化工学报 ›› 2023, Vol. 74 ›› Issue (2): 707-720.DOI: 10.11949/0438-1157.20221393

白剑钊1( ), 郭子轩1, 王德武1,2, 刘燕1, 王若瑾1, 唐猛3(

), 郭子轩1, 王德武1,2, 刘燕1, 王若瑾1, 唐猛3( ), 张少峰1,2(

), 张少峰1,2( )

)

收稿日期:2022-10-21

修回日期:2022-12-29

出版日期:2023-02-05

发布日期:2023-03-21

通讯作者:

唐猛,张少峰

作者简介:白剑钊(1996—),男,硕士研究生,852521522@qq.com

基金资助:

Jianzhao BAI1( ), Zixuan GUO1, Dewu WANG1,2, Yan LIU1, Ruojin WANG1, Meng TANG3(

), Zixuan GUO1, Dewu WANG1,2, Yan LIU1, Ruojin WANG1, Meng TANG3( ), Shaofeng ZHANG1,2(

), Shaofeng ZHANG1,2( )

)

Received:2022-10-21

Revised:2022-12-29

Online:2023-02-05

Published:2023-03-21

Contact:

Meng TANG, Shaofeng ZHANG

摘要:

以空气-水为实验介质,在喷淋密度78~182 m3·(m2·h)-1、气相动能因子1.19~2.77 m·s-1·(kg·m-3)0.5、摇摆幅值Θ=5°~15°、周期T=8~20 s的条件下,测定了气液并流模式下立体旋流筛板(TRST)的压降,考察了气液通量、塔板数量、位置和方式对压降的影响,并与直立和倾斜工况对比。结果表明:增加倾斜及摇摆角度干板压降略微下降;摇摆时的湿板压降介于直立和倾斜之间,受摇摆角度影响较大,基本不受周期影响;增大气量有利于抵抗倾斜及摇摆的影响,而增大液量会使倾斜及摇摆的影响作用加剧。整体上,塔板顺、逆向安装时的湿板压降分别在100 Pa和170 Pa以内,而逆向安装的变化率约为顺向的2倍,这是由于逆向安装下改变了气液流动方向,增大了能量损失。建立了气液并流摇摆工况下TRST的湿压降预测模型,相对误差在15%以内。

中图分类号:

白剑钊, 郭子轩, 王德武, 刘燕, 王若瑾, 唐猛, 张少峰. 摇摆对气液并流模式立体旋流筛板压降的影响研究[J]. 化工学报, 2023, 74(2): 707-720.

Jianzhao BAI, Zixuan GUO, Dewu WANG, Yan LIU, Ruojin WANG, Meng TANG, Shaofeng ZHANG. Effect of roll on pressure drop in concurrent gas-liquid columns with tridimensional rotational flow sieve tray[J]. CIESC Journal, 2023, 74(2): 707-720.

| 参数 | 数值 |

|---|---|

| 塔板高度h/mm | 25 |

| 外筒直径/mm | 69 |

| 内筒直径/mm | 13 |

| 扭转角β/(°) | 90 |

| 筛板厚度/mm | 1.5 |

| 筛孔个数 | 45 |

| 筛孔直径/mm | 2.5 |

表1 TRST几何结构参数

Table 1 Geometric parameters of TRST structure

| 参数 | 数值 |

|---|---|

| 塔板高度h/mm | 25 |

| 外筒直径/mm | 69 |

| 内筒直径/mm | 13 |

| 扭转角β/(°) | 90 |

| 筛板厚度/mm | 1.5 |

| 筛孔个数 | 45 |

| 筛孔直径/mm | 2.5 |

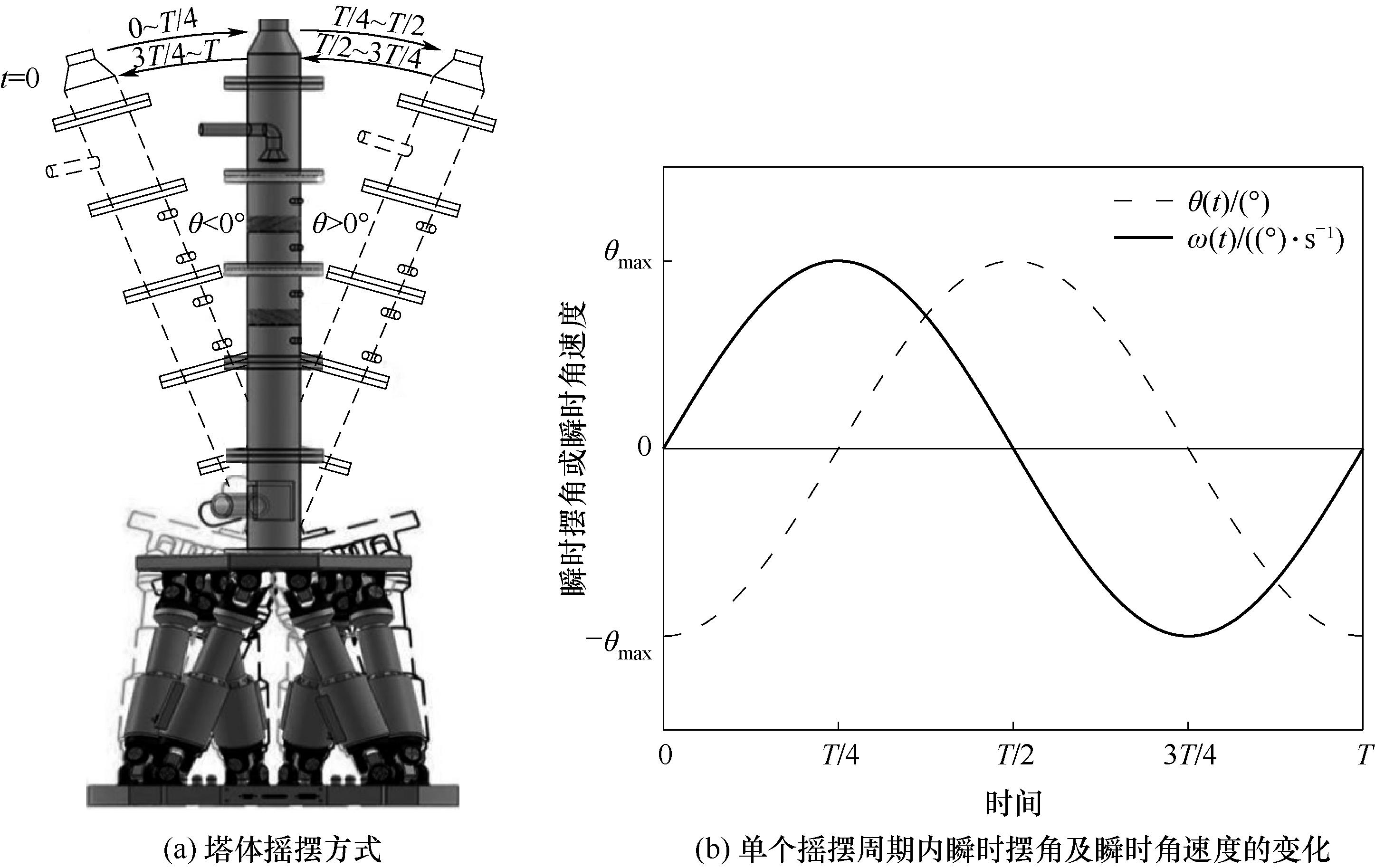

图3 摇摆塔瞬时摆角变化和瞬时角速度的变化

Fig.3 Rolling mode and the variation of both the instantaneous rolling angle and angular velocity during the rolling of the column

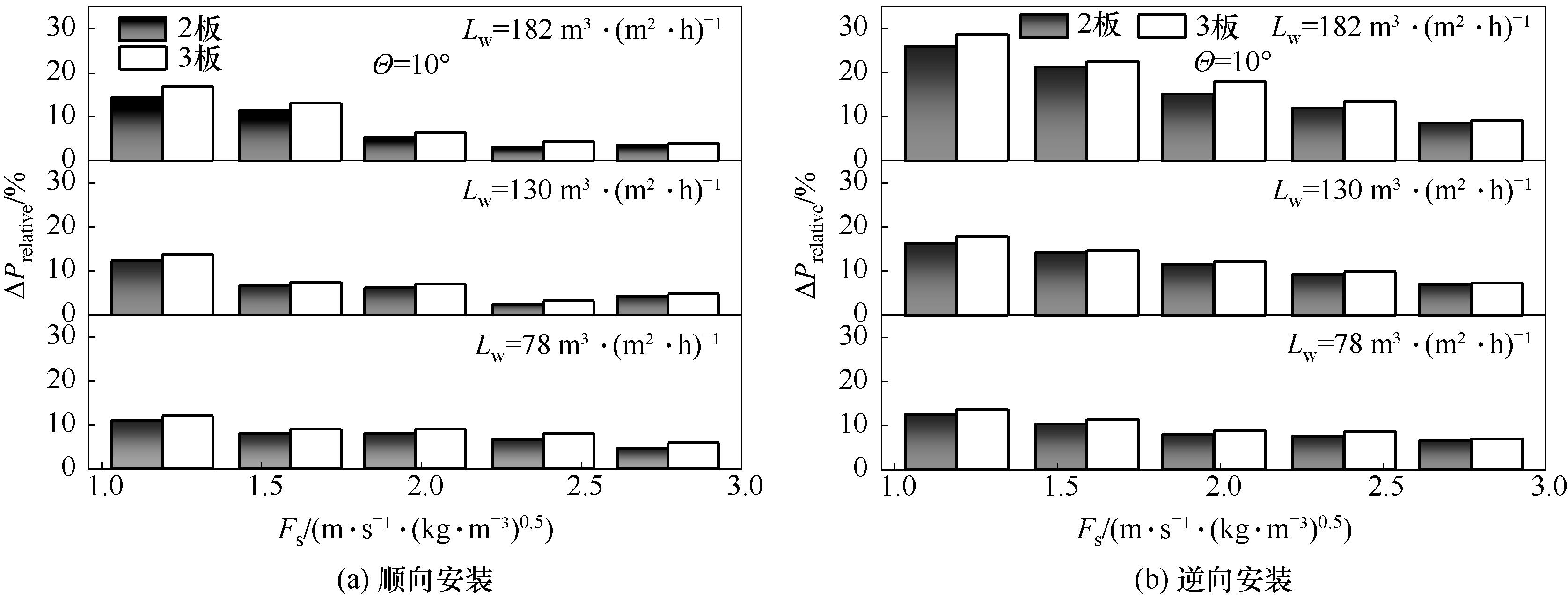

图7 倾斜时不同塔板安装位置及方式下湿板压降变化率

Fig.7 Wet plate pressure drop variation rate under different tray installation positions and modes under inclined conditions

| 1 | 苏健, 梁英波, 丁麟, 等. 碳中和目标下我国能源发展战略探讨[J]. 中国科学院院刊, 2021, 36(9): 1001-1009. |

| Su J, Liang Y B, Ding L, et al. Research on China's energy development strategy under carbon neutrality[J]. Bulletin of Chinese Academy of Sciences, 2021, 36(9): 1001-1009. | |

| 2 | 夏潇远. 全球天然气市场2021年回顾及2022年展望[J]. 国际石油经济, 2022, 30(3): 28-35, 104. |

| Xia X Y. Review of global gas market in 2021 and prospect for 2022[J]. International Petroleum Economics, 2022, 30(3): 28-35, 104. | |

| 3 | Dashliborun A M, Zhang J, Taghavi S M, et al. Marinization of multiphase reactors through the prism of chemical engineers[J]. Industrial & Engineering Chemistry Research, 2019, 58(8): 2607-2630. |

| 4 | Assima G P, Motamed-Dashliborun A, Larachi F. Emulation of gas-liquid flow in packed beds for offshore floating applications using a swell simulation hexapod[J]. AIChE Journal, 2015, 61(7): 2354-2367. |

| 5 | Kim H J, Choi D K, Ahn S I. GTL FPSO—an alternative solution to offshore stranded gas[J]. Journal of Petroleum Technology, 2014, 66(6): 41-51. |

| 6 | Zou X Q, Qiu R, Yuan M, et al. Sustainable offshore oil and gas fields development: techno-economic feasibility analysis of wind-hydrogen-natural gas nexus[J]. Energy Reports, 2021, 7: 4470-4482. |

| 7 | 谢彬, 喻西崇, 韩旭亮, 等. FLNG研究现状及在中国南海深远海气田开发中的应用前景[J]. 中国海上油气, 2017, 29(2): 127-134. |

| Xie B, Yu X C, Han X L, et al. Research status of FLNG and its application prospect for deep water gas field development in South China Sea[J]. China Offshore Oil and Gas, 2017, 29(2): 127-134. | |

| 8 | 谢彬, 赵晶瑞, 喻西崇. FLNG外输系统在中国南海的适用性分析及国产化研究思考[J]. 中国海上油气, 2020, 32(5): 152-158. |

| Xie B, Zhao J R, Yu X C. Applicability analysis and localization thoughts of FLNG transfer system in the South China Sea[J]. China Offshore Oil and Gas, 2020, 32(5): 152-158. | |

| 9 | Zhao W H, Yang J M, Hu Z Q, et al. Recent developments on the hydrodynamics of floating liquid natural gas (FLNG)[J]. Ocean Engineering, 2011, 38(14/15): 1555-1567. |

| 10 | 薄玉宝. 浮式液化天然气(FLNG)技术在中国海上开发应用探讨[J]. 中国海洋平台, 2013, 28(3): 1-5, 9. |

| Bo W B. Floating liquefied natural gas (FLNG) technology in China offshore development application to discussion[J]. China Offshore Platform, 2013, 28(3): 1-5, 9. | |

| 11 | Mahmud M A, Mazumder M, Xu Q, et al. Sloshing impact on gas pretreatment for LNG plants located in a stranded offshore location[J]. Industrial & Engineering Chemistry Research, 2018, 57(17): 5764-5775. |

| 12 | 洪宗平, 叶楚梅, 吴洪, 等. 天然气脱碳技术研究进展[J]. 化工学报, 2021, 72(12): 6030-6048. |

| Hong Z P, Ye C M, Wu H, et al. Research progress in CO2 removal technology of natural gas[J]. CIESC Journal, 2021, 72(12): 6030-6048. | |

| 13 | Dashliborun A M, Larachi F. Hydrodynamics of gas-liquid cocurrent upflow in oscillating packed beds for offshore marine applications[J]. Chemical Engineering Science, 2017, 170: 583-596. |

| 14 | Dashliborun A M, Larachi F. Hydrodynamics of gas-liquid cocurrent downflow in floating packed beds[J]. Chemical Engineering Science, 2015, 137: 665-676. |

| 15 | Son Y, Kim G, Lee S, et al. Experimental investigation of liquid distribution in a packed column with structured packing under permanent tilt and roll motions using electrical resistance tomography[J]. Chemical Engineering Science, 2017, 166: 168-180. |

| 16 | Huang Y, Di X N, Ma J, et al. Experimental investigation on pressure drop of a laboratory-scale random packing column under roll and heave motion[J]. The Canadian Journal of Chemical Engineering, 2018, 97: 1172-1180. |

| 17 | Di X N, Chen S J, Wang W H, et al. Experimental investigation of mass transfer performance in laboratory and pilot-scale structured-packing columns under roll motion[J]. Chemical Engineering Science, 2018, 177: 27-38. |

| 18 | 马鹏飞. 板式塔在FLNG装置上的适应性研究[D]. 青岛: 中国石油大学, 2017. |

| Ma P F. Studies on adaptation of plate column in FLNG unit[D]. Qingdao: China University of Petroleum, 2017. | |

| 19 | 程强. 适用于FLNG上的两种新型塔板性能评价研究[D]. 青岛: 中国石油大学, 2018. |

| Cheng Q. Study on performance evaluation of two new types of tray on FLNG[D]. Qingdao: China University of Petroleum, 2018. | |

| 20 | Xiang L Y, Wu L K, Gao L D, et al. Pilot scale applied research on CO2 removal of natural gas using a rotating packed bed with propylene carbonate[J]. Chemical Engineering Research and Design, 2019, 150: 33-39. |

| 21 | 张亮亮, 付纪文, 罗勇, 等. 面向海洋工程的超重力过程强化技术及应用[J]. 化工学报, 2020, 71(1): 1-15. |

| Zhang L L, Fu J W, Luo Y, et al. Higee process intensification technology and application for oceaneering[J]. CIESC Journal, 2020, 71(1): 1-15. | |

| 22 | Tran L T, Le T M, Nguyen T M, et al. Simultaneous removal efficiency of H2S and CO2 by high-gravity rotating packed bed: experiments and simulation[J]. Open Chemistry, 2021, 19(1): 288-298. |

| 23 | 唐猛, 王德武, 刘燕, 等. 立体旋流筛板并、逆流操作时压降的对比研究[J]. 化学工程, 2019, 47(8): 22-28. |

| Tang M, Wang D W, Liu Y, et al. Comparison of pressure drops of the tridimensional rotational flow sieve tray under gas-liquid concurrent flow and countercurrent flow conditions[J]. Chemical Engineering(China), 2019, 47(8): 22-28. | |

| 24 | Tang M, Zhang S F, Wang D W, et al. Experimental study and modeling development of pressure drop in concurrent gas-liquid columns with a tridimensional rotational flow sieve tray[J]. Chemical Engineering Science, 2018, 191: 383-397. |

| 25 | 王丽瑶, 唐猛, 张少峰, 等. 立体旋流筛板并流时的流型特征及其操作域[J]. 化学工程, 2017, 45(12): 21-25, 29. |

| Wang L Y, Tang M, Zhang S F, et al. Flow patterns characteristics and operating regions of a tridimensional rotational flow sieve tray in concurrent flow[J]. Chemical Engineering(China), 2017, 45(12): 21-25, 29. | |

| 26 | Wang H K, Tang M, Wang D W, et al. Flow characteristics of blade unit of a tridimensional rotational flow sieve tray under concurrent gas-liquid flow[J]. AIChE Journal, 2020, 126: 112-118. |

| 27 | Wang H K, Tang M, Dai S J, et al. Experimental study on CO2 mass transfer in blade unit of tridimensional rotational flow sieve tray[J]. 2022, 281: 119891. |

| 28 | Journée J M J, Massie W W. Offshore Hydromechanics[M]. Delft: Delft University of Technology, 2001. |

| 29 | 邸晓宁. FLNG运动条件下填料塔性能基础研究[D]. 大连: 大连理工大学, 2021. |

| Di X N. Basic study on the performance of packing columns under FLNG motion condition[D]. Dalian: University of Technology, 2021. | |

| 30 | 张金红. 摇摆状态下气水两相流流型及阻力特性研究[D]. 哈尔滨: 哈尔滨工程大学, 2009. |

| Zhang J H. Study on flow pattern and resistance characteristics of air-water two-phase flow in rolling motion[D]. Harbin: Harbin Engineering University, 2009. | |

| 31 | 幸奠川. 摇摆对矩形通道内流动阻力特性的影响研究[D]. 哈尔滨: 哈尔滨工程大学, 2013. |

| Xing D C. Investigations on effects of rolling motion on characteristics of flow resistance in rectangular duct[D]. Harbin: Harbin Engineering University, 2013. | |

| 32 | Hajiloo M, Chang B H, Mills A F. Interfacial shear in downward two-phase annular co-current flow[J]. International Journal of Multiphase Flow, 2001, 27(6): 1095-1108. |

| 33 | Berna C, Escrivá A, Muñoz-Cobo J L, et al. Review of droplet entrainment in annular flow: characterization of the entrained droplets[J]. Progress in Nuclear Energy, 2015, 79: 64-86. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [3] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [4] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [5] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [6] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [7] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [8] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [9] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [10] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [11] | 盛林, 昌宇, 邓建, 骆广生. 阶梯式T型微通道内有序气泡群的形成和流动特性研究[J]. 化工学报, 2023, 74(1): 416-427. |

| [12] | 苏巧玲, 王军锋, 张伟, 詹水清, 吴天一. 低电导率工质中气泡的极化运动实验研究[J]. 化工学报, 2022, 73(9): 3861-3869. |

| [13] | 张童, 杨扬, 叶丁丁, 陈蓉, 朱恂, 廖强. 催化剂分布对可渗透阳极微流体燃料电池性能特性影响的研究[J]. 化工学报, 2022, 73(9): 4156-4162. |

| [14] | 禹言芳, 刘桓辰, 孟辉波, 刘励图, 李毓, 吴剑华. Lightnin静态混合器内气泡分散流体动力学特性实验研究[J]. 化工学报, 2022, 73(8): 3565-3575. |

| [15] | 李亚飞, 邓建强, 何阳. 跨临界CO2快速膨胀过程中非平衡冷凝和闪蒸机理的数值研究[J]. 化工学报, 2022, 73(7): 2912-2923. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号