化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5082-5093.DOI: 10.11949/0438-1157.20210355

高颂1,2( ),徐燕燕1,2,3,李继香1,2,叶爽1,2(

),徐燕燕1,2,3,李继香1,2,叶爽1,2( ),黄伟光1,2,3

),黄伟光1,2,3

收稿日期:2021-03-09

修回日期:2021-08-15

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

叶爽

作者简介:高颂(1996—),男,基金资助:

Song GAO1,2( ),Yanyan XU1,2,3,Jixiang LI1,2,Shuang YE1,2(

),Yanyan XU1,2,3,Jixiang LI1,2,Shuang YE1,2( ),Weiguang HUANG1,2,3

),Weiguang HUANG1,2,3

Received:2021-03-09

Revised:2021-08-15

Online:2021-10-05

Published:2021-10-05

Contact:

Shuang YE

摘要:

了解离心泵内微气泡的发生特性,对于优化现有基于旋转流场的微气泡发生装置的性能、提高工业废水废气的污染物去除率至关重要。在考虑气泡破碎合并的前提下,通过将双流体模型(TFM)与群体平衡模型(PBM)进行耦合,求解离心泵内气液两相旋转流场,研究了入口体积气含率(IGVF)、入口气泡尺寸对泵内气泡沿程尺寸变化、出口气泡尺寸分布的影响,并结合Luo等的破碎合并模型分析成因。结果表明,随IGVF增加,叶轮内气体聚集引起局部气含率陡升,气泡由破碎主导转变为合并主导,而后在蜗壳内气含率恢复正常,气泡又变为破碎主导,总体上出口气泡尺寸逐渐增大。另外,入口气泡尺寸对出口气泡尺寸的影响对IGVF敏感,当IGVF较低时,随入口气泡尺寸增大,出口气泡尺寸先增大后减小;而当IGVF较高时,由于泵内气体聚集,入口气泡尺寸的影响并不明显。

中图分类号:

高颂,徐燕燕,李继香,叶爽,黄伟光. 基于TFM-PBM耦合模型的离心泵内微气泡破碎合并的模拟研究[J]. 化工学报, 2021, 72(10): 5082-5093.

Song GAO,Yanyan XU,Jixiang LI,Shuang YE,Weiguang HUANG. Simulation study of microbubbles' break-up and coalescence in centrifugal pump based on TFM-PBM coupling model[J]. CIESC Journal, 2021, 72(10): 5082-5093.

| 流量 | 扬程 | 转速 | 叶轮入口直径 | 叶轮出口直径 | 叶片出口宽度 | 出口直径D3/mm | 叶片数Z |

|---|---|---|---|---|---|---|---|

| Q/(m3/h) | H/mm | n/(r/min) | D1/mm | D2/mm | b2/mm | ||

| 15 | 17 | 3000 | 50 | 115 | 9.2 | 40 | 7 |

表 1 离心泵的主要设计参数

Table 1 Parameters of centrifugal pump

| 流量 | 扬程 | 转速 | 叶轮入口直径 | 叶轮出口直径 | 叶片出口宽度 | 出口直径D3/mm | 叶片数Z |

|---|---|---|---|---|---|---|---|

| Q/(m3/h) | H/mm | n/(r/min) | D1/mm | D2/mm | b2/mm | ||

| 15 | 17 | 3000 | 50 | 115 | 9.2 | 40 | 7 |

| 气泡组 | 直径/mm |

|---|---|

| bin0 | 10 |

| bin1 | 5.99 |

| bin2 | 3.59 |

| bin3 | 2.15 |

| bin4 | 1.29 |

| bin5 | 0.77 |

| bin6 | 0.46 |

| bin7 | 0.28 |

| bin8 | 0.17 |

| bin9 | 0.1 |

表2 PBM模型气泡尺寸离散

Table 2 Discrete bubble sizes in PBM

| 气泡组 | 直径/mm |

|---|---|

| bin0 | 10 |

| bin1 | 5.99 |

| bin2 | 3.59 |

| bin3 | 2.15 |

| bin4 | 1.29 |

| bin5 | 0.77 |

| bin6 | 0.46 |

| bin7 | 0.28 |

| bin8 | 0.17 |

| bin9 | 0.1 |

| 固定参数 | 对照组 |

|---|---|

| 1500,bin4,7.7 m3/h (42%Qmax) | |

| 1800,bin4,9.16 m3/h (42%Qmax) | |

| 1500,0.32%,7.7 m3/h (42%Qmax) | bin2,bin3,bin4,bin5,bin6,bin7 |

| 1500,3.25%,7.7 m3/h (42%Qmax) | bin2,bin3,bin4,bin5,bin6,bin7 |

| 1500,4.86%,7.7 m3/h (42%Qmax) | bin3,bin4,bin5,bin6 |

表3 TFM-PBM数值模拟方案

Table 3 TFM-PBM simulation scheme

| 固定参数 | 对照组 |

|---|---|

| 1500,bin4,7.7 m3/h (42%Qmax) | |

| 1800,bin4,9.16 m3/h (42%Qmax) | |

| 1500,0.32%,7.7 m3/h (42%Qmax) | bin2,bin3,bin4,bin5,bin6,bin7 |

| 1500,3.25%,7.7 m3/h (42%Qmax) | bin2,bin3,bin4,bin5,bin6,bin7 |

| 1500,4.86%,7.7 m3/h (42%Qmax) | bin3,bin4,bin5,bin6 |

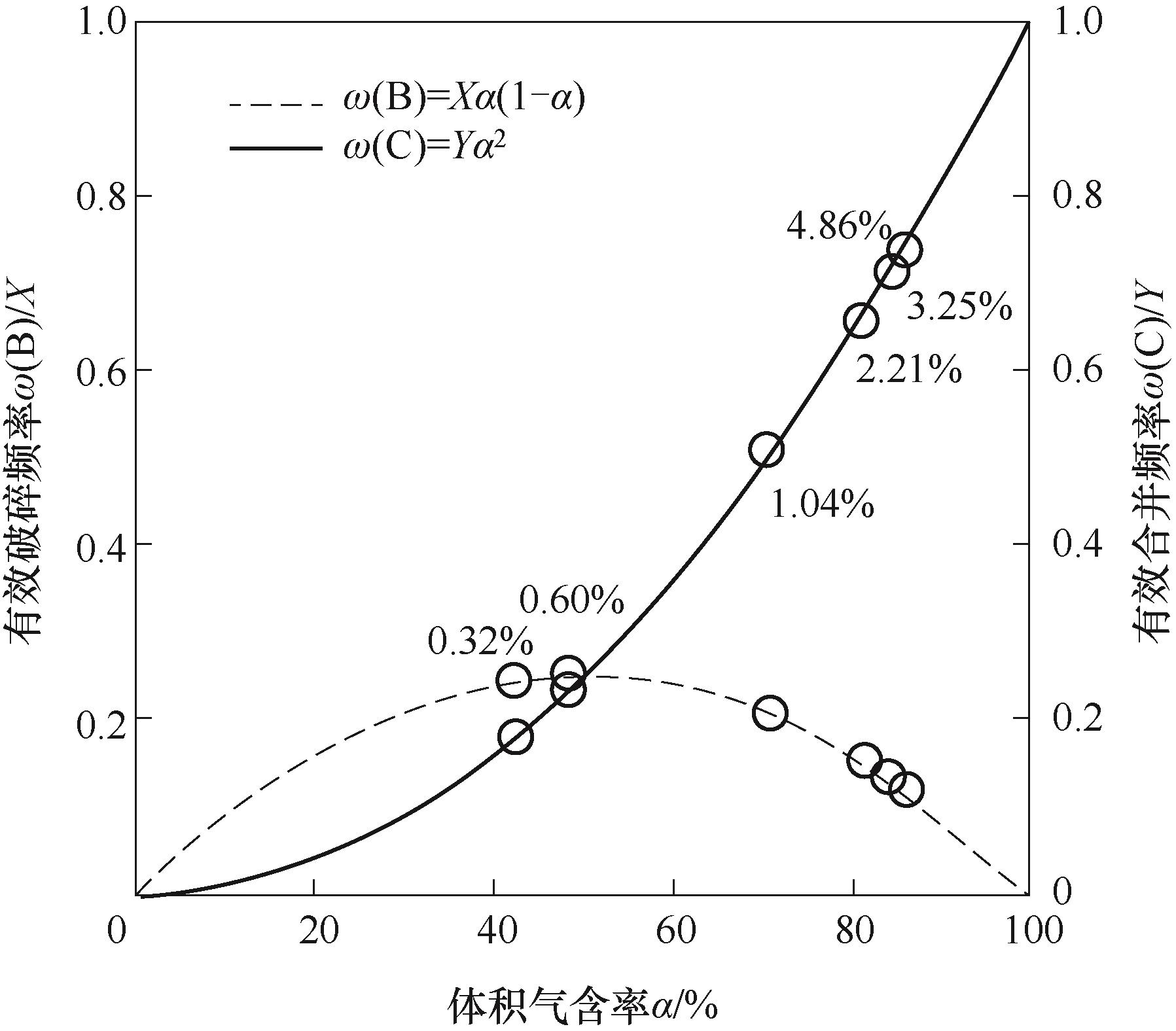

图6 有效破碎频率ω(B)、有效合并频率ω(C) 随体积气含率(α)的变化

Fig.6 Effective break-up frequency ω(B) and effective coalescence frequency ωC under different gas volume fraction α

| 入口体积气含率IGVF/% | 蜗壳内平均湍流耗散率ε/(m2/s3) |

|---|---|

| 0.32 | 17 |

| 0.60 | 17 |

| 1.04 | 19 |

| 2.21 | 26 |

| 3.25 | 38 |

| 4.86 | 42 |

表4 蜗壳内湍流耗散率随IGVF变化

Table 4 Turbulent dissipation rate of impeller and volute under different inlet gas volume fraction

| 入口体积气含率IGVF/% | 蜗壳内平均湍流耗散率ε/(m2/s3) |

|---|---|

| 0.32 | 17 |

| 0.60 | 17 |

| 1.04 | 19 |

| 2.21 | 26 |

| 3.25 | 38 |

| 4.86 | 42 |

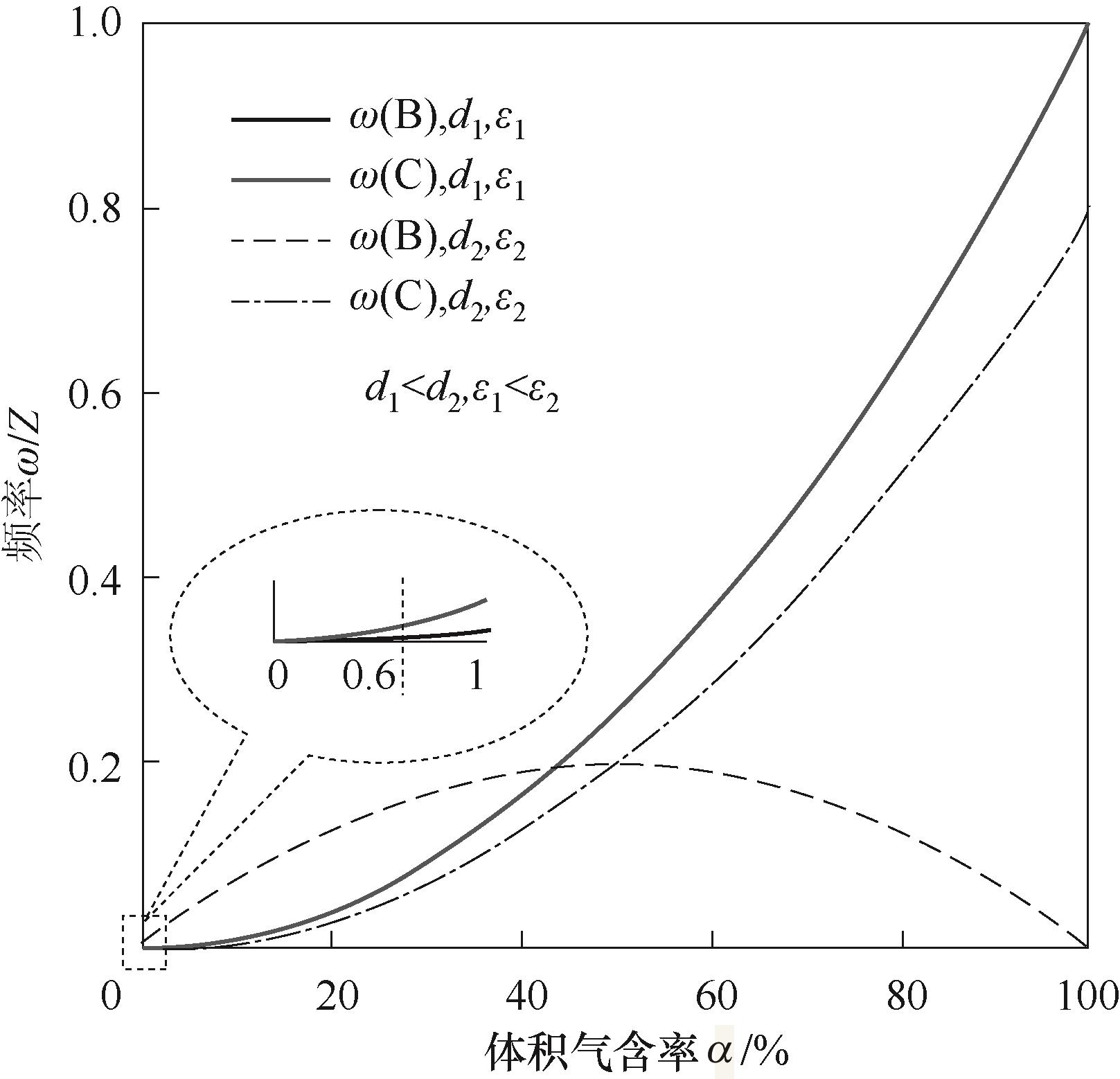

图7 有效破碎频率ω(B)、有效合并频率ω(C)随体积气含率(α)的变化

Fig.7 Effective break-up frequency ω(B) and effective coalescence frequency ωC under different gas volume fraction α

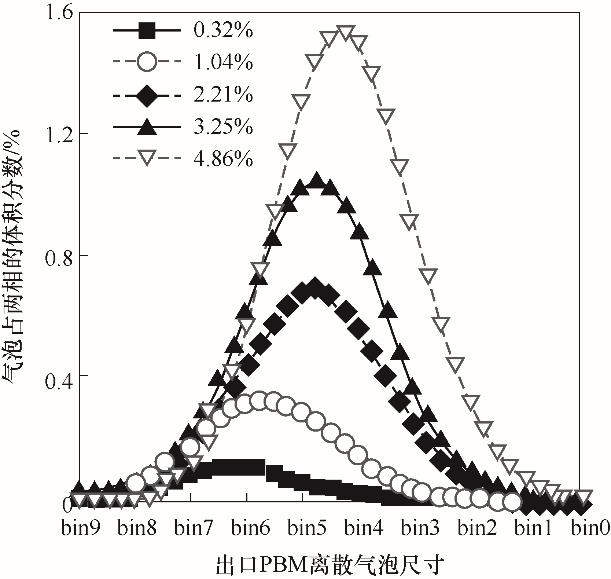

图10 泵出口气泡尺寸分布随IGVF变化(占两相,din=bin4)

Fig.10 Bubble size distribution at outlet of pump under different inlet gas volume fraction (by two-phase, din=bin4)

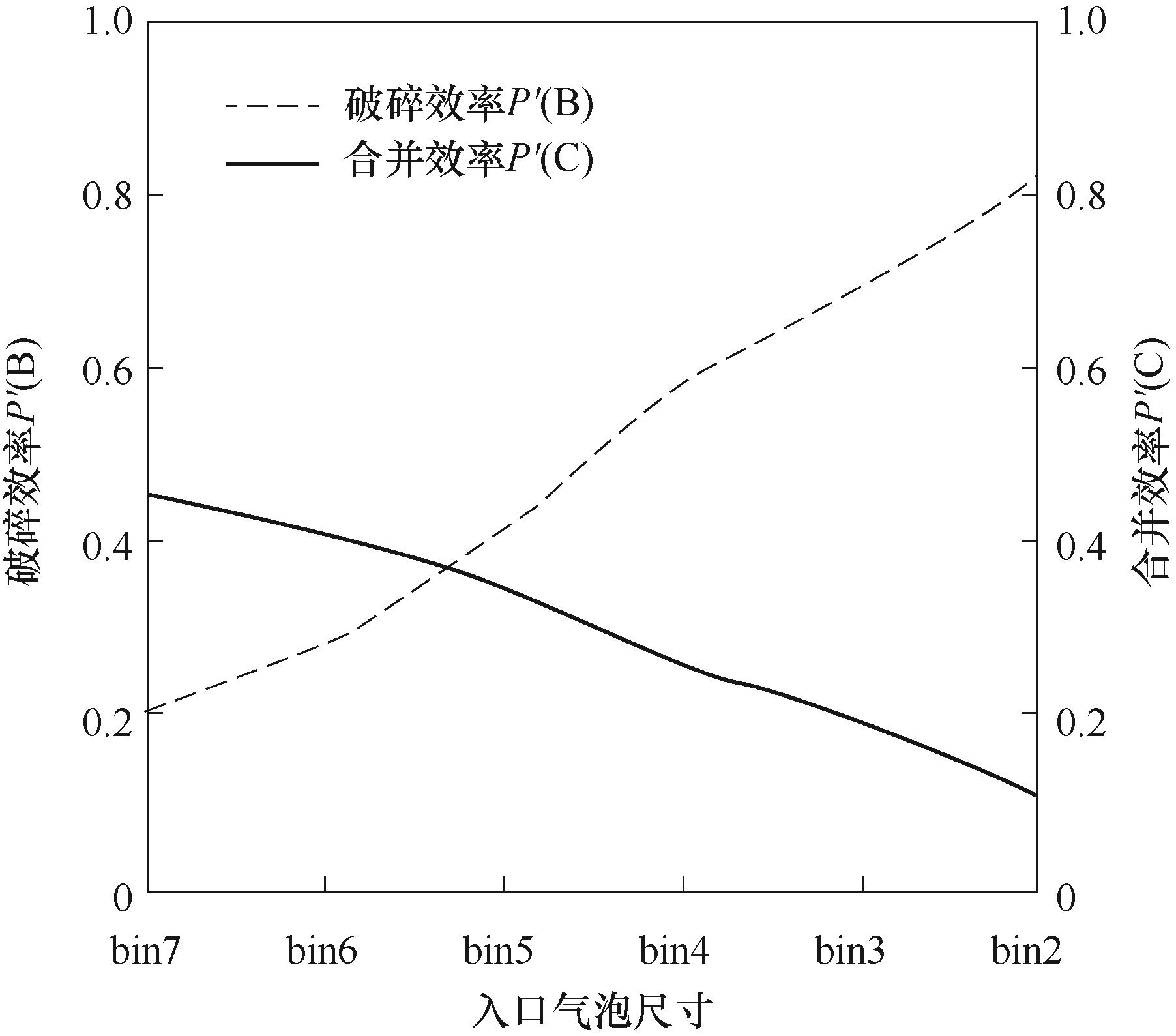

图12 叶轮内破碎效率P′(B)、合并效率P′(C)随入口气泡尺寸的变化 (IGVF=0.32%)

Fig.12 Break-up efficiency P′(B) and coalescence efficiency P′(C) in impeller under different inlet bubble size (IGVF=0.32%)

| 1 | Temesgen T, Bui T T, Han M, et al. Micro and nanobubble technologies as a new horizon for water-treatment techniques: a review[J]. Advances in Colloid and Interface Science, 2017, 246: 40-51. |

| 2 | Zhao D Z, Ding T Y, Li X S, et al. Ozone catalytic oxidation of HCHO in air over MnOx at room temperature[J]. Chinese Journal of Catalysis, 2012, 33(2/3): 396-401. |

| 3 | Xu Q Y, Nakajima M, Ichikawa S, et al. A comparative study of microbubble generation by mechanical agitation and sonication[J]. Innovative Food Science & Emerging Technologies, 2008, 9(4): 489-494. |

| 4 | Dupre V, Ponasse M, Aurelle Y, et al. Bubble formation by water release in nozzles(Ⅰ): Mechanisms[J]. Water Research, 1998, 32(8): 2491-2497. |

| 5 | Ahmed N, Jameson G J. The effect of bubble size on the rate of flotation of fine particles[J]. International Journal of Mineral Processing, 1985, 14(3): 195-215. |

| 6 | Hulburt H M, Katz S. Some problems in particle technology: a statistical mechanical formulation[J]. Chemical Engineering Science, 1964, 19(8): 555-574. |

| 7 | Kuboi R, Komasawa I, Otake T. Behavior of dispersed particles in turbulent liquid flow[J]. Journal of Chemical Engineering of Japan, 1972, 5(4): 349-355. |

| 8 | Kuboi R, Komasawa I, Otake T. Collision and coalescence of dispersed drops in turbulent liquid flow[J]. Journal of Chemical Engineering of Japan, 1972, 5(4): 423-424. |

| 9 | Coulaloglou C A, Tavlarides L L. Description of interaction processes in agitated liquid-liquid dispersions[J]. Chemical Engineering Science, 1977, 32(11): 1289-1297. |

| 10 | Lee C H, Erickson L E, Glasgow L A. Bubble breakup and coalescence in turbulent gas-liquid dispersions[J]. Chemical Engineering Communications, 1987, 59(1/2/3/4/5/6): 65-84. |

| 11 | Prince M J, Blanch H W. Bubble coalescence and break-up in air-sparged bubble columns[J]. AIChE Journal, 1990, 36(10): 1485-1499. |

| 12 | Luo H. Coalescence, breakup and liquid circulation in bubble column reactors[D]. Trondheim: The University of Trondheim, 1993. |

| 13 | Luo H, Svendsen H F. Theoretical model for drop and bubble breakup in turbulent dispersions[J]. AIChE Journal, 1996, 42(5): 1225-1233. |

| 14 | Murakami M, Minemura K. Effects of entrained air on the performance of a centrifugal pump: 1st report, performance and flow conditions[J]. Bulletin of JSME, 1974, 17(110): 1047-1055. |

| 15 | Murakami M, Minemura K. Effects of entrained air on the performance of centrifugal pumps: 2nd report, effects of number of blades[J]. Bulletin of JSME, 1974, 17(112): 1286-1295. |

| 16 | Minemura K, Murakami M. A theoretical study on air bubble motion in a centrifugal pump impeller[J]. Journal of Fluids Engineering, 1980, 102(4): 446-453. |

| 17 | Patel B R, Runstadler P W. Investigations into the two-phase behavior of centrifugal pumps[C]//Polyphase Flow in Turbomachinery. ASME, 1978: 79-100. |

| 18 | Falcimaigne J R. Multiphase flow: a cost-efficient solution for marginal field developments[C]// Proceedings of European Petroleum Conference. Cannes, France, 1992: 25-64. |

| 19 | Kumar S, Ramkrishna D. On the solution of population balance equations by discretization(I): A fixed pivot technique[J]. Chemical Engineering Science, 1996, 51(8): 1311-1332. |

| 20 | Lehr F, Mewes D. A transport equation for the interfacial area density applied to bubble columns[J]. Chemical Engineering Science, 2001, 56(3): 1159-1166. |

| 21 | Venneker B C H, Derksen J J, van den Akker H E A. Population balance modeling of aerated stirred vessels based on CFD[J]. AIChE Journal, 2002, 48(4): 673-685. |

| 22 | Zhu J J, Zhu H W, Zhang J C, et al. A numerical study on flow patterns inside an electrical submersible pump (ESP) and comparison with visualization experiments[J]. Journal of Petroleum Science and Engineering, 2019, 173: 339-350. |

| 23 | He D H, Ge Z G, Bai B F, et al. Gas–liquid two-phase performance of centrifugal pump under bubble inflow based on computational fluid dynamics–population balance model coupling model[J]. Journal of Fluids Engineering, 2020, 142(8): 081402. |

| 24 | Ge Z G, He D H, Huang R, et al. Application of CFD-PBM coupling model for analysis of gas-liquid distribution characteristics in centrifugal pump[J]. Journal of Petroleum Science and Engineering, 2020, 194: 107518. |

| 25 | 张振铎. 泡状入流条件下离心泵叶轮内气液两相流动特性及对泵性能影响实验研究[D]. 西安: 西安理工大学, 2019. |

| Zhang Z D. Experimental study on gas-liquid flow characteristics and pump performance of centrifugal pump impeller under bubble inflow[D]. Xi'an: Xi'an University of Technology, 2019. | |

| 26 | Ishii M, Hibiki T. Thermo-fluid Dynamics of Two-phase Flow[M]. New York: Springer, 2011. |

| 27 | Maxey M R, Riley J J. Equation of Motion for a small rigid sphere in a nonuniform flow[J]. The Physics of Fluids, 1983, 26(4): 883-889. |

| 28 | Legendre D, Magnaudet J. The lift force on a spherical bubble in a viscous linear shear flow[J]. Journal of Fluid Mechanics, 1998, 368: 81-126. |

| 29 | Thomas B G, Najjar F M. Finite element modelling of turbulent fluid flow and heat transfer in continuous casting[J]. Applied Mathematical Modelling, 1991, 15(5): 226-243. |

| 30 | 戈振国. 基于CFD-PBM耦合模型的离心泵气液两相流动特性研究[D]. 西安: 西安理工大学, 2019. |

| Ge Z. Investigaton on gas-liquid two-phase flow characteristics of centrifugal pump based on CFD-PBM coupling model[D]. Xi'an: Xi'an University of Technology, 2019. | |

| 31 | Si Q R, Bois G, Liao M Q, et al. A comparative study on centrifugal pump designs and two-phase flow characteristic under inlet gas entrainment conditions[J]. Energies, 2019, 13(1): 65. |

| 32 | Monte Verde W, Biazussi J L, Sassim N A, et al. Experimental study of gas-liquid two-phase flow patterns within centrifugal pumps impellers[J]. Experimental Thermal and Fluid Science, 2017, 85: 37-51. |

| 33 | Zhang J Y, Cai S J, Li Y J, et al. Visualization study of gas-liquid two-phase flow patterns inside a three-stage rotodynamic multiphase pump[J]. Experimental Thermal and Fluid Science, 2016, 70: 125-138. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [3] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [4] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [5] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [6] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [7] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [8] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [9] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [10] | 王瑞恒, 何品晶, 吕凡, 章骅. 垃圾焚烧飞灰水洗后三种固液分离方法参数比较及优化[J]. 化工学报, 2023, 74(4): 1712-1723. |

| [11] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [12] | 白剑钊, 郭子轩, 王德武, 刘燕, 王若瑾, 唐猛, 张少峰. 摇摆对气液并流模式立体旋流筛板压降的影响研究[J]. 化工学报, 2023, 74(2): 707-720. |

| [13] | 盛林, 昌宇, 邓建, 骆广生. 阶梯式T型微通道内有序气泡群的形成和流动特性研究[J]. 化工学报, 2023, 74(1): 416-427. |

| [14] | 苏巧玲, 王军锋, 张伟, 詹水清, 吴天一. 低电导率工质中气泡的极化运动实验研究[J]. 化工学报, 2022, 73(9): 3861-3869. |

| [15] | 张童, 杨扬, 叶丁丁, 陈蓉, 朱恂, 廖强. 催化剂分布对可渗透阳极微流体燃料电池性能特性影响的研究[J]. 化工学报, 2022, 73(9): 4156-4162. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号