化工学报 ›› 2023, Vol. 74 ›› Issue (7): 2800-2813.DOI: 10.11949/0438-1157.20230380

收稿日期:2023-04-17

修回日期:2023-06-02

出版日期:2023-07-05

发布日期:2023-08-31

通讯作者:

左然

作者简介:何晓崐(1987—),男,硕士,讲师,kenhe25@163.com

基金资助:

Xiaokun HE1( ), Rui LIU1, Yuan XUE2, Ran ZUO3(

), Rui LIU1, Yuan XUE2, Ran ZUO3( )

)

Received:2023-04-17

Revised:2023-06-02

Online:2023-07-05

Published:2023-08-31

Contact:

Ran ZUO

摘要:

作为第三代半导体材料的代表,AlN单晶具有禁带宽度大、击穿电场强度高、电子饱和迁移率高等特点,被广泛应用于紫外和深紫外发光器件的制造。金属有机化学气相沉积(MOCVD)是生长AlN单晶薄膜最主要的技术。由于Al—N键在三种Ⅲ族氮化物(AlN、GaN和InN)中最强,导致MOCVD生长AlN过程的气相寄生反应最为严重,进而造成AlN的生长速率和效率过低、生长窗口过窄等问题。此外,较高的Al—N键能还导致含Al粒子在表面的迁移率过低,致使薄膜表面形貌变差。这些问题都与薄膜生长过程发生的化学反应密切相关。分别从气相反应路径和表面反应机理两方面,较全面地总结了前人针对MOCVD生长AlN薄膜机理开展的研究工作,并介绍了本课题组近年来在该方向取得的研究成果。最后归纳了现阶段MOCVD生长AlN研究中存在的问题与不足,并在此基础上进行了展望。

中图分类号:

何晓崐, 刘锐, 薛园, 左然. MOCVD生长AlN单晶薄膜的气相和表面化学反应综述[J]. 化工学报, 2023, 74(7): 2800-2813.

Xiaokun HE, Rui LIU, Yuan XUE, Ran ZUO. Review of gas phase and surface reactions in AlN MOCVD[J]. CIESC Journal, 2023, 74(7): 2800-2813.

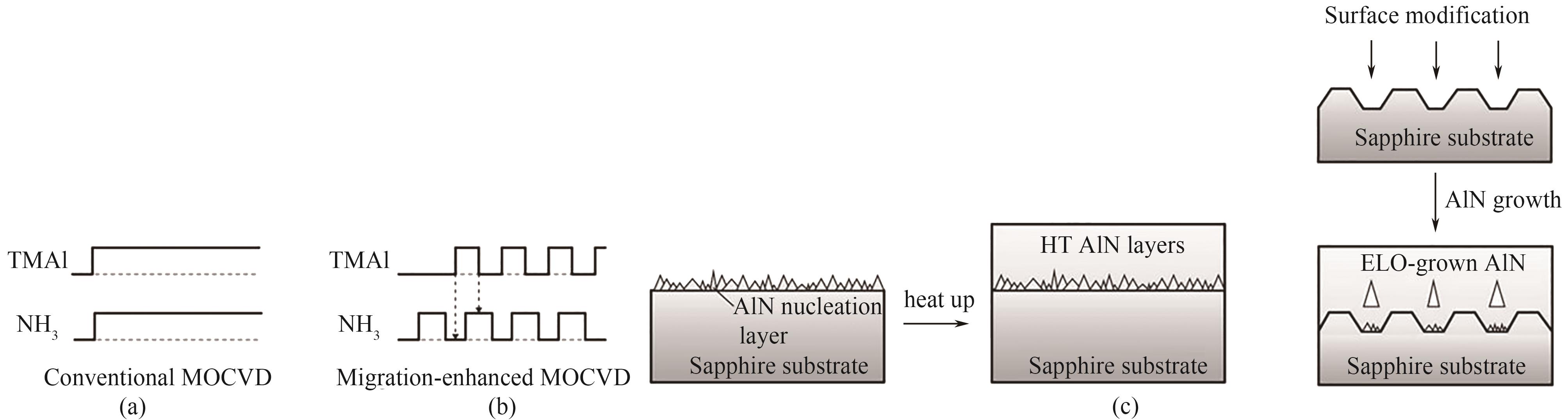

图2 (a) 传统的MOCVD方法;(b) MEMOCVD方法:在传统低温形核层上生长高温AlN,TMAl和NH3交替供应,以增强表面迁移率;(c)侧向外延方法:晶体从未修饰的蓝宝石坑槽向上生长,然后横向生长,覆盖修饰区域,横向生长抑制了位错的蔓延[24]

Fig.2 (a) Conventional MOCVD; (b) Process of MEMOCVD: High-temperature AlN layer is grown on the low-temperature AlN nucleation layer with an alternative supply of TMAl and NH3 for alleviating the low surface mobility of Al atoms; (c) Process of nano-scale lateral overgrowth: Crystals grow upward from unmodified sapphire pit grooves and then laterally, covering the modified region and the spread of dislocations is suppressed[24]

| 方法 | 优点 | 缺点 | 文献 |

|---|---|---|---|

| 实验测量 | 可获知气相物质种类和浓度;获得生长速率及其与压力、温度、反应器结构等之间的关系 | 价格昂贵,无法针对各种不同的实验条件分别进行观测,无法直接观测到化学反应中间过程以及反应过渡态 | [ |

| CFD仿真 | 结合反应动力学,可模拟不同反应器内、不同操作条件下的生长过程,获得生长速率与温度、压力之间的关系;可直观显示不同反应物质的浓度分布 | 反应动力学数据,如速率常数、指前因子、气相物质的物化性质等需通过实验测量或量化计算获得;需要将真实环境进行适当简化 | [ |

| 量化计算 | 可以在分子水平上预测化学反应,获得分子构型和能量,确定反应势能面和过渡态,判断反应发生的概率,获得反应动力学数据,如活化能、指前因子等 | 无法获知反应器各部位的温度和压强,因此无法预测实际生长中反应是否发生和反应速率大小,无法建立反应速率与温度、压强、浓度的关系 | [ |

表1 AlN-MOCVD气相反应机理的研究方法

Table 1 Methods for studying the gas phase reaction mechanism of AlN-MOCVD

| 方法 | 优点 | 缺点 | 文献 |

|---|---|---|---|

| 实验测量 | 可获知气相物质种类和浓度;获得生长速率及其与压力、温度、反应器结构等之间的关系 | 价格昂贵,无法针对各种不同的实验条件分别进行观测,无法直接观测到化学反应中间过程以及反应过渡态 | [ |

| CFD仿真 | 结合反应动力学,可模拟不同反应器内、不同操作条件下的生长过程,获得生长速率与温度、压力之间的关系;可直观显示不同反应物质的浓度分布 | 反应动力学数据,如速率常数、指前因子、气相物质的物化性质等需通过实验测量或量化计算获得;需要将真实环境进行适当简化 | [ |

| 量化计算 | 可以在分子水平上预测化学反应,获得分子构型和能量,确定反应势能面和过渡态,判断反应发生的概率,获得反应动力学数据,如活化能、指前因子等 | 无法获知反应器各部位的温度和压强,因此无法预测实际生长中反应是否发生和反应速率大小,无法建立反应速率与温度、压强、浓度的关系 | [ |

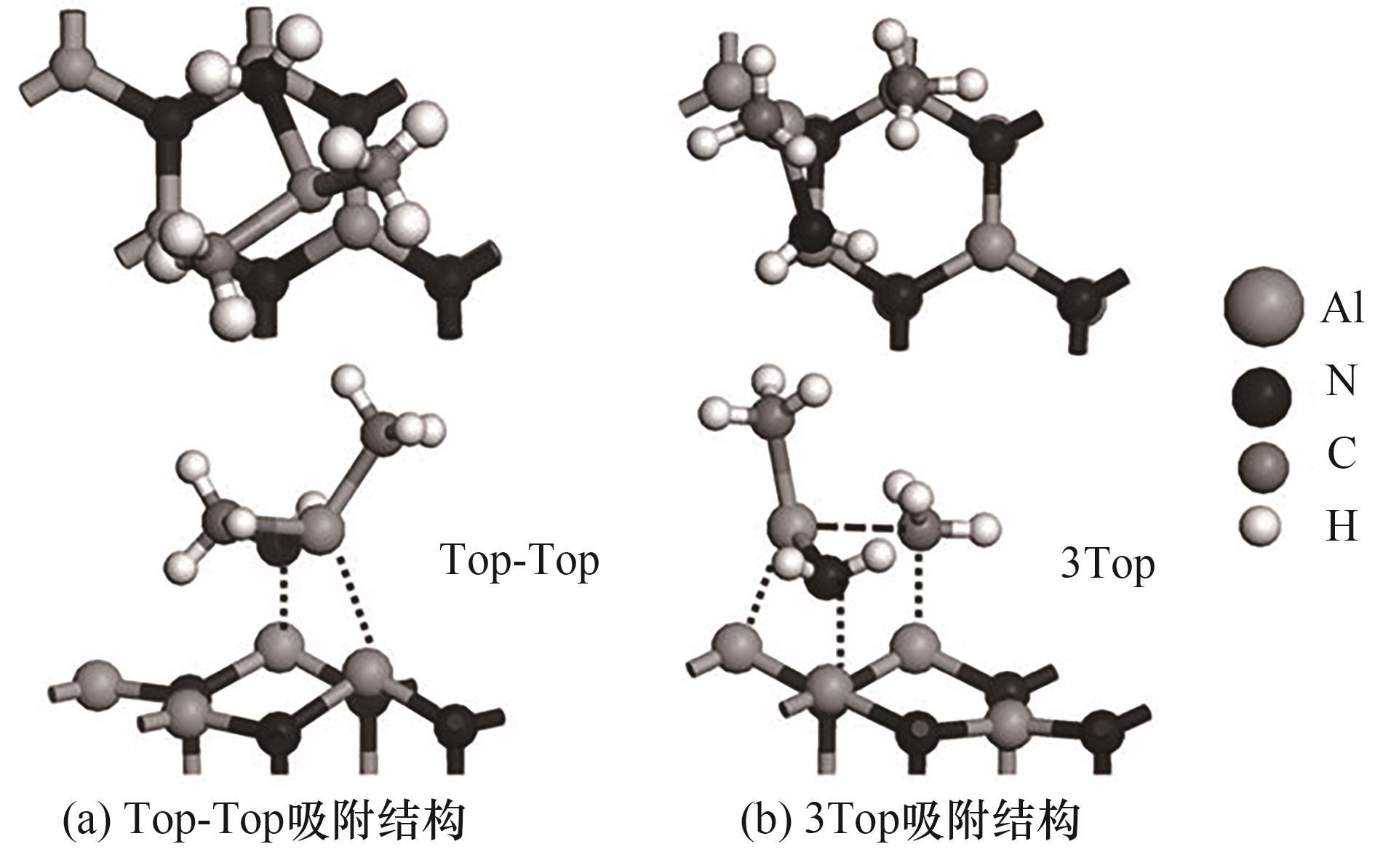

图9 DMAlNH2在理想AlN(0001)-Al面上的吸附(虚线表示与表面原子之间成键;短划线表示吸附质分子内可能断裂的键)[83]

Fig.9 Adsorption structures of DMAlNH2 on the ideal AlN(0001)-Al terminated surface (the dotted line indicates the bond with surface atom, the dashed line indicates the possible broken bond in the adsorbate)[83]

| 1 | 郝跃, 薛军帅, 张进成. Ⅲ族氮化物InAlN半导体异质结研究进展[J]. 中国科学: 信息科学, 2012, 42(12): 1577-1587. |

| Hao Y, Xue J S, Zhang J C. Research progress in the group-Ⅲ nitride InAlN semiconductor heterostructures[J]. SCIENTIA SINICA Informationis, 2012, 42(12): 1577-1587. | |

| 2 | 郑有炓. 第三代半导体材料与器件进展[M]. 南京: 南京大学出版社, 2015. |

| Zheng Y L. Research Progress of the Third Generation Semiconductor Materials and Devices[M]. Nanjing: Nanjing University Press, 2015. | |

| 3 | Hirayama H. Recent progresses of AlGaN and InAlGaN-based deep-UV LEDs [C]// 2009 Conference on Lasers and Electro-Optics and 2009 Conference on Quantum electronics and Laser Science Conference. Baltimore, MD, USA, 2009. |

| 4 | Watson I M. Metal organic vapour phase epitaxy of AlN, GaN, InN and their alloys: a key chemical technology for advanced device applications[J]. Coordination Chemistry Reviews, 2013, 257(13/14): 2120-2141. |

| 5 | Keller S, Baars S P D. Metalorganic chemical vapor deposition of group Ⅲ nitrides—a discussion of critical issues[J]. Journal of Crystal Growth, 2003, 248: 479-486. |

| 6 | Dauelsberg M, Talalaev R. Progress in modeling of Ⅲ-nitride MOVPE[J]. Progress in Crystal Growth and Characterization of Materials, 2020, 66(3): 100486. |

| 7 | Wu H L, Zhang K, He C G, et al. Recent advances in fabricating wurtzite AlN film on (0001)-plane sapphire substrate[J]. Crystals, 2022, 12(1): 38. |

| 8 | 李路, 徐俞, 曹冰, 等. AlGaN基深紫外LED的外延生长及光电性能研究[J]. 人工晶体学报, 2022, 51(7): 1158-1162. |

| Li L, Xu Y, Cao B, et al. Epitaxial growth and optoelectronic properties of AlGaN-based deep-ultraviolet LED[J]. Journal of Synthetic Crystals, 2022, 51(7): 1158-1162. | |

| 9 | Bardhan A, Raghavan S. Growth design for high quality Al x Ga(1- x)N layer with high AlN-fraction on Si(111) substrate by MOCVD[J]. Journal of Crystal Growth, 2022, 578: 126418. |

| 10 | Zhang Y H, Yang J, Zhao D G, et al. High-quality AlN growth on flat sapphire at relatively low temperature by crystal island shape control method[J]. Applied Surface Science, 2022, 606: 154919. |

| 11 | M A A Z Md Sahar, Hassan Z, Ng S S, et al. An insight into growth transition in AlN epitaxial films produced by metal-organic chemical vapour deposition at different growth temperatures[J]. Supperlattices and Microstructures, 2022, 161: 107095. |

| 12 | Chen Y X, Ben J W, Xu F J, et al. Review on the progress of AlGaN-based ultraviolet light-emitting diodes[J]. Fundamental Research, 2021, 1(6): 717-734. |

| 13 | Chen K, Zhang Y C, Zhang J C, et al. Ultrathin GaN film and AlGaN/GaN heterostructure grown on thick AlN buffer by MOCVD[J]. Ceramics International, 2022, 48(24): 36193-36200. |

| 14 | Li Y F, Hu X T, Song Y M, et al. The role of AlN thickness in MOCVD growth of N-polar GaN[J]. Journal of Alloys and Compounds, 2021, 884: 161134. |

| 15 | Yang Q K, Li Z H, Peng D Q, et al. Growth of high quality GaN on (0001) 4H-SiC with an ultrathin AlN nucleation layer[J]. Journal of Crystal Growth, 2023, 607: 127107. |

| 16 | Ramesh R, Arivazhagan P, Prabakaran K, et al. Influence of AlN interlayer on AlGaN/GaN heterostructures grown by metal organic chemical vapour deposition[J]. Materials Chemistry and Physics, 2021, 259: 124003. |

| 17 | Lange A P, Mahajan S. Influence of trimethylaluminum predoses on the growth morphology, film-substrate interface, and microstructure of MOCVD-grown AlN on (111) Si[J]. Journal of Crystal Growth, 2019, 511: 106-117. |

| 18 | Kakanakova-Georgieva A, Ciechonski R R, Forsberg U, et al. Hot-wall MOCVD for highly efficient and uniform growth of AlN[J]. Crystal Growth & Design, 2009, 9(2): 880-884. |

| 19 | Brunner F, Protzmann H, Heuken M, et al. High-temperature growth of AlN in a production scale 11×2′ MOVPE reactor[J]. 2008, 5(6): 1799-1801. |

| 20 | Ding K, Avrutin V, Özgür Ü, et al. Status of growth of group Ⅲ-nitride heterostructures for deep ultraviolet light-emitting diodes[J]. Crystals, 2017, 7(10): 300. |

| 21 | Nagamatsu K, Miyagawa T, Tomita A, et al. High growth temperature for AlN by jet stream gas flow metalorganic vapor phase epitaxy[J]. Scientific Reports, 2023, 13: 2438. |

| 22 | Demir I, Li H, Robin Y, et al. Sandwich method to grow high quality AlN by MOCVD[J]. Journal of Physics D: Applied Physics, 2018, 51: 085104. |

| 23 | Hirayama H, Maeda N, Fujikawa S, et al. Recent progress and future prospects of AlGaN based high-efficiency deep-ultraviolet light-emitting diodes[J]. Japanese Journal of Applied Physics, 2014, 53: 100209. |

| 24 | Park J S, Kim J K, Cho J, et al. Review—group Ⅲ-nitride-based ultraviolet light-emitting diodes: ways of increasing external quantum efficiency[J]. ECS Journal of Solid State Science and Technology, 2017, 6(4): Q42-Q52. |

| 25 | Jacko M G, Price S J. The pyrolysis of trimethylgallium[J]. Canadian Journal of Chemistry, 1963, 41(6): 1560-1567. |

| 26 | Jacko M G, Price S J. The pyrolysis of trimethylindium[J]. Canadian Journal of Chemistry, 1964, 42(5): 1198-1205. |

| 27 | Suzuki N, Anayama C, Masu K, et al. Pyrolysis and photolysis of trimethylaluminum[J]. Japanese Journal of Applied Physics, 1986, 25(8R): 1236-1242. |

| 28 | Zhang Z, Pan Y, Yang J Z, et al. Experimental study of trimethyl aluminum decomposition[J]. Journal of Crystal Growth, 2017, 473: 6-10. |

| 29 | Mihopoulos T G. Reaction and transport processes in OMCVD : selective and group Ⅲ-nitride growth[D]. Massachusettes, Boston: Massachusettes Institute of Techonology, 1999. |

| 30 | Uchida T, Kusakabe K, Ohkawa K. Influence of polymer formation on metalorganic vapor-phase epitaxial growth of AlN[J]. Journal of Crystal Growth, 2007, 304(1): 133-140. |

| 31 | Creighton J R, Wang G T, Breiland W G, et al. Nature of the parasitic chemistry during AlGaInN OMVPE[J]. Journal of Crystal Growth, 2004, 261: 204-213. |

| 32 | Ohkawa K, Nakamura K, Hirako A, et al. Influence of polymerization among Al- and Ga-containing molecules on growth rate and Al content in AlGaN[J]. Journal of Crystal Growth, 2019, 516: 17-20. |

| 33 | Tang L, Zuo R, Zhang H. Quantum chemical study on nanoparticles formation mechanism in AlGaN MOCVD growth[J]. Journal of Crystal Growth, 2019, 525: 125201. |

| 34 | An J D, Dai X Y, Zhang Q, et al. Gas-phase chemical reaction mechanism in the growth of AlN during high-temperature MOCVD: a thermodynamic study[J]. ACS Omega, 2020, 5(20): 11792-11798. |

| 35 | 何晓崐, 薛园, 左然. MOCVD生长InN气相反应路径的量子化学研究[J]. 化工学报, 2022, 73(12): 5638-5647. |

| He X K, Xue Y, Zuo R. Quantum chemistry study on gas reaction path in InN MOCVD growth[J]. CIESC Journal, 2022, 73(12): 5638-5647. | |

| 36 | 刘洋. AlN及高Al组分AlGaN材料的MOCVD生长方法研究[D]. 西安: 西安电子科技大学, 2019. |

| Liu Y. Study on MOCVD growth method of AlN and high Al component AlGaN materials[D]. Xi’an: Xidian University, 2019. | |

| 37 | Moscatelli D, Cavallotti C. Theoretical investigation of the gas-phase kinetics active during the GaN MOVPE[J]. Journal of Physical Chemistry A, 2007, 111(21): 4620-4631. |

| 38 | 张红, 左然. GaN-MOVPE生长的气相反应中自由基的作用[J]. 中国科学: 技术科学, 2019, 49: 1-8. |

| Zhang H, Zuo R. Effects of radicals on gas phase reactions in GaN MOVPE process[J]. Scientia Sinica: Technologica, 2019, 49: 1-8. | |

| 39 | 刘国峰, 左然. GaN-MOVPE气相自由基反应的量子化学研究[J]. 人工晶体学报, 2021, 50(3): 469-476. |

| Liu G F, Zuo R. Quantum chemistry study on gas reactions involved with radicals in GaN-MOVPE process[J]. Journal of Synthetic Crystals, 2021, 50(3): 469-476. | |

| 40 | Lisovenko A S, Morokuma K, Timoshkin A Y. Initial gas phase reactions between Al(CH3)3/AlH3 and ammonia: theoretical study[J]. Journal of Physical Chemistry A, 2015, 119(4): 744-751. |

| 41 | Creighton J R, Wang G T. Kinetics of metal organic-ammonia adduct decomposition: implications for group-Ⅲ MOCVD[J]. Journal of Physical Chemistry A, 2005, 109(46): 10554-10562. |

| 42 | Creighton J R, Wang G T, Coltrin W E. Fundamental chemistry and modeling of group-Ⅲ nitride MOVPE[J]. Journal of Crystal Growth, 2007, 298: 2-7. |

| 43 | Pu K W, Dai X Y, Miao D M, et al. A kinetics model for MOCVD deposition of AlN film based on grove theory[J]. Journal of Crystal Growth, 2017, 478: 42-46. |

| 44 | Zhang H, Zuo R, Zhong T T, et al. Quantum chemistry study on gas reaction mechanism in AlN MOVPE growth[J]. Journal of Physical Chemistry A, 2020, 124: 2961-2971. |

| 45 | Zuo R, Zhang H, Wang B L, et al. Quantum chemistry study on the adduct reaction paths as functions of temperature in GaN/AlN MOVPE growth[J]. ECS Journal of Solid State Science and Technology, 2016, 5(12): 667-673. |

| 46 | Manasevit H M, Simpson W I. The use of metal-organics in the preparation of semiconductor materials (Ⅰ): Epitaxial gallium-Ⅴ compounds[J]. Journal of the Electrochemical Society, 1969, 116(12): 1725-1732. |

| 47 | Koide Y, Itoh H, Sawaki N, et al. Epitaxial growth and properties of Al x Ga1- x N by MOVPE[J]. Journal of the Electrochemical Society, 1986, 133(9): 1956-1960. |

| 48 | Lundin W V, Nikolaev A E, Yagovkina M A, et al. High growth rate MOVPE of Al(Ga)N in planetary reactor[J]. Journal of Crystal Growth, 2012, 352(1): 209-213. |

| 49 | Dauelsberg M, Brien D, Rauf H, et al. On mechanisms governing AlN and AlGaN growth rate and composition in large substrate size planetary MOVPE reactors[J]. Journal of Crystal Growth, 2014, 393: 103-107. |

| 50 | Iba Y, Shojiki K, Kuboya S, et al. Effect of MOVPE growth conditions on AlN films on annealed sputtered AlN templates with nano-striped patterns [J]. Journal of Crystal Grrowth, 2021, 570: 126237. |

| 51 | Khan M A, Shatalov M, Maruska H P, et al. Ⅲ-nitride UV devices[J]. Japanese Journal of Applied Physics, 2005, 44(10): 7191-7206. |

| 52 | Chen C H, Liu H, Steigerwald D, et al. A study of parasitic reactions between NH3 and TMGa or TMAl[J]. Journal of Electronic Materials, 1996, 25: 1004-1008. |

| 53 | Dadgar A, Krost A, Christen J, et al. MOVPE growth of high-quality AlN[J]. Journal of Crystal Growth, 2006, 297(2): 306-310. |

| 54 | Kim S, Seo J, Lee K, et al. Gas-phase parasitic reactions and Al incorporation of AlGaN growth using TPIS-MOCVD[J]. Journal of the Korean Physical Society, 2002, 41(5): 726. |

| 55 | Tang L, Zuo R, Zhang H, et al. Quantum chemical study on gas-phase oligomerization in AlGaN MOCVD growth[J]. Computational and Theoretical Chemistry, 2019, 1116: 112573. |

| 56 | Ohkawa K, Ichinohe F, Watanabe T, et al. Metalorganic vapor-phase epitaxial growth simulation to realize high-quality and high-In-content InGaN alloys[J]. Journal of Crystal Growth, 2019, 512: 69-73. |

| 57 | Bao Q L, Zhu T K, Zhou N, et al. Effect of hydrogen carrier gas on AlN and AlGaN growth in AMEC Prismo D-Blue® MOCVD platform[J]. Journal of Crystal Growth, 2015, 419: 52-56. |

| 58 | Li Y, Chen X J, Su J. Study on formation of step bunching on 6H-SiC (0001) surface by kinetic Monte Carlo method[J]. Applied Surface Science, 2016, 371: 242-247. |

| 59 | Zheng X X, Lin C H, Ueda D, et al. Effects of the growth temperature on structural and electrical properties of AlN/GaN heterostructures grown by metal organic chemical vapor deposition[J]. Thin Solid Films, 2020, 709: 138228. |

| 60 | Lundin W V, Nikolaev A E, Yagovkina M A, et al. High growth rate MOVPE of Al(Ga)N in planetary reactor[J]. Journal of Crystal Growth, 2012, 352(1): 209-213. |

| 61 | Kumagai Y, Akiyama K, Togashi R, et al. Polarity dependence of AlN(0001) decomposition in flowing H2 [J]. Journal of Crystal Growth, 2007, 305(2): 366-371. |

| 62 | Czernecki R, Grzanka E, Strak P, et al. Influence of hydrogen pre-growth flow on indium incorporation into InGaN layers[J]. Journal of Crystal Growth, 2017, 464: 123-1126. |

| 63 | Chauhan P, Hasenöhrl S, Dobročka E, et al. Effect of temperature and carrier gas on the properties of thick In x Al1- x N layer[J]. Applied Surface Science, 2019, 470: 1-7. |

| 64 | Jindal V, Sandvik F S. Density functional theoretical study of surface structure and adatom kinetics for wurtzite AlN[J]. Applied Physics Letters, 2009, 105: 084902. |

| 65 | Kangawa Y, Akiyama T, Ito T, et al. Surface stability and growth kinetics of compound semiconductors: an ab initio-based approach[J]. Materials, 2013, 6(8): 3309-3360. |

| 66 | Akiyama T, Nakamura K, Ito T. Ab initio-based study for adatom kinetics on AlN(0001) surfaces during metal-organic vapor-phase epitaxy growth[J]. Applied Physics Letters, 2012, 100: 251601. |

| 67 | Suzuki H, Togashi R, Murakami H, et al. Theoretical analysis for surface reconstruction of AlN and InN in the presence of hydrogen[J]. Japanese Journal of Applied Physics, 2007, 46(8A): 5112-5115. |

| 68 | Chris G, van de Walle, Neugebauer J. First-principles surface phase diagram for hydrogen on GaN surfaces[J]. Physical Review Letters, 2002, 88(6): 066103. |

| 69 | Northrup J E, Felice R D. Atomic structure and stability of AlN(0001) and (000̱1) surfaces[J]. Physical Review B, 1997, 55(20): 13878-13883. |

| 70 | Feenstra R M, Dong Y, Lee C D. Recent developments in surface stidues of GaN and AlN[J]. Journal of Vacuum Science & Technologu B: Microelectronics and Nanometer Structures Processing, Measurement, and Phenomena, 2005, 23: 1174-1180. |

| 71 | Nakamura K, Hirako A, Ohkawa K. Analysis of pulsed injection of precursors in AlN-MOCVD growth by computational fluid simulation[J]. Physica Status Solidi, 2010, 7(7/8): 2268-2271. |

| 72 | Davis C S, Novikov S V, Cheng T S, et al. Surface reconstruction patterns of AlN grown by molecular beam epitaxy on sapphire[J]. Journal of Crystal Growth, 2001, 226(2/3): 203-208. |

| 73 | Bryan I, Bryan Z, Mita S, et al. Surface kinetics in AlN growth: a universal model for the control of surface morphology in Ⅲ-nitrides[J]. Journal of Crystal Growth, 2016, 438: 81-89. |

| 74 | Kempisty P, Strak P, Sakowski K, et al. Ab initio and thermodynamic picture of Al adsorption of AlN(000 1 ̲ ) surface-role of bond creation and electron transition contributions[J]. Applied Surface Science, 2020, 532: 147419. |

| 75 | Ying M J, Cheng W, Zhang O, et al. DFT study of the coverage effects for Al adsorption on Si(111) surfaces [J]. Computational Materials Science, 2012, 53(1): 382-387. |

| 76 | Zhang L B, Zhang R J, Yang B, et al. Adsorption configuration of AlN on sapphire surface using first-principles calculations[J]. Applied Surface Science, 2021, 562(1): 150163 |

| 77 | Gherasimova M, Cui G, Ren Z, et al. Heteroepitaxial evolution of AlN on GaN grown by metal-organic chemical vapor deposition[J]. Journal of Applied Physics, 2004, 95 (5): 2921-2923. |

| 78 | Zhang D G, Li Z H, Peng D Q, et al. Temperature dependence of the character of AlN nucleation layer grown on SiC substrates by MOCVD[J]. Superlattices and Microstrcutures, 2016, 99: 104-107. |

| 79 | Zhang H F, Paskov P P, Kordina O, et al. N-polar AlN nucleation layers grown by hot-wall MOCVD on SiC: effects of substrate orientation on the polarity, surface morphology and crystal quality[J]. Physica B: Condensed Matter, 2020, 580: 411819. |

| 80 | Li D D, Su X J, Chen J J, et al. Influence of sapphire substrate miscut on the surface morphology and microstructure of AlN films grown by HVPE[J]. Journal of Crystal Growth, 2022, 592: 126731. |

| 81 | Inagaki Y, Kozawa T. Chemical reaction pathways for MOVPE growth of aluminum nitride[J]. ECS Journal of Solid State Science and Technology, 2016, 5 (2): 73-75. |

| 82 | Yuan Y M, Zuo R, Mao K K, et al. Adsorption properties of AlN on Si(111) surface: a density functional study[J]. Applied Surface Science, 2018, 436: 50-57. |

| 83 | Lin P, Niu N N, Zuo R, et al. Density functional theory study on surface adsorptions in AlN metalorganic vapor phase epitaxy process[J]. Applied Surface Science, 2021, 544: 148773. |

| 84 | Wang Y H, Zuo R. Quantum chemical study of the Co-adsorption of NH3 and MMAl on ideal AlN(0001)-Al surfaces[J]. Journal of Crystal Growth, 2020, 543: 125705. |

| 85 | Lin W J, Chen J C. A numerical study of the effect of pulse duration on preventing particle generation during the AlN pulsed MOCVD process[J]. Materials Science in Semiconductor Processing, 2022, 148: 106816. |

| 86 | Endres D, Mazumder S. Numerical investigation of pulsed chemical vapor deposition of aluminum nitride to reduce particle formation[J]. Journal of Crystal Growth, 2011, 335(1): 42-50. |

| 87 | Rouf P, Sukkaew P, Ojamäe L, et al. Reduction of carbon impurities in aluminum nitride from time-resolved chemical vapor deposition using trimethylaluminum[J]. Journal of Physical Chemistry C, 2020, 124(26): 14176-14181. |

| 88 | Kueller V, Knauer A, Zeimer U, et al. Controlled coalescence of MOVPE grown AlN during lateral overgrowth[J]. Journal of Crystal Growth, 2013, 368: 83-86. |

| 89 | Jain R, Sun W, Yang J, et al. Controlled coalescence of MOVPE grown AlN during lateral overgrowth[J]. Applied Physics Letters, 2008, 93: 051113. |

| 90 | Long H L, Dai J N, Zhang Y, et al. High quality 10.6 μm AlN grown on pyramidal patterned sapphire substrate by MOCVD[J]. Applied Physics Letters, 2019,114: 042101. |

| 91 | Dong P, Yan J C, Wang J X, et al. 282-nm AlGaN-based deep ultraviolet light-emitting diodes with improved performance on nano-patterned sapphire substrates[J]. Applied Physics Letters, 2013,102: 241113. |

| 92 | Ishibashi A, Kidoguchi I, Sugahara G, et al. High-quality GaN films obtained by air-bridged lateral epitaxial growth[J]. Journal of Crystal Growth, 2000, 221(1/2/3/4): 338-344. |

| 93 | Okada N, Saito T, Fujikawa S, et al. Investigation of off-cut angle of sapphire for epitaxial lateral overgrowth of AlN and fabrication of high-quality AlN template[J]. Journal of Crystal Growth, 2022, 588: 126640. |

| 94 | Song J, Yuan G, Xiong K, et al. Epitaxial lateral overgrowth of nitrogen-polar (000 1 ¯ ) GaN by metalorganic chemical vapor deposition[J]. Crystal Growth & Deisgn, 2014, 14(5): 2510-2515. |

| [1] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [2] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [3] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [4] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [5] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [6] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [9] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [10] | 刘道银, 陈柄岐, 张祖扬, 吴琰. 颗粒聚团结构对曳力特性影响的数值模拟[J]. 化工学报, 2023, 74(6): 2351-2362. |

| [11] | 李晨曦, 刘永峰, 张璐, 刘海峰, 宋金瓯, 何旭. O2/CO2氛围下正庚烷的燃烧机理研究[J]. 化工学报, 2023, 74(5): 2157-2169. |

| [12] | 张兰河, 赖青燚, 王铁铮, 关潇卓, 张明爽, 程欣, 徐小惠, 贾艳萍. H2O2对SBR脱氮效率和污泥性能的影响[J]. 化工学报, 2023, 74(5): 2186-2196. |

| [13] | 李瑞康, 何盈盈, 卢维鹏, 王园园, 丁皓东, 骆勇名. 电化学强化钴基阴极活化过一硫酸盐的研究[J]. 化工学报, 2023, 74(5): 2207-2216. |

| [14] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [15] | 李正涛, 袁志杰, 贺高红, 姜晓滨. 疏水界面上的NaCl液滴蒸发过程内环流调控机制研究[J]. 化工学报, 2023, 74(5): 1904-1913. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号