化工学报 ›› 2021, Vol. 72 ›› Issue (S1): 170-177.DOI: 10.11949/0438-1157.20201569

马秋鸣1( ),聂磊1,潘权稳1(

),聂磊1,潘权稳1( ),山訸1,曹伟亮2,王强2,王如竹1

),山訸1,曹伟亮2,王强2,王如竹1

收稿日期:2020-11-03

修回日期:2021-01-11

出版日期:2021-06-20

发布日期:2021-06-20

通讯作者:

潘权稳

作者简介:马秋鸣(1989—),男,博士,助理研究员,基金资助:

MA Qiuming1( ),NIE Lei1,PAN Quanwen1(

),NIE Lei1,PAN Quanwen1( ),SHAN He1,CAO Weiliang2,WANG Qiang2,WANG Ruzhu1

),SHAN He1,CAO Weiliang2,WANG Qiang2,WANG Ruzhu1

Received:2020-11-03

Revised:2021-01-11

Online:2021-06-20

Published:2021-06-20

Contact:

PAN Quanwen

摘要:

电动汽车中电池组的热管理对汽车的性能和安全性十分重要。通常使用小型电池冷却器(chiller)与车载空调系统的蒸发器并联,用来冷却电池冷却板中的冷却液。为了对实际电池冷却器的换热性能进行评估和分析,设计搭建了一套完整的试验测试系统,并验证了其测试的稳定性和重复性。在此基础上,对最新设计的小型紧凑电池冷却器进行了不同工况下的性能测试和分析,得到了其换热功率和流阻随冷媒侧和冷却液侧参数改变的变化规律,最高换热功率达到了5.6 kW。

中图分类号:

马秋鸣, 聂磊, 潘权稳, 山訸, 曹伟亮, 王强, 王如竹. 电动汽车电池冷却器换热性能[J]. 化工学报, 2021, 72(S1): 170-177.

MA Qiuming, NIE Lei, PAN Quanwen, SHAN He, CAO Weiliang, WANG Qiang, WANG Ruzhu. Heat exchange performance of a battery chiller for electric vehicles[J]. CIESC Journal, 2021, 72(S1): 170-177.

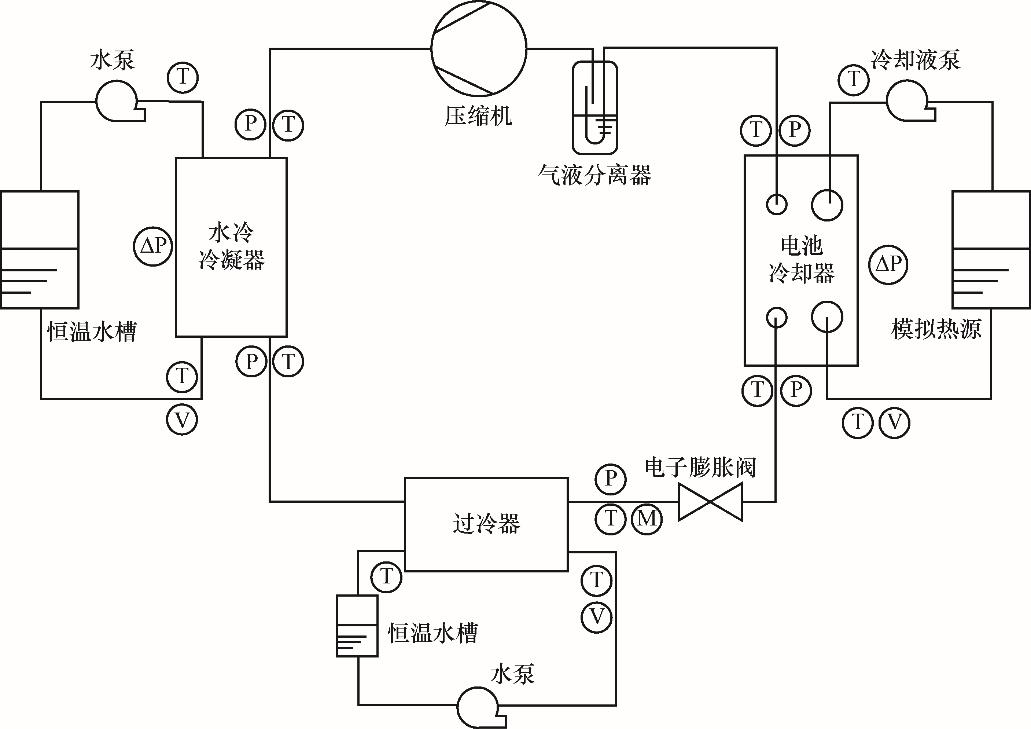

图3 试验测试系统(图中P为压力测点,T为温度测点,V为流量测点,ΔP为压差测点)

Fig.3 Experimental testing system (P—pressure measuring points; T—temperature measuring points; V—flowrate measuring points; ΔP—pressure difference measuring points)

| 部件 | 型号 | 规格 | 生产厂家 |

|---|---|---|---|

| 压缩机 | EVS50B (低压版) EVS50HLBCAA-8AA | 全封闭电动涡旋压缩机,排量50c/rev,转速1500~6000; 8.5kW~6000 r/min,0.2/1.4 MPa[G] SH/SC=10/5K; 6.3kW~6000 r/min Te/Tc=-20/45℃ SH/SC=10/5 K; 接口管径OD 15.5 mm / ID 21.3 mm 高压工作范围400~720 V;低压工作范围9~36 V 通讯协议CAN2.0;波特率500 | 上海海立新能源技术有限公司 |

| 冷凝器 | B3-020G-42D-304-4.5 | 钎焊板式换热器 总换热面积:0.8 m2 外形尺寸312 mm×76 mm×64 mm 接口管径:制冷剂侧15.5 mm,水侧19 mm | 江苏唯益换热器股份公司 |

| 过冷器 | B3-020G-10D-304-4.5 | 钎焊板式换热器 总换热面积:0.2 m2 外形尺寸312 mm×76 mm×18 mm 接口管径:制冷剂侧15.5 mm,水侧19 mm | 江苏唯益换热器股份公司 |

| 电子膨胀阀 | EAS-16K001 | 阀口通径1.6 mm 接口管径OD 11.05/ID 15.5 mm | 浙江三花汽车零部件有限公司 |

| 气液分离器 | RA-207 | 接口管径ID/OD 19/21 mm 桶身高度218 mm 配备分子筛 适用冷量10 kW | 天津双昊车用空调有限公司 |

| 高压电源 | HNX-600V-7200W | 输入380 V AC 输出6~600 V DC 12 A | 深圳市海纳信科技有限公司 |

表1 试验测试系统部件型号及主要参数

Table 1 Type and parameters of main parts of testing system

| 部件 | 型号 | 规格 | 生产厂家 |

|---|---|---|---|

| 压缩机 | EVS50B (低压版) EVS50HLBCAA-8AA | 全封闭电动涡旋压缩机,排量50c/rev,转速1500~6000; 8.5kW~6000 r/min,0.2/1.4 MPa[G] SH/SC=10/5K; 6.3kW~6000 r/min Te/Tc=-20/45℃ SH/SC=10/5 K; 接口管径OD 15.5 mm / ID 21.3 mm 高压工作范围400~720 V;低压工作范围9~36 V 通讯协议CAN2.0;波特率500 | 上海海立新能源技术有限公司 |

| 冷凝器 | B3-020G-42D-304-4.5 | 钎焊板式换热器 总换热面积:0.8 m2 外形尺寸312 mm×76 mm×64 mm 接口管径:制冷剂侧15.5 mm,水侧19 mm | 江苏唯益换热器股份公司 |

| 过冷器 | B3-020G-10D-304-4.5 | 钎焊板式换热器 总换热面积:0.2 m2 外形尺寸312 mm×76 mm×18 mm 接口管径:制冷剂侧15.5 mm,水侧19 mm | 江苏唯益换热器股份公司 |

| 电子膨胀阀 | EAS-16K001 | 阀口通径1.6 mm 接口管径OD 11.05/ID 15.5 mm | 浙江三花汽车零部件有限公司 |

| 气液分离器 | RA-207 | 接口管径ID/OD 19/21 mm 桶身高度218 mm 配备分子筛 适用冷量10 kW | 天津双昊车用空调有限公司 |

| 高压电源 | HNX-600V-7200W | 输入380 V AC 输出6~600 V DC 12 A | 深圳市海纳信科技有限公司 |

| 参数 | 测量仪表 | 量程 | 精度 | 厂商 |

|---|---|---|---|---|

制冷剂温度T/℃ 制冷剂绝对压力 p/kPa | 高温温压传感器 | T -30~125 p 184~3518 | ±1.5% | 盾安传感 |

| 低温温压传感器 | T -30~125 p 101~1025 | ±1.5% | ||

| 冷却液温度/℃ | 水温传感器 | -40~200 | ±0.5℃ | 三花汽零 |

| 冷却液压差/kPa | 压差传感器 | 0~100 | ±1% | 杭州美控 |

| 冷却液流量/(L/min) | 体积流量传感器 | 5~25 | ±1% | 长征仪表 |

| 输入电流/A | 直流电流传感器 | 0~20 A DC | ±0.5% | 杭州美控 |

| 输入电压/V | 直流电压传感器 | 0~1000 V DC | ±0.5% | 杭州美控 |

表2 传感器参数

Table 2 Sensor parameters

| 参数 | 测量仪表 | 量程 | 精度 | 厂商 |

|---|---|---|---|---|

制冷剂温度T/℃ 制冷剂绝对压力 p/kPa | 高温温压传感器 | T -30~125 p 184~3518 | ±1.5% | 盾安传感 |

| 低温温压传感器 | T -30~125 p 101~1025 | ±1.5% | ||

| 冷却液温度/℃ | 水温传感器 | -40~200 | ±0.5℃ | 三花汽零 |

| 冷却液压差/kPa | 压差传感器 | 0~100 | ±1% | 杭州美控 |

| 冷却液流量/(L/min) | 体积流量传感器 | 5~25 | ±1% | 长征仪表 |

| 输入电流/A | 直流电流传感器 | 0~20 A DC | ±0.5% | 杭州美控 |

| 输入电压/V | 直流电压传感器 | 0~1000 V DC | ±0.5% | 杭州美控 |

| 工况参数 | 数值 |

|---|---|

| 膨胀阀进口温度T3/℃ | 50 |

| 膨胀阀进口绝对压力p3/MPa | 1.5 |

| chiller出口过热度SH3/℃ | 5 |

| chiller出口绝对压力p5/MPa | 0.3 |

| 冷却液侧流量V3/(L/min) | 12 |

| 冷却液侧进口温度T11/℃ | 20 |

表3 试验测试基准工况

Table 3 Basic test conditions

| 工况参数 | 数值 |

|---|---|

| 膨胀阀进口温度T3/℃ | 50 |

| 膨胀阀进口绝对压力p3/MPa | 1.5 |

| chiller出口过热度SH3/℃ | 5 |

| chiller出口绝对压力p5/MPa | 0.3 |

| 冷却液侧流量V3/(L/min) | 12 |

| 冷却液侧进口温度T11/℃ | 20 |

| 1 | Kim S C, Won J P, Park Y S, et al. Performance evaluation of a stack cooling system using CO2 air conditioner in fuel cell vehicles [J]. International Journal of Refrigeration, 2009, 32(1): 70-77. |

| 2 | Al-Alawi B M, Bradley T H. Total cost of ownership, payback, and consumer preference modeling of plug-in hybrid electric vehicles [J]. Applied Energy, 2013, 103: 488-506. |

| 3 | Brouwer A S, Kuramochi T, van den Broek M, et al. Fulfilling the electricity demand of electric vehicles in the long term future: an evaluation of centralized and decentralized power supply systems [J]. Applied Energy, 2013, 107: 33-51. |

| 4 | Habib S, Khan M M, Abbas F, et al. A comprehensive study of implemented international standards, technical challenges, impacts and prospects for electric vehicles [J]. IEEE Access, 2018, 6: 13866-13890. |

| 5 | Opitz A, Badami P, Shen L, et al. Can Li-ion batteries be the panacea for automotive applications? [J]. Renewable and Sustainable Energy Reviews, 2017, 68: 685-692. |

| 6 | Hong S H, Jang D S, Park S, et al. Thermal performance of direct two-phase refrigerant cooling for lithium-ion batteries in electric vehicles [J]. Applied Thermal Engineering, 2020, 173: 115213. |

| 7 | Santhanagopalan S, Zhang Q, Kumaresan K, et al. Parameter estimation and life modeling of lithium-ion cells [J]. Journal of the Electrochemical Society, 2008, 155(4): A345. |

| 8 | Arora S, Kapoor A, Shen W X. A novel thermal management system for improving discharge/charge performance of Li-ion battery packs under abuse [J]. Journal of Power Sources, 2018, 378: 759-775. |

| 9 | Doucette R T, McCulloch M D. Modeling the prospects of plug-in hybrid electric vehicles to reduce CO2 emissions [J]. Applied Energy, 2011, 88(7): 2315-2323. |

| 10 | Wang H, Liu Y, Fu H, et al. Estimation of state of charge of batteries for electric vehicles [J]. International Journal of Control and Automation, 2013, 6(2): 185-194. |

| 11 | Kim D W, Lee M Y. Theoretical approach on the heating and cooling system design for an effective operation of Li-ion batteries for electric vehicles [J]. Journal of the Korea Academia-Industrial Cooperation Society, 2014, 15(5): 2545-2552. |

| 12 | Lee H S, Won J P, Lim T K, et al. Experimental study on performance characteristics of the triple fluids heat exchanger with two kinds of coolants in electric-driven air conditioning system for fuel cell electric vehicles [J]. Energy Procedia, 2017, 113: 209-216. |

| 13 | Alaoui C. Solid-state thermal management for lithium-ion EV batteries [J]. IEEE Transactions on Vehicular Technology, 2013, 62(1): 98-107. |

| 14 | Wang Q, Jiang B, Li B, et al. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles [J]. Renewable and Sustainable Energy Reviews, 2016, 64: 106-128. |

| 15 | Choi K W, Yao N P. Heat transfer in lead-acid batteries designed for electric-vehicle propulsion application [J]. Journal of the Electrochemical Society, 1979, 126(8): 1321-1328. |

| 16 | Kim G H, Pesaran A. Battery thermal management design modeling [J]. World Electric Vehicle Journal, 2007, 1(1): 126-133. |

| 17 | 黄蔚. 电动汽车电池冷却器仿真研究[D]. 贵阳: 贵州大学, 2019. |

| Huang W. Simulations of chiller for electric vehicles [D]. Guiyang: Guizhou University, 2019. | |

| 18 | Pesaran A A. Battery thermal models for hybrid vehicle simulations [J]. Journal of Power Sources, 2002, 110(2): 377-382. |

| 19 | Rao Z H, Wang S F. A review of power battery thermal energy management [J]. Renewable and Sustainable Energy Reviews, 2011, 15(9): 4554-4571. |

| 20 | Bandhauer T M, Garimella S, Fuller T F. A critical review of thermal issues in lithium-ion batteries [J]. Journal of the Electrochemical Society, 2011, 158(3): R1. |

| 21 | Drummond K P, Back D, Sinanis M D, et al. A hierarchical manifold microchannel heat sink array for high-heat-flux two-phase cooling of electronics [J]. International Journal of Heat and Mass Transfer, 2018, 117: 319-330. |

| 22 | 张荣荣, 张根祥, Stanke Edwin, 等. 电子膨胀阀在电动汽车空调和电池冷却系统中的应用[J]. 制冷与空调, 2018, 18(5): 77-80, 85. |

| Zhang R R, Zhang G X, Stanke E, et al. Electronic expansion valve in the application of the electric car air conditioning cooling system and battery [J]. Refrigeration and Air-Conditioning, 2018, 18(5): 77-80, 85. | |

| 23 | 张春秋, 罗玉林. 电动汽车电池冷却系统对空调系统性能的影响[J]. 制冷与空调, 2020, 20(2): 49-52, 72. |

| Zhang C Q, Luo Y L. Effect of battery cooling system on performance of air-conditioning system for electric vehicle [J]. Refrigeration and Air-Conditioning, 2020, 20(2): 49-52, 72. | |

| 24 | Longo G A. The effect of vapour super-heating on hydrocarbon refrigerant condensation inside a brazed plate heat exchanger [J]. Experimental Thermal and Fluid Science, 2011, 35(6): 978-985. |

| 25 | Mancin S, de del Col D, Rossetto L. R32 partial condensation inside a brazed plate heat exchanger [J]. International Journal of Refrigeration, 2013, 36(2): 601-611. |

| 26 | Sarraf K, Launay S, Tadrist L. Analysis of enhanced vapor desuperheating during condensation inside a plate heat exchanger [J]. International Journal of Thermal Sciences, 2016, 105: 96-108. |

| 27 | Longo G A, Mancin S, Righetti G, et al. HFC404A condensation inside a small brazed plate heat exchanger: comparison with the low GWP substitutes propane and propylene [J]. International Journal of Refrigeration, 2017, 81: 41-49. |

| 28 | 吴学红, 李灿, 龚毅, 等. 板式换热器相变流动的传热及压降特性[J]. 化工学报, 2017, 68(S1): 133-140. |

| Wu X H, Li C, Gong Y, et al. Heat transfer and pressure drop characteristic of phase change flow in plate heat exchanger [J]. CIESC Journal, 2017, 68(S1): 133-140. | |

| 29 | 李明春, 肖刚, 史和春, 等. 人字形波纹板相变流动及换热特性研究[J]. 工程热物理学报, 2016, 37(3): 581-585. |

| Li M C, Xiao G, Shi H C, et al. Study on phase change flow and heat transfer characteristics of chevron corrugated plate [J]. Journal of Engineering Thermophysics, 2016, 37(3): 581-585. | |

| 30 | Ian H. Bell and the CoolProp Team. CoolProp 6.1.0 documentation [EB/OL]. [2020-05-06]. . |

| 31 | Clifford A A. Multivariate error analysis: a handbook of error propagation and calculation in many-parameter system [EB/OL]. 1973. |

| [1] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [2] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [3] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [4] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [5] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [6] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [7] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [8] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [9] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [10] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [11] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [12] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [13] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [14] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [15] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号