018, 332: 371-380. |

| 28 | 张双星, 刘舫辰, 张义飞, 等. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| Zhang S X, Liu F C, Zhang Y F, et al. Experimental study on phase change heat storage and release of R-134a pulsating heat pipe[J]. CIESC Journal, 2023, 74(S1): 165-171. | |

| 29 | 杨洪海. 闭式回路脉动热管运行性能的研究[D]. 上海: 东华大学, 2006. |

| Yang H H. Investigations of the operational performance of closed loop pulsating heat pipes[D]. Shanghai: Donghua University, 2006. | |

| 30 | Yan L P, Zhang P, Xu H, et al. Visualization of thermo-hydrodynamic behavior in flat-plate pulsating heat pipe with HFE-347[J]. Journal of Thermal Science, 2021, 30(3): 926-938. |

| 31 | Xing M B, Wang R X, Xu R J. Experimental study on thermal performance of a pulsating heat pipe with surfactant aqueous solution[J]. International Journal of Heat and Mass Transfer, 2018, 127: 903-909. |

| 32 | Su Z P, Hu Y X, Zheng S B, et al. Recent advances in visualization of pulsating heat pipes: a review[J]. Applied Thermal Engineering, 2023, 221: 119867. |

| 33 | Zhang D W, He Z T, Guan J, et al. Heat transfer and flow visualization of pulsating heat pipe with silica nanofluid: an experimental study[J]. International Journal of Heat and Mass Transfer, 2022, 183: 122100. |

| 34 | 杨洪海, 肖荪, GROLL Manfred. 工质热物性对脉动热管运行性能的影响[J]. 工程热物理学报, 2010, 31(1): 97-99. |

| Yang H H, Xiao S, GROLL Manfred. Effect of thermophysical properties of working fluids on operational performance in pulsating heat pipes[J]. Journal of Engineering Thermophysics, 2010, 31(1): 97-99. | |

| 35 | Bao K L, Liu Y, Yan Y H, et al. Partial visualization study on flow, startup and heat transfer characteristics of closed-loop pulsating heat pipe with R1336mzz(Z)[J]. Applied Thermal Engineering, 2023, 226: 120218. |

| 36 | Kim J, Kim S J. Experimental investigation on working fluid selection in a micro pulsating heat pipe[J]. Energy Conversion and Management, 2020, 205: 112462. |

| 37 | Shi S Y, Cui X Y, Han H, et al. A study of the heat transfer performance of a pulsating heat pipe with ethanol-based mixtures[J]. Applied Thermal Engineering, 2016, 102: 1219-1227. |

| [1] | 李娟, 曹耀文, 朱章钰, 石雷, 李佳. 仿生正形尾鳍结构微通道流动与传热特性数值研究及结构优化[J]. 化工学报, 2024, 75(5): 1802-1815. |

| [2] | 关朝阳, 黄国庆, 张一喃, 陈宏霞, 杜小泽. 泡沫铜导离气泡强化流动沸腾换热实验研究[J]. 化工学报, 2024, 75(5): 1765-1776. |

| [3] | 王金山, 王世学, 朱禹. 冷却表面温差对高温质子交换膜燃料电池性能的影响[J]. 化工学报, 2024, 75(5): 2026-2035. |

| [4] | 师毓辉, 邢继远, 姜雪晗, 叶爽, 黄伟光. 基于PBM的离心式叶轮内气泡破碎合并数值模拟[J]. 化工学报, 2024, 75(5): 1816-1829. |

| [5] | 李怡菲, 董新宇, 王为术, 刘璐, 赵一璠. 微肋板表面干冰升华喷雾冷却传热数值模拟[J]. 化工学报, 2024, 75(5): 1830-1842. |

| [6] | 刘帆, 张芫通, 陶成, 胡成玉, 杨小平, 魏进家. 歧管式射流微通道液冷散热性能[J]. 化工学报, 2024, 75(5): 1777-1786. |

| [7] | 赵金鹏, 张永民, 兰斌, 罗节文, 赵碧丹, 王军武. 气固鼓泡床结构双流体传热模型及其模拟验证[J]. 化工学报, 2024, 75(4): 1497-1507. |

| [8] | 陈思睿, 毕景良, 王雷, 李元媛, 陆规. 气液两相流流型特征无监督提取的卷积自编码器:机理及应用[J]. 化工学报, 2024, 75(3): 847-857. |

| [9] | 邓志诚, 许世峰, 王淇冬, 王家瑞, 王斯民. 浸没燃烧处理高盐高化学需氧量废水过程与能耗分析[J]. 化工学报, 2024, 75(3): 1000-1008. |

| [10] | 李乃良, 刘常松, 杜雪平, 张一帆, 韩东太. 基于Hurst指数的严重段塞流多尺度分形特性[J]. 化工学报, 2024, 75(2): 484-492. |

| [11] | 刘昌会, 肖桐, 刘庆祎, 耿龙, 赵佳腾. 多孔二氧化钛强化的相变材料储热机理研究[J]. 化工学报, 2024, 75(2): 706-714. |

| [12] | 陶明清, 慕明昊, 程滕, 王博. 喷雾耦合降温强化旋风分离器脱除细颗粒物的研究[J]. 化工学报, 2024, 75(2): 584-592. |

| [13] | 刘志鹏, 赵长颖, 吴睿, 张智昊. 基于水电解制氢的梯度多孔传输层中气液流动可视化实验研究[J]. 化工学报, 2024, 75(2): 520-530. |

| [14] | 詹小斌, 王会彬, 蒋亚龙, 史铁林. 声共振混合器高黏度流体混合的功耗特性研究[J]. 化工学报, 2024, 75(2): 531-542. |

| [15] | 刘起超, 张世博, 周云龙, 李昱庆, 陈聪, 冉议文. 起伏振动水平管气液两相流型及转变机理[J]. 化工学报, 2024, 75(2): 493-504. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号