化工学报 ›› 2022, Vol. 73 ›› Issue (6): 2708-2721.DOI: 10.11949/0438-1157.20220399

收稿日期:2022-03-22

修回日期:2022-05-11

出版日期:2022-06-05

发布日期:2022-06-30

作者简介:石孝刚(1987—)男,博士,副教授,基金资助:

Xiaogang SHI( ),Chengxiu WANG,Jinsen GAO,Xingying LAN(

),Chengxiu WANG,Jinsen GAO,Xingying LAN( )

)

Received:2022-03-22

Revised:2022-05-11

Online:2022-06-05

Published:2022-06-30

摘要:

提升管反应器存在典型的颗粒聚团介尺度结构,其分布特性对气固流动、反应有重要影响,对介尺度结构影响规律进行分析有助于为反应器的设计与优化操作提供基础信息。采用基于能量最小多尺度(EMMS)方法的曳力模型建立了提升管气固两相流动模型,考虑了颗粒聚团对气固相间动量传递的影响。此外,进一步通过考虑颗粒聚团的存在以及颗粒聚团的非均匀性对化学反应的影响,提出了描述介尺度结构对反应速率影响的修正因子,与气固流动模型进行耦合,建立了基于介尺度结构的流动-反应综合数学模型,并进行了模型验证。进一步应用该模型,对工业催化裂化提升管反应器的流动-反应特性进行了模拟分析。结果表明,该模型可以合理描述提升管气固相互作用,能够预测出壁面附近存在较多介尺度结构的分布特性,由于聚团的存在使得重油组分难以与催化剂充分接触,生成汽柴油的反应速率较低,转化较慢,聚团的分布特性导致靠近边壁处的重油组分浓度较高,汽柴油组分浓度较低;汽柴油在聚团内部的流动阻力较大,在聚团内发生过量的二次反应生成较多焦炭,导致壁面处焦炭浓度较高。与传统基于平均化而未考虑聚团影响的模型相比,基于介尺度结构的模型所预测的汽油收率最佳值与工业实际相接近。因此,基于介尺度结构的流动-反应综合数学模型可以合理描述提升管内进行的流动-反应耦合特性,并能揭示介尺度结构对催化裂化反应过程的影响,有望为工业提升管装置反应终止剂技术的开发提供重要的基础信息。

中图分类号:

石孝刚, 王成秀, 高金森, 蓝兴英. 提升管反应器介尺度结构影响规律的数值模拟研究[J]. 化工学报, 2022, 73(6): 2708-2721.

Xiaogang SHI, Chengxiu WANG, Jinsen GAO, Xingying LAN. Numerical simulation study on influence of mesoscale structure in riser reactor[J]. CIESC Journal, 2022, 73(6): 2708-2721.

| 项 目 | 方程表达式 |

|---|---|

| 曳力模型系数β | |

| 曳力系数修正因子 | |

| εg>0.997 | |

| 0.997>εg>0.99 | |

| 0.99>εg>0.545 | |

| 0.545>εg>0.4 |

表1 EMMS曳力模型表达式

Table 1 EMMS model equations

| 项 目 | 方程表达式 |

|---|---|

| 曳力模型系数β | |

| 曳力系数修正因子 | |

| εg>0.997 | |

| 0.997>εg>0.99 | |

| 0.99>εg>0.545 | |

| 0.545>εg>0.4 |

| 空隙率 | 气速/(m/s) | 短轴 | 长短轴比 | 倾角/(°) | ||

|---|---|---|---|---|---|---|

| 一次反应Hc,1 | 二次反应Hc,2 | |||||

| 0.83 | 0.1 | 0.67 | 1 | 0 | 0.1560 | 0.8900 |

| 0.83 | 0.5 | 0.67 | 1 | 0 | 0.1930 | 0.9589 |

| 0.83 | 1 | 0.67 | 1 | 0 | 0.2107 | 0.9937 |

| 0.83 | 1.5 | 0.67 | 1 | 0 | 0.2228 | 1.0165 |

| 0.83 | 2 | 0.67 | 1 | 0 | 0.2325 | 1.0339 |

| 0.83 | 2.5 | 0.67 | 1 | 0 | 0.2409 | 1.0484 |

| 0.83 | 3 | 0.67 | 1 | 0 | 0.2485 | 1.0609 |

| 0.90 | 5 | 0.5 | 1 | 0 | 0.4511 | 1.1105 |

| 0.90 | 7.5 | 0.5 | 1 | 0 | 0.5242 | 1.1119 |

| 0.90 | 10 | 0.5 | 1 | 0 | 0.5828 | 1.1073 |

| 0.96 | 0.5 | 0.5 | 1 | 0 | 0.5638 | 1.0498 |

| 0.96 | 1 | 0.5 | 1 | 0 | 0.6299 | 1.0522 |

| … | … | … | … | … | … | … |

表2 颗粒聚团上的平均反应速率和单颗粒上的反应速率的比值

Table 2 Ratio of reaction rate on cluster to that on single particle

| 空隙率 | 气速/(m/s) | 短轴 | 长短轴比 | 倾角/(°) | ||

|---|---|---|---|---|---|---|

| 一次反应Hc,1 | 二次反应Hc,2 | |||||

| 0.83 | 0.1 | 0.67 | 1 | 0 | 0.1560 | 0.8900 |

| 0.83 | 0.5 | 0.67 | 1 | 0 | 0.1930 | 0.9589 |

| 0.83 | 1 | 0.67 | 1 | 0 | 0.2107 | 0.9937 |

| 0.83 | 1.5 | 0.67 | 1 | 0 | 0.2228 | 1.0165 |

| 0.83 | 2 | 0.67 | 1 | 0 | 0.2325 | 1.0339 |

| 0.83 | 2.5 | 0.67 | 1 | 0 | 0.2409 | 1.0484 |

| 0.83 | 3 | 0.67 | 1 | 0 | 0.2485 | 1.0609 |

| 0.90 | 5 | 0.5 | 1 | 0 | 0.4511 | 1.1105 |

| 0.90 | 7.5 | 0.5 | 1 | 0 | 0.5242 | 1.1119 |

| 0.90 | 10 | 0.5 | 1 | 0 | 0.5828 | 1.1073 |

| 0.96 | 0.5 | 0.5 | 1 | 0 | 0.5638 | 1.0498 |

| 0.96 | 1 | 0.5 | 1 | 0 | 0.6299 | 1.0522 |

| … | … | … | … | … | … | … |

| Hr表达式 | εg范围 |

|---|---|

| [0.4,0.4162] | |

| [0.4162,0.4257] | |

| [0.4257,0.5457] | |

| [0.5457,1.0] |

表3 非均匀的颗粒聚团对化学反应速率的影响因子表达式[19]

Table 3 Correlation for influence factor of heterogeneous cluster on reaction rate[19]

| Hr表达式 | εg范围 |

|---|---|

| [0.4,0.4162] | |

| [0.4162,0.4257] | |

| [0.4257,0.5457] | |

| [0.5457,1.0] |

| 参数 | 数 值 |

|---|---|

| 提升管直径D/m | 0.076 |

| 提升管高度h/m | 10 |

| 颗粒粒径dp/μm | 76 |

| 颗粒密度ρp/(kg/m3) | 1780 |

| 气体密度ρg/(kg/m3) | 1.1795 |

表4 模拟对象尺寸和物性

Table 4 Size of simulation set-up and properties of materials

| 参数 | 数 值 |

|---|---|

| 提升管直径D/m | 0.076 |

| 提升管高度h/m | 10 |

| 颗粒粒径dp/μm | 76 |

| 颗粒密度ρp/(kg/m3) | 1780 |

| 气体密度ρg/(kg/m3) | 1.1795 |

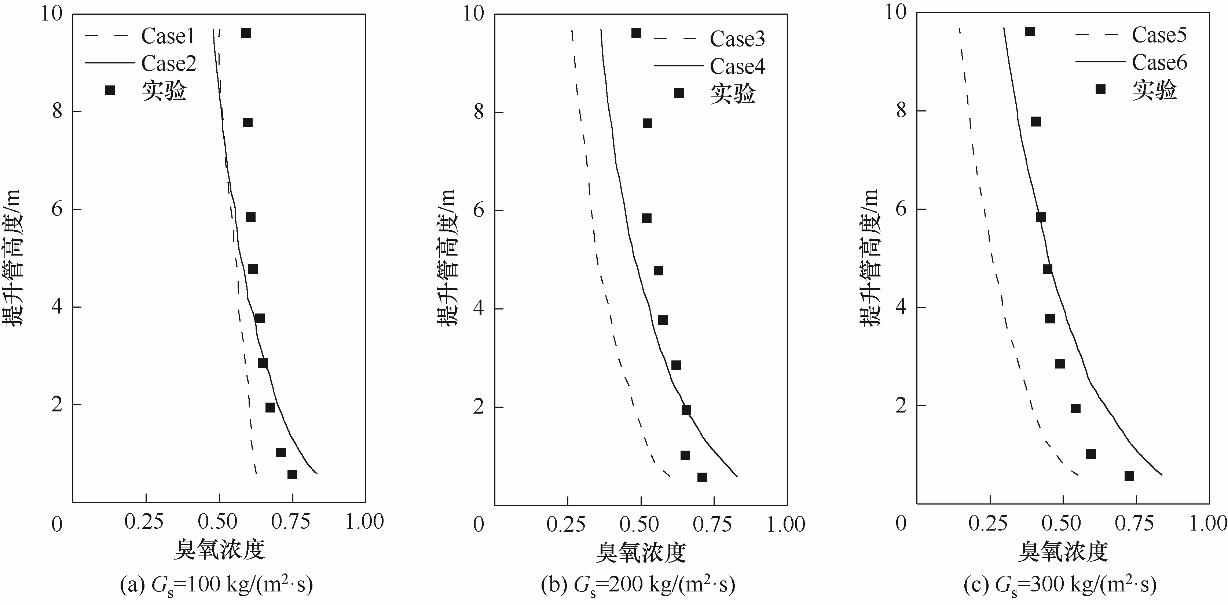

图2 提升管内臭氧浓度的轴向分布(Ug=9 m/s,虚线代表基于平均化的模型,实线代表基于介尺度结构的模型)

Fig.2 Axial distribution of ozone concentration in riser (Ug=9 m/s, dash line is for homogeneous model while solid line for mesoscale model)

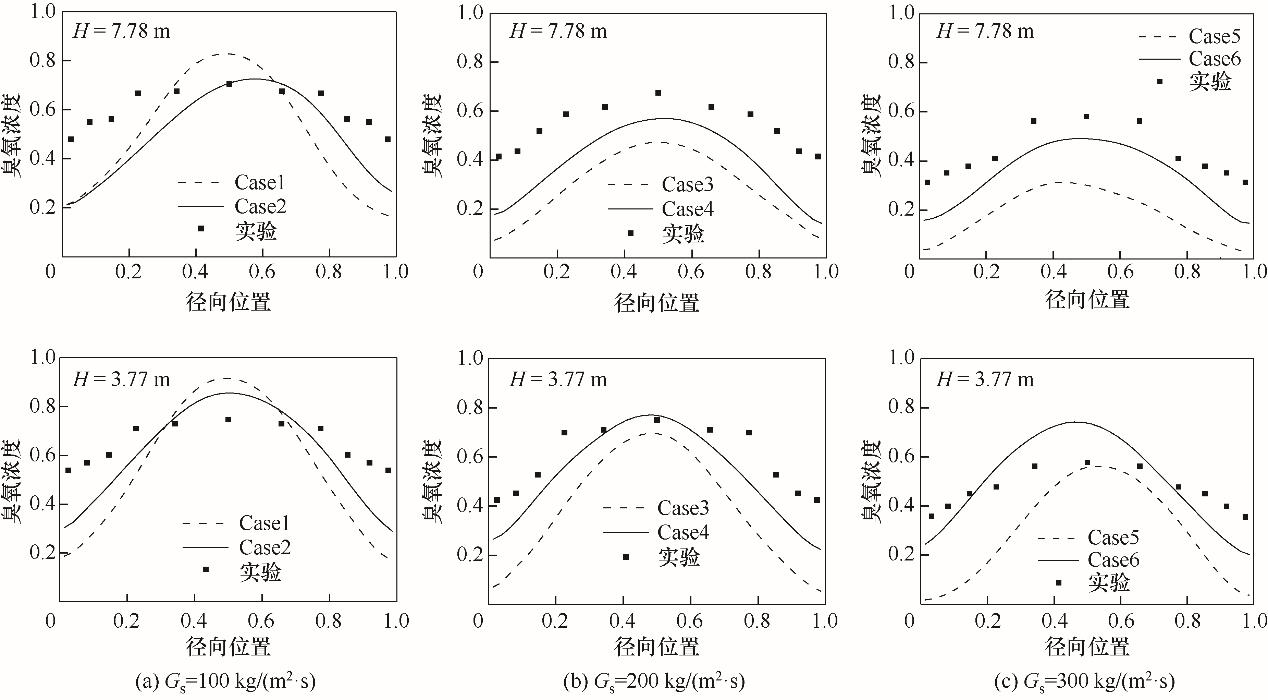

图3 提升管内臭氧浓度的径向分布(Ug=9 m/s,虚线代表基于平均化的模型,实线代表基于介尺度结构的模型)

Fig.3 Radial distribution of ozone concentration in riser(Ug=9 m/s, dash line is for homogeneous model while solid line for mesoscale model)

| 参 数 | 数值 |

|---|---|

| 原料油质量流率/(t/h) | 152 |

| 雾化蒸汽质量流率/(t/h) | 9.6 |

| 预提升蒸汽质量流率/(kg/h) | 4070 |

| 催化剂循环量/(t/h) | 1156 |

| 剂油比 | 7 |

| 物料混合温度/℃ | 550 |

表5 工业提升管反应器工艺参数

Table 5 Simulation parameter for industrial FCC riser

| 参 数 | 数值 |

|---|---|

| 原料油质量流率/(t/h) | 152 |

| 雾化蒸汽质量流率/(t/h) | 9.6 |

| 预提升蒸汽质量流率/(kg/h) | 4070 |

| 催化剂循环量/(t/h) | 1156 |

| 剂油比 | 7 |

| 物料混合温度/℃ | 550 |

图14 提升管高度方向上各产物产率变化(实线为基于介尺度结构的模型,虚线为基于平均化的模型)

Fig.14 Yield of different components along riser height (solid line for mesoscale model, and dash line for homogeneous model)

| 1 | 王成秀, 裴华健, 苏鑫, 等. 密相提升管内颗粒速度与颗粒浓度分布及发展特性[J]. 化学反应工程与工艺, 2020, 36(1): 8-16. |

| Wang C X, Pei H J, Su X, et al. Particle velocity and solids holdup characteristics and the flow development in a high density circulating fluidized bed riser[J]. Chemical Reaction Engineering and Technology, 2020, 36(1): 8-16. | |

| 2 | Zhang H, Huang W X, Zhu J X. Gas-solids flow behavior: CFB riser vs. downer[J]. AIChE Journal, 2001, 47(9): 2000-2011. |

| 3 | Manyele S V, Pärssinen J H, Zhu J X. Characterizing particle aggregates in a high-density and high-flux CFB riser[J]. Chemical Engineering Journal, 2002, 88(1/2/3): 151-161. |

| 4 | Wang J W, Ge W, Li J H. Eulerian simulation of heterogeneous gas-solid flows in CFB risers: EMMS-based sub-grid scale model with a revised cluster description[J]. Chemical Engineering Science, 2008, 63(6): 1553-1571. |

| 5 | Rossbach V, Padoin N, Meier H F, et al. Influence of ultrasonic waves on the gas-solid flow and the solids dispersion in a CFB riser: numerical and experimental study[J]. Powder Technology, 2021, 389: 430-449. |

| 6 | Jiradilok V, Gidaspow D, Damronglerd S, et al. Kinetic theory based CFD simulation of turbulent fluidization of FCC particles in a riser[J]. Chemical Engineering Science, 2006, 61(17): 5544-5559. |

| 7 | Yin L J, Wang S Y, Lu H L, et al. Simulation of effect of catalyst particle cluster on dry methane reforming in circulating fluidized beds[J]. Chemical Engineering Journal, 2007, 131(1/2/3): 123-134. |

| 8 | Wang S Y, Yin L J, Lu H L, et al. Simulation of effect of catalytic particle clustering on methane steam reforming in a circulating fluidized bed reformer[J]. Chemical Engineering Journal, 2008, 139(1): 136-146. |

| 9 | 吕林英, 蓝兴英, 吴迎亚, 等. FCC提升管反应器中颗粒聚团对裂化反应的影响[J]. 化工学报, 2015, 66(8): 2920-2928. |

| Lyu L Y, Lan X Y, Wu Y Y, et al. Effect of particles cluster on behavior of catalytic cracking reaction in FCC riser[J]. CIESC Journal, 2015, 66(8): 2920-2928. | |

| 10 | Li J H, Huang W L, Chen J H. Possible roadmap to advancing the knowledge system and tackling challenges from complexity[J]. Chemical Engineering Science, 2021, 237: 116548. |

| 11 | Shi Z S, Wang W, Li J H. A bubble-based EMMS model for gas-solid bubbling fluidization[J]. Chemical Engineering Science, 2011, 66(22): 5541-5555. |

| 12 | Guo L, Wu J, Li J H. Complexity at mesoscales: a common challenge in developing artificial intelligence[J]. Engineering, 2019, 5(5): 241-253. |

| 13 | Cloete S, Amini S, Johansen S T. On the effect of cluster resolution in riser flows on momentum and reaction kinetic interaction[J]. Powder Technology, 2011, 210(1): 6-17. |

| 14 | Chalermsinsuwan B, Piumsomboon P, Gidaspow D. Kinetic theory based computation of PSRI riser(Ⅰ): Estimate of mass transfer coefficient[J]. Chemical Engineering Science, 2009, 64(6): 1195-1211. |

| 15 | Chalermsinsuwan B, Piumsomboon P, Gidaspow D. Kinetic theory based computation of PSRI riser(Ⅱ): Computation of mass transfer coefficient with chemical reaction[J]. Chemical Engineering Science, 2009, 64(6): 1212-1222. |

| 16 | Holloway W, Sundaresan S. Filtered models for reacting gas-particle flows[J]. Chemical Engineering Science, 2012, 82: 132-143. |

| 17 | Dong W G, Wang W, Li J H. A multiscale mass transfer model for gas-solid riser flows(Ⅰ):Sub-grid model and simple tests[J]. Chemical Engineering Science, 2008, 63(10): 2798-2810. |

| 18 | Hong K, Shi Z S, Wang W, et al. A structure-dependent multi-fluid model (SFM) for heterogeneous gas-solid flow[J]. Chemical Engineering Science, 2013, 99: 191-202. |

| 19 | Liu C F, Wang W, Zhang N, et al. Structure-dependent multi-fluid model for mass transfer and reactions in gas-solid fluidized beds[J]. Chemical Engineering Science, 2015, 122: 114-129. |

| 20 | Huang Z Q, Wang L X, Zhou Q. Development of a filtered reaction rate model for reactive gas-solid flows based on fine-grid simulations[J]. AIChE Journal, 2021, 67(5): e17185. |

| 21 | Zou Z, Yan D, Zhu J Y, et al. Simulation of the fluid–solid noncatalytic reaction based on the structure-based mass-transfer model: shrinking core reaction[J]. Industrial & Engineering Chemistry Research, 2020, 59(40): 17729-17739. |

| 22 | Wu Y Y, Peng L, Qin L Q, et al. Validation and application of CPFD models in simulating hydrodynamics and reactions in riser reactor with Geldart A particles[J]. Powder Technology, 2018, 323: 269-283. |

| 23 | Wu Y Y, Shi X G, Wang C X, et al. CPFD simulation of hydrodynamics, heat transfer, and reactions in a downer reactor for coal pyrolysis with binary particles[J]. Energy & Fuels, 2019, 33(12): 12295-12307. |

| 24 | Wang M, Lan X Y, Wang C X, et al. Numerical simulation of the pilot-scale high-density circulating fluidized bed riser[J]. Industrial & Engineering Chemistry Research, 2021, 60(7): 3184-3197. |

| 25 | Shi X G, Wu Y Y, Wang M, et al. Physicochemical processes occurring inside clusters consisting of FCC catalyst particles[J]. Chemical Engineering & Technology, 2017, 40(5): 847-853. |

| 26 | Wang C. High density gas-solids circulating fluidized bed riser and downer reactors[D]. Ontario :The University of Western Ontario, 2013. |

| 27 | Gidaspow D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions[M]. USA: Academic Press, 1994. |

| 28 | Lan X Y, Xu C M, Wang G, et al. CFD modeling of gas-solid flow and cracking reaction in two-stage riser FCC reactors[J]. Chemical Engineering Science, 2009, 64(17): 3847-3858. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [9] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [10] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [11] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [12] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [13] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [14] | 于源, 陈薇薇, 付俊杰, 刘家祥, 焦志伟. 几何相似涡流空气分级机环形区流场变化规律研究及预测[J]. 化工学报, 2023, 74(6): 2363-2373. |

| [15] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号