CIESC Journal ›› 2020, Vol. 71 ›› Issue (6): 2743-2751.DOI: 10.11949/0438-1157.20200077

• Material science and engineering, nanotechnology • Previous Articles Next Articles

Yuan SANG1,2( ),Maoqiao XIANG1,Miao SONG1,2,Qingshan ZHU1,2(

),Maoqiao XIANG1,Miao SONG1,2,Qingshan ZHU1,2( )

)

Received:2020-01-19

Revised:2020-03-22

Online:2020-06-05

Published:2020-06-05

Contact:

Qingshan ZHU

通讯作者:

朱庆山

作者简介:桑元(1994—),男,硕士研究生,基金资助:CLC Number:

Yuan SANG, Maoqiao XIANG, Miao SONG, Qingshan ZHU. Preparation of nearly-stoichiometric TiN powder by chemical vapor deposition in fluidized-bed[J]. CIESC Journal, 2020, 71(6): 2743-2751.

桑元, 向茂乔, 宋淼, 朱庆山. 流化床化学气相沉积法制备近化学计量比的TiN粉体[J]. 化工学报, 2020, 71(6): 2743-2751.

Add to citation manager EndNote|Ris|BibTeX

| 气体 | 气体流量/(ml/min) |

|---|---|

| Ar | 300 |

| TiCl4 | 70 |

| N2 | 70 |

| H2 | 210 |

Table 1 Flow of reactant gases in experiment

| 气体 | 气体流量/(ml/min) |

|---|---|

| Ar | 300 |

| TiCl4 | 70 |

| N2 | 70 |

| H2 | 210 |

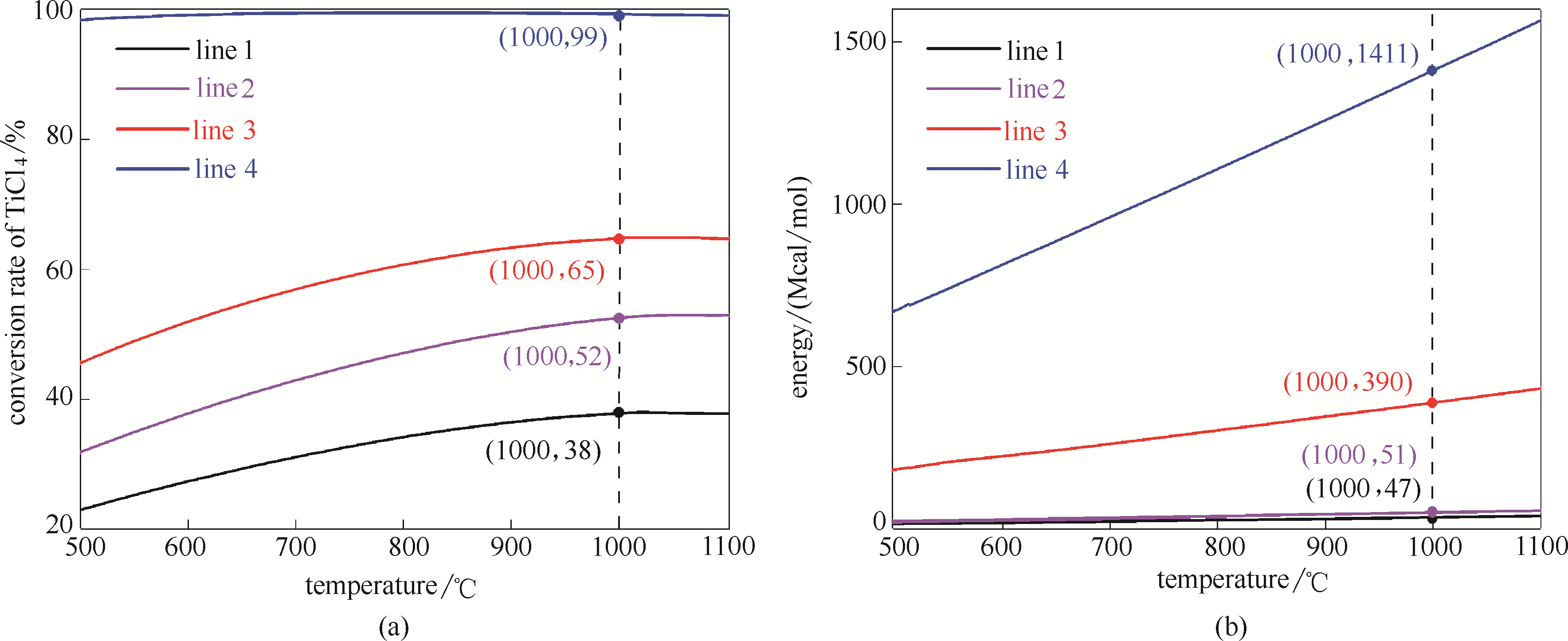

Fig.4 Conversion rate of TiCl4 (a) and theoretical energy consumption (b) of different feed ratios in TiCl4-N2-H2 systemline 1—n(TiCl4)∶n(N2)∶n(H2) = 1∶0.5∶2; line 2—n(TiCl4)∶n(N2)∶n(H2) =1∶1∶3; line 3—n(TiCl4)∶n(N2)∶n(H2) = 1∶50∶2;line 4—n(TiCl4)∶n(N2)∶n(H2) = 1∶0.5∶200

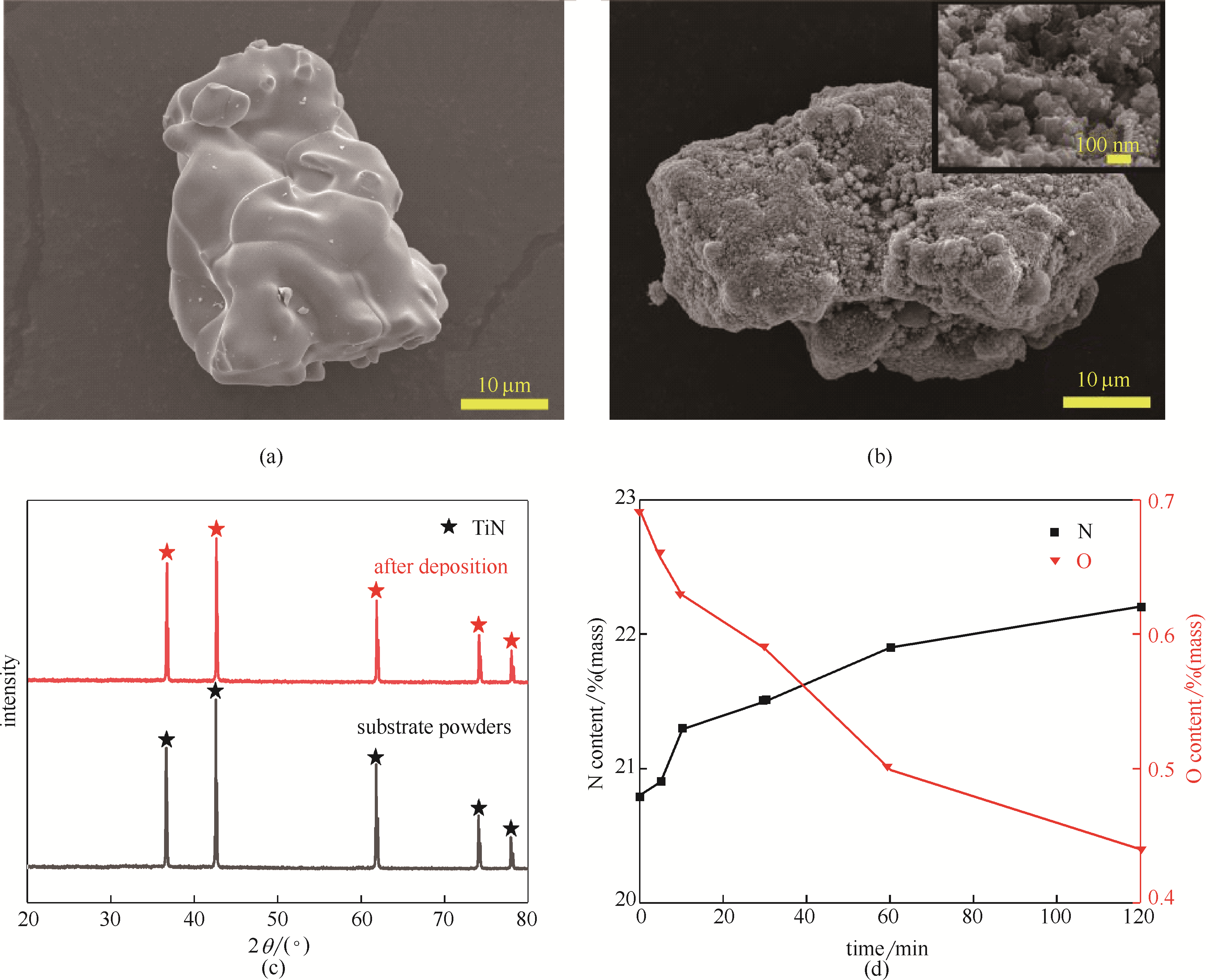

Fig.6 Fluidization pressure drop of TiN seeds with different particle size (a), macro photos (b) and SEM (c) of TiN seeds with average particle size of 21.16 μm after deposition, SEM of seeds with an average particle size of 52.95 μm after deposition (d)

Fig.7 SEM of 52.95 μm seeds before and after 120 min deposition [(a)—(b)], XRD patterns of TiN seeds before and after deposition (c), relationship between content of O/N in seeds and deposition time (d)

| 1 | Nagakura S, Kusunoki T, Kakimoto F, et al. Lattice parameter of the non-stoichiometric compound TiNx[J]. J. Appl. Cryst., 1975, 8(1): 65-66. |

| 2 | Liang H L, Jin X, Zhou D Y, et al. Thickness dependent microstructural and electrical properties of TiN thin films prepared by DC reactive magnetron sputtering[J]. Ceram. Int., 2015, 42(2): 2642-2647. |

| 3 | Liu M J, Dong Y Z, Wu Y M, et al. Titanium nitride nanocrystals on nitrogen-doped graphene as efficient electrocatalysts for oxygen reduction reaction[J]. Chem. J. Eur., 2013, 19(44): 14781-14786. |

| 4 | He P, Wang Y, Zhou H S. Titanium nitride catalyst cathode in a Li-air fuel cell with an acidic aqueous solution[J]. Chem. Commun., 2011, 47(38): 10701-10703. |

| 5 | Musthafa O T, Sampath S. High performance platinized titanium nitride catalyst for methanol oxidation[J]. Chem. Commun., 2008, 7(1): 67-69. |

| 6 | Gray B M, Hector A l, Jura M, et al. Effect of oxidative surface treatments on charge storage at titanium nitride surfaces for supercapacitor applications[J]. J. Mater. Chem. A., 2017, 5(9): 4550-4559. |

| 7 | Dong S M, Chen X, Cui G L, et al. One dimensional MnO2/titanium nitride nanotube coaxial arrays for high performance electrochemical capacitive energy storage[J]. Energy Environ Sci., 2011, 4(9): 3502-3508. |

| 8 | Kim W M, Kim S H, Lee K S, et al. Titanium nitride thin film as an adhesion layer for surface plasmon resonance sensor chips[J]. Appl. Surf. Sci., 2012, 261(Complete): 749-752. |

| 9 | Wang Y, Yuan H Y, Lu X L, et al. All solid-state pH electrode based on titanium nitride sensitive film[J]. Electroanalysis, 2006, 18(15): 1493-1498. |

| 10 | Ishii S, Shinde S L, Jevasuwan W, et al. Hot electron excitation from titanium nitride using visible light[J]. ACS Photonics, 2016, 3(9): 1552-1557. |

| 11 | Ajikumar P L, Kamruddin M, Nithya R, et al. Surface nitridation of Ti and Cr in ammonia atmosphere[J]. Scr. Mater., 2004, 51(5): 361-366. |

| 12 | Wexler D, Calka A, Mosbah A Y. Ti-TiN hardmetals prepared by in situ formation of TiN during reactive ball milling of Ti in Ammonia[J]. J. Alloy Compd., 2000, 309(1/2): 201-207. |

| 13 | Lee K O, Cohen J J, Kenneth B. Fluidized-bed combustion synthesis of titanium nitride[J]. P. Combust. Inst., 2000, 28(1): 1373-1380. |

| 14 | Zhang H, Li F, Jia Q. Preparation of titanium nitride ultrafine powders by sol-gel and microwave carbothermal reduction nitridation methods[J]. Ceram. Int., 2009, 35(3): 1071-1075. |

| 15 | Luo M, Gao J Q, Zhang X, et al. Processing of porous TiN/C ceramics from biological templates[J]. Materials Letters, 2007, 61(1): 186-188. |

| 16 | Mosbah A, Calka A, Wexler D. Rapid synthesis of titanium nitride powder by electrical discharge assisted mechanical milling[J]. J. Alloy Compd., 2006, 424(1/2): 279-282. |

| 17 | 石青娟. 非化学计量比TiNx的制备及相稳定性研究[D]. 秦皇岛: 燕山大学, 2009. |

| Shi Q J. Study of the preparation and phase stability of non-stoichiometric TiNx[D]. Qinhuangdao: Yanshan University, 2009. | |

| 18 | Song M, Xiang M Q, Yang Y F, et al. Synthesis of stoichiometric TiN from TiH2 powder and its nitridation Mechanism[J]. Ceram. Int., 2018, 44(14): 16947-16952. |

| 19 | Drygaś M, Czosnek C, Paine R T, et al. Two-stage aerosol synthesis of titanium nitride TiN and titanium oxynitride TiOxNy nanopowders of spherical particle morphology[J]. Chem. Mater., 2006, 18(13): 3122-3129. |

| 20 | Bang J H, Suslick K S. Dual templating synthesis of mesoporous titanium nitride microspheres[J]. Adv. Mater., 2009, 21(31): 3186-3190. |

| 21 | Yoo J B, Yoo H J, Jung H J, et al. Titanium oxynitride microspheres with the rock-salt structure for use as visible-light photocatalysts[J]. J. Mater. Chem. A., 2016, 4(3): 869-876. |

| 22 | Berge L M, Gruner W. Investigation of the effect of a nitrogen-containing atmosphere on the carbothermal reduction of titanium dioxide[J]. Int. J. Refract. Met. H., 2002, 20(3): 235-251. |

| 23 | 戴遐明, 李庆丰. 粉体的气、固相合成[J]. 中国粉体技术, 2000, 10(6): 15-20. |

| Dai X M, Li Q F. Vapor and solid synthesis of powders[J]. China Powder Science and Technology, 2000, 10(6): 15-20. | |

| 24 | 刘志宏, 张淑英, 刘智勇. 化学气相沉积制备粉体材料的原理及研究进展[J]. 粉末冶金材料科学与工程, 2009, 14(6): 359-363. |

| Liu Z H, Zhang S Y, Liu Z Y. Principle and research development of powder materials prepared by chemical vapor deposition[J]. Mater. Sci. Eng. Powder. Metall., 2009, 14(6): 359-363. | |

| 25 | Shin D H, Yong C H, Uhm H S. Production of nanocrystalline titanium nitride powder by atmospheric microwave plasma torch in hydrogen/nitrogen gas[J]. J. Am. Ceram. Soc., 2005, 88(10): 2736-2739. |

| 26 | Wen Q, Qian W Z, Nie J Q, et al. 100 mm long, semiconducting triple-walled carbon nanotubes[J]. Adv. Mater., 2010, 22(16): 1867-1871. |

| 27 | 刘马林. 流化床-化学气相沉积技术在先进核燃料制备中的应用进展[J]. 化工进展, 2019, 38(4): 1646-1653. |

| Liu M L. Research activities on FB-CVD technology application in advanced nuclear fuel fabrication[J]. Chem. Ind. & Eng. Pro., 2019, 38(4): 1646-1653. | |

| 28 | Du J, Dutta S, Ydstie B E. Modeling and control of solar-grade silicon production in a fluidized bed reactor[J]. AIChE J., 2014, 60(5): 1740-1751. |

| 29 | Luo X, Wu S, Yang Y, et al. Deposition characteristics of titanium coating deposited on SiC fiber by cold-wall chemical vapor deposition[J]. Mater. Chem. Phys., 2016, 184: 189-196. |

| 30 | Slavens G J. Vapor-phase reactions to prepare titanium nitride powder[R]. Report of Investigations. United States: Bureau of Mines, 1992. |

| 31 | He S Y, Sun H Y, Hu C Q, et al. Direct reduction of fine iron ore concentrate in a conical fluidized bed[J]. Powder Technology, 2017, 313: 161-168. |

| 32 | Geldart D. Types of gas fluidization[J]. Powder Technology, 1973, 7(5): 285-292. |

| 33 | 郭慕孙, 李洪钟. 流态化手册[M]. 北京: 化学工业出版社, 2008: 110. |

| Guo M S, Li H Z. Handbook of Fluidization[M]. Beijing: Chemical Industry Press, 2008: 110. | |

| 34 | Lei C, Zhu Q S, Li H Z. Experimental and theoretical study on the fluidization behaviors of iron powder at high temperature[J]. Chemical Engineering Science, 2014, 118: 50-59. |

| 35 | Roberts G C, Nenes A. A continuous-flow streamwise thermal-gradient CCN chamber for atmospheric measurements[J]. Aerosol. Sci. Technol., 2005, 39(3): 206-221. |

| 36 | Zhu L P, Ohashi M, Yamanaka Y. Novel synthesis of TiN fine powders by nitridation with ammonium chloride[J]. Materials Research Bulletin, 2002, 37(3): 475-483. |

| 37 | Koch R, Hu D Z, Das A K. Compressive stress in polycrystalline Volmer-Weber films[J]. Phys. Rev. Lett., 2005, 94(14): 146101. |

| 38 | Eichfeld S M, Colon V O, Nie Y F. Controlling nucleation of monolayer WSe2 during metal-organic chemical vapor deposition growth[J]. 2D Mater, 2016, 3(2): 025015. |

| 39 | 张军, 张磊, 李国栋, 等. 化学气相沉积ZrB2涂层的微观形貌及晶粒择优生长[J]. 材料研究学报, 2017, 31(3): 168-174. |

| Zhang J, Zhang L, Li G D, et al. Micro-morphology and preferential growth of ZrB2 coating prepared by chemical vapor deposition[J]. Chinese Journal of Materials Research, 2017, 31(3): 168-174. |

| [1] | Lei WU, Jiao LIU, Changcong LI, Jun ZHOU, Gan YE, Tiantian LIU, Ruiyu ZHU, Qiuli ZHANG, Yonghui SONG. Catalytic microwave pyrolysis of low-rank pulverized coal for preparation of high value-added modified bluecoke powders containing carbon nanotubes [J]. CIESC Journal, 2023, 74(9): 3956-3967. |

| [2] | Zhenbao LI, Chao LI, Hu WANG, Shaorui WANG, Quan LI. The microscopic mechanism on MPP inhibiting explosion of Al-Mg alloy powder [J]. CIESC Journal, 2023, 74(8): 3608-3614. |

| [3] | Xueyan WEI, Yong QIAN. Experimental study on the low to medium temperature oxidation characteristics and kinetics of micro-size iron powder [J]. CIESC Journal, 2023, 74(6): 2624-2638. |

| [4] | Hanbing HE, Zhen LIU, Yong CHEN, Xiaofeng WANG, Jing ZENG. Synthesis and slurry control of manganese oxide powder for direct ink writing electrode [J]. CIESC Journal, 2023, 74(5): 2239-2247. |

| [5] | Simin YI, Yali MA, Weiqiang LIU, Jinshuai ZHANG, Yan YUE, Qiang ZHENG, Songyan JIA, Xue LI. Study on ammonia evaporation and hydration kinetics of microcrystalline magnesite [J]. CIESC Journal, 2023, 74(4): 1578-1586. |

| [6] | Ke YANG, Chensheng WANG, Hong JI, Kai ZHENG, Zhixiang XING, Haipu BI, Juncheng JIANG. Experimental study on inhibition of methane explosion by polydopamine coated mixed powder [J]. CIESC Journal, 2022, 73(9): 4245-4254. |

| [7] | Shiyi GE, Yao YANG, Zhengliang HUANG, Jingyuan SUN, Jingdai WANG, Yongrong YANG. Analyzing particle growth and morphology evolution of polyethylene based on electrostatic separation [J]. CIESC Journal, 2022, 73(4): 1585-1596. |

| [8] | Huijun SHANG, Hengli LI, Jiayi LIU, Feng PAN, Zhan DU, Linbing SUN. Effect of Co on the pre-reduction process of WO3-Co3O4 and carbonization performance of its product [J]. CIESC Journal, 2022, 73(12): 5592-5604. |

| [9] | Bei PEI, Mengjiao XU, Shuangming WEI, Jiaqi GUO, Shiliang LI, Ziwei HU. Comparison of explosion characteristics of methane/graphite powder and methane/pulverized coal [J]. CIESC Journal, 2022, 73(10): 4769-4779. |

| [10] | Maoqiao XIANG, Yuqi GENG, Qingshan ZHU. Research advances in preparation technology and quality of silicon nitride powder [J]. CIESC Journal, 2022, 73(1): 73-84. |

| [11] | Haifeng LU, Jiakun CAO, Xiaolei GUO, Haifeng LIU. Study on fine powders discharged from hopper based on interparticle interactions analysis [J]. CIESC Journal, 2021, 72(8): 4047-4054. |

| [12] | HOU Yujie, LIANG Lin, JIANG Zixu, YAN Xingqing, YU Xiaozhe, LYU Xianshu, YU Jianliang. Experimental study on the dust explosion venting behavior by the addition of inert gas [J]. CIESC Journal, 2021, 72(5): 2887-2895. |

| [13] | ZHOU Jian, JIANG Qian, YANG Yi, FENG Shasha, ZHONG Zhaoxiang, XING Weihong. Effect of sintering additives on properties of silicon carbide porous ceramics prepared at low temperature [J]. CIESC Journal, 2021, 72(4): 2293-2299. |

| [14] | TIAN Fengshi, DONG Xinxin, SHU Xueming, ZHAO Jinlong. Experimental study on expansion rate and fire extinguishing effectiveness after modification of vermiculite powder and ionic solution [J]. CIESC Journal, 2021, 72(3): 1761-1768. |

| [15] | WEI Juan, WANG Yujun, LUO Guangsheng. Influence of pore volume and heating process on preparation of aluminum nitride powder by carbothermal reduction method [J]. CIESC Journal, 2021, 72(2): 1156-1168. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||