化工学报 ›› 2020, Vol. 71 ›› Issue (2): 602-613.DOI: 10.11949/0438-1157.20191275

收稿日期:2019-10-25

修回日期:2019-12-04

出版日期:2020-02-05

发布日期:2020-02-05

通讯作者:

熊源泉

作者简介:周海军(1986—),男,博士研究生,基金资助:

Haijun ZHOU( ),Yuanquan XIONG(

),Yuanquan XIONG( )

)

Received:2019-10-25

Revised:2019-12-04

Online:2020-02-05

Published:2020-02-05

Contact:

Yuanquan XIONG

摘要:

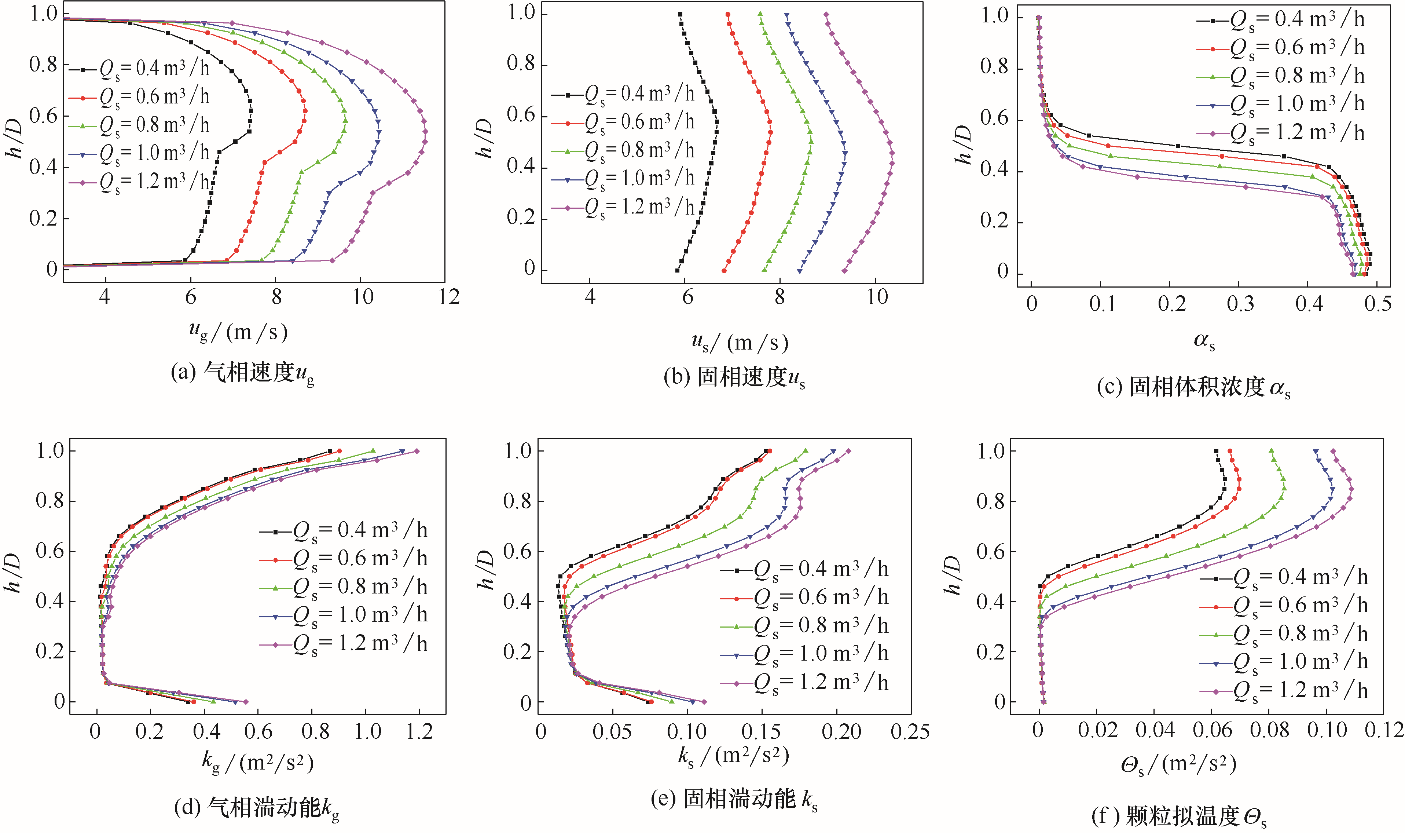

针对水平管高压密相气力输送数理模型的缺陷与不足,引入Savage径向分布函数修正的颗粒动理学理论、基于Berzi摩擦压应力模型构建的摩擦应力模型以及修正的三段式曳力模型,在欧拉-欧拉方法的基础上建立了一个能同时兼顾水平管高压密相气力输送中稀相流、过渡流以及密相流输送特性的三维非稳态数理模型。并采用该数理模型考察了补充风对水平管高压密相气力输送的影响,模拟结果精准地预测了水平管压降及其随补充风的变化规律,而且其预测的水平管固相体积浓度分布与ECT图也是相吻合的,从而验证了数理模型的可靠性。模拟结果表明:随着补充风的增加,气固两相速度和湍动能以及颗粒拟温度增大,固相体积浓度减小。

中图分类号:

周海军, 熊源泉. 补充风对水平管高压密相气力输送影响的模拟研究[J]. 化工学报, 2020, 71(2): 602-613.

Haijun ZHOU, Yuanquan XIONG. Simulation study on influence of supplementary gas on dense-phase pneumatic conveying in horizontal pipe under high pressure[J]. CIESC Journal, 2020, 71(2): 602-613.

图1 高压密相气力输送试验装置1—高压气瓶;2—缓冲罐;3—流化风流量计;4—充压风流量计;5—补充风流量计;6—储料罐;7—输送管道;8—差压变送器;9—压力传感器;10—可视段;11—温度传感器;12—在线取样器;13—荷重传感器;14—电动调节阀;15—控制柜

Fig.1 Experimental facility schematic diagram of dense-phase pneumatic conveying under high pressure

| No. | 补充风流量,Qs /(m3/h) | 表观气速,Ug/(m/s) | 固相质量流量,Ms/(kg/s) | 进口固相体积浓度,αs,in | 进口固相平均速度,us,inlet/(m/s) | 出口气相压力,Pout/MPa |

|---|---|---|---|---|---|---|

| 1 | 0.40 | 4.71 | 0.213 | 0.318 | 4.43 | 2.91 |

| 2 | 0.60 | 5.62 | 0.206 | 0.286 | 5.30 | 2.91 |

| 3 | 0.80 | 6.43 | 0.194 | 0.245 | 6.09 | 2.92 |

| 4 | 1.00 | 7.24 | 0.181 | 0.199 | 6.79 | 2.93 |

| 5 | 1.20 | 8.10 | 0.168 | 0.184 | 7.72 | 2.93 |

表1 输送试验工况参数

Table 1 Conveying experiment parameters

| No. | 补充风流量,Qs /(m3/h) | 表观气速,Ug/(m/s) | 固相质量流量,Ms/(kg/s) | 进口固相体积浓度,αs,in | 进口固相平均速度,us,inlet/(m/s) | 出口气相压力,Pout/MPa |

|---|---|---|---|---|---|---|

| 1 | 0.40 | 4.71 | 0.213 | 0.318 | 4.43 | 2.91 |

| 2 | 0.60 | 5.62 | 0.206 | 0.286 | 5.30 | 2.91 |

| 3 | 0.80 | 6.43 | 0.194 | 0.245 | 6.09 | 2.92 |

| 4 | 1.00 | 7.24 | 0.181 | 0.199 | 6.79 | 2.93 |

| 5 | 1.20 | 8.10 | 0.168 | 0.184 | 7.72 | 2.93 |

| 自然堆积固相体积浓度,αs,b | 全水分, Mc | 密度,ρs/(kg/m3) | 颗粒平均粒径,ds/μm | 颗粒刚度,kn/(Pa?m) |

|---|---|---|---|---|

| 0.50 | 5.45% | 1496 | 204.3 | 3000 |

表2 内蒙褐煤煤粉的主要物性参数

Table 2 Main physical properties of pulverized lignite

| 自然堆积固相体积浓度,αs,b | 全水分, Mc | 密度,ρs/(kg/m3) | 颗粒平均粒径,ds/μm | 颗粒刚度,kn/(Pa?m) |

|---|---|---|---|---|

| 0.50 | 5.45% | 1496 | 204.3 | 3000 |

| αs,max | ess | ?i | esw | ? | μw | a |

|---|---|---|---|---|---|---|

| 0.60 | 0.8 | 32.0° | 0.5 | 1.0×10-5 | 0.5 | 1.8×10-6 |

表3 数理模型参数

Table 3 Mathematical model parameters

| αs,max | ess | ?i | esw | ? | μw | a |

|---|---|---|---|---|---|---|

| 0.60 | 0.8 | 32.0° | 0.5 | 1.0×10-5 | 0.5 | 1.8×10-6 |

| 网格划分规格 | 端面格数 | 轴向网格尺寸/mm | 总网格数/万 | 水平管模拟压降/kPa | 水平管试验压降/kPa |

|---|---|---|---|---|---|

| Mesh A | 180 | 2 | 21.60 | 3.84 | 4.14 |

| Mesh B | 288 | 1.5 | 46.08 | 3.91 | |

| Mesh C | 420 | 1.25 | 80.64 | 4.07 | |

| Mesh D | 576 | 1 | 138.24 | 4.08 |

表4 不同网格尺寸下模拟预测的水平管压降

Table 4 Predicted pressure drop of horizontal pipe with different grid scale

| 网格划分规格 | 端面格数 | 轴向网格尺寸/mm | 总网格数/万 | 水平管模拟压降/kPa | 水平管试验压降/kPa |

|---|---|---|---|---|---|

| Mesh A | 180 | 2 | 21.60 | 3.84 | 4.14 |

| Mesh B | 288 | 1.5 | 46.08 | 3.91 | |

| Mesh C | 420 | 1.25 | 80.64 | 4.07 | |

| Mesh D | 576 | 1 | 138.24 | 4.08 |

图5 不同补充风下模拟预测的水平管压降与其试验值的对比

Fig.5 Comparison of predicted pressure drop of horizontal pipe with its experimental data at different supplementary gas flow rates

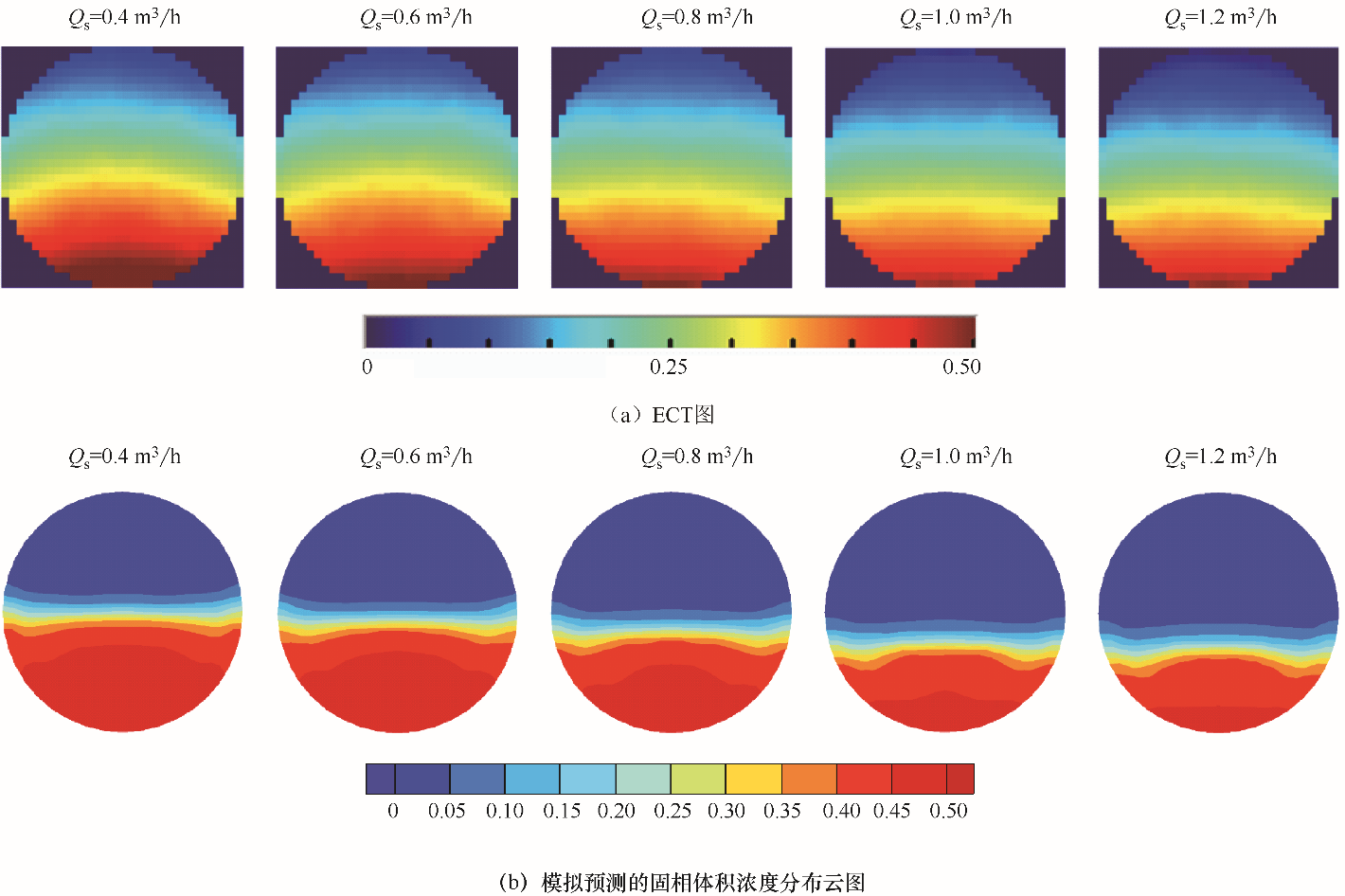

图9 不同补充风下模拟预测的固相体积浓度分布云图与ECT图的对比

Fig.9 Comparison of predicted solids volume fraction distribution with ECT image at different supplementary gas flow rates

图10 不同补充风下模拟预测的水平高压密相气力输送特性参数沿高度方向的分布

Fig.10 Predicted conveying parameters of horizontal pipe vs dimensionless height at different supplementary gas flow rates

图12 不同补充风下模拟获得的固相摩擦切应力分布云图

Fig.12 Predicted solids frictional shear stress at cross section of horizontal pipe at different supplementary gas flow rates

| 1 | 华贲. 低碳时代石油化工产业资源与能源走势[J]. 化工学报, 2013, 64(1): 76-83. |

| Hua B. Resources and energy trends of petrochemical industry in low carbon era[J]. CIESC Journal, 2013, 64(1): 76-83. | |

| 2 | Lu P, Yang P J, Zheng X W, et al. Pilot-scale experimental study on phase diagrams of pressurized pneumatic conveying with pulverized coal[J]. Energy & Fuels, 2017, 31(9): 10260-10266. |

| 3 | 鹿鹏, 姜瑞雪, 张桂臣, 等. 加压气力输送流型与压力脉动Hilbert-Huang变换的关联研究[J]. 中国电机工程学报, 2014, 34(5): 718-723. |

| Lu P, Jiang R X, Zhang G C, et al. Flow regimes of pressurized pneumatic conveying and association study based on Hilbert-Huang transform[J]. Proceedings of the CSEE, 2014, 34(5): 718-723. | |

| 4 | 朱立平, 彭小敏, 黄飞, 等. 表观气速对密相气力输送流型影响的模拟[J]. 化工学报, 2012, 63(2): 470-478. |

| Zhu L P, Peng X M, Huang F, et al. Numerical simulation of flow patterns in dense pneumatic conveying at different superficial gas velocities[J]. CIESC Journal, 2012, 63(2): 470-478. | |

| 5 | Sun S S, Yuan Z L, Peng Z B, et al. Computational investigation of particle flow characteristics in pressurised dense phase pneumatic conveying systems[J]. Powder Technology, 2018, 329: 241-251. |

| 6 | 谢灼利, 黎明, 张政. 水平管气力输送的数值模拟研究[J]. 高校化学工程学报, 2006, 20(3): 331-337. |

| Xie Z L, Li M, Zhang Z. Numerical simulation of horizontal pneumatic conveying[J]. Journal of Chemical Engineering of Chinese Universities, 2006, 20(3): 331-337. | |

| 7 | Pu W H, Zhao C S, Xiong Y Q, et al. Numerical simulation on dense phase pneumatic conveying of pulverized coal in horizontal pipe at high pressure[J]. Chem. Eng. Sci., 2010, 65(8): 2500-2512. |

| 8 | 蒲文灏, 赵长遂, 熊源泉, 等. 水平管加压密相煤粉气力输送数值模拟[J]. 化工学报, 2008, 59(10): 2601-2607. |

| Pu W H, Zhao C S, Xiong Y Q, et al. Numerical simulation of dense pneumatic conveying of pulverized coal in horizontal pipe at high pressure[J]. Journal of Chemical Industry and Engineering (China), 2008, 59(10): 2601-2607. | |

| 9 | Jenkins J T, Savage S B. A theory for the rapid flow of identical, smooth, nearly elastic, spherical particles[J]. J. Fluid Mech., 1983, 130: 187-202. |

| 10 | Savage S B, Jeffrey D J. The stress tensor in a granular flow at high shear rates[J]. J. Fluid Mech., 1981, 110: 255-272. |

| 11 | Wang Y, Williams K, Jones M, et al. CFD simulation methodology for gas-solid flow in bypass pneumatic conveying—a review[J]. Appl. Therm. Eng., 2017, 125: 185-208. |

| 12 | Chialvo S, Sun J, Sundaresan S. Bridging the rheology of granular flows in three regimes[J]. Phys. Rev. E., 2012, 85(2): 021305. |

| 13 | Makkawi Y, Ocone R. A model for gas-solid flow in a horizontal duct with a smooth merge of rapid-intermediate-dense flows[J]. Chem. Eng. Sci., 2006, 61(13): 4271-4281. |

| 14 | Tardos G I, Mcnamara S, Talu I. Slow and intermediate flow of a frictional bulk powder in the Couette geometry[J]. Powder Technology, 2003, 131(1): 23-39. |

| 15 | Vescovi D, di Prisco C, Berzi D. From solid to granular gases: the steady state for granular materials[J]. Int. J. Numer. Anal. Methods Geomech., 2013, 37(17): 2937-2951. |

| 16 | 陈程, 祁海鹰. EMMS曳力模型及其颗粒团模型的构建和检验[J]. 化工学报, 2014, 65(6): 2003-2012. |

| Chen C, Qi H Y. Development and validation of cluster and EMMS drag model[J]. CIESC Journal, 2014, 65(6): 2003-2012. | |

| 17 | Peng C, Lyu M, Wang S N, et al. Effect of fractal gas distributor on the radial distribution of particles in circulating turbulent fluidized bed[J]. Powder Technology, 2018, 326: 443-453. |

| 18 | Xu G L, Lu P, Liang C, et al. Effect of powder properties on discharge characteristics of cohesive carbonaceous fuel powders from a top discharge blow tank at high pressure[J]. Chem. Eng. Commun., 2018, 205(11): 1604-1621. |

| 19 | 沈湘林, 熊源泉. 煤粉加压密相输送实验研究[J]. 中国电机工程学报, 2005, 25(24): 103-107. |

| Shen X L, Xiong Y Q. Experimental study on dense-phase pneumatic conveying of pulverized coal at high pressures[J]. Proceedings of the CSEE, 2005, 25(24): 103-107. | |

| 20 | 贺春辉, 陈先梅, 倪红亮, 等. 发送罐出料方式对煤粉高压密相气力输送特性的影响[J]. 中国电机工程学报, 2012, 32(23): 32-39. |

| He C H, Chen X M, Ni H L, et al. Influences of discharge types of blow tank on dense phase pneumatic conveying of pulverized coal at high pressure[J]. Proceedings of the CSEE, 2012, 32(23): 32-39. | |

| 21 | Savage S B. Analyses of slow high-concentration flows of granular materials[J]. J. Fluid Mech., 1998, 377: 1-26. |

| 22 | Lee C H, Huang Z H, Chiew Y M. A three-dimensional continuum model incorporating static and kinetic effects for granular flows with applications to collapse of a two-dimensional granular column[J]. Physics of Fluids, 2015, 27(11): 113303. |

| 23 | Srivastava A, Sundaresan S. Analysis of a frictional-kinetic model for gas-particle flow[J]. Powder Technology, 2003, 129(1/2/3): 72-85. |

| 24 | Johnson P C, Jackson P R. Frictional-collisional equations of motion for participate flows and their application to chutes[J]. J. Fluid Mech., 1990, 210: 501-535. |

| 25 | Berzi D, di Prisco C G, Vescovi D. Constitutive relations for steady, dense granular flows[J]. Phys. Rev. E., 2011, 84(3): 031301. |

| 26 | Nikolopoulos A, Nikolopoulos N, Charitos A, et al. High-resolution 3-D full-loop simulation of a CFB carbonator cold model[J]. Chem. Eng. Sci., 2013, 90(10): 137-150. |

| 27 | Schneiderbauer S, Aigner A, Pirker S. A comprehensive frictional-kinetic model for gas-particle flows: analysis of fluidized and moving bed regimes[J]. Chem. Eng. Sci., 2012, 80(10): 279-292. |

| 28 | Lyu S H, Li X L, Li G H. Effects of momentum transfer on particle dispersions of dense gas-particle two-phase turbulent flows[J]. Adv. Powder Technol., 2014, 25(1): 274-280. |

| 29 | Mckeen T, Pugsley T. Simulation and experimental validation of a freely bubbling bed of FCC catalyst[J]. Powder Technology, 2003, 129(1): 139-152. |

| 30 | Klinzing G E, Rizk F, Marcus R, et al. Pneumatic conveying of solids: a theoretical and practical approach[J]. Ind. Eng. Chem. Res., 2011, 55(39): 10455-10464. |

| 31 | Johnson P C, Jackson R. Frictional-collisional constitutive relations for granular materials, with application to plane shearing[J]. J. Fluid Mech., 1987, 176: 67-93. |

| 32 | Geldart D, Ling S J. Dense phase conveying of fine coal at high total pressures[J]. Powder Technology, 1990, 62(3): 243-252. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [4] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [5] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [6] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [7] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [8] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [9] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [10] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [11] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [12] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [13] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [14] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [15] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号