CIESC Journal ›› 2020, Vol. 71 ›› Issue (11): 5169-5177.DOI: 10.11949/0438-1157.20200234

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Xiaoling ZHANG1,2( ),Jianing BAO5,Yunjia LI1,2,Lin HUANGFU1,2,Wensong LI3,Shiqiu GAO2,Guangwen XU4,Changming LI2,Jian YU2(

),Jianing BAO5,Yunjia LI1,2,Lin HUANGFU1,2,Wensong LI3,Shiqiu GAO2,Guangwen XU4,Changming LI2,Jian YU2( )

)

Received:2020-03-05

Revised:2020-05-17

Online:2020-11-05

Published:2020-11-05

Contact:

Jian YU

张霄玲1,2( ),鲍佳宁5,李运甲1,2,皇甫林1,2,李文松3,高士秋2,许光文4,李长明2,余剑2(

),鲍佳宁5,李运甲1,2,皇甫林1,2,李文松3,高士秋2,许光文4,李长明2,余剑2( )

)

通讯作者:

余剑

作者简介:张霄玲(1995—),女,硕士研究生,基金资助:CLC Number:

Xiaoling ZHANG,Jianing BAO,Yunjia LI,Lin HUANGFU,Wensong LI,Shiqiu GAO,Guangwen XU,Changming LI,Jian YU. Preparation and industrial application of MnOx particle catalyst for low temperature denitration[J]. CIESC Journal, 2020, 71(11): 5169-5177.

张霄玲,鲍佳宁,李运甲,皇甫林,李文松,高士秋,许光文,李长明,余剑. 工业MnOx颗粒催化剂的制备及其低温脱硝应用研究[J]. 化工学报, 2020, 71(11): 5169-5177.

Add to citation manager EndNote|Ris|BibTeX

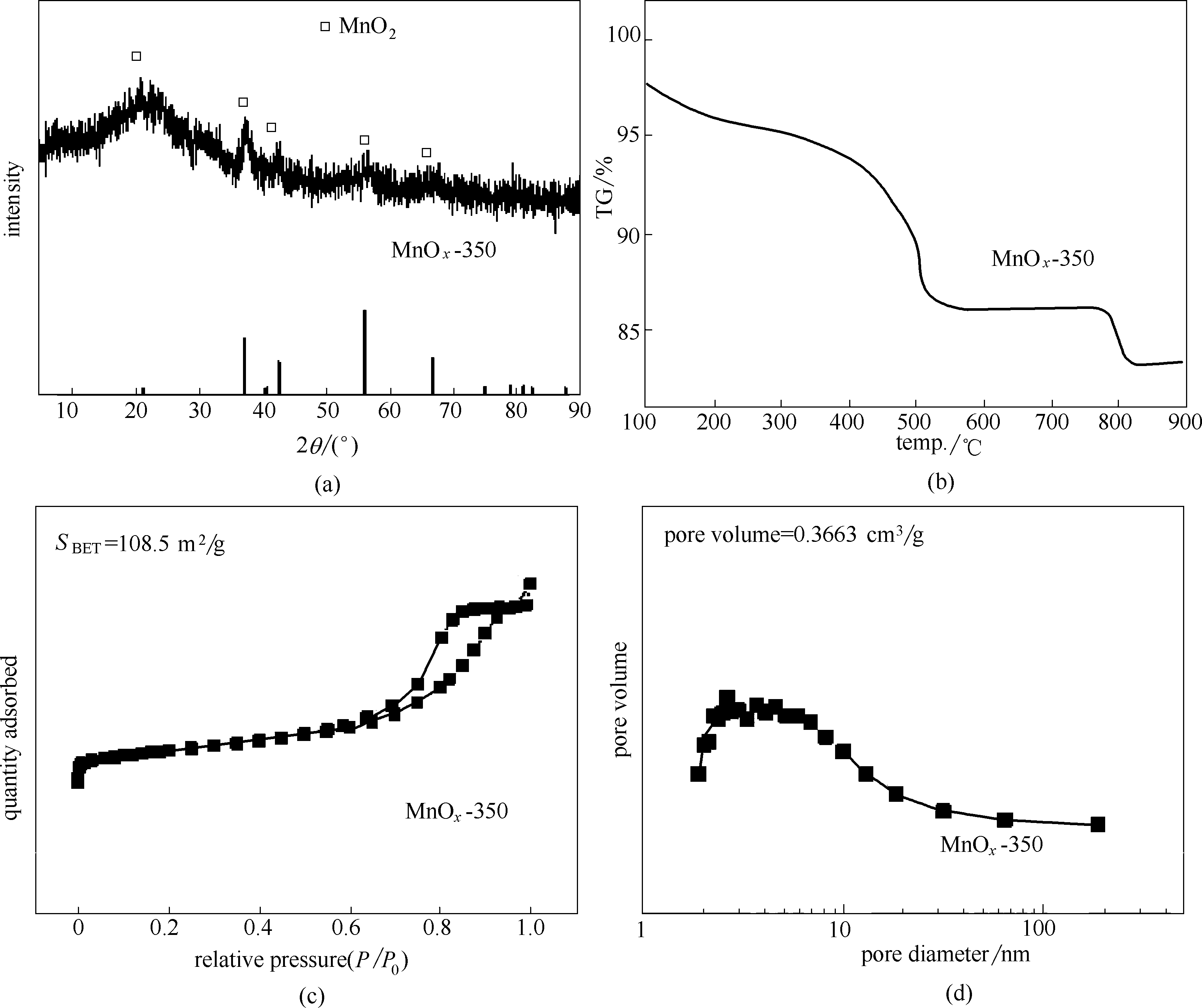

Fig.2 XRD pattern (a), TG curve(b), N2 adsorption-desorption isotherms (c) and pore size distribution by N2 adsorption branch (d) of fresh granular MnOx-350 catalyst

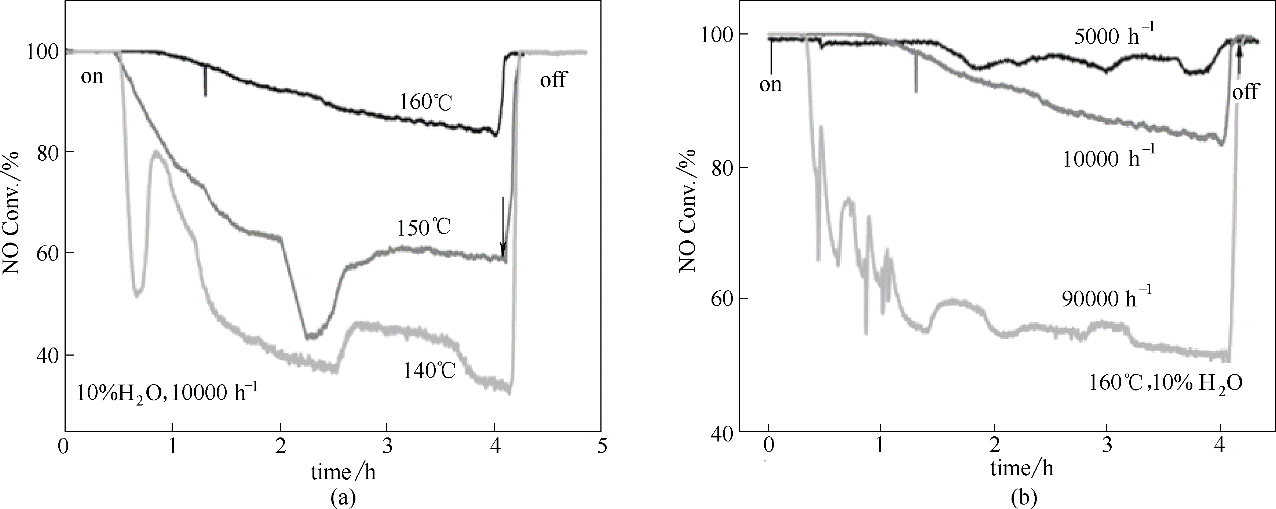

Fig.3 The catalytic performance of MnOx-350 catalyst under different reaction temperature and space velocity in simulated flue gas contained 10%(vol.) water vapor

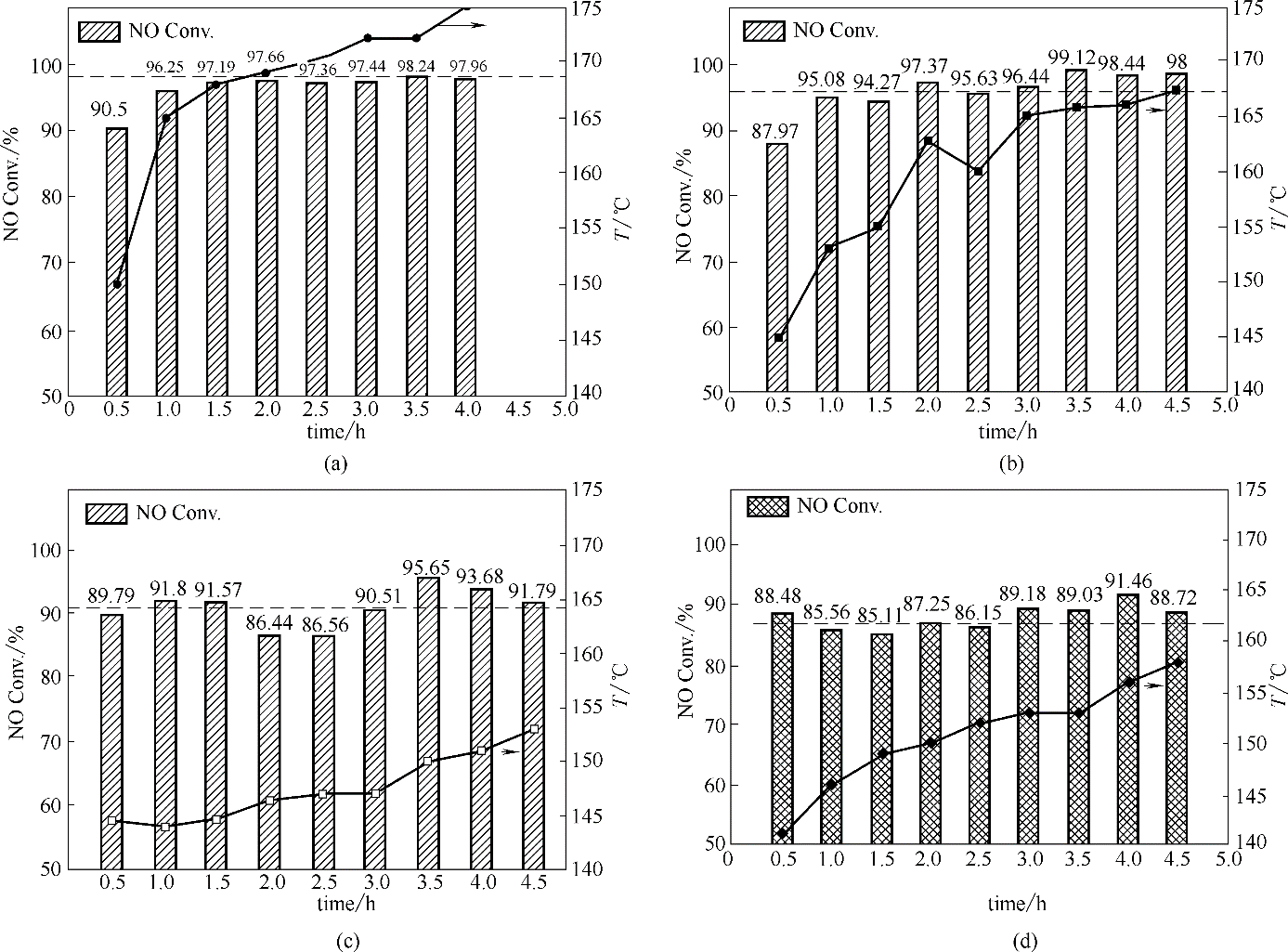

Fig.4 The activity test of MnOx catalyst for the flue gas from CCHP system: NO conversion at different temperature range of 165—175℃(a), 155—165℃(b), 145—155℃(c) and after operation for 1180 h (d)

| Sample | SBET/ (m2/g) | Pore volume/(cm3/g) | Pore size/nm |

|---|---|---|---|

| MnOx - 350 | 108.5 | 0.3663 | 8.381 |

| MnOx -350 - 1180 | 63.35 | 0.2963 | 10.64 |

| MnOx - 350 -hy | 56.29 | 0.2420 | 10.99 |

| MnOx - 500 | 32.16 | 0.2507 | 31.73 |

Table 1 Specific surface, pore volume and pore size of different catalysts

| Sample | SBET/ (m2/g) | Pore volume/(cm3/g) | Pore size/nm |

|---|---|---|---|

| MnOx - 350 | 108.5 | 0.3663 | 8.381 |

| MnOx -350 - 1180 | 63.35 | 0.2963 | 10.64 |

| MnOx - 350 -hy | 56.29 | 0.2420 | 10.99 |

| MnOx - 500 | 32.16 | 0.2507 | 31.73 |

| 1 | 蔡霓, 石君君, 唐俊勋, 等. 工业尾气SCR脱硝技术研究进展[J]. 广州化工, 2019, 47(18): 14-15+23. |

| Cai N, Shi J J, Tang J X, et al. Research progress on SCR denitrification technology for industry tail gas[J]. Guangzhou Chemical Industry, 2019, 47(18): 14-15+23. | |

| 2 | 谭青, 冯雅晨. 我国烟气脱硝行业现状与前景及SCR脱硝催化剂的研究进展[J]. 化工进展, 2011, 30(S1): 709-713. |

| Tan Q, Feng Y C. Present status and perspective of Chinas flue gas denitration industry and research process of SCR catalyst[J]. Chemical Industry and Engineering Progress, 2011, 30(S1): 709-713. | |

| 3 | 华贲. 天然气发电与分布式供能系统[J]. 中国电业, 2011, (10): 1-6. |

| Hua B. Natural gas power generation vs distributed energy supply system[J]. China Electric Power, 2011, (10): 1-6. | |

| 4 | 雷珊, 杨娟, 余剑, 等. 含钛高炉渣制备SCR烟气脱硝催化剂[J]. 化工学报, 2014, 65(4): 1251-1259. |

| Lei S, Yang J, Yu J, et al. SCR denitration catalyst prepared from titanium-bearing blast furnace slag[J]. CIESC Journal, 2014, 65(4): 1251-1259. | |

| 5 | Wang C, Li C M, Li Y J,et al. Destructive influence of cement dust on the structure and DeNOx performance of V-based SCR catalyst[J]. Industrial & Engineering Chemistry Research, 2019,58(43): 19847-19854. |

| 6 | 于超, 李长明, 张喻升, 等. 典型陶瓷基体对催化滤芯中催化剂分散及脱硝活性的影响[J]. 化工学报, 2018, 69(2): 682-689. |

| Yu C, Li C M, Zhang Y S, et al. Effect of ceramic matrices on dispersion of loaded catalyst and DeNOx activity of catalytic filters[J]. CIESC Journal, 2018, 69(2): 682-689. | |

| 7 | 郭凤, 余剑, 初茉, 等. 溶胶-凝胶原位合成宽活性温度V2O5/TiO2脱硝催化剂[J]. 化工学报, 2014, 65(6): 2098-2105. |

| Guo F, Yu J, Chu M, et al. Preparation of V2O5/TiO2 catalyst with in-situ sol-gel method for denitration in wide temperature window[J]. CIESC Journal, 2014, 65(6): 2098-2105. | |

| 8 | 曾红, 刘平乐, 张喻升, 等. 表面涂覆型低温脱硝催化剂的开发与中试应用[J]. 过程工程学报, 2017, 17(6): 1208-1216. |

| Zeng H, Liu P L, Zhang Y S, et al. Development and pilot test of surface-coating SCR denitration catalyst at low temperature[J]. The Chinese Journal of Process Engineering, 2017, 17(6): 1208-1216. | |

| 9 | Peña D A, Uphade B S, Smirniotis P G. TiO2-supported metal oxide catalysts for low-temperature selective catalytic reduction of NO with NH3: evaluation and characterization of first row transition metals[J]. Catalysis, 2004, 221(2): 421-431. |

| 10 | 王鲁元, 程星星, 王志强, 等. 低温催化脱硝技术的研究进展[J]. 化工进展, 2016, 35(7): 2222-2235. |

| Wang L Y, Cheng X X, Wang Z Q, et al. Recent research progress in catalytic reduction of NOx at low temperature[J]. Chemical Industry and Engineering Progress, 2016, 35(7): 2222-2235. | |

| 11 | 张静, 杜梦帆, 周树宇, 等. 锰基低温SCR脱硝催化剂研究进展[J]. 山东化工, 2019, 48(13): 54-57. |

| Zhang J, Du M F, Zhou S Y, et al. Progress of Mn-based catalysts at low temperature SCR of NOx[J]. Shandong Chemical Industry, 2019, 48(13): 54-57. | |

| 12 | 侯鑫, 李飞, 仵静, 等. 锰基NH3-SCR低温脱硝催化剂研究进展[J]. 工业催化, 2017, 25(6): 1-8. |

| Hou X, Li F, Wu J, et al. Studies of the behaviors of DeNOx low-temperature NH3-SCR catalysts[J]. Industrial Catalysis, 2017, 25(6): 1-8. | |

| 13 | 唐晓龙, 郝吉明, 徐文国, 等. 低温条件下Nano-MnOx上NH3选择性催化还原NO[J]. 环境科学, 2007, 28(2): 289-294. |

| Tang X L, Hao J M, Xu W G, et al. Nano-MnOx catalyst for the selective catalytic reduction of NO by NH3 in low temperature[J]. Environmental Science, 2007, 28(2): 289-294. | |

| 14 | 李晨露, 唐晓龙, 易红宏, 等. Mn基低温SCR催化剂的抗H2O、抗SO2研究进展[J]. 化工进展, 2017, 36(3): 934-943. |

| Li C L, Tang X L, Yi H H, et al. Review on manganese based catalysts resistant to H2O and SO2 for SCR reduction at low temperature[J]. Chemical Industry and Engineering Progress, 2017, 36(3): 934-943. | |

| 15 | 王金玉, 朱怀志, 安泽文, 等. Mn基脱硝催化剂抗水抗硫改性的模拟与实验研究[J]. 化工学报, 2019, 70(12): 4635-4644. |

| Wang J Y, Zhu H Z, An Z W, et al. Simulation and experimental study on modification of water and sulfur resistance by Mn-based denitration catalyst[J]. CIESC Journal, 2019, 70(12): 4635-4644. | |

| 16 | Gao F Y, Tang X L, Yi H H, et al. Improvement of activity, selectivity and H2O & SO2-tolerance of micromesoporous CrMn2O4 spinel catalyst for low-temperature NH3-SCR of NOx[J]. Applied Surface Science, 2019, 466: 411-424. |

| 17 | 耿春香, 刘文蓉, 柴倩倩, 等. Mn-Ce/TiO2低温脱硝催化剂的性能[J]. 化工进展, 2012, 31(6): 1353-1356. |

| Geng C X, Liu W R, Chai Q Q, et al. Study on the denitration characteristics of Mn-Ce/TiO2 catalyst at low temperature[J]. Chemical Industry and Engineering Progress, 2012, 31(6): 1353-1356. | |

| 18 | Yang S, Qi F, Xiong S, et al. MnOx supported on Fe-Ti spinel: a novel Mn based low temperature SCR catalyst with a high N2 selectivity[J]. Applied Catalysis B: Environmental, 2016, 181: 570-580. |

| 19 | Wang X, Wu S, Zou W, et al. Fe-Mn/Al2O3 catalysts for low temperature selective catalytic reduction of NO with NH3[J]. Chinese Journal of Catalysis, 2016, 37(8): 1314-1323. |

| 20 | Li Y, Wan Y, Li Y, et al. Low-temperature selective catalytic reduction of NO with NH3 over Mn2O3-doped Fe2O3 hexagonal microsheets[J]. ACS Applied Material and Intefaces, 2016, 8(8): 5224-5233. |

| 21 | Liu Z, Yi Y, Zhang S, et al. Selective catalytic reduction of NOx with NH3 over Mn-Ce mixed oxide catalyst at low temperatures[J]. Catalysis Today, 2013, 216: 76-81. |

| 22 | Gao F, Tang X, Yi H, et al. Promotional mechanisms of activity and SO2 tolerance of Co- or Ni-doped MnOx-CeO2 catalysts for SCR of NOx with NH3 at low temperature[J]. Chemical Engneering Journal, 2017, 317: 20-31. |

| 23 | Qiao J, Wang N, Wang Z, et al. Porous bimetallic Mn2Co1Ox catalysts prepared by a one-step combustion method for the low temperature selective catalytic reduction of NOx with NH3[J]. Catalysis Communicationn, 2015, 72: 111-115. |

| 24 | Zhang L, Shi L, Huang L, et al. Rational design of high performance DeNOx catalysts based on MnxCo3-xO4 nanocages derived from metal organic frameworks[J]. ACS Catalysis, 2014, 4(6): 1753-1763. |

| 25 | Sheng Z Y, Ma D R, Yu D Q, et al. Synthesis of novel MnOx@TiO2 core-shell nanorod catalyst for low-temperature NH3-selective catalytic reduction of NOx with enhanced SO2 tolerance[J]. Chinese Journal of Catalysis, 2018, 39: 821-830. |

| 26 | Li C, Tang X, Yi H, et al. Rational design of template-free MnOx-CeO2 hollow nanotube as de-NOx catalyst at low temperature[J]. Applied Surface Science, 2018, 428: 924-932. |

| 27 | Yu J, Guo F, Wang Y L, et al. Sulfur poisoning resistant mesoporous Mn-base catalyst for low-temperature SCR of NO with NH3 [J]. Applied Catalysis B: Environmental, 2010, 95: 160-168. |

| 28 | 刘育松, 高凤雨, 唐晓龙, 等. 制备条件对锰氧化物SCR脱硝性能的影响[J]. 环境工程学报, 2016, 10(1): 295-300. |

| Liu Y L, Gao F Y, Tang X L, et al. Effects of preparation conditions on selective catalytic reduction of NO by NH3 over MnOx catalyst[J]. Environmental Science, 2016, 10(1): 295-300. | |

| 29 | Xiong S, Liao Y, Xiao X, et al. The mechanism of the effect of H2O on the low temperature selective catalytic reduction of NO with NH3 over Mn-Fe spinel[J]. Catalysis Science and Technology, 2015, 5: 2132-2140. |

| 30 | Kang M, Park E D, Kim J M, et al. Manganese oxide catalysts for NOx reduction with NH3 at low temperatures [J]. Applied Catalysis A, 2007, 327(2): 261-269. |

| 31 | Tang X, Hao J, Xu W, et al. Low temperature selective catalytic reduction of NOx with NH3 over amorphous MnOx catalysts prepared by three methods [J]. Catalysis Communication, 2007, 8(3): 329-334. |

| [1] | Baomin DAI, Qilong WANG, Shengchun LIU, Jianing ZHANG, Xinhai LI, Fandi ZONG. Thermodynamic performance analysis of combined cooling and heating system based on combination of CO2 with the zeotropic refrigerant assisted subcooled [J]. CIESC Journal, 2023, 74(S1): 64-73. |

| [2] | Yihao ZHANG, Zhenlei WANG. Fault detection using grouped support vector data description based on maximum information coefficient [J]. CIESC Journal, 2023, 74(9): 3865-3878. |

| [3] | Manzheng ZHANG, Meng XIAO, Peiwei YAN, Zheng MIAO, Jinliang XU, Xianbing JI. Working fluid screening and thermodynamic optimization of hazardous waste incineration coupled organic Rankine cycle system [J]. CIESC Journal, 2023, 74(8): 3502-3512. |

| [4] | Jipeng ZHOU, Wenjun HE, Tao LI. Reaction engineering calculation of deactivation kinetics for ethylene catalytic oxidation over irregular-shaped catalysts [J]. CIESC Journal, 2023, 74(6): 2416-2426. |

| [5] | Hanbing HE, Zhen LIU, Yong CHEN, Xiaofeng WANG, Jing ZENG. Synthesis and slurry control of manganese oxide powder for direct ink writing electrode [J]. CIESC Journal, 2023, 74(5): 2239-2247. |

| [6] | Chengze WANG, Kaili GU, Jinhua ZHANG, Jianxuan SHI, Yiwei LIU, Jinxiang LI. Sulfidation couples with aging to enhance the reactivity of zerovalent iron toward Cr(Ⅵ) in water [J]. CIESC Journal, 2023, 74(5): 2197-2206. |

| [7] | Xiaoyong GAO, Fuyu HUANG, Wanpeng ZHENG, Diao PENG, Yixu YANG, Dexian HUANG. Scheduling optimization of refinery and chemical production process considering the safety and stability of scheduling operation [J]. CIESC Journal, 2023, 74(4): 1619-1629. |

| [8] | Yilin LIU, Yu LI, Yaxiong YU, Zheqing HUANG, Qiang ZHOU. Construction of two parameter mesoscale heat transfer model for gas-solid flow based on resetting temperature method [J]. CIESC Journal, 2022, 73(6): 2612-2621. |

| [9] | Tianqi TANG, Yurong HE. Effect of magnetic field on the mesoscale structure evolution process in a wet particle fluidized bed [J]. CIESC Journal, 2022, 73(6): 2636-2648. |

| [10] | Hui YANG, Hongze LI, Quan CHEN, Zexi ZHENG, Ran LI, Qicheng SUN. Dynamics of the transition of mass flow to funnel flow in a silo [J]. CIESC Journal, 2022, 73(6): 2722-2731. |

| [11] | Liyuan LI, Jianqiang WANG, Yi CHEN, Youdi GUO, Jian ZHOU, Zhicheng LIU, Yangdong WANG, Zaiku XIE. Study on the mesoscale mechanism of coking and deactivation of ZSM-5 catalyst in methanol to propylene reaction [J]. CIESC Journal, 2022, 73(6): 2669-2676. |

| [12] | Biao HAN, Chao SHANG, Yongheng JIANG, Dexian HUANG. Object-oriented refinery plant-wide scheduling optimization model and program framework [J]. CIESC Journal, 2022, 73(4): 1623-1630. |

| [13] | Wei ZHOU, Fuye WANG, Ning HE, Haibin YU, Xinbin MA, Jiaxu LIU. Study on the relationship of active centers and catalytic performance of Cu/SSZ-13 for NH3-SCR [J]. CIESC Journal, 2022, 73(2): 672-680. |

| [14] | Meng HUO, Xiaowan PENG, Jin ZHAO, Qiuwei MA, Chun DENG, Bei LIU, Guangjin CHEN. COSMO-RS based solvent screening and H2/CO separation experiments for CO absorption by ionic liquids [J]. CIESC Journal, 2022, 73(12): 5305-5313. |

| [15] | Shiyang YE, Min CHENG, Xu JI, Yiyang DAI, Yagu DANG, Kexin BI, Zhiwei ZHAO, Li ZHOU. High-throughput computational screening strategy for high-performance COF materials: separation of hexane isomers [J]. CIESC Journal, 2022, 73(11): 5138-5149. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||