化工学报 ›› 2021, Vol. 72 ›› Issue (S1): 227-235.DOI: 10.11949/0438-1157.20210154

收稿日期:2021-01-25

修回日期:2021-03-01

出版日期:2021-06-20

发布日期:2021-06-20

通讯作者:

高鑫

作者简介:张亚爽(1996—),女,硕士研究生,基金资助:

ZHANG Yashuang( ),LI Hong,CONG Haifeng,HAN Hongming,LI Xingang,GAO Xin(

),LI Hong,CONG Haifeng,HAN Hongming,LI Xingang,GAO Xin( )

)

Received:2021-01-25

Revised:2021-03-01

Online:2021-06-20

Published:2021-06-20

Contact:

GAO Xin

摘要:

微波加热薄膜蒸发技术在促进极性/非极性混合物分离领域潜力巨大,但仍面临着能源利用效率低和加热不均的挑战,而电场分布不均是其根本原因,但影响电场分布的因素十分复杂且不可控,因此,从蒸发器结构及流体流动形式视角出发可为解决微波能高效利用的瓶颈提供新思路。为此本文提出了液桥式螺旋降膜蒸发器,通过COMSOL建立三维模型并模拟计算了微波能强化蒸发器上的螺旋降膜流动与蒸发过程,以蒸发率和温度变异系数作为评价指标,探究液膜厚度、螺距、蒸发器直径、流量以及时间对微波能利用效率的影响规律,研究结果表明该种结构在一定微波入射功率下,液膜蒸发率可达29.26%,温度变异系数降至0.0867,为微波能强化蒸发分离装置的设计提供了依据。

中图分类号:

张亚爽, 李洪, 从海峰, 韩红明, 李鑫钢, 高鑫. 微波强化液桥式螺旋降膜蒸发器数值模拟[J]. 化工学报, 2021, 72(S1): 227-235.

ZHANG Yashuang, LI Hong, CONG Haifeng, HAN Hongming, LI Xingang, GAO Xin. Numerical simulation of microwave-enhanced spiral liquid-bridge falling film evaporator[J]. CIESC Journal, 2021, 72(S1): 227-235.

| 参数 | 数值 |

|---|---|

| 水的介电常数[ | 88.15-0.414T+0.131e-2T2-0.046e-4T3 |

| 水的介电损耗[ | 28.472-0.971T+1.555e-2T2-1.205e-4T3+4.638e-7T4-1.387e-9T5+2.82e-12T6 |

| 初始温度,T0 | 25 K |

| 弹簧截面固定宽度,B | 0.12 mm |

| 蒸发潜热,?Hwater | 2257.6 kJ/kg |

| 玻璃的相对介电常数 | 4.2 |

| 空气的相对介电常数 | 1 |

| 蒸发率测量时间 | 30 min |

表1 基本参数设置

Table 1 Basic parameters setting

| 参数 | 数值 |

|---|---|

| 水的介电常数[ | 88.15-0.414T+0.131e-2T2-0.046e-4T3 |

| 水的介电损耗[ | 28.472-0.971T+1.555e-2T2-1.205e-4T3+4.638e-7T4-1.387e-9T5+2.82e-12T6 |

| 初始温度,T0 | 25 K |

| 弹簧截面固定宽度,B | 0.12 mm |

| 蒸发潜热,?Hwater | 2257.6 kJ/kg |

| 玻璃的相对介电常数 | 4.2 |

| 空气的相对介电常数 | 1 |

| 蒸发率测量时间 | 30 min |

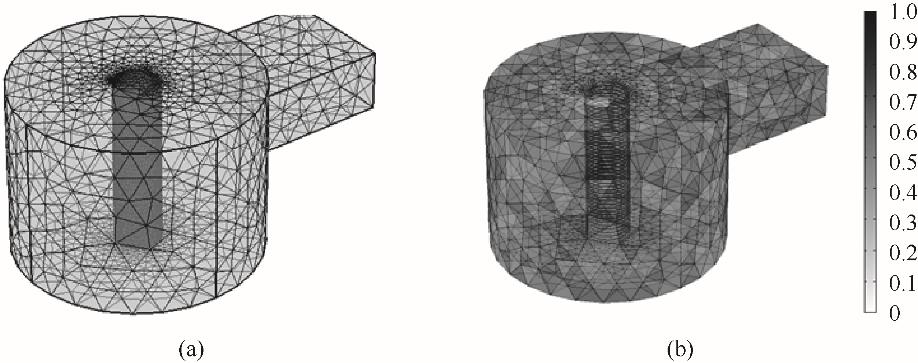

图3 微波辅助螺旋降膜蒸发器的网格划分(a)与质量评价(b)

Fig.3 Meshing scheme (a) and quality evaluation of mesh (b) for microwave-assisted spiral falling film evaporation equipment

| 1 | Stefanidis G D, Muñoz A N, Sturm G S J, et al. A helicopter view of microwave application to chemical processes: reactions, separations, and equipment concepts [J]. Reviews in Chemical Engineering, 2014, 30(3): 233-259. |

| 2 | Wei W, Shao Z S, Zhang Y Y, et al. Fundamentals and applications of microwave energy in rock and concrete processing — a review [J]. Applied Thermal Engineering, 2019, 157: 113751. |

| 3 | Yu S Z, Duan Y, Mao X N, et al. Pyrolysis of methyl ricinoleate by microwave-assisted heating coupled with atomization feeding [J]. Journal of Analytical and Applied Pyrolysis, 2018, 135: 176-183. |

| 4 | Rattanadecho P, Suwannapum N, Watanasungsuit A, et al. Drying of dielectric materials using a continuous microwave belt drier (case study: ceramics and natural rubber) [J]. Journal of Manufacturing Science and Engineering, 2007, 129(1): 157-163. |

| 5 | Meera G, Rohit K R, Saranya S, et al. Microwave assisted synthesis of five membered nitrogen heterocycles [J]. RSC Advances, 2020, 10(59): 36031-36041. |

| 6 | Altman E, Stefanidis G D, van Gerven T, et al. Process intensification of reactive distillation for the synthesis of n-propyl propionate: the effects of microwave radiation on molecular separation and esterification reaction [J]. Industrial & Engineering Chemistry Research, 2010, 49(21): 10287-10296. |

| 7 | Chronopoulos T, Fernandez-Diez Y, Maroto-Valer M M, et al. CO2 desorption via microwave heating for post-combustion carbon capture [J]. Microporous and Mesoporous Materials, 2014, 197: 288-290. |

| 8 | Proestos C, Komaitis M. Application of microwave-assisted extraction to the fast extraction of plant phenolic compounds [J]. LWT - Food Science and Technology, 2008, 41(4): 652-659. |

| 9 | Jacotet-Navarro M, Rombaut N, Fabiano-Tixier A S, et al. Ultrasound versus microwave as green processes for extraction of rosmarinic, carnosic and ursolic acids from rosemary [J]. Ultrasonics Sonochemistry, 2015, 27: 102-109. |

| 10 | Gao X, Shu D D, Li X G, et al. Improved film evaporator for mechanistic understanding of microwave-induced separation process [J]. Frontiers of Chemical Science and Engineering, 2019, 13(4): 759-771. |

| 11 | Li H, Liu J H, Li X G, et al. Microwave-induced polar/nonpolar mixture separation performance in a film evaporation process [J]. AIChE Journal, 2019, 65(2): 745-754. |

| 12 | 黄卡玛, 杨晓庆. 微波加快化学反应中非热效应研究的新进展[J]. 自然科学进展, 2006, 16(3): 273-279. |

| Huang K M, Yang X Q. New progress in research on non-thermal effects in microwave accelerated chemical reaction [J]. Process in Natural Science, 2006, 16(3): 273-279. | |

| 13 | Ayappa K G, Brandon S, Derby J J, et al. Microwave driven convection in a square cavity [J]. AIChE Journal, 1994, 40(7): 1268-1272. |

| 14 | Santos T, Valente M A, Monteiro J, et al. Electromagnetic and thermal history during microwave heating [J]. Applied Thermal Engineering, 2011, 31(16): 3255-3261. |

| 15 | Tang Z M, Huang K M, Liao Y H, et al. Study on stability of electric field in multimode microwave heating cavity [J]. International Journal of Applied Electromagnetics and Mechanics, 2016, 50(2): 321-330. |

| 16 | Sturm G S J, Verweij M D, Gerven T V, et al. On the parametric sensitivity of heat generation by resonant microwave fields in process fluids [J]. International Journal of Heat and Mass Transfer, 2013, 57(1): 375-388. |

| 17 | Gao X, Liu X S, Yan P, et al. Numerical analysis and optimization of the microwave inductive heating performance of water film [J]. International Journal of Heat and Mass Transfer, 2019, 139: 17-30. |

| 18 | Pham N D, Khan M I H, Karim M A. A mathematical model for predicting the transport process and quality changes during intermittent microwave convective drying [J]. Food Chemistry, 2020, 325: 126932. |

| 19 | Sebera V, Nasswettrová A, Nikl K. Finite element analysis of mode stirrer impact on electric field uniformity in a microwave applicator [J]. Drying Technology, 2012, 30(13): 1388-1396. |

| 20 | 曹湘琪, 姚斌, 郑勤红, 等. 凹弧面内筒壁对微波反应器加热效率及均匀性的影响[J]. 现代制造工程, 2016, (9): 13-16, 38. |

| Cao X Q, Yao B, Zheng Q H, et al. Influence of the cylindrical inner wall for concave cambered surface to microwave heating efficiency and uniformity [J]. Modern Manufacturing Engineering, 2016, (9): 13-16, 38. | |

| 21 | Feng H, Yin Y, Tang J M. Microwave drying of food and agricultural materials: basics and heat and mass transfer modeling [J]. Food Engineering Reviews, 2012, 4(2): 89-106. |

| 22 | Nishioka M, Miyakawa M, Daino Y, et al. Single-mode microwave reactor used for continuous flow reactions under elevated pressure [J]. Industrial & Engineering Chemistry Research, 2013, 52(12): 4683-4687. |

| 23 | 李伊帆, 王凤霞, 解田, 等. 双端口旋转对微波加热均匀性和互耦的影响 [J]. 太赫兹科学与电子信息学报, 2020, 18(2): 264-268, 277. |

| Li Y F, Wang F X, Xie T, et al. Influence of dual port rotation on microwave heating uniformity and mutual coupling [J]. Journal of Terahertz Science and Electronic Information Technology, 2020, 18(2): 264-268, 277. | |

| 24 | 王永福, 周荣琪, 段占庭. 二元混合物降膜蒸发的数值模拟[J]. 化工学报, 2002, 53(9): 946-950. |

| Wang Y F, Zhou R Q, Duan Z T. Numerical simulation of falling film evaporation of binary mixture [J]. Journal of Chemical Industry and Engineering (China), 2002, 53(9): 946-950. | |

| 25 | Yeong S P, Law M C, Lee C C V, et al. Modelling batch microwave heating of water [J]. IOP Conference Series: Materials Science and Engineering, 2017, 217: 012035. |

| 26 | Wu Y Y. Simultaneous heat and mass transfer in laminar falling film on the outside of a circular tube [J]. International Journal of Heat and Mass Transfer, 2016, 93: 1089-1099. |

| 27 | Lee G L, Law M C, Lee V C C. Numerical modelling of liquid heating and boiling phenomena under microwave irradiation using OpenFOAM [J]. International Journal of Heat and Mass Transfer, 2020, 148: 119096. |

| 28 | Carwile L C, Hoge H J. Thermal conductivity of Pyrex glass: selected values [R]. Defense Technical Information Center, 1966. |

| 29 | Li H, Shi S L, Lin B Q, et al. A fully coupled electromagnetic, heat transfer and multiphase porous media model for microwave heating of coal [J]. Fuel Processing Technology, 2019, 189: 49-61. |

| 30 | 卿培亮. 微波加热管内降膜蒸发过程的传热研究[D]. 成都: 四川大学, 2006. |

| Qing P L. Investigation on heat transfer of falling film evaporation by microwave heating [D]. Chengdu: Sichuan University, 2006. | |

| 31 | Cong H F, Zhao Z Y, Li X G, et al. Liquid-bridge flow in the channel of helical string and its application to gas-liquid contacting process [J]. AIChE Journal, 2018, 64(9): 3360-3368. |

| 32 | Kent S, Kent E F. Microwave heating of dielectric lossy objects [J]. Journal of Microwave Power and Electromagnetic Energy, 2002, 37(2): 63-71. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [7] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [8] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [9] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [10] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [11] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [12] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [13] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [14] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [15] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号