CIESC Journal ›› 2023, Vol. 74 ›› Issue (5): 2170-2178.DOI: 10.11949/0438-1157.20230096

• Energy and environmental engineering • Previous Articles Next Articles

Yuhao CHEN( ), Xiaoping CHEN(

), Xiaoping CHEN( ), Jiliang MA, Cai LIANG

), Jiliang MA, Cai LIANG

Received:2023-02-10

Revised:2023-04-03

Online:2023-06-29

Published:2023-05-05

Contact:

Xiaoping CHEN

通讯作者:

陈晓平

作者简介:陈宇豪(1999—),男,硕士研究生,cyh9982@163.com

基金资助:CLC Number:

Yuhao CHEN, Xiaoping CHEN, Jiliang MA, Cai LIANG. Gaseous pollutants emissions from rotary kiln combustion of municipal sewage sludge[J]. CIESC Journal, 2023, 74(5): 2170-2178.

陈宇豪, 陈晓平, 马吉亮, 梁财. 市政污泥回转窑焚烧气态污染物排放特性研究[J]. 化工学报, 2023, 74(5): 2170-2178.

Add to citation manager EndNote|Ris|BibTeX

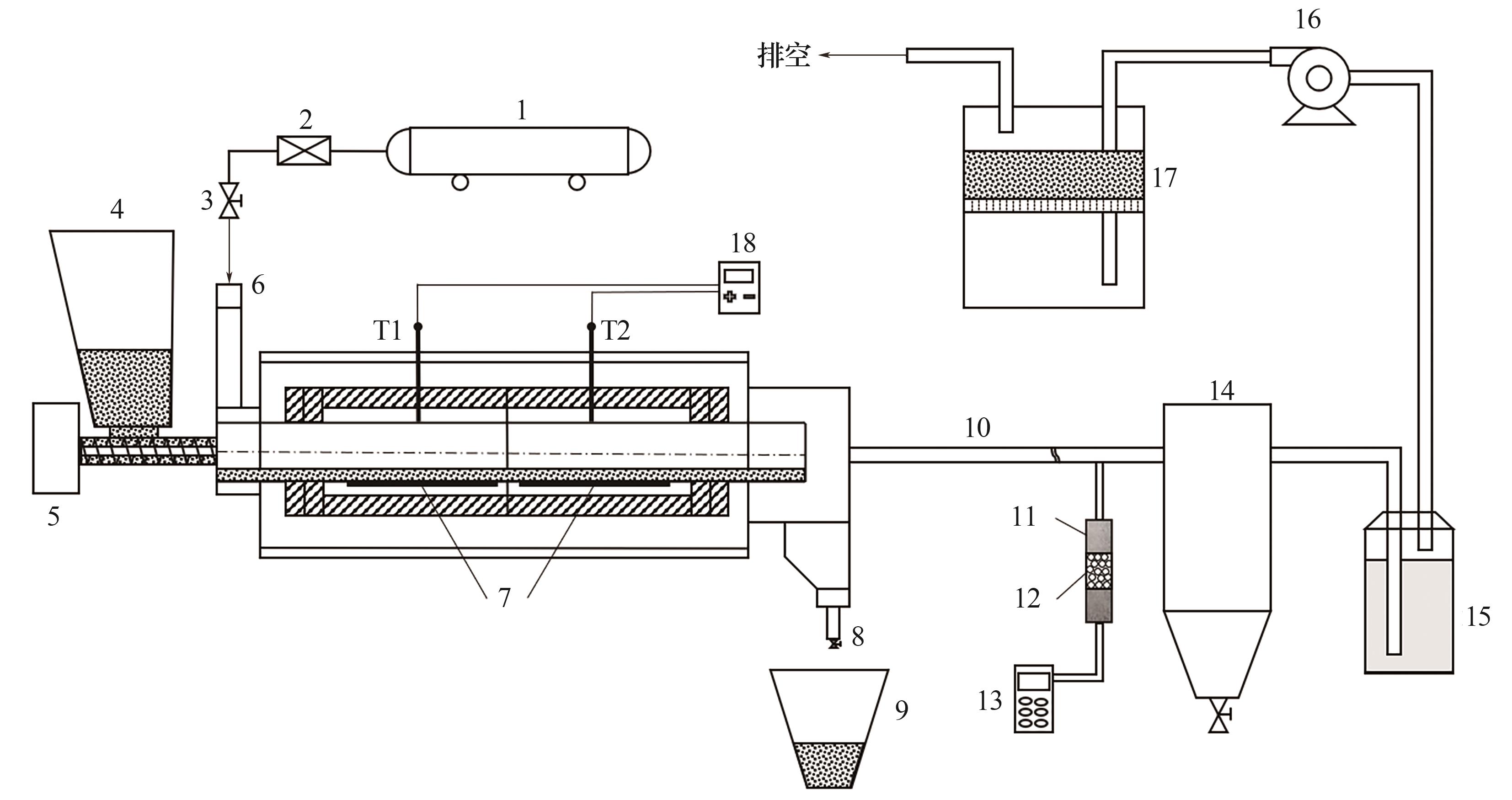

Fig.1 System diagram of rotary kiln test platform1—air compressor; 2—flowmeter; 3—valve; 4—stock bin; 5—worm feeder; 6—air inlet; 7—electrical heating; 8—slag discharge; 9—slag collection;10—insulation pipe; 11—filter cotton (dust removal); 12—anhydrous calcium chloride (desiccation); 13—flue gas analyzer; 14—bag-type dust remover;15—lye tank; 16—induced draft fan; 17—activated carbon; 18—digital display controller

| 试样 | 工业分析(空气干燥基)/% | 元素分析(干燥基)/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mt | Ad | Vd | FCd | C | H | O | N | S | ||

| 污泥 | 10.05 | 51.53 | 41.32 | 7.15 | 19.78 | 3.63 | 21.61 | 2.98 | 0.83 | |

Table 1 Results of industrial and elemental analysis of municipal sludge

| 试样 | 工业分析(空气干燥基)/% | 元素分析(干燥基)/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mt | Ad | Vd | FCd | C | H | O | N | S | ||

| 污泥 | 10.05 | 51.53 | 41.32 | 7.15 | 19.78 | 3.63 | 21.61 | 2.98 | 0.83 | |

| 成分 | 含量/% |

|---|---|

| SiO2 | 41.78 |

| Al2O3 | 23.56 |

| Fe2O3 | 9.58 |

| CaO | 4.14 |

| MgO | 2.51 |

| SO3 | 1.65 |

| TiO2 | 0.75 |

| K2O | 1.77 |

| Na2O | 1.13 |

| MnO2 | 0.34 |

| P2O5 | 9.12 |

| 总量 | 96.33 |

Table 2 Ash component of municipal sludge

| 成分 | 含量/% |

|---|---|

| SiO2 | 41.78 |

| Al2O3 | 23.56 |

| Fe2O3 | 9.58 |

| CaO | 4.14 |

| MgO | 2.51 |

| SO3 | 1.65 |

| TiO2 | 0.75 |

| K2O | 1.77 |

| Na2O | 1.13 |

| MnO2 | 0.34 |

| P2O5 | 9.12 |

| 总量 | 96.33 |

| 炉体倾角/(°) | 物料停留时间/min | 质量流率/(g/s) |

|---|---|---|

| 3.0 | 8.0 | 1.00 |

| 2.5 | 9.0 | 0.90 |

| 2.0 | 10.5 | 0.85 |

| 1.5 | 11.5 | 0.78 |

| 1.0 | 12.5 | 0.64 |

Table 3 Mass flow rate inside the material furnace under cold condition

| 炉体倾角/(°) | 物料停留时间/min | 质量流率/(g/s) |

|---|---|---|

| 3.0 | 8.0 | 1.00 |

| 2.5 | 9.0 | 0.90 |

| 2.0 | 10.5 | 0.85 |

| 1.5 | 11.5 | 0.78 |

| 1.0 | 12.5 | 0.64 |

| 30 | 刘刚, 池涌, 蒋旭光, 等. 模拟危险废物颗粒回转窑内运动特性试验研究[J]. 工程热物理学报, 2005, 26(2): 343-346. |

| Liu G, Chi Y, Jiang X G, et al. Mass transfer of simulative hazardous waste particles in rotary kiln[J]. Journal of Engineering Thermophysics, 2005, 26(2): 343-346. | |

| 31 | 何丽娜. 村镇生活垃圾冷态回转窑运动规律研究[D]. 天津: 天津大学, 2017. |

| He L N. Study on movement law of cold rotary kiln for village domestic waste[D]. Tianjin: Tianjin University, 2017. | |

| 32 | Sullivan J D, Maier C G, Ralston O C. Passage of solid particles through rotary cylindrical kilns[EB/OL]//UNT Digital Library. United States: Government Printing Office, 1927[2023-03-14]. . |

| 33 | 张瑞宇, 张付申. 生物干化污泥混煤燃烧特性及污染物排放规律研究[J]. 环境科学与技术, 2015, 38(S2): 66-71. |

| Zhang R Y, Zhang F S. Co-combustion properties and typical pollutant emissions of biodried sludge with coal[J]. Environmental Science & Technology, 2015, 38(S2): 66-71. | |

| 34 | 侯祥松, 李金平, 张海, 等. 石灰石脱硫对循环流化床中N2O排放浓度的影响[J]. 电站系统工程, 2005, 21(3): 1-3. |

| Hou X S, Li J P, Zhang H, et al. Limestone effects on N2O emission in CFB combustors[J]. Power System Engineering, 2005, 21(3): 1-3. | |

| 35 | 柯希玮, 蔡润夏, 吕俊复, 等. 钙基脱硫剂对循环流化床NO x 排放影响研究进展[J]. 洁净煤技术, 2019, 25(1): 1-11. |

| Ke X W, Cai R X, Lyu J F, et al. Research progress of the effects of Ca-based sorbents on the NO x reaction in circulating fluidized bed boilers[J]. Clean Coal Technology, 2019, 25(1): 1-11. | |

| 36 | Fu S L, Song Q, Tang J S, et al. Effect of CaO on the selective non-catalytic reduction deNO x process: experimental and kinetic study[J]. Chemical Engineering Journal, 2014, 249: 252-259. |

| 37 | Schäfer S, Bonn B. Hydrolysis of HCN as an important step in nitrogen oxide formation in fluidised combustion (Ⅱ): Heterogeneous reactions involving limestone[J]. Fuel, 2002, 81(13): 1641-1646. |

| 38 | Shimizu T, Ishizu K, Kobayashi S, et al. Hydrolysis and oxidation of hydrogen cyanide over limestone under fluidized bed combustion conditions[J]. Energy & Fuels, 1993, 7(5): 645-647. |

| 39 | Elled A L, Åmand L E, Leckner B, et al. Influence of phosphorus on sulphur capture during co-firing of sewage sludge with wood or bark in a fluidised bed[J]. Fuel, 2006, 85(12/13): 1671-1678. |

| 1 | 2021年中国生态环境状况公报(摘录)[J]. 环境保护, 2022, 50(12): 61-74. |

| China ecological environment status bulletin 2021 (excerpt)[J]. Environmental Protection, 2022, 50(12): 61-74. | |

| 2 | 侯海盟. 城市下水污泥循环流化床焚烧及排放特性试验研究[D]. 北京: 中国科学院大学, 2013. |

| Hou H M. Experimental study on incineration and emission characteristics of municipal sewage sludge in circulating fluidized bed[D]. Beijing: University of Chinese Academy of Sciences, 2013. | |

| 3 | Werle S, Wilk R K. A review of methods for the thermal utilization of sewage sludge: the Polish perspective[J]. Renewable Energy, 2010, 35(9): 1914-1919. |

| 4 | Werther J, Ogada T. Sewage sludge combustion[J]. Progress in Energy and Combustion Science, 1999, 25(1): 55-116. |

| 5 | Vesilind A P, Ramsey T B. Effect of drying temperature on the fuel value of wastewater sludge[J]. Waste Management & Research, 1996, 14(2): 189-196. |

| 6 | 付少闯. 干化污泥焚烧及其污染物排放规律研究[D]. 郑州: 郑州大学, 2019. |

| Fu S C. Study on dry sludge incineration and pollutant discharge[D]. Zhengzhou: Zhengzhou University, 2019. | |

| 7 | Slim J, Wakefield R. The utilization of sewage-sludge in the manufacture of Clay Bricks[J]. Water Sa., 1991, 17(3): 197-202. |

| 8 | 陈汝超. 化工区危废污泥干化焚烧项目的工艺设计与运行[J]. 中国给水排水, 2017, 33(20): 50-52. |

| Chen R C. Process design and operation of hazardous waste sludge drying and incineration project in a chemical industry park[J]. China Water & Wastewater, 2017, 33(20): 50-52. | |

| 9 | Murakami T, Suzuki Y, Nagasawa H, et al. Combustion characteristics of sewage sludge in an incineration plant for energy recovery[J]. Fuel Processing Technology, 2009, 90(6): 778-783. |

| 10 | 俞伟伟. 污泥干化焚烧烟气脱硫工艺论证及优化研究[J]. 环境卫生工程, 2020, 28(3): 38-43. |

| Yu W W. Demonstration and optimization study on desulfurization process of flue gas from sludge drying and incineration[J]. Environmental Sanitation Engineering, 2020, 28(3): 38-43. | |

| 11 | 李春雨. 典型危险废物在两段式回转窑焚烧系统内的热处置和结渣特性研究及其应用[D]. 杭州: 浙江大学, 2011. |

| Li C Y. Studies and application on thermal disposal and slagging characteristics for typical hazardous waste in two-stage incineration system with rotary kiln[D]. Hangzhou: Zhejiang University, 2011. | |

| 12 | Ogada T, Werther J. Combustion characteristics of wet sludge in a fluidized bed: release and combustion of the volatiles[J]. Fuel, 1996, 75(5): 617-626. |

| 13 | Sun C L, Koziński J A. Ignition behaviour of pulp and paper combustible wastes[J]. Fuel, 2000, 79(13): 1587-1593. |

| 14 | Zha J R, Huang Y J, Clough P T, et al. Desulfurization using limestone during sludge incineration in a fluidized bed furnace: increased risk of particulate matter and heavy metal emissions[J]. Fuel, 2020, 273: 117614. |

| 15 | 马培东, 王里奥, 周在江, 等. 水泥旋窑并行处理城市污水厂污泥的污染物排放研究[J]. 环境工程学报, 2009, 3(9): 1683-1686. |

| Ma P D, Wang L A, Zhou Z J, et al. Study on pollutant emission from cement rotary kiln parallel treating municipal sludge[J]. Chinese Journal of Environmental Engineering, 2009, 3(9): 1683-1686. | |

| 16 | Yang D J, Ko J C, Kim J K, et al. Co-incineration characteristics of sewage sludge and industrial waste using the rotary kiln incinerator[J]. Journal of Korea Organic Resource Recycling Association, 2009, 17(3): 91-99. |

| 17 | Yang S Q, Kong Q F, Zeng D W, et al. Simulation research of a counter-flow rotary kiln hazardous waste incineration system[J]. International Journal of Coal Science & Technology, 2022, 9(1): 60. |

| 18 | 房点. 干化污泥在流化床内燃烧特性及污染物排放特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. |

| Fang D. Study on combustion characteristics and pollutants emission of dried sludge in fluidized bed[D]. Harbin: Harbin Institute of Technology, 2016. | |

| 19 | 刘志强, 刘青, 蒋文斌, 等. 循环流化床锅炉SO2和NO x 排放的影响规律研究[J]. 锅炉技术, 2013, 44(3): 23-27. |

| Liu Z Q, Liu Q, Jiang W B, et al. The effect of the emission in circulating fluidized bed boilers[J]. Boiler Technology, 2013, 44(3): 23-27. | |

| 20 | Kilpinen P, Hupa M. Homogeneous N2O chemistry at fluidized bed combustion conditions: a kinetic modeling study[J]. Combustion and Flame, 1991, 85(1/2): 94-104. |

| 21 | Aamand L E, Leckner B, Andersson S. Formation of nitrous oxide in circulating fluidized-bed boilers[J]. Energy & Fuels, 1991, 5(6): 815-823. |

| 22 | 江子箫, 陈晓平, 蒋志坚, 等. 城市污泥流化床燃烧过程中气态污染物排放特性[J]. 化工进展, 2018, 37(1): 368-374. |

| Jiang Z X, Chen X P, Jiang Z J, et al. Gaseous pollutants emissions from fluidized bed combustion of municipal sewage sludge[J]. Chemical Industry and Engineering Progress, 2018, 37(1): 368-374. | |

| 23 | Folgueras M B, Marı́a Dı́az R, Xiberta J. Sulphur retention during co-combustion of coal and sewage sludge[J]. Fuel, 2004, 83(10): 1315-1322. |

| 24 | 王勇强, 陆方, 周月桂. 粒径对贫煤空气分级NO x 排放特性影响的试验研究[J]. 动力工程学报, 2021, 41(11): 926-932. |

| Wang Y Q, Lu F, Zhou Y G. Experimental study on the effect of coal particle sizes on NO x emission characteristics of lean coal under air-staged combustion conditions[J]. Journal of Chinese Society of Power Engineering, 2021, 41(11): 926-932. | |

| 25 | 刘彦, 齐学义, 丁宁, 等. 煤粉再燃过程中NO均相与异相还原反应相对贡献的研究[J]. 动力工程, 2009, 29(10): 946-949, 955. |

| Liu Y, Qi X Y, Ding N, et al. Study on relative contributions of homogeneous and heterogeneous reaction during NO reduction in pulverized coal reburning[J]. Journal of Power Engineering, 2009, 29(10): 946-949, 955. | |

| 26 | 龚艳艳. 煤燃烧过程中燃料型NO x 生成及还原机理研究进展[J]. 煤质技术, 2022, 37(3): 9-23. |

| Gong Y Y. Research progress on formation and reduction mechanism of fuel-NO x during coal combustion[J]. Coal Quality Technology, 2022, 37(3): 9-23. | |

| 27 | 李爱民, 蔡九菊, 王志, 等. 固体废弃物在回转窑内混合特性的试验[J]. 东北大学学报, 2002, 23(2): 152-155. |

| Li A M, Cai J J, Wang Z, et al. Experimental research on the mixing characteristics of solid waste in rotary kiln[J]. Journal of Northeastern University, 2002, 23(2): 152-155. | |

| 28 | Boateng A A, Barr P V. Modelling of particle mixing and segregation in the transverse plane of a rotary kiln[J]. Chemical Engineering Science, 1996, 51(17): 4167-4181. |

| 29 | 李爱民, 李水清, 严建华, 等. 固体废弃物在回转窑内停留时间的试验研究[J]. 化学反应工程与工艺, 2002, 18(2): 152-157. |

| Li A M, Li S Q, Yan J H, et al. Experimental research on mean residence time of solid materials in rotary kiln[J]. Chemical Reaction Engineering and Technology, 2002, 18(2): 152-157. |

| [1] | Zehao MI, Er HUA. DFT and COSMO-RS theoretical analysis of SO2 absorption by polyamines type ionic liquids [J]. CIESC Journal, 2023, 74(9): 3681-3696. |

| [2] | Jintong LI, Shun QIU, Wenshou SUN. Oxalic acid and UV enhanced arsenic leaching from coal in flue gas desulfurization by coal slurry [J]. CIESC Journal, 2023, 74(8): 3522-3532. |

| [3] | Chunyu LIU, Huanyu ZHOU, Yue MA, Changtao YUE. Drying characteristics and mathematical model of CaO-conditioned oil sludge [J]. CIESC Journal, 2023, 74(7): 3018-3027. |

| [4] | Yuanhao QU, Wenyi DENG, Xiaodan XIE, Yaxin SU. Study on electro-osmotic dewatering of sludge assisted by activated carbon/graphite [J]. CIESC Journal, 2023, 74(7): 3038-3050. |

| [5] | Lanhe ZHANG, Qingyi LAI, Tiezheng WANG, Xiaozhuo GUAN, Mingshuang ZHANG, Xin CHENG, Xiaohui XU, Yanping JIA. Effect of H2O2 on nitrogen removal and sludge properties in SBR [J]. CIESC Journal, 2023, 74(5): 2186-2196. |

| [6] | Jiahui SHEN, Kanhong WANG, Dawei YU, Dazhou HU, Yuansong WEI. Free ammonia conditioning promoted micro-molecule organics release and methanogenesis of thickened sludge [J]. CIESC Journal, 2022, 73(9): 4147-4155. |

| [7] | Xinyi LUO, Chao FENG, Jing LIU, Yu QIAO. Phosphorus recovery from products of sewage sludge via different thermal treatment processes [J]. CIESC Journal, 2022, 73(9): 4034-4044. |

| [8] | Jun ZHANG, Sheng HU, Jing GU, Haoran YUAN, Yong CHEN. Catalytic hydrogenation of furfural over magnetic polymetallic materials derived from electroplating sludge in methanol [J]. CIESC Journal, 2022, 73(7): 2996-3006. |

| [9] | Guanyi CHEN, Tujun TONG, Rui LI, Yanshan WANG, Beibei YAN, Ning LI, Li'an HOU. Influence of pyrolysis time on sludge-derived biochar performance for peroxymonosulfate activation [J]. CIESC Journal, 2022, 73(5): 2111-2119. |

| [10] | Jiayi WANG, Chuigang FAN, Songgeng LI. Role of carbon-oxygen complexes on low temperature reduction of NO by coal char [J]. CIESC Journal, 2022, 73(5): 2140-2148. |

| [11] | Chaoyu SONG, Yaxuan XIONG, Jinhua ZHANG, Yuhe JIN, Chenhua YAO, Huixiang WANG, Yulong DING. Preparation and performance study of incinerated slag based shape-stable phase change composites [J]. CIESC Journal, 2022, 73(5): 2279-2287. |

| [12] | Shan CHENG, Rui LUO, Hong TIAN, Zhenqi WANG, Jingchun HUANG, Yu QIAO. Effect of hydrothermal carbonization temperature on transformation path of organic nitrogen in sludge [J]. CIESC Journal, 2022, 73(11): 5220-5229. |

| [13] | Xiaoyang YANG, Baofeng WANG, Xutao SONG, Fengling YANG, Fangqin CHENG. Migration of sulfur and nitrogen during co-hydrothermal carbonization process of sewage sludge and high-sulfur coal [J]. CIESC Journal, 2022, 73(11): 5211-5219. |

| [14] | Li ZHANG, Jianhua WU, Shuhui CUI, Feng YAN, Hao SUN, Feiyue QIAN. Analysis of bacterial function in combined PN/A granular sludge and solid phase denitrification processes [J]. CIESC Journal, 2022, 73(11): 5128-5137. |

| [15] | Lanhe ZHANG, Lu WANG, Zimeng LI, Hong TANG, Jingbo GUO, Yanping JIA, Mingshuang ZHANG. The treatment of anionic surfactant wastewater using electrode ultrafiltration membrane bioreactor [J]. CIESC Journal, 2022, 73(10): 4679-4691. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||