化工学报 ›› 2025, Vol. 76 ›› Issue (6): 3073-3083.DOI: 10.11949/0438-1157.20241441

张畅( ), 解强(

), 解强( ), 沙雨桐, 王炳杰, 梁鼎成, 刘金昌

), 沙雨桐, 王炳杰, 梁鼎成, 刘金昌

收稿日期:2024-12-12

修回日期:2025-01-06

出版日期:2025-06-25

发布日期:2025-07-09

通讯作者:

解强

作者简介:张畅(2000—),女,硕士研究生,zc13763409978@163.com

基金资助:

Chang ZHANG( ), Qiang XIE(

), Qiang XIE( ), Yutong SHA, Bingjie WANG, Dingcheng LIANG, Jinchang LIU

), Yutong SHA, Bingjie WANG, Dingcheng LIANG, Jinchang LIU

Received:2024-12-12

Revised:2025-01-06

Online:2025-06-25

Published:2025-07-09

Contact:

Qiang XIE

摘要:

竹炭在储能等领域有巨大的应用潜力。然而,无机成分尤其是硅会严重影响其性能。采用KOH浸渍竹材、与竹材共炭化后酸洗脱除硅及其他无机组分,考察KOH浓度、浸渍时间、炭化温度对脱硅脱灰效果的影响;借助ICP-MS等方法表征脱灰效果、探究脱灰机理。此外,将竹炭制为硬炭,表征电化学性能。结果表明,KOH可有效负载到竹材上,竹材在3 mol·L-1 KOH溶液中浸渍4 h,650℃下炭化后酸洗,竹炭灰分含量可降低至0.55%、脱灰率达84.76%,Si的含量降低至0.3%、脱硅率达76.19%;低灰竹炭制备硬炭的电化学性能显著优于未脱灰样品;50 mA·g-1的电流密度下首次库仑效率达到70.67%;低灰竹基硬炭经过50 mA·g-1~5 A·g-1电流密度的循环后,在50 mA·g-1下可逆比容量可恢复至365 mAh·g-1。碱浸竹材炭化后酸洗是深度脱灰脱硅的有效途径,低灰竹基硬炭的电化学性能优异。

中图分类号:

张畅, 解强, 沙雨桐, 王炳杰, 梁鼎成, 刘金昌. 低灰低硅竹炭的制备及衍生硬炭的电化学性能[J]. 化工学报, 2025, 76(6): 3073-3083.

Chang ZHANG, Qiang XIE, Yutong SHA, Bingjie WANG, Dingcheng LIANG, Jinchang LIU. Preparation of bamboo char with low ash and silicon content and electrochemical properties of its derived hard carbon[J]. CIESC Journal, 2025, 76(6): 3073-3083.

| 样品 | 水分(Mad)/% | 灰分(Ad)/% | 挥发分(Vdaf)/% | 固定碳(FCdaf)/% |

|---|---|---|---|---|

| B | 6.76 | 1.30 | 83.87 | 16.13 |

| BC | 1.24 | 3.61 | 11.88 | 88.12 |

| HBC | 1.3 | 2.73 | 10.11 | 89.89 |

表1 竹材及竹炭的工业分析指标

Table 1 Results of proximate analysis of bamboo and bamboo char samples

| 样品 | 水分(Mad)/% | 灰分(Ad)/% | 挥发分(Vdaf)/% | 固定碳(FCdaf)/% |

|---|---|---|---|---|

| B | 6.76 | 1.30 | 83.87 | 16.13 |

| BC | 1.24 | 3.61 | 11.88 | 88.12 |

| HBC | 1.3 | 2.73 | 10.11 | 89.89 |

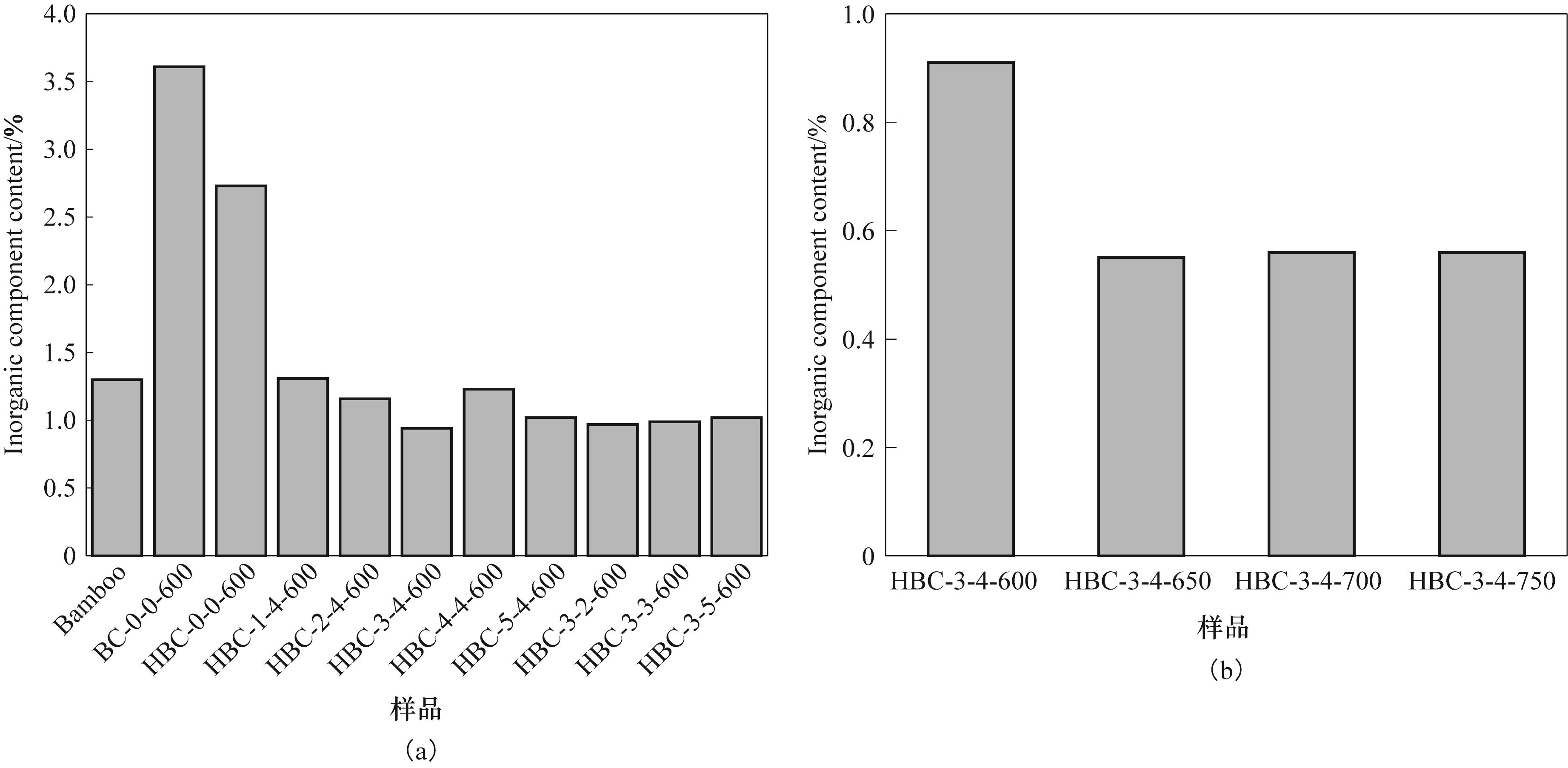

图1 (a)竹材、竹炭及碱浸处理竹炭样品的灰分含量,(b)不同炭化温度竹炭样品无机组分含量

Fig.1 (a) The ash content of bamboo, bamboo char and bamboo char treated by alkali leaching, (b) The inorganic component content of bamboo char samples carbonized at different temperatures

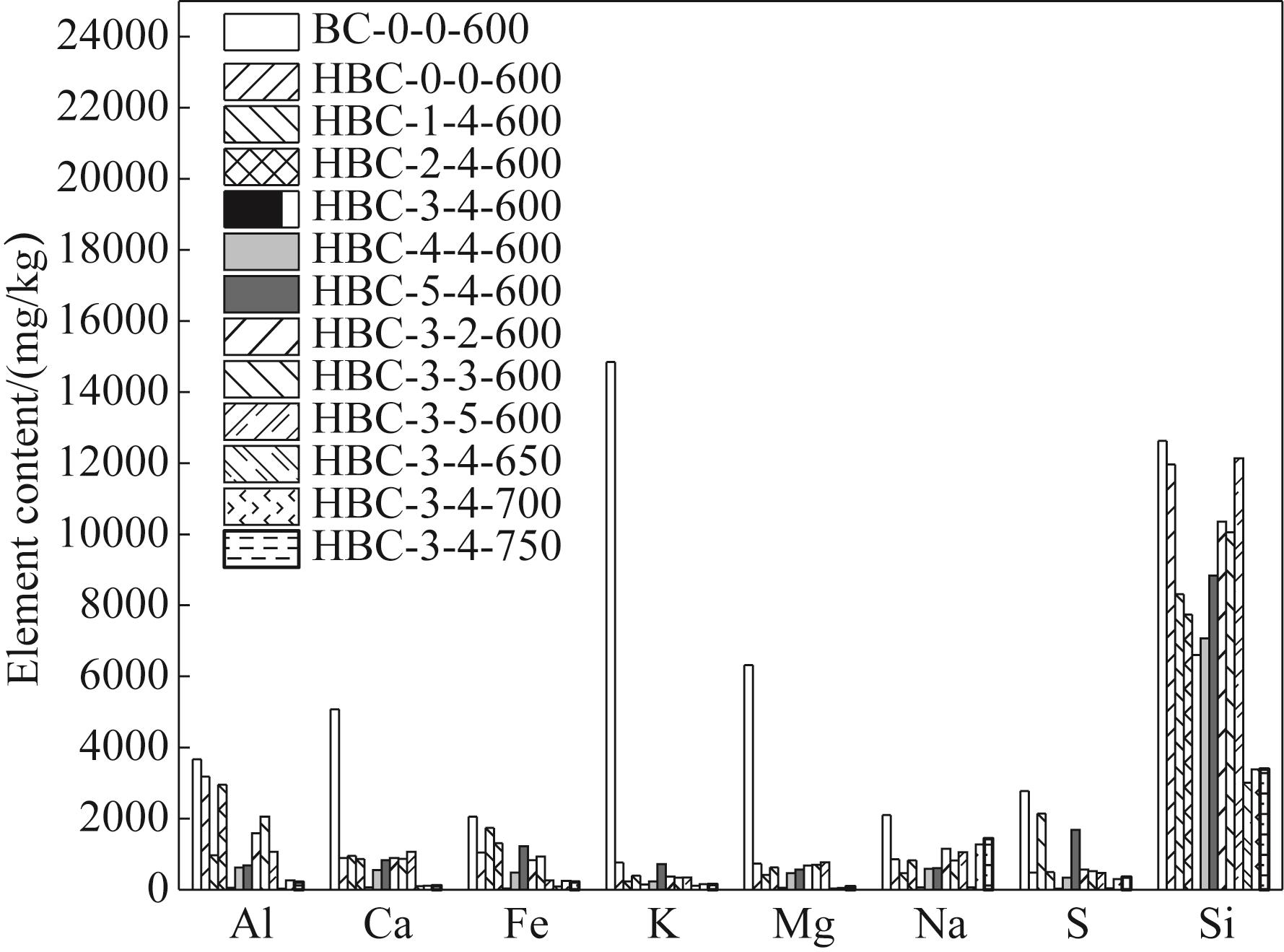

图2 竹炭、酸洗竹炭及KOH浸渍处理竹炭样品元素含量

Fig.2 The element content of bamboo char, bamboo char after acid washing and bamboo char treated by KOH impregnation and acid washing

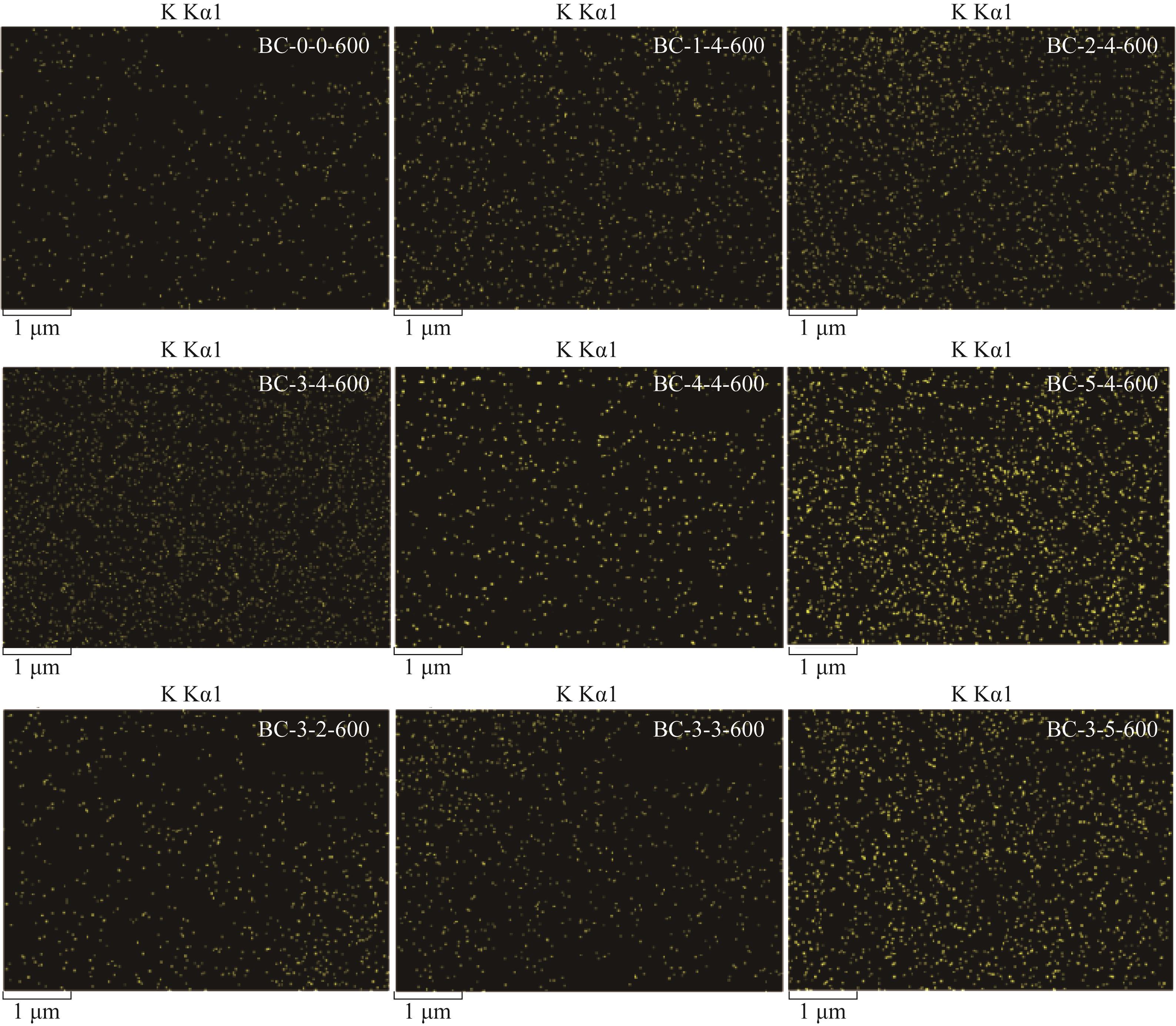

图3 竹炭、不同浓度KOH浸4 h竹炭及3 mol·L-1KOH浸不同时间竹炭样品的EDS图

Fig.3 EDS diagrams of bamboo char, bamboo char impregnated by KOH with different concentrations for 4 h and bamboo char impregnated in 3 mol·L-1 KOH for different time

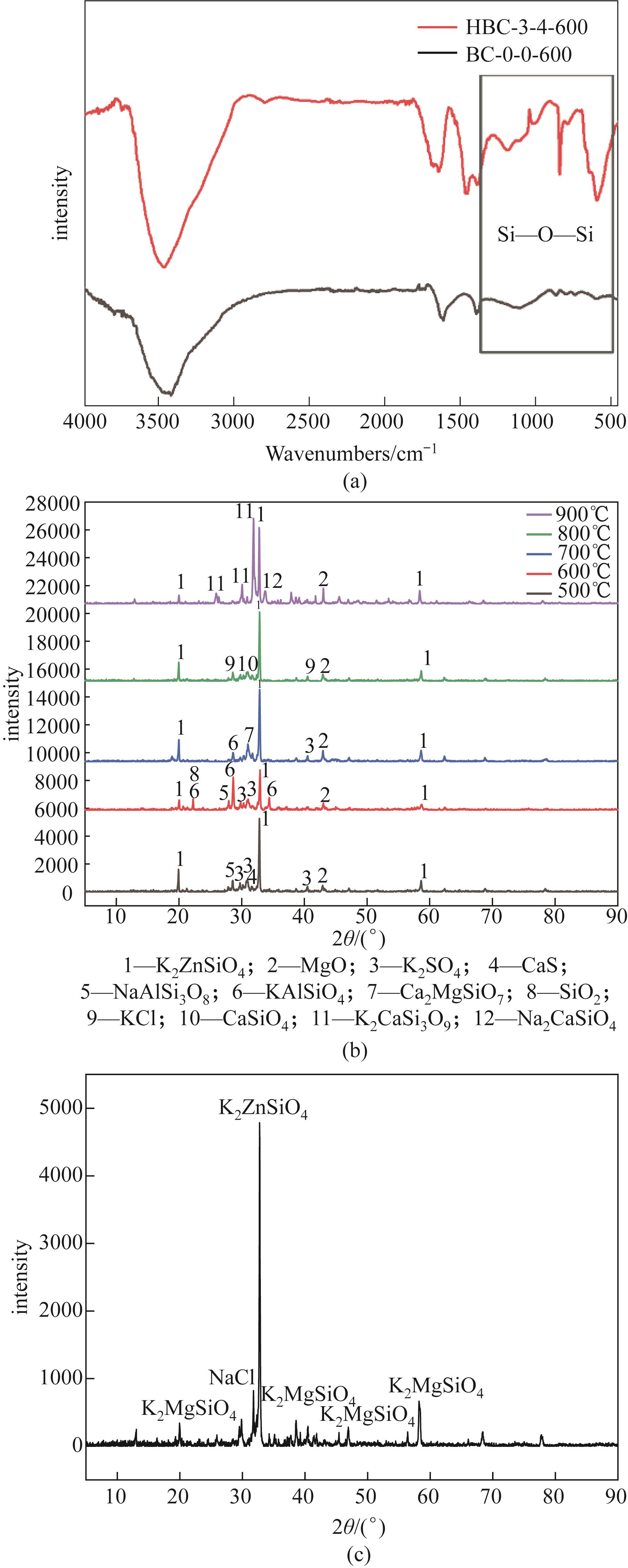

图4 (a)竹炭及处理样品的红外光谱图,(b)不同温度炭化的竹炭灰分XRD图,(c)650℃炭化的竹炭灰分的XRD图

Fig.4 (a) Infrared spectra of bamboo char and treated samples, (b) XRD patterns of ash from bamboo char carbonized at different temperatures, (c) XRD patterns of ash from bamboo char carbonized at 650℃

炭化 温度/℃ | 元素含量/% | ||||||

|---|---|---|---|---|---|---|---|

| K | O | Si | Na | Al | Mg | Ca | |

| 600 | 79.89 | 17.52 | 0.49 | 0.38 | 0.13 | 0.27 | 0.20 |

| 650 | 79.96 | 17.49 | 0.43 | 0.40 | 0.10 | 0.25 | 0.18 |

| 700 | 80.01 | 17.43 | 0.39 | 0.45 | 0.09 | 0.24 | 0.17 |

| 750 | 78.10 | 18.02 | 1.43 | 0.51 | 0.23 | 0.20 | 0.22 |

| 800 | 73.41 | 20.51 | 3.82 | 0.63 | 0.48 | 0.14 | 0.39 |

表2 3mol·L-1KOH浸渍4 h处理竹材在不同温度下炭化得到竹炭的灰分XRF结果

Table 2 XRF analysis results of ashes of bamboo char samples obtained by carbonization of bamboo treated with 3 mol·L-1 KOH for 4 h at different temperatures

炭化 温度/℃ | 元素含量/% | ||||||

|---|---|---|---|---|---|---|---|

| K | O | Si | Na | Al | Mg | Ca | |

| 600 | 79.89 | 17.52 | 0.49 | 0.38 | 0.13 | 0.27 | 0.20 |

| 650 | 79.96 | 17.49 | 0.43 | 0.40 | 0.10 | 0.25 | 0.18 |

| 700 | 80.01 | 17.43 | 0.39 | 0.45 | 0.09 | 0.24 | 0.17 |

| 750 | 78.10 | 18.02 | 1.43 | 0.51 | 0.23 | 0.20 | 0.22 |

| 800 | 73.41 | 20.51 | 3.82 | 0.63 | 0.48 | 0.14 | 0.39 |

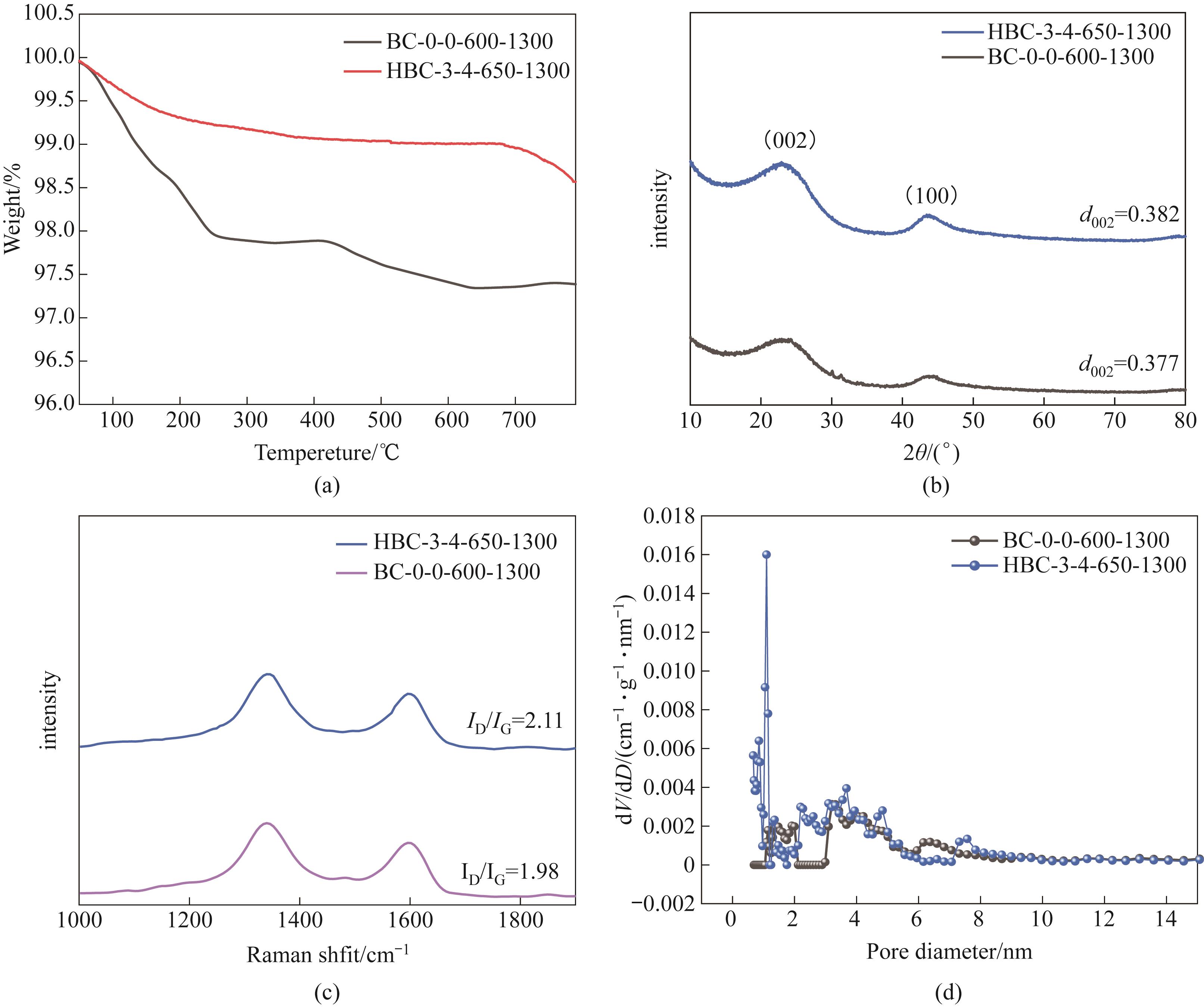

图5 BC-0-0-600-1300及HBC-3-4-650-1300的热重曲线(a)、XRD图(b)、拉曼图(c)、孔径分布(d)

Fig.5 BC-0-0-600-1300 and HBC-3-4-650-1300 Thermogravimetric diagram (a), XRD spectrum (b), Raman spectrum (c), and pore size distribution diagram (d)

图7 BC-0-0-600-1300和HBC-3-4-650-1300的(a)、(b)充放电图(c)、(d)交流阻抗图(e)、(f)倍率图

Fig.7 BC-0-0-600-1300 and HBC-3-4-650-1300 the initial galvanostatic charge-discharge profiles[(a), (b)]; AC impedance diagram[(c), (d)]; rate diagram[(e), (f)]

| 样品 | 可逆比容量/(mAh·g -1) | 首次库仑 效率/% | 孔结构 |

|---|---|---|---|

| 低灰竹基硬炭 | 365 | 70.67 | ≤1 |

| 未脱硅竹炭衍生硬炭[ | 348.5 | 84.1 | 2~4 nm |

表3 未脱硅竹基硬炭和低灰低硅竹基硬炭电化学性能及孔结构比较

Table 3 Comparison of bamboo-based hard carbon and low ash bamboo-based hard carbon

| 样品 | 可逆比容量/(mAh·g -1) | 首次库仑 效率/% | 孔结构 |

|---|---|---|---|

| 低灰竹基硬炭 | 365 | 70.67 | ≤1 |

| 未脱硅竹炭衍生硬炭[ | 348.5 | 84.1 | 2~4 nm |

| 样品或文献 | 首次库伦 效率/% | 首次放电比 容量/(mAh·g -1) | 充放电循环 性能/(mAh·g -1) |

|---|---|---|---|

| HBC-3-4-650-1300 | 70.67 | 536.9 | 348.5 |

| [ | 84.1 | 414.3 | 295.9 |

| [ | 83.7 | 363.2 | 272.8 |

| [ | 84.4 | 378.8 | 283.9 |

表4 HBC-3-4-650-1300与其他竹基硬炭的电化学性能比较

Table 4 The electrochemical performances of HBC-3-4-650-1300 compare with other bamboo-based hard carbons

| 样品或文献 | 首次库伦 效率/% | 首次放电比 容量/(mAh·g -1) | 充放电循环 性能/(mAh·g -1) |

|---|---|---|---|

| HBC-3-4-650-1300 | 70.67 | 536.9 | 348.5 |

| [ | 84.1 | 414.3 | 295.9 |

| [ | 83.7 | 363.2 | 272.8 |

| [ | 84.4 | 378.8 | 283.9 |

| [1] | Kressman R, Long S. GCB‐Bioenergy reaches a new high in impact factor and goes open access[J]. GCB Bioenergy, 2016, 8(1): 936-953. |

| [2] | Park S, Song J J, Lee W C, et al. Advances in biomass-derived electrode materials for energy storage and circular carbon economy[J]. Chemical Engineering Journal, 2023, 470: 144234. |

| [3] | Yang X M, He H H, Lv T, et al. Fabrication of biomass-based functional carbon materials for energy conversion and storage[J]. Materials Science and Engineering R: Reports, 2023, 154: 100736. |

| [4] | Ashok Kumar S S, Bashir S, Pershaanaa M, et al. A review on the recent progress of the plant-based porous carbon materials as electrodes for high-performance supercapacitors[J]. Journal of Materials Science, 2023, 58(15): 6516-6555. |

| [5] | Zhang G X, Chen Y M, Chen Y G, et al. Activated biomass carbon made from bamboo as electrode material for supercapacitors[J]. Materials Research Bulletin, 2018, 102: 391-398. |

| [6] | Chai Y L, Wan C C, Cheng W J, et al. Biomass-derived carbon for dye-sensitized solar cells: a review[J]. Journal of Materials Science, 2023, 58(14): 6057-6075. |

| [7] | Du B X, Xing J W, Ran Z Y, et al. Dielectric and energy storage properties of polypropylene by deashing method for DC polymer film capacitors[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2021, 28(6): 1917-1924. |

| [8] | Liou T H, Wu S J. Characteristics of microporous/mesoporous carbons prepared from rice husk under base- and acid-treated conditions[J]. Journal of Hazardous Materials, 2009, 171(1/2/3): 693-703. |

| [9] | Zhou S Y, Li X H, Wang Z X, et al. Effect of activated carbon and electrolyte on properties of supercapacitor[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1328-1333. |

| [10] | Zhang Y F, Zhang C X, Huang G X, et al. Tailoring the textural properties of hierarchical porous carbons for supercapacitors[J]. Materials Letters, 2015, 159: 377-380. |

| [11] | Yang X M, Lv T, Qiu J S. High mass‐loading biomass‐based porous carbon electrodes for supercapacitors: review and perspectives[J]. Small, 2023, 19(22): 2300336. |

| [12] | Gou L, Jing W F, Li Y, et al. Lattice-coupled Si/MXene confined by hard carbon for fast sodium-ion conduction[J]. ACS Applied Energy Materials, 2021, 4(7): 7268-7277. |

| [13] | Dong D, Xiao Y. Recent progress and challenges in coal-derived porous carbon for supercapacitor applications[J]. Chemical Engineering Journal, 2023, 470: 144441. |

| [14] | Kharrazi S M, Soleimani M, Jokar M, et al. Pretreatment of lignocellulosic waste as a precursor for synthesis of high porous activated carbon and its application for Pb (Ⅱ) and Cr (Ⅵ) adsorption from aqueous solutions[J]. International Journal of Biological Macromolecules, 2021, 180: 299-310. |

| [15] | Chen D Y, Zhuang X Z, Gan Z Y, et al. Co-pyrolysis of light bio-oil leached bamboo and heavy bio-oil: effects of mass ratio, pyrolysis temperature, and residence time on the biochar[J]. Chemical Engineering Journal, 2022, 437: 135253. |

| [16] | 张振, 杨胜杰, 张晓丽, 等. 超级电容器用竹基活性炭原料脱灰工艺的研究[J]. 电池工业, 2013, 18(1): 55-57. |

| Zhang Z, Yang S J, Zhang X L,et al. Research on the deashing technology for super capacitor using bamboo-based activated carbon material[J]. Chinese Battery Industry, 2013, 18(1): 55-57. | |

| [17] | Yang J F, Feng Z X, Gao Q, et al. Ash thermochemical behaviors of bamboo lignin from kraft pulping: influence of washing process[J]. Renewable Energy, 2021, 174: 178-187. |

| [18] | Liu X, Tang X, Ran H, et al. Si supply could alter N uptake and assimilation of saplings—A 15N tracer study of four subtropical species[J] Forests, 2023, 14: 1353. |

| [19] | Yang W T, Gong X X, Ji H B, et al. Qualitative and quantitative characterization of nutrient content and morphology in seeds of bamboo, rice, and wheat[J]. Journal of Cereal Science, 2021, 101: 103273. |

| [20] | Rusch F, Wastowski A D, De Lira T S, et al. Description of the component properties of species of bamboo: a review[J]. Yordsre, 2023, 13(3): 2487-2495. |

| [21] | Gao Q, Ni L M, He Y Y, et al. Effect of hydrothermal pretreatment on deashing and pyrolysis characteristics of bamboo shoot shells[J]. Energy, 2022, 247: 123510. |

| [22] | Zhang J B, Zhong Z P, Shen D K, et al. Preparation of bamboo-based activated carbon and its application in direct carbon fuel cells[J]. Energy & Fuels, 2011, 25(5): 2187-2193. |

| [23] | Ellerbrock R, Stein M, Schaller J. Comparing amorphous silica, short-range-ordered silicates and silicic acid species by FTIR[J]. Scientific Reports, 2022, 12(1): 11708. |

| [24] | Su M F, Ni L M, Rong S W, et al. The ash-forming element migration and mineral transformation during the bamboo combustion process[J]. ACS Omega, 2024, 9(20): 21974-21982. |

| [25] | Zheng H, Wang Z Y, Deng X, et al. Characteristics and nutrient values of biochars produced from giant reed at different temperatures[J]. Bioresource Technology, 2013, 130: 463-471. |

| [26] | Liu L, Tan Z, Gong H, et al. Migration and transformation mechanisms of nutrient elements (N, P, K) within biochar in straw-biochar-soil-plant systems: a review[J]. 2019, 7: 22-32. |

| [27] | Zhang X W, Deng H K, Yang J, et al. Isoconversional kinetics of pyrolysis of vaporthermally carbonized bamboo[J]. Renewable Energy, 2020, 149: 701-707. |

| [28] | Pothaya S, Poochai C, Tammanoon N, et al. Bamboo-derived hard carbon/carbon nanotube composites as anode material for long-life sodium-ion batteries with high charge/discharge capacities[J]. Rare Metals, 2024, 43(1): 124-137. |

| [29] |

Chen L, Bai L, Yeo J, et al. Wood-derived carbon with selectively introduced C O groups toward stable and high capacity anodes for sodium storage[J]. ACS Appl. Mater. Interfaces, 2020, 12: 27499-27507. O groups toward stable and high capacity anodes for sodium storage[J]. ACS Appl. Mater. Interfaces, 2020, 12: 27499-27507.

|

| [30] | Sun D, Zhao L, Sun P, et al. Rationally regulating closed pore structures by pitch coating to boost sodium storage performance of hard carbon in low‐voltage platforms[J]. Advanced Functional Materials, 2024, 34(40): 2403642. |

| [31] | Kuai J, Xie J, Wang J D, et al. Comparison and optimization of biomass-derived hard carbon as anode materials for sodium-ion batteries[J]. Chemical Physics Letters, 2024, 842: 141214. |

| [32] | Xu T Y, Qiu X, Zhang X, et al. Regulation of surface oxygen functional groups and pore structure of bamboo-derived hard carbon for enhanced sodium storage performance[J]. Chemical Engineering Journal, 2023, 452: 139514. |

| [33] | Kuai J, Xie J, Wang J D, et al. Optimizing hard carbon materials for sodium-ion batteries: insights from particle size and soft carbon-coating strategy[J]. Journal of Power Sources, 2025, 627: 235792. |

| [1] | 胡家玮, 王聪, 刘美婧. 一种抑制隧道排水管道中结晶体形成的双层阻垢疏水涂层[J]. 化工学报, 2025, 76(6): 3053-3072. |

| [2] | 姬海燕, 刘家印, 吴海军, 何璟琳, 靳紫恒, 魏钿航, 江霞. 低温等离子体在生物质气化制氢中的应用研究进展[J]. 化工学报, 2025, 76(6): 2419-2433. |

| [3] | 康佳, 刘欢, 李海燕, 罗茂亮, 姚洪. 宽温区HCl/NaOH热介质中碳钢腐蚀行为及涂层性能研究[J]. 化工学报, 2025, 76(6): 2872-2885. |

| [4] | 郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261. |

| [5] | 李坤, 黄锐, 丛君, 马海涛, 常龙娇, 罗绍华. NCM622正极材料结构形态和储锂特性的同步演变[J]. 化工学报, 2025, 76(4): 1831-1840. |

| [6] | 林纬, 杜建, 姚晨, 朱家豪, 汪威, 郑小涛, 徐建民, 喻九阳. 电化学水软化过程中离子输运与成核机理研究[J]. 化工学报, 2025, 76(4): 1788-1799. |

| [7] | 吴迪, 刘世朋, 王文伟, 姜久春, 杨晓光. 机械压力对锂金属电池性能影响的研究进展[J]. 化工学报, 2025, 76(4): 1422-1431. |

| [8] | 戴文智, 沈雄健, 宋晓博, 杨新乐. 生物质双级蒸发双回热有机朗肯循环系统环境分析[J]. 化工学报, 2025, 76(3): 1230-1242. |

| [9] | 马钟琛, 魏子杰, 朱明涛, 叶恒棣, 郭学益, 谭磊. 一步氧化法制备锰酸锂正极材料用电池级四氧化三锰[J]. 化工学报, 2025, 76(3): 1363-1374. |

| [10] | 翟紫航, 蒋杰, 李锦锦, 赵玲, 奚桢浩. 基于2,5-呋喃二甲酸的三元无规共聚酯PBSF的制备与性能[J]. 化工学报, 2025, 76(2): 868-878. |

| [11] | 肖志华, 房浩楠, 郑方植, 孙冬, 陶丽达, 李永峰, 徐春明, 马新龙. NaCl辅助构筑高性能沥青基硬炭负极材料[J]. 化工学报, 2025, 76(2): 846-857. |

| [12] | 李文宝, 胡锦鹏, 杜淼, 潘鹏举, 单国荣. 强韧P(SBMA-co-AAc)/SiO2复合水凝胶海洋防污减阻涂层[J]. 化工学报, 2025, 76(2): 787-796. |

| [13] | 徐子易, 席阳, 宋泽文, 周海骏. 碳纳米材料在锌离子电池中的应用研究进展[J]. 化工学报, 2025, 76(1): 40-52. |

| [14] | 纪之骄, 张晓方, 甘汶, 薛云鹏. 载体对单原子电催化剂合成氨性能的影响与调控策略[J]. 化工学报, 2025, 76(1): 18-39. |

| [15] | 郭珊, 田雨, 徐永滨, 王朋, 刘治明. 废旧电池再资源化制备高性能中熵合金催化剂及其性能研究[J]. 化工学报, 2025, 76(1): 231-240. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号