化工学报 ›› 2020, Vol. 71 ›› Issue (12): 5452-5460.DOI: 10.11949/0438-1157.20200444

收稿日期:2020-04-29

修回日期:2020-06-29

出版日期:2020-12-05

发布日期:2020-12-05

通讯作者:

丁国良

作者简介:陆天宏(1995—),男,硕士研究生,基金资助:

LU Tianhong( ),ZHOU Faxian,ZHUANG Dawei,DING Guoliang(

),ZHOU Faxian,ZHUANG Dawei,DING Guoliang( )

)

Received:2020-04-29

Revised:2020-06-29

Online:2020-12-05

Published:2020-12-05

Contact:

DING Guoliang

摘要:

通过搭建可视化试验台观测了重力场中水平金属纤维表面的液滴形状,并测量了液滴形状参数,包括液滴直径、高度、接触角、接触线宽度和接触线高度。通过拟合参数关联式,求解了液滴固-液界面子模型和气-液界面子模型的描述方程,开发了一种椭球形的纤维液滴形状模型。液滴模型的轮廓预测结果和观测试验得到的液滴图像吻合度较好,可以在±10%的误差范围内描述98%的试验结果,平均偏差为4.6%。

中图分类号:

陆天宏,周发贤,庄大伟,丁国良. 重力场中水平纤维悬垂液滴形状的模型研究[J]. 化工学报, 2020, 71(12): 5452-5460.

LU Tianhong,ZHOU Faxian,ZHUANG Dawei,DING Guoliang. Model of droplet shape on horizontal metal fiber in gravity field[J]. CIESC Journal, 2020, 71(12): 5452-5460.

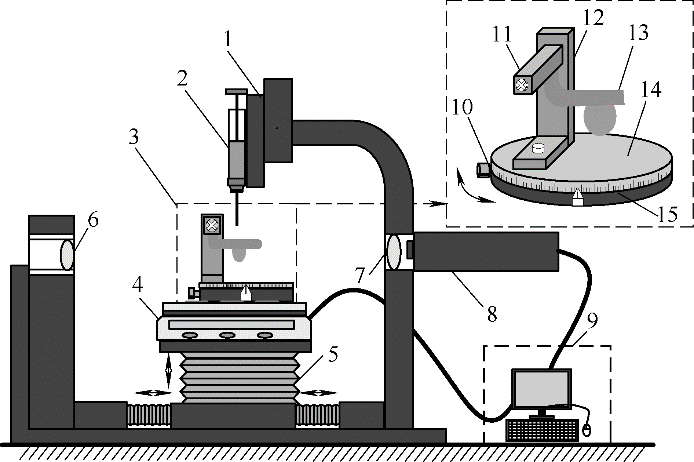

图2 试验装置1—步进电机;2—注射器;3—样件及旋转台;4—电子天平;5—移动平台;6—LED冷光源;7—透镜;8—CCD相机;9—计算机;10—精调螺旋;11—固定螺母;12—固定支架;13—样件;14—旋转台;15—旋转台基座

Fig.2 Schematic diagram of experimental apparatus

| 1 | Zhao C Y, Lu T J, Hodson H P. Thermal radiation in ultralight metal foams with open cells[J]. International Journal of Heat and Mass Transfer, 2004, 47: 2927-2939. |

| 2 | Muzychka Y S. Constructral multi-scale design of compact micro-tube heat sinks and heat exchangers[J]. International Journal of Thermal Sciences, 2007, 46: 245-252. |

| 3 | 李菊香, 涂善东. 多孔泡沫金属换热器内流体的流动和传热分析[J]. 石油化工高等学校学报, 2008, (2): 80-83+88. |

| Li J X, Tu S D. Analysis on flow and heat transfer of fluid in porous metal foam heat exchanger[J]. Journal of Petrochemical Universities, 2008, (2): 80-83+88. | |

| 4 | Lai Z C, Hu H T, Ding G L, et al. Influence of pore density and porosity on the wet air flow in metal foam under different operation conditions[J]. International Journal of Refrigeration, 2018, (88): 117-128. |

| 5 | 屈治国, 徐治国, 陶文铨, 等. 通孔金属泡沫中的空气自然对流传热实验研究[J]. 西安交通大学学报, 2009, 43(1): 1-4. |

| Qu Z G, Xu Z G, Tao W Q, et al. Experimental study of natural convective heat transfer in horizontally -positioned cellular metal foams with open cells[J]. Journal of Xian Jiaotong University, 2009, 43(1): 1-4. | |

| 6 | 朴勇日, 吴晓敏, 马强, 等. 填充泡沫铜圆管内R32单相流动换热[J]. 化工学报, 2017, 68(6): 2275-2279. |

| Pak Y, Wu X M, Ma Q, et al. Single-phase heat transfer characteristics of R32 flowing through metallic foam filled channel[J]. CIESC Journal, 2017, 68(6): 2275-2279. | |

| 7 | Hu H T, Weng X M, Zhuang D W, et al. Heat transfer and pressure drop characteristics of wet air flow in metal foam under dehumidifying conditions[J]. Applied Thermal Engineering, 2016, 93: 1124-1134. |

| 8 | 汪双凤, 李炅, 张伟保. 开孔泡沫金属用于紧凑型热交换器的研究进展[J]. 化工进展, 2008, (5): 675-678. |

| Wang S F, Li J, Zhang W B. Research progress of open cell metal foams used in compact heat exchanger[J]. Chemical Industry and Engineering Progress, 2008, (5): 675-678. | |

| 9 | 程文龙, 韩丰云, 韦文静. 单相流体通过多孔金属换热器换热性能的理论分析[J]. 化工学报, 2011, 62 (10): 2721-2725. |

| Cheng W L, Han F Y, Wei W J. Theoretical analysis on heat transfer in porous metal foam heat exchanger[J]. CIESC Journal, 2011, 62(10): 2721-2725. | |

| 10 | 翁晓敏, 高扬, 许旭东, 等. 湿工况下泡沫金属内换热和压降的数值模拟和实验验证[J]. 化工学报, 2016, 67(4): 1193-1199. |

| Weng X M, Gao Y, Xu X D, et al. Numerical simulation and experimental validation of heat transfer and pressure drop characteristics in metal foam under wet conditions [J]. CIESC Journal, 2016, 67(4): 1193-1199. | |

| 11 | Zhu Y, Hu H T, Sun S, et al. Heat transfer measurements and correlation of refrigerant flow boiling in tube filled with copper foam[J]. International Journal of Refrigeration, 2014, (38): 215-226. |

| 12 | 程云, 李菊香, 莫光东. 水在开孔泡沫铜中的池沸腾传热特性[J]. 化工学报, 2013, 64(4): 1231-1235. |

| Cheng Y, Li J X, Mo G D. Pool boiling heat transfer of water in porous copper foam[J]. CIESC Journal, 2013, 64(4): 1231-1235. | |

| 13 | 冀文涛, 屈治国, 郭剑飞, 等. 水平管外开孔铜泡沫R134a池沸腾换热实验研究[J]. 工程热物理学报, 2010, 31(7): 1185-1188. |

| Ji W T, Qu Z G, Guo J F, et al. Pool boiling heat transfer of R134a outside horizontal open-cell copper foam tubes[J]. Journal of Engineering Thermophysics, 2010, 31(7): 1185-1188. | |

| 14 | Mohammad G, Zhang J. Conjugate solid-liquid phase change heat transfer in heatsink filled with phase change material-metal foam[J]. International Journal of Heat and Mass Transfer, 2020, 146: 118832. |

| 15 | 彭冬华, 陈振乾, 施明恒. 泡沫金属内相变材料融化传热过程的数值模拟[J]. 工程热物理学报, 2009, 30(6): 1025-1028. |

| Peng D H, Chen Z Q, Shi M H. Numerical simulation of phase change material thawing process in metallic foams[J]. Journal of Engineering Thermophysics, 2009, 30(6): 1025-1028. | |

| 16 | 程文龙, 韦文静. 高孔隙率泡沫金属相变材料储能、传热特性[J]. 太阳能学报, 2007, (7): 739-744. |

| Cheng W L, Wei W J. Energy storage and heat transfer characteristics of high porosity foam metal phase change materials[J]. Acta Energiae Solaris Sinica, 2007, (7): 739-744. | |

| 17 | Park K C, Chhatre S S, Strinivasan S, et al. Optimal design of permeable fiber network structures for fog harvesting[J]. Langmuir, 2013, 29(43): 13269-13277. |

| 18 | 赖展程, 胡海涛, 庄大伟, 等. 泡沫金属结构对排水性能的影响[J]. 化工学报, 2016, 67(7): 2756-2760. |

| Lai Z C, Hu H T, Zhuang D W, et al. Influence of structure on drainage performance of metal foam[J]. CIESC Journal, 2016, 67(7): 2756-2760. | |

| 19 | Eral H B, De Ruiter J, De Ruiter R, et al. Drops on functional fibers: from barrels to clamshells and back[J]. Soft Matter, 2011, 7: 5138-5143. |

| 20 | Lu Z, Ng T W, Yu Y. Fast modeling of clam-shell drop morphologies on cylindrical surfaces[J]. International Journal of Heat and Mass Transfer, 2016, 93: 1132-1136. |

| 21 | McHale G, Newton M I, Carroll B J. The shape and stability of small liquid drops on fibers[J]. Oil & Gas Science and Technology, 2001, 56: 47-54. |

| 22 | Davoudi M, Amrei M M, Tafreshi H V, et al. Measurement of inflection angle and correlation of shape factor of barrel-shaped droplets on horizontal fibers[J]. Separation and Purification Technology, 2018, 204: 127-132. |

| 23 | 李健, 程煌煌, 郑科城, 等. 基于液滴轮廓割线的纤维接触角测量方法模拟研究[J]. 科学技术与工程, 2016, 16(13): 190-195. |

| Li J, Cheng H H, Zheng K C, et al. Simulation research on measuring method of fiber contact angle based on drop profile cutting line[J]. Science Technology and Engineering, 2016, 16(13): 190-195. | |

| 24 | McHale G, Newton M I. Global geometry and the equilibrium shapes of liquid drops on fibers[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2002, 206: 79-86. |

| 25 | Amrei M M, Davoudi M, Chase G G, et al. Effects of roughness on droplet apparent contact angles on a fiber[J]. Separation and Purification Technology, 2017, 180: 107-113. |

| 26 | Farhan N M, Aziz H, Tafreshi H V. Simple method for measuring intrinsic contact angle of a fiber with liquids[J]. Experiments in Fluids, 2019, 60: 87. |

| 27 | Berim G O, Ruckenstein E. Cylindrical droplet on nanofibers: a step toward the clam-shell drop description[J]. The Journal of Physical Chemistry B, 2005, 109: 12515-12524. |

| 28 | Farhan N M, Vahedi T H. Universal expression for droplet-fiber detachment force[J]. Journal of Applied Physics, 2018, 124(7): 075301. |

| 29 | 庄大伟, 杨艺菲, 胡海涛, 等. 竖直平板间液桥形状的观测与预测模型开发[J]. 化工学报, 2016, 67(6): 2224-2229. |

| Zhuang D W, Yang Y F, Hu H T, et al. Visualization and prediction model on shape of liquid bridge[J]. CIESC Journal, 2016, 67(6): 2224-2229. | |

| 30 | Yang Y F, Zhuang D W, Ding G L, et al. A mathematic model for predicting the volume of water bridge retaining between vertical fin surfaces[J]. International Journal of Refrigeration, 2016, 67: 157-166. |

| [1] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [2] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [3] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [4] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [5] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [6] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [7] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [8] | 于旭东, 李琪, 陈念粗, 杜理, 任思颖, 曾英. 三元体系KCl + CaCl2 + H2O 298.2、323.2及348.2 K相平衡研究及计算[J]. 化工学报, 2023, 74(8): 3256-3265. |

| [9] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [10] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [11] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [12] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [13] | 尹刚, 李伊惠, 何飞, 曹文琦, 王民, 颜非亚, 向禹, 卢剑, 罗斌, 卢润廷. 基于KPCA和SVM的铝电解槽漏槽事故预警方法[J]. 化工学报, 2023, 74(8): 3419-3428. |

| [14] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [15] | 刘春雨, 周桓宇, 马跃, 岳长涛. CaO调质含油污泥干燥特性及数学模型[J]. 化工学报, 2023, 74(7): 3018-3027. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号