化工学报 ›› 2020, Vol. 71 ›› Issue (11): 5337-5351.DOI: 10.11949/0438-1157.20200064

收稿日期:2020-01-16

修回日期:2020-06-16

出版日期:2020-11-05

发布日期:2020-11-05

通讯作者:

刘翠伟

作者简介:李玉星(1970—),男,教授,基金资助:

Yuxing LI1,3( ),Yuanbo YIN1,3,Yazhen WANG2,Cuiwei LIU1,3(

),Yuanbo YIN1,3,Yazhen WANG2,Cuiwei LIU1,3( )

)

Received:2020-01-16

Revised:2020-06-16

Online:2020-11-05

Published:2020-11-05

Contact:

Cuiwei LIU

摘要:

天然气泄漏导致的预混爆炸,会严重威胁周围人员的生命及财产安全,因此掌握气体预混爆炸在建筑物周围产生压力场的分布至关重要。基于Fluent软件,建立了适用于甲烷无约束爆炸超压的计算模型,并通过实验数据对其修正,结果表明:在化学计量浓度下参与燃烧爆炸的预混气体体积约为总体积的1/3,即当量体积。在此基础上建立了适用于甲烷约束爆炸的仿真模型,分析了建筑物高度和宽度对建筑周围压力场的影响,并进一步研究了气体爆炸对建筑物内部压力场分布的影响。结果表明,在建筑物不失效前提下,背对爆炸源一侧中上部为较安全区域,在紧急爆炸事故中,盲目的向下逃生,反而容易受到爆炸超压的强烈冲击。

中图分类号:

李玉星,尹渊博,王雅真,刘翠伟. 甲烷爆炸对建筑物内外压力场分布的影响[J]. 化工学报, 2020, 71(11): 5337-5351.

Yuxing LI,Yuanbo YIN,Yazhen WANG,Cuiwei LIU. Effect of methane explosion on distribution of pressure field inside and outside buildings[J]. CIESC Journal, 2020, 71(11): 5337-5351.

| 超压 | 伤害作用 |

|---|---|

| 0.02~0.03 | 轻微损伤 |

| 0.03~0.05 | 听觉器官损伤或骨折 |

| 0.05~0.10 | 内脏严重损伤或死亡 |

| >0.10 | 大部分人员死亡 |

表1 冲击波超压对人体的伤害作用

Table 1 Damage effect of shock wave overpressure on human body

| 超压 | 伤害作用 |

|---|---|

| 0.02~0.03 | 轻微损伤 |

| 0.03~0.05 | 听觉器官损伤或骨折 |

| 0.05~0.10 | 内脏严重损伤或死亡 |

| >0.10 | 大部分人员死亡 |

| 超压 | 破坏作用 |

|---|---|

| 0.005~0.006 | 门窗玻璃部分破碎 |

| 0.006~0.015 | 受压面门窗不玻璃破碎 |

| 0.015~0.02 | 窗框损坏 |

| 0.02~0.03 | 墙裂缝 |

| 0.04~0.05 | 墙大裂缝,屋瓦掉下 |

| 0.06~0.07 | 木建筑房柱折断、松动 |

| 0.07~0.10 | 砖墙倒塌 |

| 0.10~0.20 | 防震钢筋混泥土破坏,小房屋倒塌 |

| 0.20~0.30 | 大型钢架结构破坏 |

表2 冲击波超压对建筑物的破坏作用

Table 2 Damage effect of shock wave overpressure on buildings

| 超压 | 破坏作用 |

|---|---|

| 0.005~0.006 | 门窗玻璃部分破碎 |

| 0.006~0.015 | 受压面门窗不玻璃破碎 |

| 0.015~0.02 | 窗框损坏 |

| 0.02~0.03 | 墙裂缝 |

| 0.04~0.05 | 墙大裂缝,屋瓦掉下 |

| 0.06~0.07 | 木建筑房柱折断、松动 |

| 0.07~0.10 | 砖墙倒塌 |

| 0.10~0.20 | 防震钢筋混泥土破坏,小房屋倒塌 |

| 0.20~0.30 | 大型钢架结构破坏 |

| 编号 | 不同区域网格大小 | 网格数 |

|---|---|---|

| 1# | 点火区0.01 m×0.01 m,可燃物区0.04 m×0.04 m,空气区0.2 m×0.2 m | 23150 |

| 2# | 点火区0.005 m×0.005 m,可燃物区0.02 m×0.02 m,空气区0.1 m×0.1 m | 45044 |

| 3# | 点火区0.0025 m×0.0025 m,可燃物区0.01 m×0.01 m,空气区0.05 m×0.05 m | 65103 |

表3 网格信息

Table3 Grid information

| 编号 | 不同区域网格大小 | 网格数 |

|---|---|---|

| 1# | 点火区0.01 m×0.01 m,可燃物区0.04 m×0.04 m,空气区0.2 m×0.2 m | 23150 |

| 2# | 点火区0.005 m×0.005 m,可燃物区0.02 m×0.02 m,空气区0.1 m×0.1 m | 45044 |

| 3# | 点火区0.0025 m×0.0025 m,可燃物区0.01 m×0.01 m,空气区0.05 m×0.05 m | 65103 |

| 湍流模型 | 峰值超压ΔP/Pa | 到达时间/s |

|---|---|---|

| SAS | 578.87 | 0.19 |

| k-ε standard | 1020.3 | 0.07 |

| k-ε RNG | 不收敛 | |

| k-ε realizable | 805.34 | 0.11 |

| k- | 点火未成功 | |

| k- | 1684.7 | 0.16 |

表4 不同湍流模型峰值超压与到达时间对比

Table 4 Comparison of peak overpressure and arrival time of different turbulence models

| 湍流模型 | 峰值超压ΔP/Pa | 到达时间/s |

|---|---|---|

| SAS | 578.87 | 0.19 |

| k-ε standard | 1020.3 | 0.07 |

| k-ε RNG | 不收敛 | |

| k-ε realizable | 805.34 | 0.11 |

| k- | 点火未成功 | |

| k- | 1684.7 | 0.16 |

| 球体点火区域半径/m | 等价点火能/mJ | 爆炸峰值超压ΔP/Pa |

|---|---|---|

| 0.004 | 100 | 578.87 |

| 0.006 | 350 | 582.15 |

| 0.008 | 830 | 583.67 |

| 0.01 | 1600 | 580.45 |

表5 点火能量对爆炸超压的影响

Table 5 Effect of ignition energy on explosion overpressure

| 球体点火区域半径/m | 等价点火能/mJ | 爆炸峰值超压ΔP/Pa |

|---|---|---|

| 0.004 | 100 | 578.87 |

| 0.006 | 350 | 582.15 |

| 0.008 | 830 | 583.67 |

| 0.01 | 1600 | 580.45 |

| 工况编号 | 预混立方体边长a/m | 甲烷体积浓度/% | 监测体积范围/(m×m) | 点火方式 |

|---|---|---|---|---|

| 1 | 1 | 9.5 | 20×15 | 中心点火 |

| 2 | 2 | 9.5 | 20×15 | 中心点火 |

| 3 | 3 | 9.5 | 20×15 | 中心点火 |

表6 不同体积立方形预混气体爆炸工况条件

Table 6 Explosion conditions of different volume cubic premixed gases

| 工况编号 | 预混立方体边长a/m | 甲烷体积浓度/% | 监测体积范围/(m×m) | 点火方式 |

|---|---|---|---|---|

| 1 | 1 | 9.5 | 20×15 | 中心点火 |

| 2 | 2 | 9.5 | 20×15 | 中心点火 |

| 3 | 3 | 9.5 | 20×15 | 中心点火 |

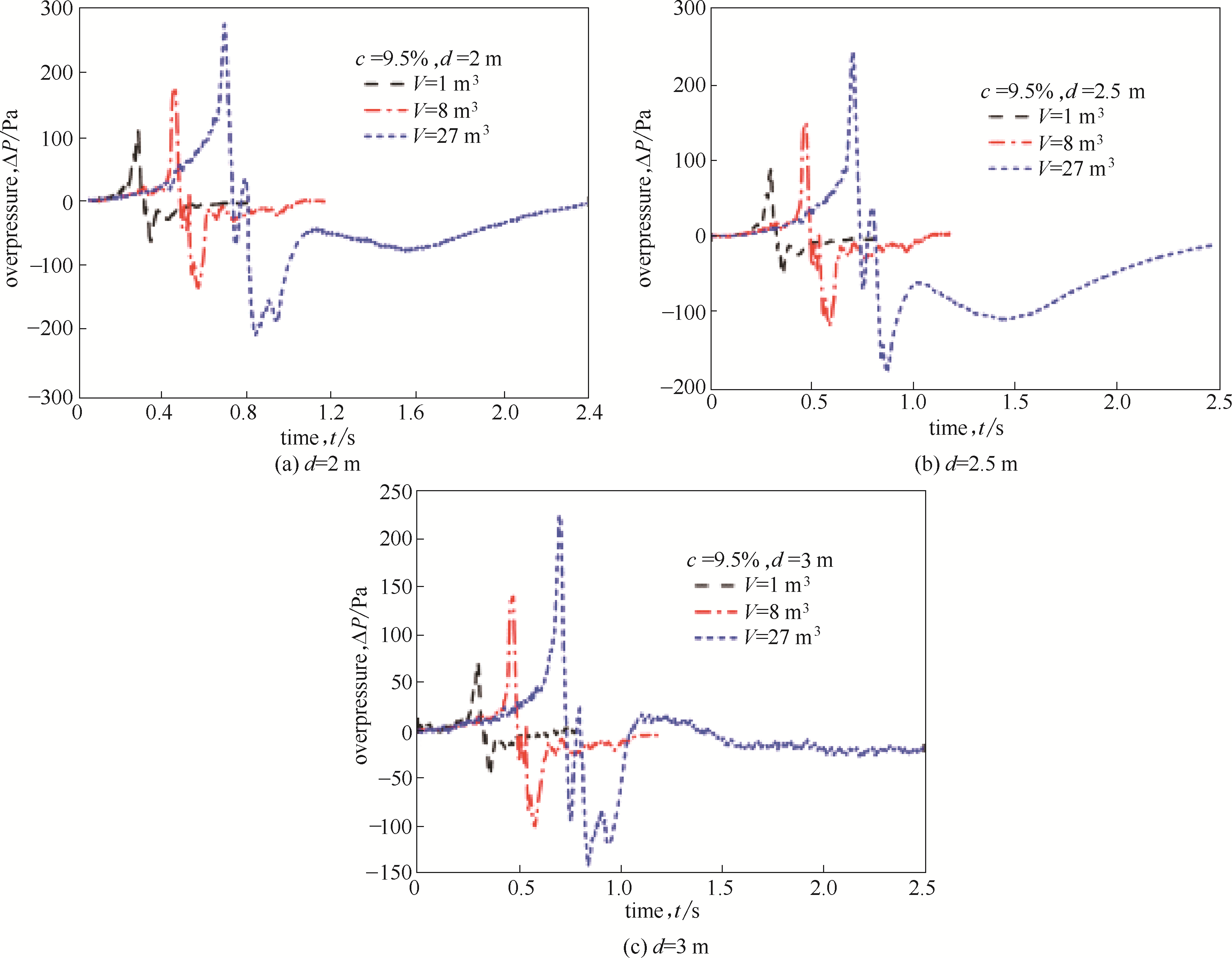

图4 无约束甲烷/空气预混爆炸在不同混合物体积、不同检测距离的实验数据结果

Fig.4 Experimental results for unconstrained methane/air premixed explosions in different mixture volumes and different detection distances

| 预混气云边长/m | 监测点位置/m | 正超压/Pa | 负超压/Pa | ||||

|---|---|---|---|---|---|---|---|

| 模拟值 | 实验值 | 比值 | 模拟值 | 实验值 | 比值 | ||

| 1 | 2 | 252.93 | 108.62 | 2.33 | -180.75 | -64.66 | 2.80 |

| 2.5 | 203.34 | 88.21 | 2.31 | -128.64 | -47.16 | 2.73 | |

| 3 | 165.57 | 69.13 | 2.40 | -112.26 | -45.65 | 2.46 | |

| 2 | 2 | 555.72 | 173.28 | 3.21 | -436.62 | -137.07 | 3.19 |

| 2.5 | 508.08 | 147.16 | 3.45 | -362.61 | -119.21 | 3.04 | |

| 3 | 411.36 | 140.43 | 2.93 | -295.29 | -103.04 | 2.87 | |

| 3 | 2 | 894.93 | 276.72 | 3.23 | -714.45 | -212.06 | 3.37 |

| 2.5 | 763.65 | 241.05 | 3.17 | -567.99 | -178.17 | 3.19 | |

| 3 | 680.22 | 223.91 | 3.04 | -437.85 | -144.78 | 3.02 | |

表7 Fluent模型正负超压原始模拟计算值与实验值对比

Table 7 The positive and negative overpressure original Fluent simulation results and experimental data

| 预混气云边长/m | 监测点位置/m | 正超压/Pa | 负超压/Pa | ||||

|---|---|---|---|---|---|---|---|

| 模拟值 | 实验值 | 比值 | 模拟值 | 实验值 | 比值 | ||

| 1 | 2 | 252.93 | 108.62 | 2.33 | -180.75 | -64.66 | 2.80 |

| 2.5 | 203.34 | 88.21 | 2.31 | -128.64 | -47.16 | 2.73 | |

| 3 | 165.57 | 69.13 | 2.40 | -112.26 | -45.65 | 2.46 | |

| 2 | 2 | 555.72 | 173.28 | 3.21 | -436.62 | -137.07 | 3.19 |

| 2.5 | 508.08 | 147.16 | 3.45 | -362.61 | -119.21 | 3.04 | |

| 3 | 411.36 | 140.43 | 2.93 | -295.29 | -103.04 | 2.87 | |

| 3 | 2 | 894.93 | 276.72 | 3.23 | -714.45 | -212.06 | 3.37 |

| 2.5 | 763.65 | 241.05 | 3.17 | -567.99 | -178.17 | 3.19 | |

| 3 | 680.22 | 223.91 | 3.04 | -437.85 | -144.78 | 3.02 | |

| 分组研究 | 工况编号 | 障碍物高度h/m | 障碍物宽度b/m | 障碍物到爆心距离d/m | 监测体积范围/m×m×m |

|---|---|---|---|---|---|

| A组:障碍物高度研究 | A-1 | 2 | 2 | 2 | 20×20×15 |

| A-2 | 3 | 2 | 2 | 20×20×15 | |

| A-3 | 4 | 2 | 2 | 20×20×15 | |

| A-4 | 5 | 2 | 2 | 20×20×15 | |

| A-5 | 6 | 2 | 2 | 20×20×15 | |

| B组:障碍物宽度研究 | B-1 | 4 | 1 | 2 | 20×20×15 |

| B-2 | 4 | 2 | 2 | 20×20×15 | |

| B-3 | 4 | 3 | 2 | 20×20×15 | |

| B-4 | 4 | 4 | 2 | 20×20×15 | |

| B-5 | 4 | 5 | 2 | 20×20×15 |

表8 障碍物研究工况条件设置表

Table 8 Obstacle research conditions setting table

| 分组研究 | 工况编号 | 障碍物高度h/m | 障碍物宽度b/m | 障碍物到爆心距离d/m | 监测体积范围/m×m×m |

|---|---|---|---|---|---|

| A组:障碍物高度研究 | A-1 | 2 | 2 | 2 | 20×20×15 |

| A-2 | 3 | 2 | 2 | 20×20×15 | |

| A-3 | 4 | 2 | 2 | 20×20×15 | |

| A-4 | 5 | 2 | 2 | 20×20×15 | |

| A-5 | 6 | 2 | 2 | 20×20×15 | |

| B组:障碍物宽度研究 | B-1 | 4 | 1 | 2 | 20×20×15 |

| B-2 | 4 | 2 | 2 | 20×20×15 | |

| B-3 | 4 | 3 | 2 | 20×20×15 | |

| B-4 | 4 | 4 | 2 | 20×20×15 | |

| B-5 | 4 | 5 | 2 | 20×20×15 |

| 工况编号 | ΔPmax+/Pa | ΔPmax-/Pa |

|---|---|---|

| A-3 | 253.04 | -196.93 |

| C | 251.51 | -164.02 |

表9 工况A-3与工况C最大正负超压对比

Table 9 Maximum overpressure comparison between case A-3 and case C

| 工况编号 | ΔPmax+/Pa | ΔPmax-/Pa |

|---|---|---|

| A-3 | 253.04 | -196.93 |

| C | 251.51 | -164.02 |

| 14 | Kim W K. Prediction model for self-similar propagation and blast wave generation of premixed flames[J]. International Journal of Hydrogen Energy, 2015, 40(34): 11087-11092. |

| 15 | Strehlow R A, Luckritz R T, Adamczyk A A, et al. The blast wave generated by spherical flames[J]. Combustion & Flame, 1979, 35(79): 297-310. |

| 16 | Li P L, Huang P, LIU Z Y, et al. Experimental study on vented explosion overpressure of methane/air mixtures in manhole[J]. Journal of Hazardous Materials, 2019, 374(15): 349-355. |

| 17 | Huang K, Sun Z Y, Tian Y C, et al. Turbulent combustion evolution of stoichiometric H2/CH4/air mixtures within a spherical space[J].International Journal of Hydrogen Energy, 2019,45(27): 10613-10622. |

| 18 | Ciccarelli G, Johansen C T, Parravani M. The role of shock-flame interactions on flame acceleration in an obstacle laden channel[J]. Combustion & Flame, 2010, 157(11): 2125-2136. |

| 19 | Harrison A J, Eyre J A. The effect of obstacle arrays on the combustion of large premixed gas/air clouds[J]. Combustion Science and Technology, 1987, 52(1/2/3): 121-137. |

| 20 | Wang C, Huang F, Addai E K, et al. Effect of concentration and obstacles on flame velocity and overpressure of methane-air mixture[J]. Journal of Loss Prevention in the Process Industries, 2016, 43: 302-310. |

| 21 | Hall R, Masri A R, Yaroshchyk P, et al. Effects of position and frequency of obstacles on turbulent premixed propagating flames[J]. Combustion and Flame, 2009, 156(2): 439-446. |

| 22 | Kundu S, Zanganeh J, Moghtaderi B. A review on understanding explosions from methane-air mixture[J]. Journal of Loss Prevention in the Process Industries, 2016, 40: 507-523. |

| 23 | Ibrahim S S, Masri A R. The effects of obstructions on overpressure resulting from premixed flame deflagration[J]. 2001, 14(3): 213-221. |

| 24 | Xu H, Li Y, Zhu P, et al. Experimental study on the mitigation via an ultra-fine water mist of methane/coal dust mixture explosions in the presence of obstacles[J]. Journal of Loss Prevention in the Process Industries, 2013, 26(4): 815-820. |

| 25 | Yu D M, Feng C G, Zeng Q X, et al. The damage of explosions and the division of their injury regions[J]. China Safety Science Journal, 1995(S2):13-17. |

| 1 | Vanderstraeten B, Tuerlinckx D, Berghmans J, et al. Experimental study of the pressure and temperature dependence of the upper flammability limit of methane/air mixtures[J]. Journal of Hazardous Materials, 1997, 56(3): 237-246. |

| 2 | Bunev V A, Bolshova T A, Babkin V S. The nature of the upper laminar flammability limit in methane-air mixtures at high pressures[J]. Doklady Physical Chemistry, 2013, 452(1): 197-199. |

| 3 | Checkel M D, Ting S K, Bushe W K. Flammability limits and burning velocities of ammonia/nitric oxide mixtures[J]. Journal of Loss Prevention in the Process Industries, 1995, 8(4): 215-220. |

| 4 | Chen J R, Tsai H Y, Chien J H, et al. Flow and flame visualization near the upper flammability limits of methane/air and propane/air mixtures at elevated pressures[J]. Journal of Loss Prevention in the Process Industries, 2011, 24(5): 662-670. |

| 5 | Gieras M, Klemens R, Rarata G, et al. Determination of explosion parameters of methane-air mixtures in the chamber of 40 dm3 at normal and elevated temperature[J]. Journal of Loss Prevention in the Process Industries, 2006, 19(2/3): 263-270. |

| 6 | Cui G, Wang S, Liu J G, et al. Explosion characteristics of a methane/air mixture at low initial temperatures[J]. Fuel, 2018, 234(15): 886-893. |

| 7 | Huang L B, Wang Y, Pei S F, et al. Effect of elevated pressure on the explosion and flammability limits of methane-air mixtures[J]. Energy, 2019, 186(1): 115840. |

| 8 | Zheng W, Kaplan C R, Houim R W, et al. Flame acceleration and transition to detonation: effects of a composition gradient in a mixture of methane and air[J]. Proceedings of the Combustion Institute, 2018, 37(3): S1540748918305364. |

| 9 | Guo Y B, He L G, Wang D G, et al. Numerical investigation of surface conduit parallel gas pipeline explosive based on the TNT equivalent weight method[J]. Journal of Loss Prevention in the Process Industries, 2016, 44: 360-368. |

| 10 | Fernando D A, Enrique G F, Juan F S P, et al. Characteristic overpressure–impulse–distance curves for vapour cloud explosions using the TNO multi-energy model[J]. Journal of Hazardous Materials, 2006, 137(2): 734-741. |

| 11 | Dobashi R, Kawamura S, Kuwana K, et al. Consequence analysis of blast wave from accidental gas explosions[J]. Proc. of Combust. Inst., 2011, 33(2): 2295-2301. |

| 12 | Bao Q, Fang Q, Yang S, et al. Experimental investigation on the deflagration load under unconfined methane-air explosions[J]. Fuel, 2016, 185: 565-576. |

| 13 | Gostintsev Y A, Istratov A G, Shulenin Y V. Self-similar propagation of a free turbulent flame in mixed gas mixtures[J]. Combustion Explosion & Shock Waves, 1988, 24(5): 563-569. |

| 26 | 李少鹏, 陈国华, 赵杰, 等. 开敞空间可燃气云爆炸冲击波超压及灾害动力响应研究评述[J]. 中国安全生产科学技术, 2019, 15(11): 11-17. |

| Li S P, Chen G H, Zhao J, et al. Research review on explosion shock wave overpressure and disaster dynamic response of open space combustible gas cloud[J]. Journal of Safety Science and Technology, 2019, 15(11): 11-17. | |

| 27 | 张斌. 大涡模拟滤波网格分析及网格自适应控制研究与应用[D]. 上海: 上海交通大学, 2011. |

| Zhang B. Grid analysis of large eddy simulation filter and research and application of grid adaptive control [D]. Shanghai: Shanghai Jiao Tong University, 2011. | |

| 28 | Ales T, Miroslav M, Kozubková M. CFD simulation of vented explosion and turbulent flame propagation[J]. EPJ Web of Conferences, 2015, 92: 02101. |

| 29 | Kim W K, Mogi T, Kuwana K, et al. Prediction model for self-similar propagation and blast wave generation of premixed flames[J]. International Journal of Hydrogen Energy, 2015, 40(34): 11087-11092. |

| 30 | Kim W K, Mogi T, Kuwana K, et al. Self-similar propagation of expanding spherical flames in large scale gas explosions[J]. Proceedings of the Combustion Institute, 2015, 35(2): 2051-2058. |

| 31 | Malhotra A, Carson D, Mcfadden S. Blast pressure leakage into buildings and effects on humans[J]. Procedia Engineering, 2017, 210: 386-392. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [7] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [8] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [9] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [10] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [11] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [12] | 于旭东, 李琪, 陈念粗, 杜理, 任思颖, 曾英. 三元体系KCl + CaCl2 + H2O 298.2、323.2及348.2 K相平衡研究及计算[J]. 化工学报, 2023, 74(8): 3256-3265. |

| [13] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [14] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [15] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号