化工学报 ›› 2020, Vol. 71 ›› Issue (5): 2283-2291.DOI: 10.11949/0438-1157.20191468

徐士鸣( ),刘志强,吴曦,张又文,胡军勇,吴德兵,冷强,金东旭,王平

),刘志强,吴曦,张又文,胡军勇,吴德兵,冷强,金东旭,王平

收稿日期:2019-12-04

修回日期:2020-01-14

出版日期:2020-05-05

发布日期:2020-05-05

通讯作者:

徐士鸣

作者简介:徐士鸣(1957—),男,教授,博导,基金资助:

Shiming XU( ),Zhiqiang LIU,Xi WU,Youwen ZHANG,Junyong HU,Debing WU,Qiang LENG,Dongxu JIN,Ping WANG

),Zhiqiang LIU,Xi WU,Youwen ZHANG,Junyong HU,Debing WU,Qiang LENG,Dongxu JIN,Ping WANG

Received:2019-12-04

Revised:2020-01-14

Online:2020-05-05

Published:2020-05-05

Contact:

Shiming XU

摘要:

低品位热能制氢技术首先是将热能转换为溶液浓差能,然后通过逆电渗析(RED)反应器将溶液浓差能转换成氢能。为了验证RED反应器能将溶液浓差能转换为氢能,探索关键运行参数变化对能量转换过程的影响。设计了一个由40个膜对所构成的RED反应器,以NaCl水溶液为工作溶液,NaOH水溶液为电极液的制氢系统。通过改变浓/稀溶液入口浓度,溶液过膜流速以及输出电流来考察对RED反应器产氢率、制氢效率和能量转换效率的影响。实验结果发现,浓/稀溶液入口浓度,过膜流速变化均会影响RED反应器的输出电流。在外电路短接条件下,输出电流越大,反应器产氢率和制氢效率越高,但能量转换效率越低。

中图分类号:

徐士鸣, 刘志强, 吴曦, 张又文, 胡军勇, 吴德兵, 冷强, 金东旭, 王平. 溶液浓差能驱动的逆电渗析反应器制氢实验研究[J]. 化工学报, 2020, 71(5): 2283-2291.

Shiming XU, Zhiqiang LIU, Xi WU, Youwen ZHANG, Junyong HU, Debing WU, Qiang LENG, Dongxu JIN, Ping WANG. Experimental study on the hydrogen production with RED reactor powered by concentration gradient energy[J]. CIESC Journal, 2020, 71(5): 2283-2291.

| 实验设备 | 型号 | 参数 | 精度 |

|---|---|---|---|

| 电导率仪 | METTLER TOLEDO FE38 | 电导率 | ±0.5% mS·cm-1 |

| 数字万用表 | KEITHLEY | 电流、电压 | ±0.016% V / 0.17% A |

| 电子分析天平 | OHAUS Scout SE | 质量 | 0.001g |

| 低温恒温槽 | Biosafer - 1020DC | 温度 | ±0.05 K |

| 蠕动泵 | LONGER BT300 - 2J | 体积流率 | — |

| 电极液蠕动泵 | Kamoer KCP PRO2-N40 | 体积流率 | ±5% ml·min-1 |

| 可调直流电阻器 | ZX92A | 电阻 | ±0.1%Ω |

表1 实验设备型号、参数及精度

Table 1 Mode, parameter and accuracy of experiment equipment

| 实验设备 | 型号 | 参数 | 精度 |

|---|---|---|---|

| 电导率仪 | METTLER TOLEDO FE38 | 电导率 | ±0.5% mS·cm-1 |

| 数字万用表 | KEITHLEY | 电流、电压 | ±0.016% V / 0.17% A |

| 电子分析天平 | OHAUS Scout SE | 质量 | 0.001g |

| 低温恒温槽 | Biosafer - 1020DC | 温度 | ±0.05 K |

| 蠕动泵 | LONGER BT300 - 2J | 体积流率 | — |

| 电极液蠕动泵 | Kamoer KCP PRO2-N40 | 体积流率 | ±5% ml·min-1 |

| 可调直流电阻器 | ZX92A | 电阻 | ±0.1%Ω |

| 名称 | 参数 | 符号 | 单位 | 数值 |

|---|---|---|---|---|

| RED反应器外形 | 电池单元数 | N | — | 40 |

| 长 | — | cm | 25 | |

| 宽 | — | cm | 20 | |

| 电极 | 长 | — | cm | 10 |

| 宽 | — | cm | 10 | |

| 网孔 | — | mm×mm | 1×3 | |

| 离子交换膜 | 选择性系数① | αCEM | — | 0.96 |

| αAEM | — | 0.95 | ||

| 面电阻② | RCEM | Ω·cm2 | 6.1 | |

| RAEM | Ω·cm2 | 3.5 | ||

| 膜厚 | δm | mm | 0.16 | |

| 水渗透率 | — | ml·bar-1·m-2·h-1③ | 3.5,3 | |

| 爆破强度 | — | kg·cm-2 | 4.7,5 | |

| 丝网隔垫 | 隔垫厚 | δ | mm | 0.22 |

| 孔隙率 | ε | % | 67 | |

| 阻挡系数 | f | — | 1.73 | |

| 遮蔽系数 | β | — | 2.02 |

表2 RED反应器内各部件基本参数

Table 2 Basic parameters of each part in RED reactor

| 名称 | 参数 | 符号 | 单位 | 数值 |

|---|---|---|---|---|

| RED反应器外形 | 电池单元数 | N | — | 40 |

| 长 | — | cm | 25 | |

| 宽 | — | cm | 20 | |

| 电极 | 长 | — | cm | 10 |

| 宽 | — | cm | 10 | |

| 网孔 | — | mm×mm | 1×3 | |

| 离子交换膜 | 选择性系数① | αCEM | — | 0.96 |

| αAEM | — | 0.95 | ||

| 面电阻② | RCEM | Ω·cm2 | 6.1 | |

| RAEM | Ω·cm2 | 3.5 | ||

| 膜厚 | δm | mm | 0.16 | |

| 水渗透率 | — | ml·bar-1·m-2·h-1③ | 3.5,3 | |

| 爆破强度 | — | kg·cm-2 | 4.7,5 | |

| 丝网隔垫 | 隔垫厚 | δ | mm | 0.22 |

| 孔隙率 | ε | % | 67 | |

| 阻挡系数 | f | — | 1.73 | |

| 遮蔽系数 | β | — | 2.02 |

| 浓度/(mol·L-1) | 过膜流速/ (cm·s-1) | 输出电流/A | |

|---|---|---|---|

| 稀溶液 | 浓溶液 | ||

| 0.01~0.15 | 1~5 | 0.1~0.5 | 0.1~0.35 |

表3 实验参数变化范围

Table 3 Ranges of experimental parameters

| 浓度/(mol·L-1) | 过膜流速/ (cm·s-1) | 输出电流/A | |

|---|---|---|---|

| 稀溶液 | 浓溶液 | ||

| 0.01~0.15 | 1~5 | 0.1~0.5 | 0.1~0.35 |

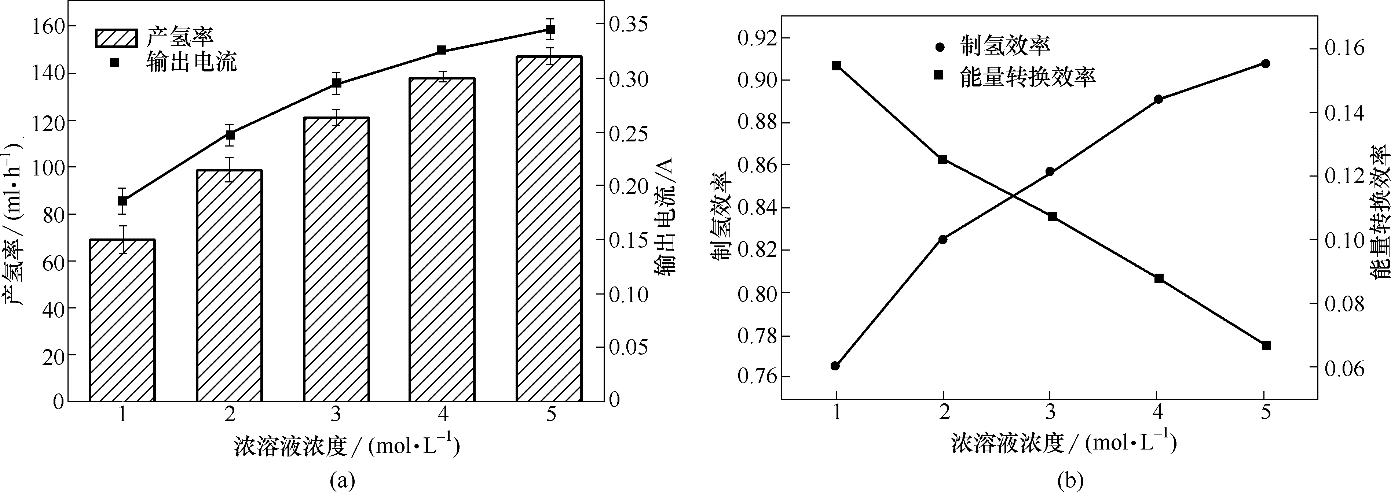

图4 RED反应器短路电流、产氢率、制氢及能量转换效率随浓溶液入口浓度的变化

Fig.4 Variations of short circuit current, hydrogen production rate, hydrogen production and energy conversion efficiency of RED reactor with inlet concentration of HC

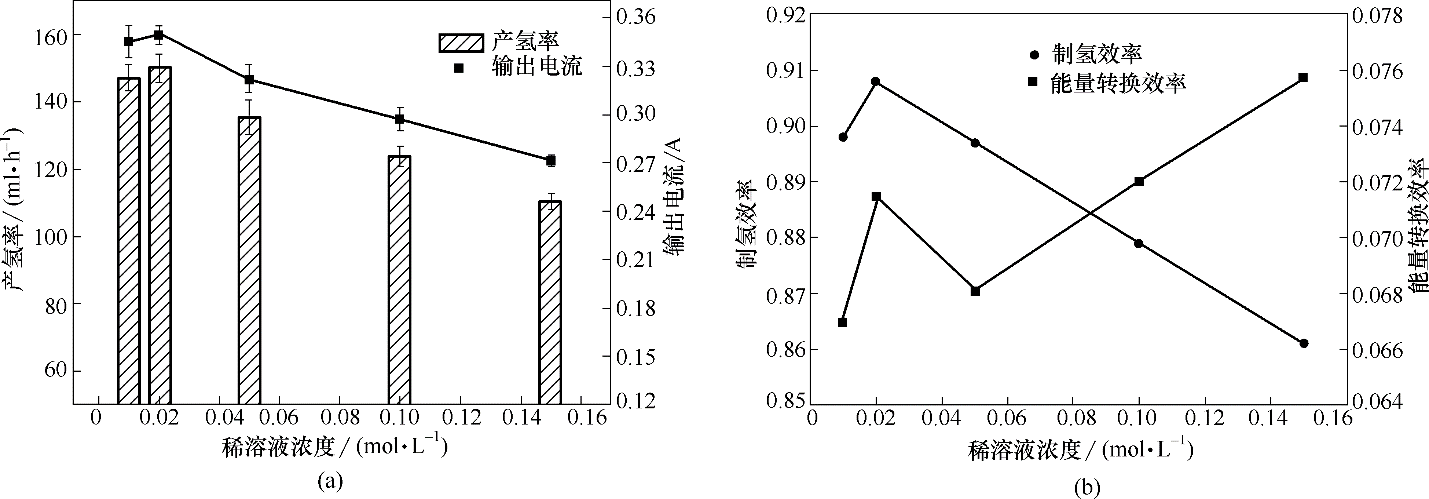

图5 RED反应器短路电流、产氢率、制氢及能量转换效率随稀溶液入口浓度的变化

Fig.5 Variations of short circuit current, hydrogen production rate, hydrogen production and energy conversion efficiency of RED reactor with inlet concentration of LC

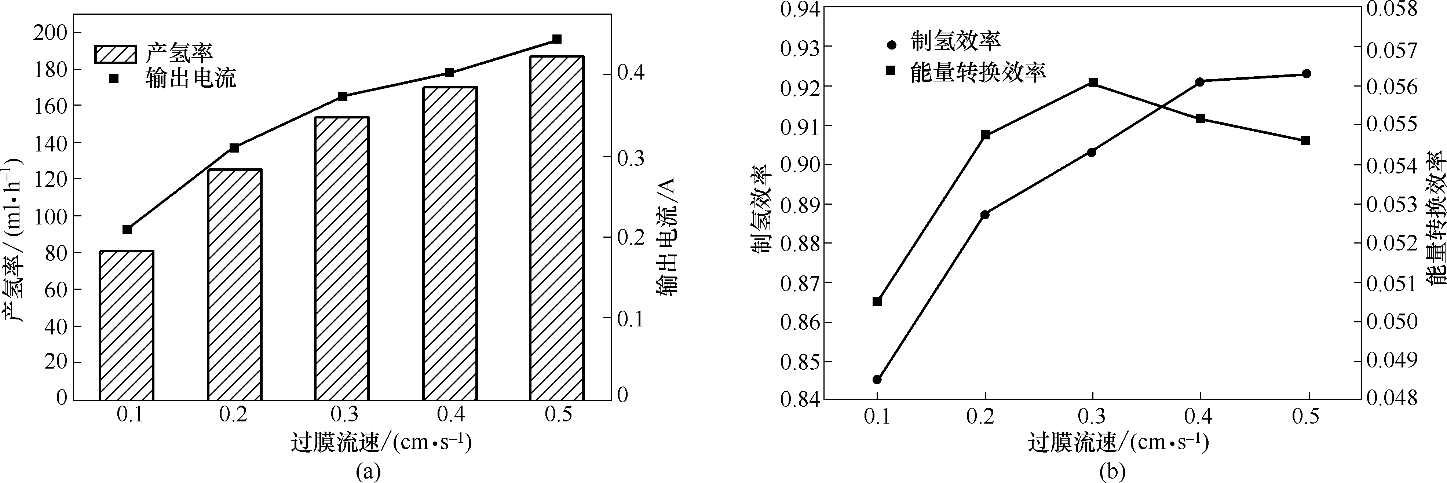

图6 RED反应器短路电流、产氢率、制氢及能量转换效率随过膜流速的变化

Fig.6 Variations of short circuit current, hydrogen production rate, hydrogen production and energy conversion efficiency of RED reactor with solution flow velocity on membrane

图7 RED反应器输出能量、制氢及能量转换效率随输出电流的变化

Fig.7 Variations of output energy, hydrogen production and energy conversion efficiency of RED reactor with current output

| 1 | Momirlan M, Veziroglu T N. The properties of hydrogen as fuel tomorrow in sustainable energy system for a cleaner planet[J]. International Journal of Hydrogen Energy, 2005, 30(7): 795-802. |

| 2 | Lei Q, Wang B G, Wang P C, et al. Hydrogen generation with acid/alkaline amphoteric water electrolysis[J]. Journal of Energy Chemistry, 2019, 38: 162-169. |

| 3 | Santos D M F, Sequeira C A C, Figueiredo J L. Hydrogen production by alkaline water electrolysis[J]. Quimica Nova, 2013, 36(8): 1176-1193. |

| 4 | Zeng K, Zhang D K. Recent progress in alkaline water electrolysis for hydrogen production and applications[J]. Progress in Energy and Combustion Science, 2010, 36(3): 307-326. |

| 5 | 温福宇, 杨金辉, 宗旭, 等. 太阳能光催化制氢研究进展[J]. 化学进展, 2009, 21(11): 2285-2302. |

| Wen F Y, Yang J H, Zong X, et al. Photocatalytic hydrogen production utilizing solar energy[J]. Progress in Chemistry, 2009, 21(11): 2285-2302. | |

| 6 | 吴曦, 徐士鸣. 一种低品位热能驱动的电极液自循环式制氢方法: 201910103003.0[P]. 2019-02-01. |

| Wu X, Xu S M. Low-grade heat energy driven electrode liquid self-circulating hydrogen production method: 201910103003.0[P]. 2019-02-01. | |

| 7 | Khawaji A D, Kutubkhanah I K, Wie J M. Advances in seawater desalination technologies[J]. Desalination, 2008, 221(1/2/3): 47-69. |

| 8 | Xu S M, Xu L, Wu X, et al. Air-gap diffusion distillation: theory and experiment[J]. Desalination, 2019, 467: 64-78. |

| 9 | 解利昕, 李凭力, 王世昌. 海水淡化技术现状及各种淡化方法评述[J]. 化工进展, 2003, 22(10): 1081-1084. |

| Xie L X, Li P L, Wang S C. A review of seawater desalination and comparison of desalting processes[J]. Chemical Industry and Engineering Progress, 2003, 22(10): 1081-1084. | |

| 10 | Hatzell M C, Zhu X P, Logan B E. Simultaneous hydrogen generation and waste acid neutralization in a reverse electrodialysis system[J]. ACS Sustainable Chemistry & Engineering, 2014, 2(9): 2211-2216. |

| 11 | Chen X, Jiang C, Zhang Y, et al. Storable hydrogen production by reverse electro-electrodialysis (REED) [J]. Journal of Membrane Science, 2017, 544: 397-405. |

| 12 | 徐士鸣, 吴德兵, 吴曦, 等. 氯化锂溶液为工质的溶液浓差发电实验研究[J]. 大连理工大学学报, 2017, 57(4): 337-343. |

| Xu S M, Wu D B, Wu X, et al. Experimental study of solution concentration difference power generation with lithium chloride solution as working fluid[J]. Journal of Dalian University of Technology, 2017, 57(4): 337-343. | |

| 13 | 徐士鸣, 张凯, 吴曦, 等. 电流与浓差对逆电渗析电堆内质量传递的影响[J]. 化工学报, 2018, 69(10): 4206-4215. |

| Xu S M, Zhang K, Wu X, et al. Influence of current density and concentration difference between solutions on mass transfer in reverse electro-dialysis stack[J]. CIESC Journal, 2018, 69(10): 4206-4215. | |

| 14 | 吴德兵, 徐士鸣, 吴曦, 等. 不同单价电解质水溶液对逆电渗析电堆工作特性的影响[J]. 化工进展, 2019, 38(6): 2738-2744. |

| Wu D B, Xu S M, Wu X, et al. Influences of different monovalent electrolyte aqueous solution on the performance characteristics of reverse electrodialysis stack[J]. Chemical Industry and Engineering Progress, 2019, 38(6): 2738-2744. | |

| 15 | 徐士鸣, 何其琛, 吴曦, 等. 顺、逆流串联电路逆电渗析电堆发电系统能量转换效率研究[J]. 大连理工大学学报, 2019, 59(1): 20-27. |

| Xu S M, He Q C, Wu X, et al. Investigation on energy conversion efficiency of series RED stacks power generation system in solution co-flow or counter-flow[J]. Journal of Dalian University of Technology, 2019, 59(1): 20-27. | |

| 16 | 何其琛, 徐士鸣, 吴曦, 等. 顺流串联逆电渗析电堆数对能量转换效率的影响研究[J]. 膜科学与技术, 2018, 38(5): 23-30. |

| He Q C, Xu S M, Wu X, et al. Study on the influence of series RED stack numbers on energy conversion efficiency in co-flow RED system[J]. Membrane Science and Technology, 2018, 38(5): 23-30. | |

| 17 | Hu J Y, Xu S M, Wu X, et al. Theoretical simulation and evaluation for the performance of the hybrid multi-effect distillation—reverse electrodialysis power generation system[J]. Desalination, 2018, 443: 172-183. |

| 18 | 徐士鸣, 徐志杰, 吴曦, 等. 溶液浓差能驱动的逆电渗析有机废水氧化降解机理研究[J]. 环境科学学报, 2018, 38(12): 4642-4651. |

| Xu S M, Xu Z J, Wu X, et al. Study on the mechanism of organic wastewater oxidation degradation with reverse electrodialysis powered by concentration gradient energy of solutions[J]. Acta Scientiae Circumstantiae, 2018, 38(12): 4642-4651. | |

| 19 | 徐士鸣, 冷强, 吴曦, 等. 逆电渗析反应器阴、阳极联合降解酸性橙Ⅱ实验研究[J]. 环境科学学报, 2019, 39(7): 2163-2171. |

| Xu S M, Leng Q, Wu X, et al. Experimental investigate on the joint degradation for acid Orange 7 by anode and cathode in RED reactor[J]. Acta Scientiae Circumstantiae, 2019, 39(7): 2163-2171. | |

| 20 | Vermaas D A, Veerman J, Yip N Y, et al. High efficiency in energy generation from salinity gradients with reverse electrodialysis[J]. ACS Sustainable Chemistry & Engineering, 2013, 1(10): 1295-1302. |

| 21 | Post J W, Hamelers H V M, Buisman C J N. Energy recovery from controlled mixing salt and fresh water with a reverse electrodialysis system[J]. Environmental Science & Technology, 2008, 42(15): 5785-5790. |

| 22 | Tufa R A, Rugiero E, Chanda D, et al. Salinity gradient power-reverse electrodialysis and alkaline polymer electrolyte water electrolysis for hydrogen production[J]. Journal of Membrane Science, 2016, 514: 155-164. |

| 23 | Kim Y, Logan B E. Hydrogen production from inexhaustible supplies of fresh and salt water using microbial reverse-electrodialysis electrolysis cells[J]. Proc. Natl. Acad. Sci. USA, 2011, 108: 16176-16181. |

| 24 | Hatzell M C, Ivanov I, Cusick R D, et al. Comparison of hydrogen production and electrical power generation for energy capture in closed-loop ammonium bicarbonate reverse electrodialysis systems[J]. Physical Chemistry Chemical Physics, 2014, 16(4): 1632-1638. |

| 25 | Millet P, Grigoriev S. Water electrolysis technologies[M]//Renewable Hydrogen Technologies: Production, Purification, Storage, Applications and Safety. Elsevier, 2013: 19-41. |

| 26 | Nam J Y, Cusick R D, Kim Y, et al. Hydrogen generation in microbial reverse-electrodialysis electrolysis cells using a heat-regenerated salt solution[J]. Environmental Science and Technology, 2012, 46(9): 5240-5246. |

| 27 | Veerman J, Saakes M, Metz S J, et al. Reverse electrodialysis: a validated process model for design and optimization[J]. Chemical Engineering Journal, 2011, 166(1): 256-268. |

| 28 | Hong S K, Kim C S, Hwang K S, et al. Experimental and numerical studies on pressure drop in reverse electrodialysis: effect of unit cell configuration[J]. Journal of Mechanical Science and Technology, 2016, 30(11): 5287-5292. |

| 29 | Hu J Y, Xu S M, Wu X, et al. Exergy analysis for the multi-effect distillation - reverse electrodialysis heat engine[J]. Desalination, 2019, 467: 158-169. |

| 30 | Hu J Y, Xu S M, Wu X, et al. Multi-stage reverse electrodialysis: strategies to harvest salinity gradient energy[J]. Energy Conversion and Management, 2019, 183: 803-815. |

| 31 | Schiebahn S, Grube T, Robinius M, et al. Power to gas: technological overview, systems analysis and economic assessment for a case study in Germany[J]. International Journal of Hydrogen Energy, 2015, 40(12): 4285-4294. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [3] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [4] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [5] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [6] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [7] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [8] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [9] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [10] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [11] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [12] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [13] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [14] | 周小文, 杜杰, 张战国, 许光文. 基于甲烷脉冲法的Fe2O3-Al2O3载氧体还原特性研究[J]. 化工学报, 2023, 74(6): 2611-2623. |

| [15] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号