• •

殷布泽1( ), 黄维和2, 欧阳欣3, 赵雪峰4, 孟岚4, 胡其会1, 李玉星1(

), 黄维和2, 欧阳欣3, 赵雪峰4, 孟岚4, 胡其会1, 李玉星1( )

)

收稿日期:2025-08-26

修回日期:2026-01-07

出版日期:2026-01-08

通讯作者:

李玉星

作者简介:殷布泽(1996—),男,博士研究生,b22060012@s.upc.edu.cn

基金资助:

Buze YIN1( ), Weihe HUANG2, Xin OUYANG3, Xuefeng ZHAO4, Lan MENG4, Qihui HU1, Yuxing LI1(

), Weihe HUANG2, Xin OUYANG3, Xuefeng ZHAO4, Lan MENG4, Qihui HU1, Yuxing LI1( )

)

Received:2025-08-26

Revised:2026-01-07

Online:2026-01-08

Contact:

Yuxing LI

摘要:

CO2管道运输是碳捕集、封存与利用(Carbon Capture Utilization and Storage,CCUS)的重要环节。CO2具有很强的可压缩性和相变特性,一旦发生泄漏CO2会产生降压膨胀和强烈的相变,导致在泄漏口产生持续的高压平台为裂纹扩展提供能量,这对管道韧性止裂非常不利。所以建立一种预测CO2减压波曲线的计算模型,为CO2管道韧性止裂评价提供理论研究手段是非常有必要的。本文首先根据CO2的物性特性提出了“类气”和“类液”CO2的概念。收集了目前公开的类气和类液CO2快速降压的减压波数据,并结合均相成核理论描述过热和过冷极限对减压平台值进行了分析,以现有的均相等熵模型为基础提出了改进方法。改进后模型关于类气和类液CO2减压波平台的计算误差分别从10-40%和10-35%降低至±10%以内。

中图分类号:

殷布泽, 黄维和, 欧阳欣, 赵雪峰, 孟岚, 胡其会, 李玉星. 基于成核理论改进的减压波计算模型[J]. 化工学报, DOI: 10.11949/0438-1157.20250953.

Buze YIN, Weihe HUANG, Xin OUYANG, Xuefeng ZHAO, Lan MENG, Qihui HU, Yuxing LI. Improved decompression wave model based on nucleation theory[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250953.

| 实验编号 | 初始压力(MPa) | 初始温度(℃) | 初始熵值(kJ·kg-1·K-1) | ||

|---|---|---|---|---|---|

| Maxey(1983) | 6.00 | 23.2 | 0.94518 | ||

| Munkejord (2020) test.3 | 4.04 | 10.2 | 0.98959 | ||

| Hammer (2025) test.28 | 5.73 | 23.4 | 1.7484 | ||

| Hammer (2025) test.30 | 6.39 | 36.4 | 1.7909 | ||

| Hammer (2025) test.31 | 4.09 | 16.0 | 1.8743 | ||

| Cosham(2012) test.2 | 3.90 | 4.9 | 1.8248 | ||

| Cosham(2012) test.3 | 3.91 | 5.1 | 1.8250 | ||

| Cosham(2012) test.4 | 3.90 | 20.2 | 1.9151 | ||

| Cosham(2012) test.13 | 3.68 | 10.9 | 1.8885 | ||

| Cosham(2012) test.14 | 3.68 | 10.9 | 1.8885 | ||

| Cosham(2012) test.16 | 3.88 | 5.0 | 1.0236 | ||

|  | ||||

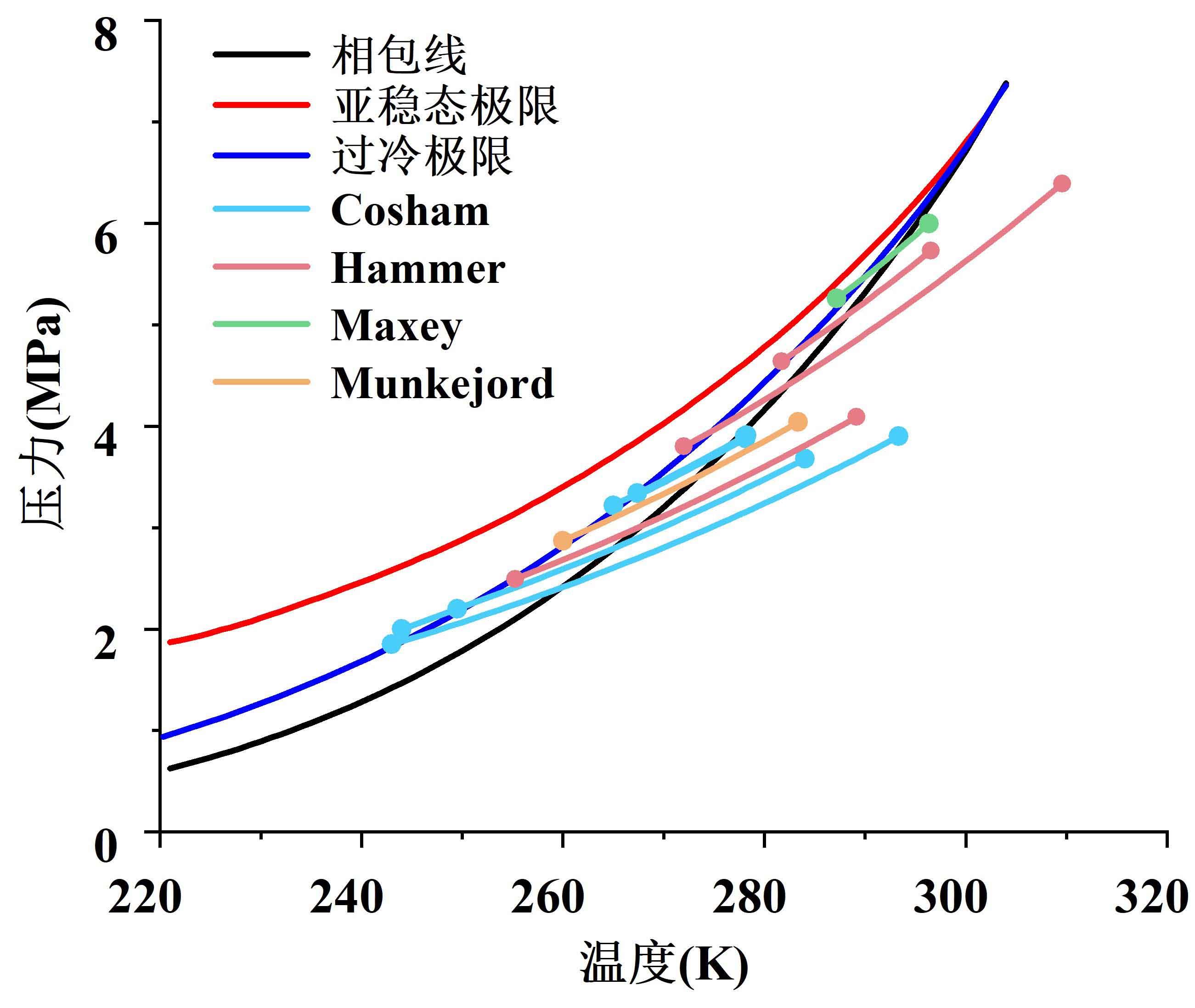

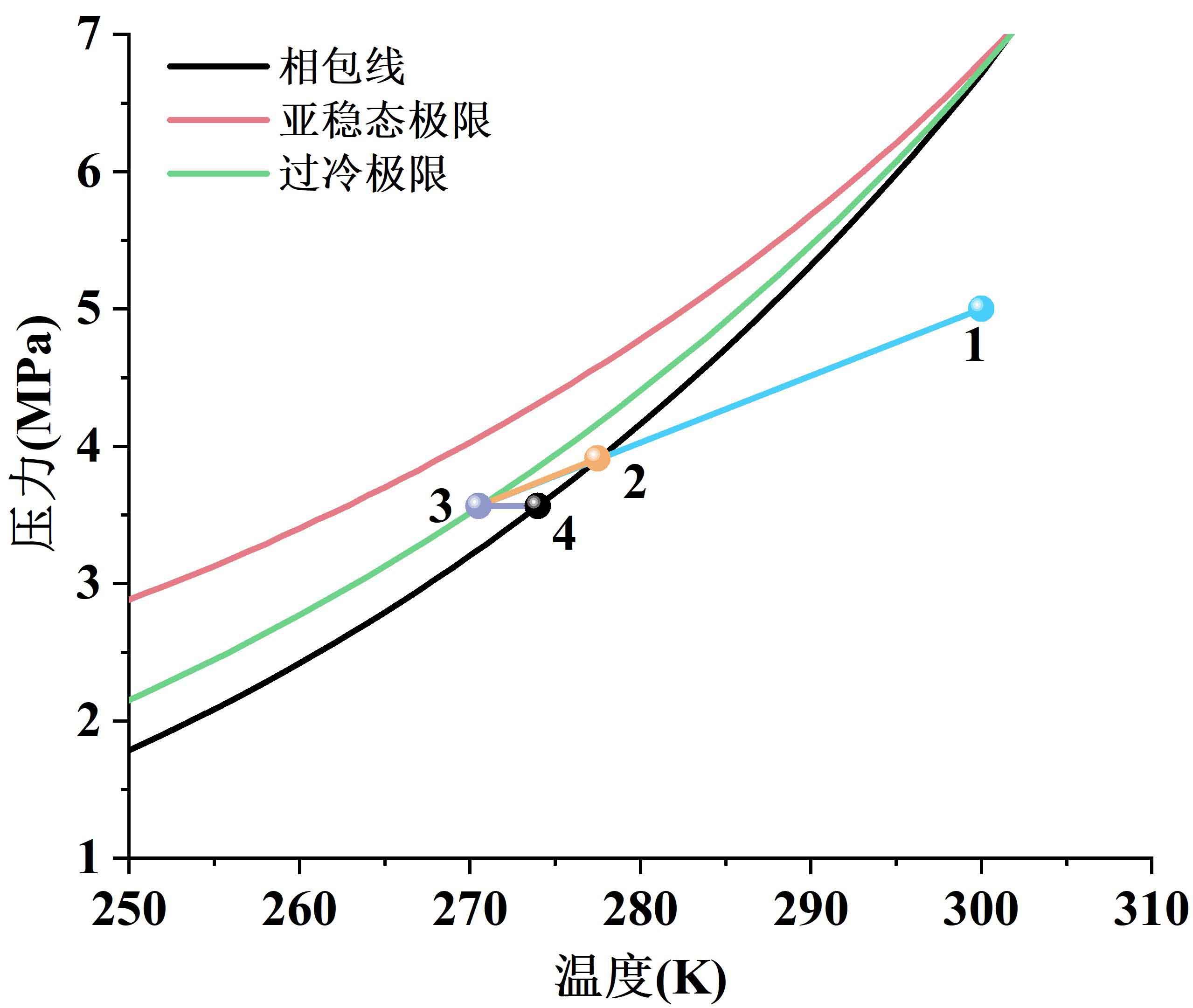

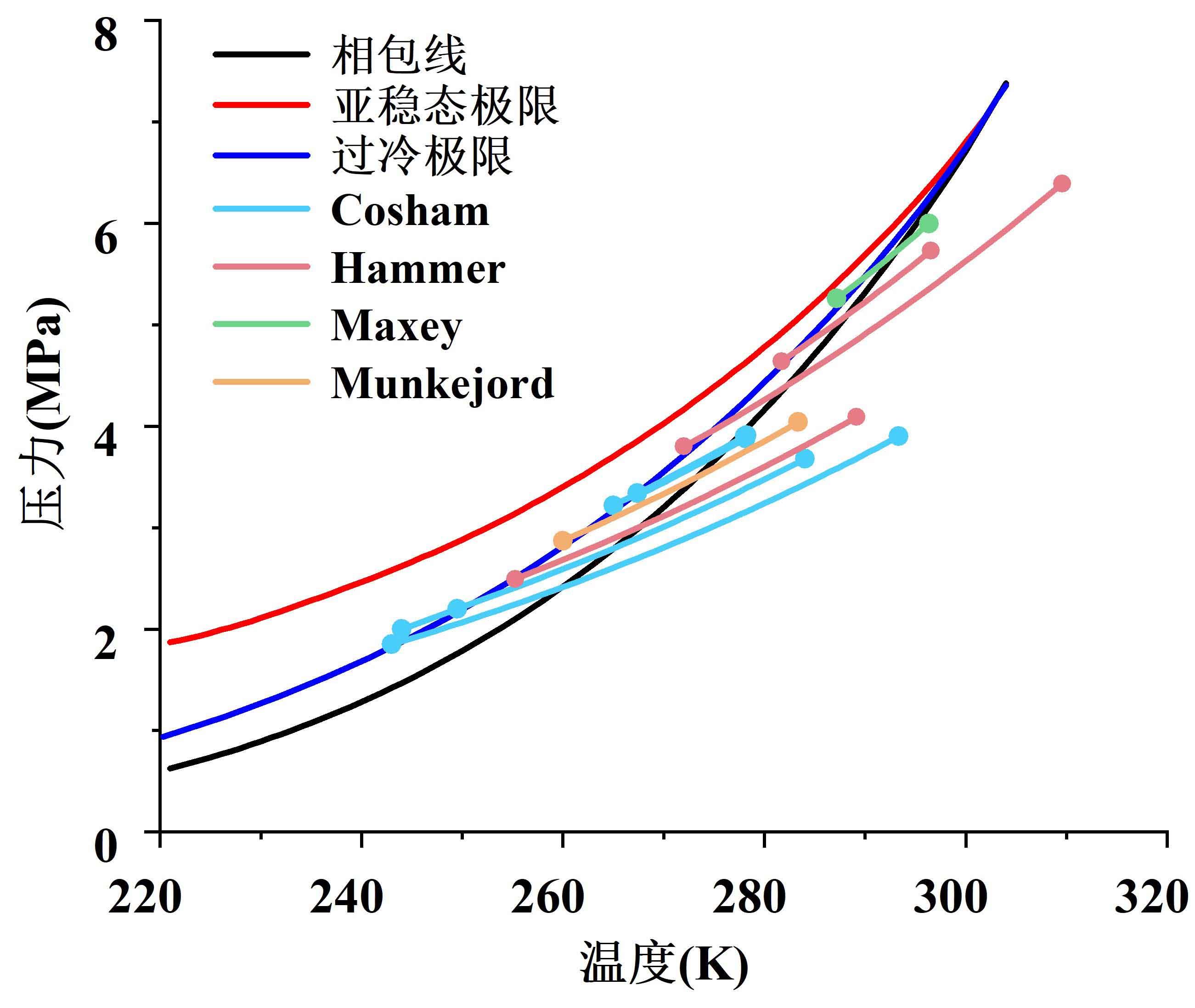

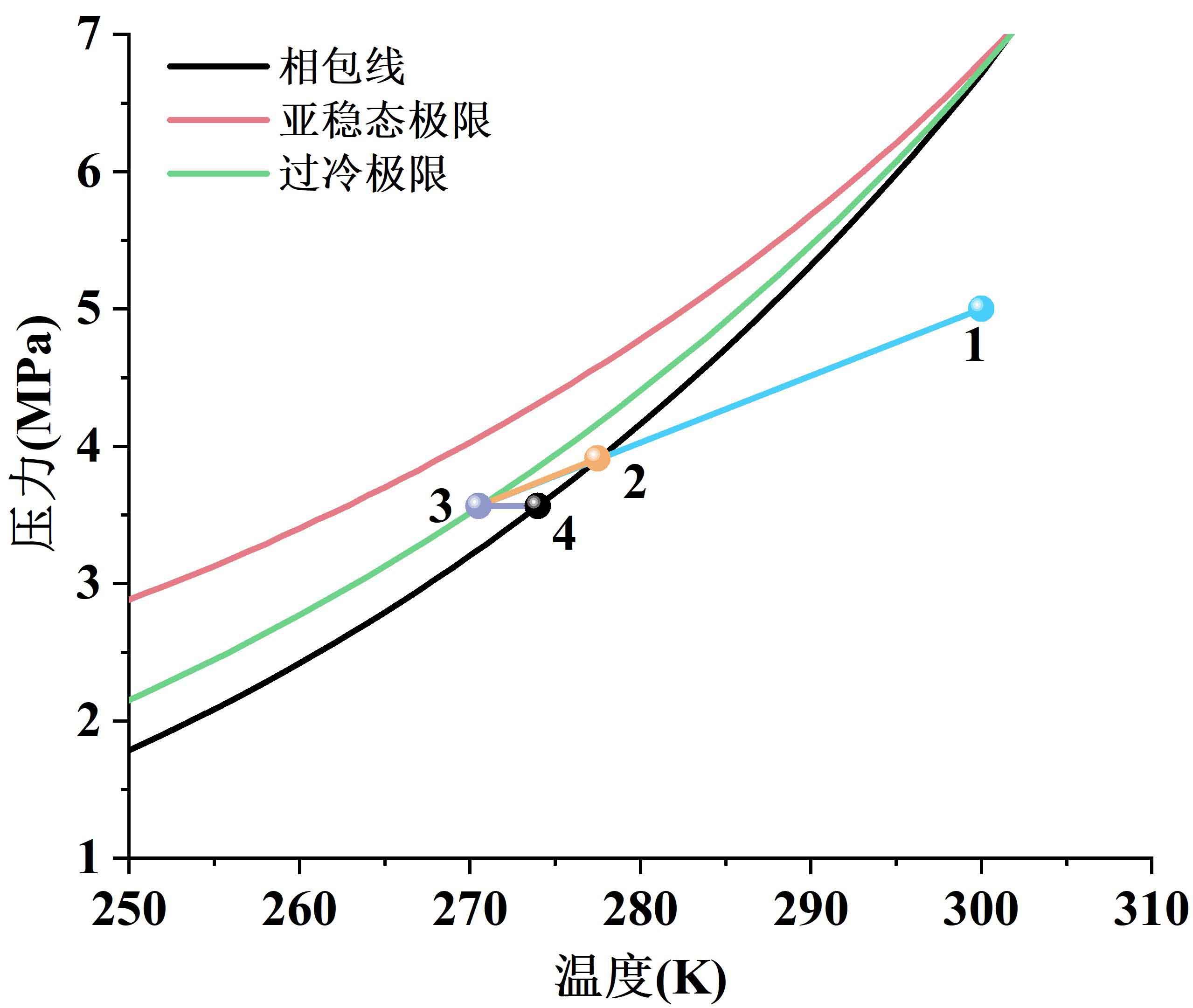

图 7 类气CO2减压波实验降压路径分布 Fig. 7 Distribution of pressure reduction path in gas-like CO2 decompression wave experiment | 图 8 类气减压波模型改进示意图 Fig. 8 Schematic of gas-like CO2 decompression wave model improvement | ||||

表1 类气CO2减压波实验参数表

Table 1 Decompression wave experimental parameters of gas-like CO2

| 实验编号 | 初始压力(MPa) | 初始温度(℃) | 初始熵值(kJ·kg-1·K-1) | ||

|---|---|---|---|---|---|

| Maxey(1983) | 6.00 | 23.2 | 0.94518 | ||

| Munkejord (2020) test.3 | 4.04 | 10.2 | 0.98959 | ||

| Hammer (2025) test.28 | 5.73 | 23.4 | 1.7484 | ||

| Hammer (2025) test.30 | 6.39 | 36.4 | 1.7909 | ||

| Hammer (2025) test.31 | 4.09 | 16.0 | 1.8743 | ||

| Cosham(2012) test.2 | 3.90 | 4.9 | 1.8248 | ||

| Cosham(2012) test.3 | 3.91 | 5.1 | 1.8250 | ||

| Cosham(2012) test.4 | 3.90 | 20.2 | 1.9151 | ||

| Cosham(2012) test.13 | 3.68 | 10.9 | 1.8885 | ||

| Cosham(2012) test.14 | 3.68 | 10.9 | 1.8885 | ||

| Cosham(2012) test.16 | 3.88 | 5.0 | 1.0236 | ||

|  | ||||

图 7 类气CO2减压波实验降压路径分布 Fig. 7 Distribution of pressure reduction path in gas-like CO2 decompression wave experiment | 图 8 类气减压波模型改进示意图 Fig. 8 Schematic of gas-like CO2 decompression wave model improvement | ||||

| 实验编号 | 初始压力(MPa) | 初始温度(℃) | 初始熵值(kJ·kg-1·K-1) |

|---|---|---|---|

| Munkejord (2020) test.6 | 10.4 | 40 | 1.3379 |

| Munkejord (2020) test.8 | 12.22 | 24.6 | 1.1440 |

| Log(2024) test.4 | 12.54 | 21.1 | 1.1121 |

| Log(2024) test.19 | 12.47 | 10.2 | 1.0255 |

| Log(2024) test.22 | 12.48 | 14.9 | 1.0625 |

| Log(2024) test.23 | 12.19 | 28(31.5) | 1.1737 |

| Log(2024) test.24 | 11.56 | 34.8(35.8) | 1.2459 |

| Log(2024) test.25 | 12.27 | 4.6 | 0.9828 |

| Botros(2016) test.31 | 11.11 | 36.5 | 1.2724 |

| Botros(2016) test.32A | 11.27 | 8.74 | 1.0211 |

| Cosham(2012) test.20 | 3.79 | 0.1 | 0.9985 |

| Cosham(2012) test.21 | 4.53 | 5 | 1.0382 |

| Cosham(2012) test.22 | 10.05 | 20 | 1.1246 |

| Cosham(2012) test.23 | 14.94 | 35.6 | 1.2098 |

| Cosham(2012) test.24 | 6.04 | 20 | 1.1802 |

| Cosham(2012) test.25 | 10.09 | 20 | 1.1242 |

表2 类液CO2全尺寸泄漏减压波实验参数表

Table 2 Decompression wave experimental parameters of liquid-like CO2

| 实验编号 | 初始压力(MPa) | 初始温度(℃) | 初始熵值(kJ·kg-1·K-1) |

|---|---|---|---|

| Munkejord (2020) test.6 | 10.4 | 40 | 1.3379 |

| Munkejord (2020) test.8 | 12.22 | 24.6 | 1.1440 |

| Log(2024) test.4 | 12.54 | 21.1 | 1.1121 |

| Log(2024) test.19 | 12.47 | 10.2 | 1.0255 |

| Log(2024) test.22 | 12.48 | 14.9 | 1.0625 |

| Log(2024) test.23 | 12.19 | 28(31.5) | 1.1737 |

| Log(2024) test.24 | 11.56 | 34.8(35.8) | 1.2459 |

| Log(2024) test.25 | 12.27 | 4.6 | 0.9828 |

| Botros(2016) test.31 | 11.11 | 36.5 | 1.2724 |

| Botros(2016) test.32A | 11.27 | 8.74 | 1.0211 |

| Cosham(2012) test.20 | 3.79 | 0.1 | 0.9985 |

| Cosham(2012) test.21 | 4.53 | 5 | 1.0382 |

| Cosham(2012) test.22 | 10.05 | 20 | 1.1246 |

| Cosham(2012) test.23 | 14.94 | 35.6 | 1.2098 |

| Cosham(2012) test.24 | 6.04 | 20 | 1.1802 |

| Cosham(2012) test.25 | 10.09 | 20 | 1.1242 |

| [1] | International Energy Agency. CO2 emissions in 2022[R]. Paris: IEA; 2023 |

| [2] | Huang W H, Li Y X, Chen P C. China's CO2 pipeline development strategy under carbon neutrality[J]. Natural Gas Industry B, 2023, 10(5): 502-510. |

| [3] | 胡其会, 李玉星, 张建, 等."双碳"战略下中国CCUS技术现状及发展建议[J]. 油气储运, 2022, 41(4): 361-371. |

| Hu Q H, Li Y X, Zhang J, et al. Current status and development suggestions of CCUS technology in China under the "Double Carbon" strategy[J]. Oil & Gas Storage and Transportation, 2022, 41(4):361-371. | |

| [4] | 张对红, 李玉星. 中国超临界CO2管道输送技术进展及展望[J]. 油气储运, 2024, 43(5): 481-491. |

| Zhang D H, Li Y X, et al. Development and prospect of supercritical CO2 pipeline transmission technology in China[J]. Oil & Gas Storage and Transportation, 2024, 43(5):481-491. | |

| [5] | Wang Y, Hu Q, Yin B, et al. Research progress on dynamic crack propagation and crack arrest models of supercritical and dense-phase CO2 pipelines[J]. Journal of Pipeline Science and Engineering, 2025: 100255. |

| [6] | 赫一凡,于帅,闫兴清,等.基于特征线法的CO2减压波传播模型构建及止裂壁厚研究[J].化工学报,2023,74(12):5038-5047+5075. |

| He Y F, Yu S, Yan X Q, et al. Construction of CO2 decompression wave propagation model based on method of characteristics and research on crack arrest wall thickness[J]. CIESC Journal,2023,74(12):5038-5047+5075. | |

| [7] | 孙明源.CO2输送管道裂纹扩展及止裂技术研究进展[J].安全、健康和环境,2023,23(11):40-47. |

| Sun M Y. Research Progress on Crack Propagation and Crack Arrest Technology of CO2 Transport Pipeline[J]. Safety Health & Environment,2023,23(11):40-47. | |

| [8] | 霍军良,唐治国,邱宗君,等.节流作用下CO2管道放空过程的冻堵风险实验研究[J].化工学报,2025,76(4):1898-1908. |

| Huo J L, Tang Z G, Qiu Z J, et al. Experimental research on risk of freezing and plugging during CO2 pipeline venting under | |

| [9] | 范振宁,梁海宁,房茂立,等.CO2管道不同相态节流放空特性研究与对比[J].化工学报,2025,76(7):3742-3751. |

| Fan Z N, Liang H N, Fang M L, et al. Research and comparison of throttling and venting characteristics of CO2 pipelines in different phase states[J]. CIESC Journal,2025,76(7):3742-3751. | |

| [10] | 殷布泽,黄维和,苗青,等.CO2管道泄漏减压特性与裂纹扩展研究现状及发展趋势[J].油气储运,2023,42(9):1042-1054. |

| Yin B Z, Huang W H, Miao Q, et al. Status and development trends of research on CO2 decompression characteristics and crack propagation[J]. Oil & Gas Storage and Transportation,2023,42(9):1042-1054. | |

| [11] | 陈磊,闫兴清,胡延伟,等.二氧化碳管道意外泄漏减压过程的断裂控制研究进展[J].化工进展,2022,41(3):1241-1255. |

| Chen L, Yan X Q, Hu Y W, et al. Research progress on fracture control of accidental leakage and decompression in CO2 pipeline transportation[J]. Chemical Industry and Engineering Progress,2022,41(3):1241-1255. | |

| [12] | 郭晓璐,喻健良,闫兴清,等.超临界CO2管道泄漏特性研究进展[J].化工学报,2020,71(12):5430-5442. |

| Guo X L, Yu J L, Yan X Q, et al. Research progress on leakage characteristics of supercritical CO2 pipeline[J]. CIESC Journal,2020,71(12):5430-5442. | |

| [13] | Botros K K, Geerligs J, Rothwell B, et al. Measurements of decompression wave speed in pure carbon dioxide and comparison with predictions by equation of state[J]. Journal of Pressure Vessel Technology, 2016, 138(3): 031302. |

| [14] | Botros K K, Geerligs J, Rothwell B, et al. Measurements of decompression wave speed in simulated anthropogenic carbon dioxide mixtures containing hydrogen[J]. Journal of Pressure Vessel Technology, 2017, 139(2): 021201. |

| [15] | Cosham A, Jones D G, Armstrong K, et al. The decompression behaviour of carbon dioxide in the dense phase[C]//International Pipeline Conference. American Society of Mechanical Engineers, 2012, 45141: 447-464. |

| [16] | Munkejord S T, Austegard A, Deng H, et al. Depressurization of CO2 in a pipe: High-resolution pressure and temperature data and comparison with model predictions[J].Energy, 2020, 211: 118560. |

| [17] | Log A M, Hammer M, Munkejord S T. A flashing flow model for the rapid depressurization of CO2 in a pipe accounting for bubble nucleation and growth[J]. International Journal of Multiphase Flow, 2024, 171: 104666. |

| [18] | Log A M, Hammer M, Deng H, et al. Depressurization of CO2 in a pipe: Effect of initial state on non-equilibrium two-phase flow[J]. International Journal of Multiphase Flow, 2024, 170: 104624. |

| [19] | Hammer M, Log A M, Deng H, et al. Decompression-induced condensation of carbon dioxide: Experiments, and prediction of the supercooling limit using classical nucleation theory[J]. Chemical Engineering Science, 2025, 309: 121415. |

| [20] | Dall'Acqua D, Terenzi A, Leporini M, et al. A new tool for modelling the decompression behaviour of CO2 with impurities using the Peng-Robinson equation of state[J]. Applied Energy, 2017, 206: 1432-1445. |

| [21] | 李玉星,王财林,胡其会,等.含杂质超临界CO2管道减压波波速的预测模型[J].油气储运,2021,40(9):1027-1032. |

| Li Y X, Wang C L, Hu Q H, et al. Prediction model of decompression wave velocity in supercritical CO2 pipelines containing impurities[J]. Oil & Gas Storage and Transportation,2021,40(9):1027-1032. | |

| [22] | 王洪利,马一太,李敏霞,等.汽液相变及亚稳态理论研究[J].工程热物理学报,2008,(6):901-904. |

| Wang H L, Ma Y T, Li M X, et al. Theoretical research on liquid-vapor phase change and metastable state[J]. Journal of Engineering Thermophysics,2008,(6):901-904. | |

| [23] | 顾帅威.不同相态CO2管道减压过程流动与温降特性研究[D].中国石油大学(华东),2019. |

| Gu S W. A study on the flow characteristics and temperature drop of CO2 pipelines in different phase states[D]. China University of Petroleum (East China),2019. | |

| [24] | 刘兴.卧式储罐过热液体爆沸过程实验研究[D].大连理工大学,2024. |

| Liu X. Experimental Study on Explosive Boiling Process of Superheated Liquid in Horizontal Tank[D]. Dalian University of Technology,2024. | |

| [25] | Gu S, Li Y, Teng L, et al. A new model for predicting the decompression behavior of CO2 mixtures in various phases[J]. Process Safety and Environmental Protection, 2018, 120: 237-247. |

| [26] | Flåtten T, Lund H. Relaxation two-phase flow models and the subcharacteristic condition[J]. Mathematical Models and Methods in Applied Sciences, 2011, 21(12): 2379-2407. |

| [27] | Peng D Y, Robinson D B. A new two-constant equation of state[J]. Industrial & Engineering Chemistry Fundamentals, 1976, 15(1): 59-64. |

| [28] | Span R, Wagner W. A new equation of state for carbon dioxide covering the fluid region from the triple‐point temperature to 1100 K at pressures up to 800 MPa[J]. Journal of physical and chemical reference data, 1996, 25(6): 1509-1596. |

| [29] | 马德良,高明侠.液体过热亚稳态极限的计算[J].徐州师范大学学报(自然科学版),1999, 17(2):41-43. |

| Ma D L, Gao M X. Calculation of Superheat Metastable State Limits of Liquids[J]. Journal of Xuzhou Normal University (Natural Science Edition),1999, 17(2):41-43. | |

| [30] | Vehkamäki H. Classical nucleation theory in multicomponent systems[M]. Berlin, Heidelberg: Springer Berlin Heidelberg, 2006. |

| [31] | Friedlander S K. Smoke, Dust, and Haze: Fundamentals of Aerosol Dynamics[J]. Oxford University Press, 2000. |

| [32] | Wilemski G, Wyslouzil B E. Binary nucleation kinetics. I. Self‐consistent size distribution[J]. The Journal of chemical physics, 1995, 103(3): 1127-1136. |

| [33] | Aursand P, Gjennestad M A, Aursand E, et al. The spinodal of single-and multi-component fluids and its role in the development of modern equations of state[J]. Fluid Phase Equilibria, 2017, 436: 98-112. |

| [34] | Magen O, Kozak Y, Di Lucchio L, et al. Predicting nucleation pressure under rapid depressurization: Bridging positive and negative pressure regions[J]. International Journal of Heat and Mass Transfer, 2025, 251: 127309. |

| [1] | 周怀荣, 伊嘉伟, 曹阿波, 郭奥雪, 王东亮, 杨勇, 杨思宇. 共电解耦合CO2间接加氢制甲醇工艺集成设计与性能评价[J]. 化工学报, 2025, 76(9): 4586-4600. |

| [2] | 范振宁, 梁海宁, 房茂立, 赫一凡, 于帅, 闫兴清, 安佳然, 乔帆帆, 喻健良. CO2管道不同相态节流放空特性研究与对比[J]. 化工学报, 2025, 76(7): 3742-3751. |

| [3] | 徐鹏国, 孟子衡, 朱干宇, 李会泉, 王晨晔, 孙振华, 田国才. 粗碳酸锂CO2微气泡深度碳化工艺与动力学研究[J]. 化工学报, 2025, 76(7): 3325-3338. |

| [4] | 江锦波, 陈竹鑫, 肖洋溢, 彭新, 陈源, 于辰, 孟祥铠, 彭旭东. 运行工况对超临界CO2干气密封端面热力学过程及稳态性能影响研究[J]. 化工学报, 2025, 76(6): 2913-2928. |

| [5] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [6] | 蔡天姿, 张海丰, 林海丹, 张子龙, 周鹏宇, 王柏林, 李小年. 硼掺杂氮基石墨烯检测变压器油中溶解气体CO和CO2的密度泛函理论研究[J]. 化工学报, 2025, 76(4): 1841-1851. |

| [7] | 周印洁, 吉思蓓, 何松阳, 吉旭, 贺革. 机器学习辅助高通量筛选金属有机骨架用于富碳天然气中分离CO2[J]. 化工学报, 2025, 76(3): 1093-1101. |

| [8] | 李一白, 刘世昌, 王靖, 刘永忠. 氢气驱动电化学CO2捕集系统的过程模拟与多离子耦合传输机制[J]. 化工学报, 2025, 76(11): 5951-5964. |

| [9] | 邹立, 马砺, 张鹏宇, 魏高明, 郭睿智, 赵钦新. 煅烧电石渣强化生物质气化制氢特性及其反应动力学研究[J]. 化工学报, 2025, 76(11): 6040-6057. |

| [10] | 金雨昕, 吴文莉, 童婳, 叶代启, 陈礼敏. 高分散双位点Co物种协同催化CO2氧化乙烷脱氢制乙烯的研究[J]. 化工学报, 2025, 76(10): 5128-5140. |

| [11] | 卢昕悦, 陈锐莹, 姜夏雪, 梁海瑞, 高歌, 叶正芳. 耦合LNG冷能的液态空气储能系统和液态CO2储能系统对比分析[J]. 化工学报, 2024, 75(9): 3297-3309. |

| [12] | 刘旭升, 李泽洋, 杨宇森, 卫敏. 电催化二氧化碳还原制备气态产物的研究进展[J]. 化工学报, 2024, 75(7): 2385-2408. |

| [13] | 赵亭亭, 鄢立祥, 唐福利, 肖敏之, 谭烨, 宋刘斌, 肖忠良, 李灵均. 光辅助锂-二氧化碳电池催化剂的设计策略与反应机理研究进展[J]. 化工学报, 2024, 75(5): 1750-1764. |

| [14] | 王迪, 陈伟倩, 孙灵芳, 周云龙. 光热-跨临界压缩二氧化碳储能循环动态特性研究[J]. 化工学报, 2024, 75(5): 2047-2059. |

| [15] | 王佳琪, 魏皓琦, 苟阿静, 刘佳兴, 周昕霖, 葛坤. 纳米粒子作用下CO2水合物生成机理研究[J]. 化工学报, 2024, 75(3): 956-966. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号