CIESC Journal ›› 2021, Vol. 72 ›› Issue (11): 5751-5760.DOI: 10.11949/0438-1157.20210662

• Energy and environmental engineering • Previous Articles Next Articles

Junhua PEI1,2( ),Liang YANG1,2(

),Liang YANG1,2( ),Xin WANG1,2,Han HU1,2,Daoping LIU1,2

),Xin WANG1,2,Han HU1,2,Daoping LIU1,2

Received:2021-05-14

Revised:2021-07-20

Online:2021-11-12

Published:2021-11-05

Contact:

Liang YANG

裴俊华1,2( ),杨亮1,2(

),杨亮1,2( ),汪鑫1,2,胡晗1,2,刘道平1,2

),汪鑫1,2,胡晗1,2,刘道平1,2

通讯作者:

杨亮

作者简介:裴俊华(1996—),男,硕士研究生,基金资助:CLC Number:

Junhua PEI, Liang YANG, Xin WANG, Han HU, Daoping LIU. Experimental study on kinetics of methane hydrate formation enhanced by copper foam[J]. CIESC Journal, 2021, 72(11): 5751-5760.

裴俊华, 杨亮, 汪鑫, 胡晗, 刘道平. 泡沫铜强化甲烷水合物生成动力学实验研究[J]. 化工学报, 2021, 72(11): 5751-5760.

Add to citation manager EndNote|Ris|BibTeX

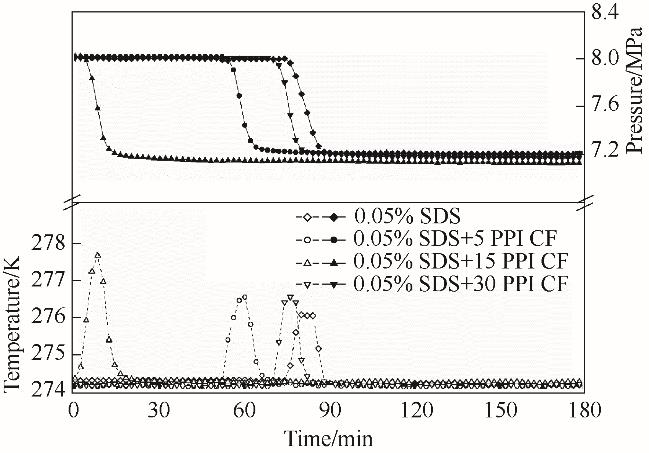

Fig.3 Variation of temperature and pressure during hydration and methane storage of copper foam system with different pore density filled with SDS solution

| Hydrate systems | P/MPa | tin/min | Cs,max/(mmol·mol-1) | Rs,max/(mmol·mol-1·min-1) | t90/min |

|---|---|---|---|---|---|

| 0.05% SDS + 5 PPI CF | 8.0 | 52.1 | 129.1 | 19.24 | 61.4 |

| 0.05% SDS + 15 PPI CF | 8.0 | 1.5 | 139.0 | 20.73 | 10.1 |

| 0.05% SDS + 30 PPI CF | 8.0 | 68.8 | 131.8 | 21.04 | 77.5 |

| 0.05% SDS + 15 PPI CF | 7.0 | 39.5 | 135.7 | 19.57 | 52.1 |

| 0.05% SDS + 15 PPI CF | 6.0 | 49.4 | 133.2 | 15.00 | 74.6 |

| 0.05% SDS + 15 PPI CF | 5.0 | 63.8 | 129.5 | 11.58 | 77.2 |

| 0.05% SDS | 8.0 | 73.5 | 127.8 | 14.77 | 85.3 |

| 0.05% SDS | 7.0 | 58.6 | 122.8 | 15.14 | 81.7 |

| 0.05% SDS | 6.0 | 84.3 | 98.2 | 14.32 | 104.2 |

| 0.05% SDS | 5.0 | — | 9.0 | 0.68 | — |

Table 1 Experimental results of all gas storage

| Hydrate systems | P/MPa | tin/min | Cs,max/(mmol·mol-1) | Rs,max/(mmol·mol-1·min-1) | t90/min |

|---|---|---|---|---|---|

| 0.05% SDS + 5 PPI CF | 8.0 | 52.1 | 129.1 | 19.24 | 61.4 |

| 0.05% SDS + 15 PPI CF | 8.0 | 1.5 | 139.0 | 20.73 | 10.1 |

| 0.05% SDS + 30 PPI CF | 8.0 | 68.8 | 131.8 | 21.04 | 77.5 |

| 0.05% SDS + 15 PPI CF | 7.0 | 39.5 | 135.7 | 19.57 | 52.1 |

| 0.05% SDS + 15 PPI CF | 6.0 | 49.4 | 133.2 | 15.00 | 74.6 |

| 0.05% SDS + 15 PPI CF | 5.0 | 63.8 | 129.5 | 11.58 | 77.2 |

| 0.05% SDS | 8.0 | 73.5 | 127.8 | 14.77 | 85.3 |

| 0.05% SDS | 7.0 | 58.6 | 122.8 | 15.14 | 81.7 |

| 0.05% SDS | 6.0 | 84.3 | 98.2 | 14.32 | 104.2 |

| 0.05% SDS | 5.0 | — | 9.0 | 0.68 | — |

| 1 | Koh C A, Sloan E D. Natural gas hydrates: recent advances and challenges in energy and environmental applications[J]. AIChE Journal, 2007, 53(7): 1636-1643. |

| 2 | 陈光进, 孙长宇, 马庆兰. 气体水合物科学与技术[M]. 北京: 化学工业出版社, 2008:6-8. |

| Chen G J, Sun C Y, Ma Q L. Gas Hydrate Science and Technology[M]. Beijing: Chemical Industry Press, 2008:6-8. | |

| 3 | Veluswamy H P, Kumar A, Seo Y, et al. A review of solidified natural gas (SNG) technology for gas storage via clathrate hydrates[J]. Applied Energy, 2018, 216: 262-285. |

| 4 | Yang M J, Zhao J, Zheng J N, et al. Hydrate reformation characteristics in natural gas hydrate dissociation process: a review[J]. Applied Energy, 2019, 256: 113878. |

| 5 | Zhong D L, Lu Y Y, Sun D J, et al. Performance evaluation of methane separation from coal mine gas by gas hydrate formation in a stirred reactor and in a fixed bed of silica sand[J]. Fuel, 2015, 143: 586-594. |

| 6 | Xiao P, Yang X M, Sun C Y, et al. Enhancing methane hydrate formation in bulk water using vertical reciprocating impact[J]. Chemical Engineering Journal, 2018, 336: 649-658. |

| 7 | Fujita S, Watanabe K, Mori Y H. Clathrate-hydrate formation by water spraying onto a porous metal plate exuding a hydrophobic liquid coolant[J]. AIChE Journal, 2009, 55(4): 1056-1064. |

| 8 | Yamamura K, Fukuzaki J I, Mori Y H. Clathrate hydrate formation using liquid jets impinging on each other: an observational study using paired water jets or water and methylcyclohexane jets[J]. Chemical Engineering Science, 2011, 66(9): 1844-1858. |

| 9 | Partoon B, Sabil K M, Lau K K, et al. Production of gas hydrate in a semi-batch spray reactor process as a means for separation of carbon dioxide from methane[J]. Chemical Engineering Research and Design, 2018, 138: 168-175. |

| 10 | Li C J, Huang T. Simulation of gas bubbles with gas hydrates rising in deep water[J]. Ocean Engineering, 2016, 112: 16-24. |

| 11 | Fu W Q, Wang Z Y, Sun B J, et al. A mass transfer model for hydrate formation in bubbly flow considering bubble-bubble interactions and bubble-hydrate particle interactions[J]. International Journal of Heat and Mass Transfer, 2018, 127: 611-621. |

| 12 | Zhao J F, Wang B, Sum A K. Dynamics of hydrate formation and deposition under pseudo multiphase flow[J]. AIChE Journal, 2017, 63(9): 4136-4146. |

| 13 | Mali G A, Chapoy A, Tohidi B. Investigation into the effect of subcooling on the kinetics of hydrate formation[J]. The Journal of Chemical Thermodynamics, 2018, 117: 91-96. |

| 14 | 李文昭, 潘振, 马贵阳, 等. 表面活性剂吸附对促进甲烷水合物生成效果的影响[J]. 化工学报, 2017, 68(4): 1542-1549. |

| Li W Z, Pan Z, Ma G Y, et al. Promotion effects of surfactant adsorption on formation of methane hydrates[J]. CIESC Journal, 2017, 68(4): 1542-1549. | |

| 15 | 丁家祥, 史伶俐, 申小冬, 等. SDS对甲烷水合物生成动力学和微观结构的影响[J]. 化工学报, 2017, 68(12): 4802-4808. |

| Ding J X, Shi L L, Shen X D, et al. SDS effect on formation kinetics and microstructure of methane hydrate[J]. CIESC Journal, 2017, 68(12): 4802-4808. | |

| 16 | Naeiji P, Varaminian F. Kinetic study of carbon dioxide hydrate formation by thermal analysis in the presence of two surfactants: sodium dodecyl sulfate (SDS) and lauryl alcohol ethoxylate (LAE)[J]. Journal of Molecular Liquids, 2018, 254: 120-129. |

| 17 | Wang F, Song Y M, Liu G Q, et al. Rapid methane hydrate formation promoted by Ag&SDS-coated nanospheres for energy storage[J]. Applied Energy, 2018, 213: 227-234. |

| 18 | Al-Sowadi A, Roosta H, Dashti A, et al. The effects of SDS, SLES and THF on the growth rate, kinetic behaviors and energy consumption during ethylene hydrate formation process[J]. Journal of Molecular Liquids, 2019, 294: 111608. |

| 19 | Zhong Y, Rogers R E. Surfactant effects on gas hydrate formation[J]. Chemical Engineering Science, 2000, 55(19): 4175-4187. |

| 20 | Ganji H, Manteghian M, Sadaghiani zadeh K, et al. Effect of different surfactants on methane hydrate formation rate, stability and storage capacity[J]. Fuel, 2007, 86(3): 434-441. |

| 21 | Shi C R, Chai F Y, Yang M J, et al. Enhance methane hydrate formation using fungus confining sodium dodecyl sulfate solutions for methane storage[J]. Journal of Molecular Liquids, 2021, 333: 116020. |

| 22 | Okutani K, Kuwabara Y, Mori Y H. Surfactant effects on hydrate formation in an unstirred gas/liquid system: amendments to the previous study using HFC-32 and sodium dodecyl sulfate[J]. Chemical Engineering Science, 2007, 62(14): 3858-3860. |

| 23 | Gupta A, Lachance J, Sloan E D, et al. Measurements of methane hydrate heat of dissociation using high pressure differential scanning calorimetry[J]. Chemical Engineering Science, 2008, 63(24): 5848-5853. |

| 24 | Liu N, Zhu H Q, Zhou J L, et al. Molecular dynamics simulations on formation of CO2 hydrate in the presence of metal particles[J]. Journal of Molecular Liquids, 2021, 331: 115793. |

| 25 | Patel H E, Das S K, Sundararajan T, et al. Thermal conductivities of naked and monolayer protected metal nanoparticle based nanofluids: manifestation of anomalous enhancement and chemical effects[J]. Applied Physics Letters, 2003, 83(14): 2931-2933. |

| 26 | Najibi H, Mirzaee Shayegan M, Heidary H. Experimental investigation of methane hydrate formation in the presence of copper oxide nanoparticles and SDS[J]. Journal of Natural Gas Science and Engineering, 2015, 23: 315-323. |

| 27 | Mohammadi M, Haghtalab A, Fakhroueian Z. Experimental study and thermodynamic modeling of CO2 gas hydrate formation in presence of zinc oxide nanoparticles[J]. The Journal of Chemical Thermodynamics, 2016, 96: 24-33. |

| 28 | Liu G Q, Wang F, Luo S J, et al. Enhanced methane hydrate formation with SDS-coated Fe3O4 nanoparticles as promoters[J]. Journal of Molecular Liquids, 2017, 230: 315-321. |

| 29 | Lu Y Y, Ge B B, Zhong D L. Investigation of using graphite nanofluids to promote methane hydrate formation: application to solidified natural gas storage[J]. Energy, 2020, 199: 117424. |

| 30 | Liu N, Chen L T, Liu C X, et al. Experimental study of carbon dioxide hydrate formation in the presence of graphene oxide[J]. Energy, 2020, 211: 118994. |

| 31 | Xie Y M, Guo K H, Liang D Q, et al. Gas hydrate growth morphology outside of horizontal heat transfer tube[J]. Journal of Crystal Growth, 2005, 276(1/2): 253-264. |

| 32 | Yang L, Liu Z Z, Liu D P, et al. Enhanced natural gas hydrates formation in the suspension with metal particles and fibers[J]. Journal of Molecular Liquids, 2020, 301: 112410. |

| 33 | Lee J, Shin C, Lee Y. Experimental investigation to improve the storage potentials of gas hydrate under the unstirring condition[J]. Energy & Fuels, 2010, 24(2): 1129-1134. |

| 34 | Bhattacharya A, Calmidi V V, Mahajan R L. Thermophysical properties of high porosity metal foams[J]. International Journal of Heat and Mass Transfer, 2002, 45(5): 1017-1031. |

| 35 | Li T X, Wu D L, He F, et al. Experimental investigation on copper foam/hydrated salt composite phase change material for thermal energy storage[J]. International Journal of Heat and Mass Transfer, 2017, 115: 148-157. |

| 36 | Redlich O, Kwong J N S. On the thermodynamics of solutions(Ⅴ): An equation of state. Fugacities of gaseous solutions[J]. Chemical Reviews, 1949, 44(1): 233-244. |

| [1] | Cheng CHENG, Zhongdi DUAN, Haoran SUN, Haitao HU, Hongxiang XUE. Lattice Boltzmann simulation of surface microstructure effect on crystallization fouling [J]. CIESC Journal, 2023, 74(S1): 74-86. |

| [2] | Keke SHAO, Mengjie SONG, Zhengyong JIANG, Xuan ZHANG, Long ZHANG, Runmiao GAO, Zekang ZHEN. Experimental study on the formation and distribution of trapped air bubbles in horizontal ice slice [J]. CIESC Journal, 2023, 74(S1): 161-164. |

| [3] | Yihao ZHANG, Zhenlei WANG. Fault detection using grouped support vector data description based on maximum information coefficient [J]. CIESC Journal, 2023, 74(9): 3865-3878. |

| [4] | Linzheng WANG, Yubing LU, Ruizhi ZHANG, Yonghao LUO. Analysis on thermal oxidation characteristics of VOCs based on molecular dynamics simulation [J]. CIESC Journal, 2023, 74(8): 3242-3255. |

| [5] | Hai WANG, Hong LIN, Chen WANG, Haojie XU, Lei ZUO, Junfeng WANG. Investigation of enhanced boiling heat transfer on porous structural surfaces by high voltage electric field [J]. CIESC Journal, 2023, 74(7): 2869-2879. |

| [6] | Mengmeng ZHANG, Dong YAN, Yongfeng SHEN, Wencui LI. Effect of electrolyte types on the storage behaviors of anions and cations for dual-ion batteries [J]. CIESC Journal, 2023, 74(7): 3116-3126. |

| [7] | Ben ZHANG, Songbai WANG, Ziya WEI, Tingting HAO, Xuehu MA, Rongfu WEN. Capillary liquid film condensation and heat transfer enhancement driven by superhydrophilic porous metal structure [J]. CIESC Journal, 2023, 74(7): 2824-2835. |

| [8] | Jipeng ZHOU, Wenjun HE, Tao LI. Reaction engineering calculation of deactivation kinetics for ethylene catalytic oxidation over irregular-shaped catalysts [J]. CIESC Journal, 2023, 74(6): 2416-2426. |

| [9] | Guangyu WANG, Kai ZHANG, Kaihua ZHANG, Dongke ZHANG. Heat and mass transfer and energy consumption for microwave drying of coal slime [J]. CIESC Journal, 2023, 74(6): 2382-2390. |

| [10] | Quanbi ZHANG, Yijin YANG, Xujing GUO. Catalytic degradation of dissolved organic matter in rifampicin pharmaceutical wastewater by Fenton oxidation process [J]. CIESC Journal, 2023, 74(5): 2217-2227. |

| [11] | Simin YI, Yali MA, Weiqiang LIU, Jinshuai ZHANG, Yan YUE, Qiang ZHENG, Songyan JIA, Xue LI. Study on ammonia evaporation and hydration kinetics of microcrystalline magnesite [J]. CIESC Journal, 2023, 74(4): 1578-1586. |

| [12] | Jin YU, Binbin YU, Xinsheng JIANG. Study on quantification methodology and analysis of chemical effects of combustion control based on fictitious species [J]. CIESC Journal, 2023, 74(3): 1303-1312. |

| [13] | Bingguo ZHU, Jixiang HE, Jinliang XU, Bin PENG. Heat transfer characteristics of supercritical pressure CO2 in diverging/converging tube under cooling conditions [J]. CIESC Journal, 2023, 74(3): 1062-1072. |

| [14] | Xinya LI, Lei XING, Minghu JIANG, Lixin ZHAO. Research on performance of downhole oil-water separation hydrocyclone enhanced by inverted cone gas injection [J]. CIESC Journal, 2023, 74(3): 1134-1144. |

| [15] | Lingxin ZU, Rongting HU, Xin LI, Yudao CHEN, Guanglin CHEN. Carbon release products and denitrification bioavailability from chemical components of woody biomass [J]. CIESC Journal, 2023, 74(3): 1332-1342. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||