化工学报 ›› 2021, Vol. 72 ›› Issue (6): 3390-3398.DOI: 10.11949/0438-1157.20201589

收稿日期:2020-11-03

修回日期:2021-02-04

出版日期:2021-06-05

发布日期:2021-06-05

通讯作者:

苏延磊

作者简介:刘嘉玮(1998—),男,硕士研究生,基金资助:

LIU Jiawei( ),HAO Yufeng,SU Yanlei(

),HAO Yufeng,SU Yanlei( )

)

Received:2020-11-03

Revised:2021-02-04

Online:2021-06-05

Published:2021-06-05

Contact:

SU Yanlei

摘要:

亲水修饰是提高纳滤膜抗污染性能的重要方法。采用氯化胆碱(ChC)对石墨烯量子点(GQDs-TMC)纳滤膜进行后处理仿生修饰,模拟细胞膜上磷酰胆碱的两性离子抗污染表面。红外光谱(FTIR)和表面元素分析(EDS)表明ChC以共价键结合在纳滤膜分离层上。提高反应温度和氯化胆碱溶液浓度,可以增加纳滤膜的仿生修饰程度。ChC的季铵基团与GQDs-TMC纳滤膜分离层羧基基团形成两性离子结构,提高了仿生修饰(GQDs/ChC-TMC)纳滤膜的亲水性,降低了表面电势,提高了对染料分子和二价盐离子的截留率,并且显著增强了抗污染性能。经过酸、碱和氧化剂溶液浸泡处理及高温纳滤膜分离实验,GQDs/ChC-TMC纳滤膜的渗透率和截留率均未发生较大改变,表明仿生纳滤膜具有优异的化学稳定性和耐热稳定性。

中图分类号:

刘嘉玮, 郝雨峰, 苏延磊. 石墨烯量子点纳滤膜的仿生修饰及稳定性研究[J]. 化工学报, 2021, 72(6): 3390-3398.

LIU Jiawei, HAO Yufeng, SU Yanlei. Biomimetic modification and stability of graphene quantum dots nanofiltration membranes[J]. CIESC Journal, 2021, 72(6): 3390-3398.

| Membranes | ChC concentration/% (质量) | Solution temperature of modification/℃ |

|---|---|---|

| 0# | 0 | 90 |

| 1# | 0.25 | 90 |

| 2# | 0.50 | 90 |

| 3# | 0.75 | 90 |

| 4# | 1.00 | 90 |

| 5# | 0.75 | 50 |

| 6# | 0.75 | 60 |

| 7# | 0.75 | 70 |

| 8# | 0.75 | 80 |

表1 GQDs/ChC-TMC纳滤膜的制备条件

Table 1 Preparation conditions of GQDs/ChC-TMC nanofiltration membrane

| Membranes | ChC concentration/% (质量) | Solution temperature of modification/℃ |

|---|---|---|

| 0# | 0 | 90 |

| 1# | 0.25 | 90 |

| 2# | 0.50 | 90 |

| 3# | 0.75 | 90 |

| 4# | 1.00 | 90 |

| 5# | 0.75 | 50 |

| 6# | 0.75 | 60 |

| 7# | 0.75 | 70 |

| 8# | 0.75 | 80 |

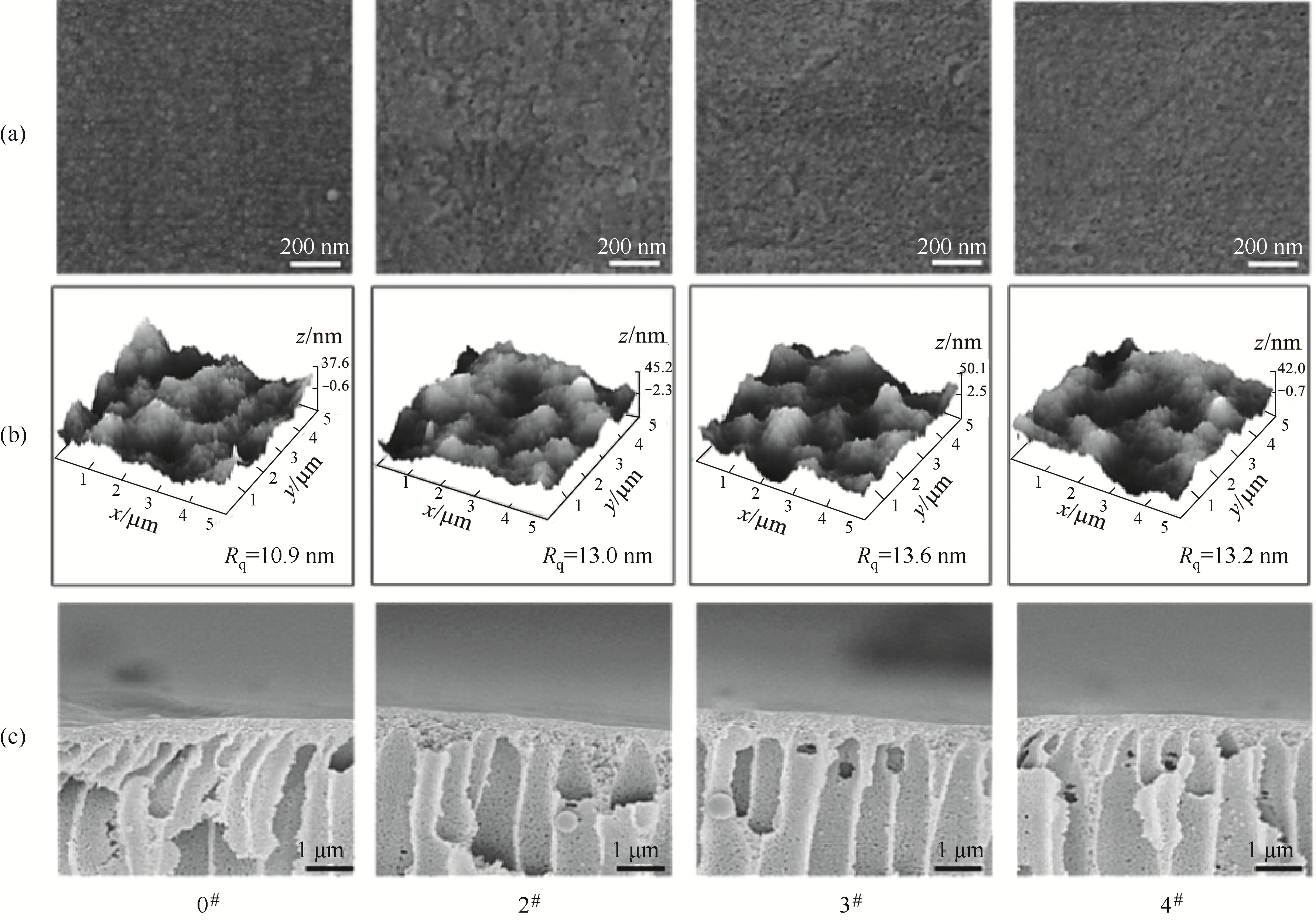

图3 GQDs/ChC-TMC纳滤膜的SEM表面图(a)、AFM图(b)、SEM断面图(c)

Fig.3 Images of the GQDs/ChC-TMC nanofiltration membranes: SEM surface image(a), AFM image(b), SEM section image(c)

| Membranes | ChC concentration / %(质量) | Solution temperature of modification/℃ | Surface roughness | Zeta potential/mV | Water contact angles/(°) |

|---|---|---|---|---|---|

| 0# | 0 | 90 | 10.9 | -45.2 | 68.3 |

| 1# | 0.25 | 90 | 12.3 | -34.4 | 59.2 |

| 2# | 0.50 | 90 | 13.0 | -17.6 | 58.7 |

| 3# | 0.75 | 90 | 13.6 | -12.7 | 49.1 |

| 4# | 1.00 | 90 | 13.2 | -9.3 | 52.1 |

表2 不同制备条件下GQDs/ChC-TMC纳滤膜样品的表面性质

Table 2 Surface properties of GQDs/ChC-TMC nanofiltration membrane prepared under different preparation conditions

| Membranes | ChC concentration / %(质量) | Solution temperature of modification/℃ | Surface roughness | Zeta potential/mV | Water contact angles/(°) |

|---|---|---|---|---|---|

| 0# | 0 | 90 | 10.9 | -45.2 | 68.3 |

| 1# | 0.25 | 90 | 12.3 | -34.4 | 59.2 |

| 2# | 0.50 | 90 | 13.0 | -17.6 | 58.7 |

| 3# | 0.75 | 90 | 13.6 | -12.7 | 49.1 |

| 4# | 1.00 | 90 | 13.2 | -9.3 | 52.1 |

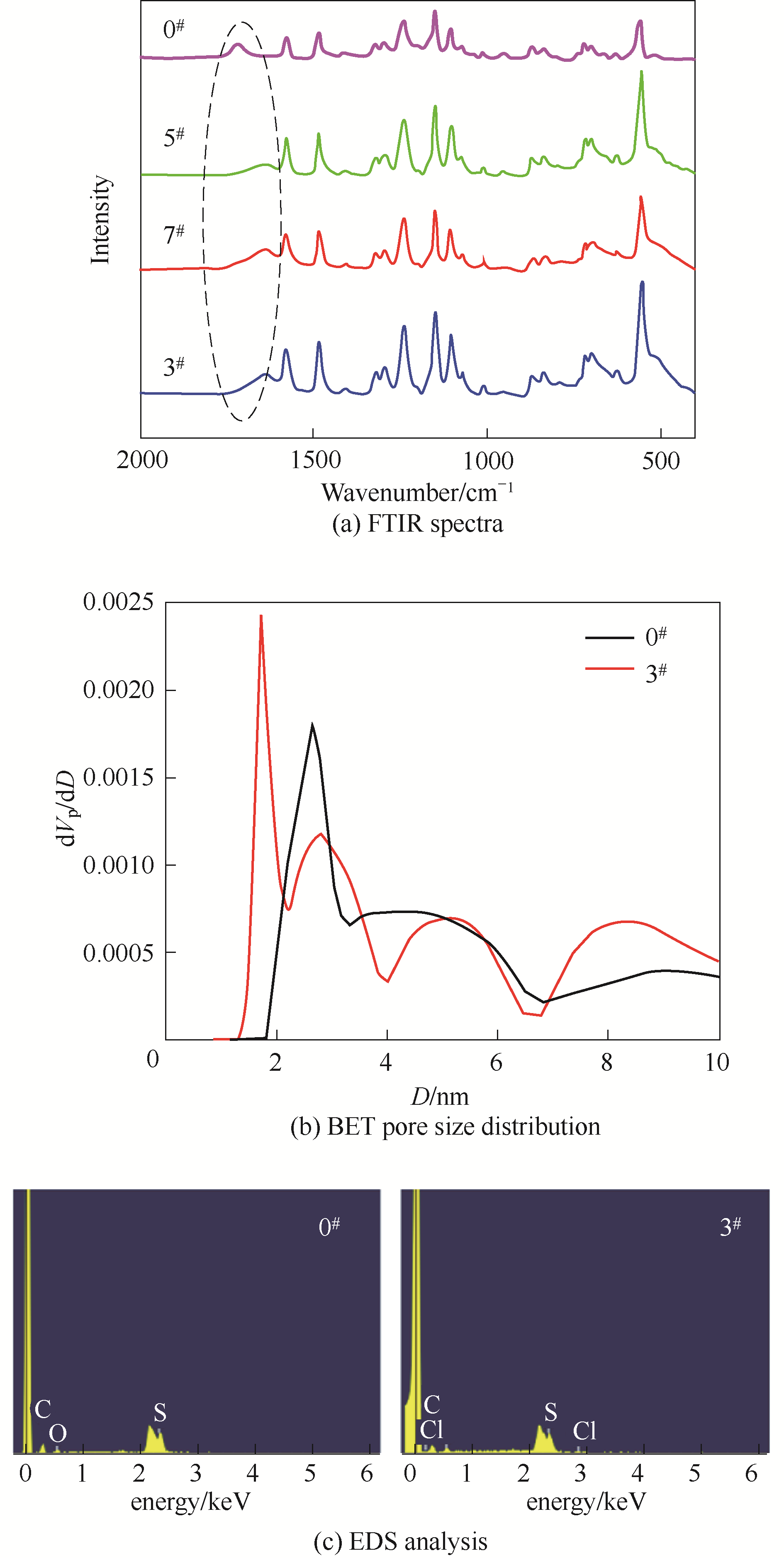

图4 GQDs-TMC和GQDs/ChC-TMC纳滤膜的红外图谱(a),BET孔径分布图(b)、EDS分析(c)

Fig.4 Characterization of GQDs-TMC and GQDs/ChC-TMC nanofiltration membranes, FTIR spectra (a), BET pore size distribution diagram (b), EDS analysis (c)

图5 反应温度(a)和ChC浓度(b)对GQDs/ChC-TMC纳滤膜分离性能的影响

Fig.5 Effect of reaction temperature (a) and ChC concentration (b) on GQDs/ChC-TMC nanofiltration membrane separation performance

| Treatments | Permeability/ ( | MB rejection/ % | |

|---|---|---|---|

| 52.4±0.5 | 50.2±0.8 | 97.8±0.8 | |

| 80℃ | 55.2±1.4 | 47.1±1.6 | 97.1±1.2 |

| 90℃ | 53.8±1.2 | 46.8±1.1 | 96.8±1.3 |

| 1 | 52.4±0.8 | 49.2±0.7 | 96.4±0.8 |

| 3%(mass) | 51.8±0.6 | 50.2±0.8 | 96.6±0.7 |

| pH=13 NaOH | 52.5±0.5 | 51.2±0.9 | 93.3±0.3 |

| pH=1 HCl | 51.6±0.6 | 49.2±1.4 | 91.6±1.0 |

表3 高温原料液和不同溶液浸泡24 h后GQDs/ChC-TMC纳滤膜的水渗透率和截留率

Table 3 Permeability and rejection rate of GQDs/ChC-TMC nanofiltration membrane for the feed solution at high temperature and after soaking 24 h in different solutions.

| Treatments | Permeability/ ( | MB rejection/ % | |

|---|---|---|---|

| 52.4±0.5 | 50.2±0.8 | 97.8±0.8 | |

| 80℃ | 55.2±1.4 | 47.1±1.6 | 97.1±1.2 |

| 90℃ | 53.8±1.2 | 46.8±1.1 | 96.8±1.3 |

| 1 | 52.4±0.8 | 49.2±0.7 | 96.4±0.8 |

| 3%(mass) | 51.8±0.6 | 50.2±0.8 | 96.6±0.7 |

| pH=13 NaOH | 52.5±0.5 | 51.2±0.9 | 93.3±0.3 |

| pH=1 HCl | 51.6±0.6 | 49.2±1.4 | 91.6±1.0 |

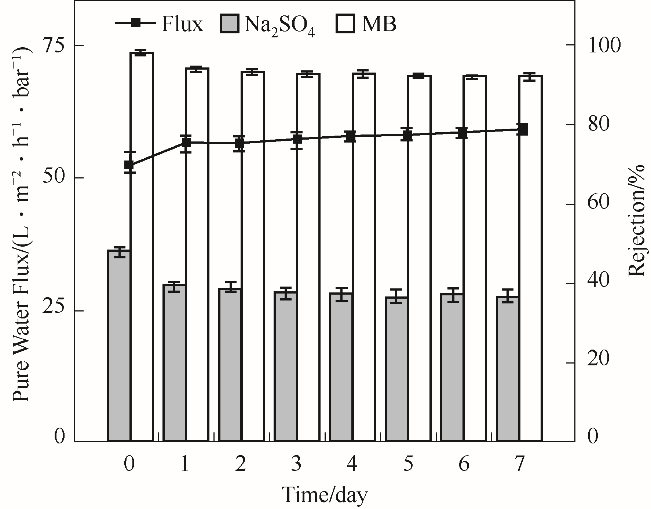

图6 GQDs/ChC-TMC纳滤膜样品在1 g·L-1?NaClO溶液浸泡后的长期稳定性

Fig.6 Long-term stability of GQDs/ChC-TMC nanofiltration membrane after soaking in 1 g·L-1 NaClO solution

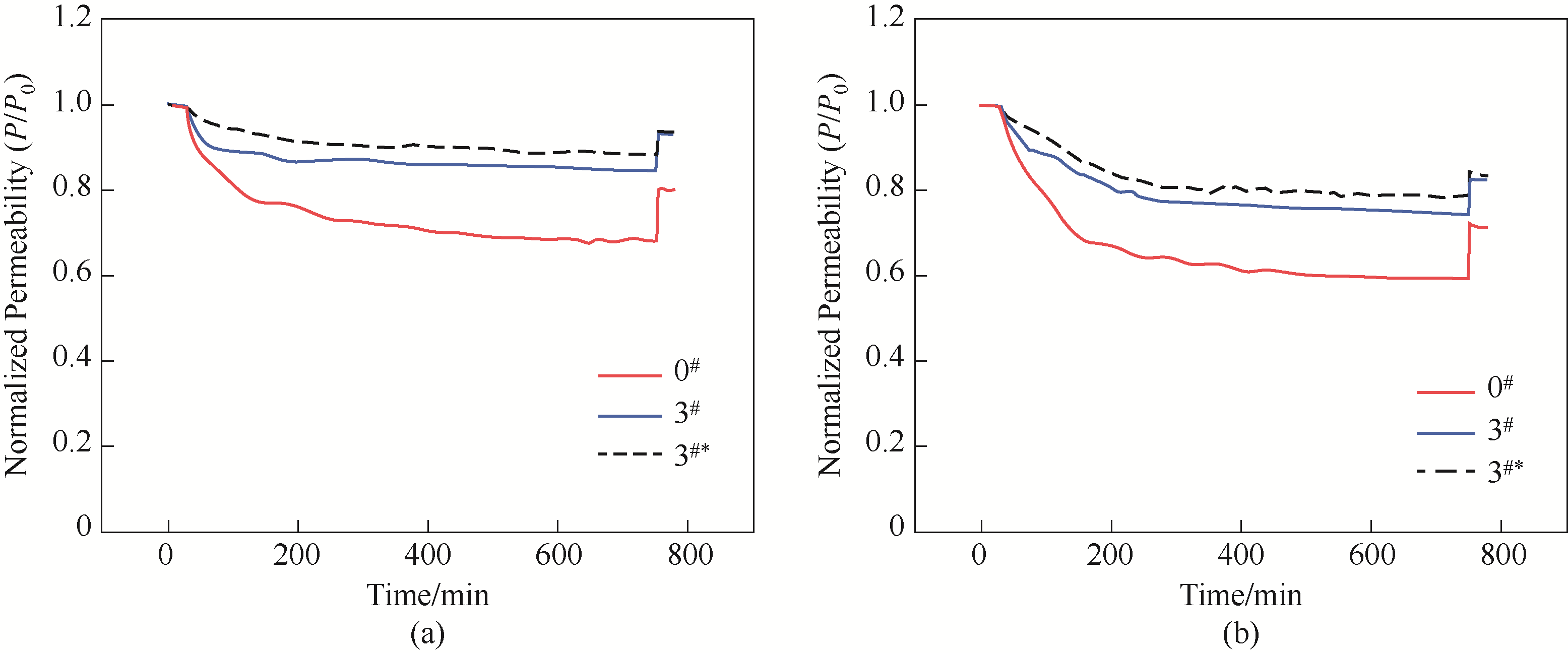

图7 GQDs-TMC和GQDs/ChC-TMC纳滤膜在HA(a)和BSA(b)污染液体系中的抗污染性能。3#样品在3.0% H2O2溶液浸泡6 h后得到3#*样品

Fig.7 Anti-fouling performance of GQDs-TMC and GQDs/ChC-TMC nanofiltration membranes operated with HA (a) and BSA (b) solutions. 3#* sample was 3# sample after immersion into 3.0% H2O2 for 6 h

| Antifouling indexes/% | HA | BSA | ||||

|---|---|---|---|---|---|---|

| 0# | 3# | 3#* | 0# | 3# | 3#* | |

| FRR | 84.2 | 94.5 | 94.3 | 71.2 | 83.6 | 83.8 |

| 28.2 | 13.8 | 10.9 | 40.7 | 24.4 | 20.8 | |

| 12.5 | 8.4 | 5.2 | 11.8 | 8.0 | 4.6 | |

| 15.8 | 5.4 | 5.7 | 28.8 | 16.4 | 16.2 | |

表4 GQDs-TMC和GQDs/ChC-TMC纳滤膜的抗污染指数

Table 4 Antifouling indexes of GQDs-TMC and GQDs/ChC-TMC nanofiltration membrane membranes

| Antifouling indexes/% | HA | BSA | ||||

|---|---|---|---|---|---|---|

| 0# | 3# | 3#* | 0# | 3# | 3#* | |

| FRR | 84.2 | 94.5 | 94.3 | 71.2 | 83.6 | 83.8 |

| 28.2 | 13.8 | 10.9 | 40.7 | 24.4 | 20.8 | |

| 12.5 | 8.4 | 5.2 | 11.8 | 8.0 | 4.6 | |

| 15.8 | 5.4 | 5.7 | 28.8 | 16.4 | 16.2 | |

| 1 | 李祥, 张忠国, 任晓晶, 等. 纳滤膜材料研究进展[J]. 化工进展, 2014, 33(5): 1210-1218, 1229. |

| Li X, Zhang Z G, Ren X J, et al. Progress in nanofiltration membrane materials[J]. Chemical Industry and Engineering Progress, 2014, 33(5): 1210-1218, 1229. | |

| 2 | 李红果, 李天祥, 朱静, 等. 膜分离技术处理工业废水研究进展[J]. 应用化工, 2018, 47(12): 2739-2743. |

| Li H G, Li T X, Zhu J, et al. Research progress of membrane separation technology for industrial wastewater treatment[J]. Applied Chemical Industry, 2018, 47(12): 2739-2743. | |

| 3 | 石紫, 王志, 王宠, 等. 染料分离有机纳滤膜制备技术研究进展[J]. 膜科学与技术, 2020, 40(1): 340-351. |

| Shi Z, Wang Z, Wang C, et al. Research progress in the preparation of organic nanofiltration membranes for dye separation[J]. Membrane Science and Technology, 2020, 40(1): 340-351. | |

| 4 | 刘威, 杭晓风, 万印华. 混凝-纳滤组合工艺处理印染整理废水[J]. 水处理技术, 2018, 44(11): 84-87, 92. |

| Liu W, Hang X F, Wan Y H. Treatment of finishing wastewater in dyeing and printing by coagulation-nanofiltration combined technology[J]. Technology of Water Treatment, 2018, 44(11): 84-87, 92. | |

| 5 | Chen D Y, Sirkar K K, Jin C, et al. Membrane-based technologies in the pharmaceutical industry and continuous production of polymer-coated crystals/particles[J]. Current Pharmaceutical Design, 2017, 23(2): 242-249. |

| 6 | 李露, 赵河立, 邵天宝, 等. 纳滤技术在海水淡化中的应用实验研究[J]. 水处理技术, 2015, 41(10): 100-103, 126. |

| Li L, Zhao H L, Shao T B, et al. Experimental study of nanofiltration technology in seawater desalination[J]. Technology of Water Treatment, 2015, 41(10): 100-103, 126. | |

| 7 | 李露, 苏立永, 邵天宝, 等. 纳滤技术在海水淡化中的应用实验研究(Ⅱ)[J]. 水处理技术, 2016, 42(12): 89-91, 95. |

| Li L, Su L Y, Shao T B, et al. Experimental study of nanofiltration technology in seawater desalination(Ⅱ)[J]. Technology of Water Treatment, 2016, 42(12): 89-91, 95. | |

| 8 | Li Y, Wong E, Mai Z H, et al. Fabrication of composite polyamide/Kevlar aramid nanofiber nanofiltration membranes with high permselectivity in water desalination[J]. Journal of Membrane Science, 2019, 592: 117396. |

| 9 | Liu M H, Yu S C, Tao J, et al. Preparation, structure characteristics and separation properties of thin-film composite polyamide-urethane seawater reverse osmosis membrane[J]. Journal of Membrane Science, 2008, 325(2): 947-956. |

| 10 | 栾仁杰, 马骁轩, 刘爱菊, 等. 高效纳滤膜的制备研究进展[J]. 山东理工大学学报(自然科学版), 2020, 34(3): 17-22. |

| Luan R J, Ma X X, Liu A J, et al. Preparation of high efficiency nanofiltration membrane[J]. Journal of Shandong University of Technology (Natural Science Edition), 2020, 34(3): 17-22. | |

| 11 | 魏源送, 王健行, 岳增刚, 等. 纳滤膜技术在废水深度处理中的膜污染及控制研究进展[J]. 环境科学学报, 2017, 37(1): 1-10. |

| Wei Y S, Wang J X, Yue Z G, et al. Fouling and control of nanofiltration membrane in the advanced treatment of wastewater: an overview[J]. Acta Scientiae Circumstantiae, 2017, 37(1): 1-10. | |

| 12 | 黄嘉臣, 罗建泉, 郭世伟, 等. 化学清洗对聚酰胺纳滤膜的影响机制研究进展[J]. 膜科学与技术, 2020, 40(1): 188-195. |

| Huang J C, Luo J Q, Guo S W, et al. Research progress on effect mechanisms of chemical cleaning on polyamide nanofiltration membrane[J]. Membrane Science and Technology, 2020, 40(1): 188-195. | |

| 13 | Hacıfazlıoğlu M C, Parlar İ, Pek T Ö, et al. Evaluation of chemical cleaning to control fouling on nanofiltration and reverse osmosis membranes after desalination of MBR effluent[J]. Desalination, 2019, 466: 44-51. |

| 14 | Li Y, Li J, de Soria R B, et al. Aramid nanofiber and modified ZIF-8 constructed porous nanocomposite membrane for organic solvent nanofiltration[J]. Journal of Membrane Science, 2020, 603: 118002. |

| 15 | Shan L L, Gu J H, Fan H W, et al. Microphase diffusion-controlled interfacial polymerization for an ultrahigh permeability nanofiltration membrane[J]. ACS Applied Materials & Interfaces, 2017, 9(51): 44820-44827. |

| 16 | 曹阳, 任玉灵, 郭世伟, 等. 聚酰胺薄层复合膜的界面聚合制备过程调控研究进展[J]. 化工进展, 2020, 39(6): 2125-2134. |

| Cao Y, Ren Y L, Guo S W, et al. Research progress on process optimization for preparation of polyamide thin-film composite membrane by interfacial polymerization[J]. Chemical Industry and Engineering Progress, 2020, 39(6): 2125-2134. | |

| 17 | Guo X Y, Liu D H, Han T T, et al. Preparation of thin film nanocomposite membranes with surface modified MOF for high flux organic solvent nanofiltration[J]. AIChE Journal, 2017, 63(4): 1303-1312. |

| 18 | Li W, Shi C, Zhou A, et al. A positively charged composite nanofiltration membrane modified by EDTA for LiCl/MgCl2 separation[J]. Separation and Purification Technology, 2017, 186: 233-242. |

| 19 | 徐颜军, 徐泽海, 孟琴, 等. 新型还原氧化石墨烯/氮化碳复合纳滤膜制备及其性能[J]. 化工学报, 2019, 70(9):3565-3572. |

| Xu Y J, Xu Z H, Meng Q, et al. Preparation and performance of novel rGO/uCN composite nanofiltration membrane[J]. CIESC Journal, 2019, 70(9):3565-3572. | |

| 20 | 项军, 刘天宇, 谢宗丽, 等. 聚醚砜基膜热稳定性对复合纳滤膜性能的影响[J]. 膜科学与技术, 2020, 40(2): 60-66. |

| Xiang J, Liu T Y, Xie Z L, et al. Effect of thermal stability of polyethersulfone supporting ultrafiltraion membrane on properties of composite nanofiltration membrane[J]. Membrane Science and Technology, 2020, 40(2): 60-66. | |

| 21 | 汪菊, 牛淑锋, 费莹, 等. GO/Al2O3复合纳滤膜的制备及其稳定性能研究[J]. 化工学报, 2020, 71(6): 2795-2803. |

| Wang J, Niu S F, Fei Y, et al. Fabrication and stability of GO/Al2O3 composite nanofiltration membranes[J]. CIESC Journal, 2020, 71(6): 2795-2803. | |

| 22 | Peng H W, Tang Q Q, Tang S H, et al. Surface modified polyamide nanofiltration membranes with high permeability and stability[J]. Journal of Membrane Science, 2019, 592: 117386. |

| 23 | Qiang R B, Hu L F, Hou K M, et al. Water-soluble graphene quantum dots as high-performance water-based lubricant additive for steel/steel contact[J]. Tribology Letters, 2019, 67(2): 1-9. |

| 24 | Bi R, Zhang R N, Shen J L, et al. Graphene quantum dots engineered nanofiltration membrane for ultrafast molecular separation[J]. Journal of Membrane Science, 2019, 572: 504-511. |

| 25 | Liu P S, Chen Q, Wu S S, et al. Surface modification of cellulose membranes with zwitterionic polymers for resistance to protein adsorption and platelet adhesion[J]. Journal of Membrane Science, 2010, 350(1/2): 387-394. |

| 26 | Chen S F, Li L Y, Zhao C, et al. Surface hydration: principles and applications toward low-fouling/nonfouling biomaterials[J]. Polymer, 2010, 51(23): 5283-5293. |

| 27 | Zhao X T, Su Y L, Chen W J, et al. Grafting perfluoroalkyl groups onto polyacrylonitrile membrane surface for improved fouling release property[J]. Journal of Membrane Science, 2012, 415/416: 824-834. |

| 28 | Shahkaramipour N, Tran T N, Ramanan S, et al. Membranes with surface-enhanced antifouling properties for water purification[J]. Membranes, 2017, 7(1): E13. |

| 29 | Rezania J, Shockravi A, Vatanpour V, et al. Preparation and performance evaluation of carboxylic acid containing polyamide incorporated microporous ultrafiltration PES membranes[J]. Polymers for Advanced Technologies, 2019, 30(2): 407-416. |

| 30 | Zhang Y, Su Y L, Peng J M, et al. Composite nanofiltration membranes prepared by interfacial polymerization with natural material tannic acid and trimesoyl chloride[J]. Journal of Membrane Science, 2013, 429: 235-242. |

| 31 | Li B, Jain P, Ma J, et al. Trimethylamine N-oxide-derived zwitterionic polymers: a new class of ultralow fouling bioinspired materials[J]. Science Advances, 2019, 5(6): eaaw9562. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [3] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [4] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [5] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [6] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [7] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [8] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [9] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [10] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [11] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [12] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [13] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [14] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [15] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号