化工学报 ›› 2022, Vol. 73 ›› Issue (3): 1221-1231.DOI: 10.11949/0438-1157.20211215

周宇航1,2( ),陈建义1,2(

),陈建义1,2( ),王亚安1,2,张丁于1,2,马红莹1,2,叶松1,2

),王亚安1,2,张丁于1,2,马红莹1,2,叶松1,2

收稿日期:2021-08-23

修回日期:2022-01-01

出版日期:2022-03-15

发布日期:2022-03-14

通讯作者:

陈建义

作者简介:周宇航(1997—),女,博士研究生,基金资助:

Yuhang ZHOU1,2( ),Jianyi CHEN1,2(

),Jianyi CHEN1,2( ),Ya’an WANG1,2,Dingyu ZHANG1,2,Hongying MA1,2,Song YE1,2

),Ya’an WANG1,2,Dingyu ZHANG1,2,Hongying MA1,2,Song YE1,2

Received:2021-08-23

Revised:2022-01-01

Online:2022-03-15

Published:2022-03-14

Contact:

Jianyi CHEN

摘要:

管柱式气液分离器(gas-liquid cylindrical cyclone,GLCC)是一种耦合离心力与重力作用的分离设备,常用于深海油气分离。气相带液(liquid carry-over,LCO)是影响GLCC分离性能的关键问题,且LCO率与GLCC上部筒体内的液膜流型有密切关系。因此,通过调控液膜流型来控制LCO率是一种可行方法。提出了一种向上分支的双入口管柱式气液分离器,并在其分支管增设一个阀门以控制两入口间流量比,达到调控液膜流型的目的。利用高速摄像机,通过改变入口气、液流量和阀门开度,系统研究了液膜的分布特征;并利用数值模拟对GLCC液膜流型、内部流线及速度特性做了研究。支路流通面积比从100%改变至0时,流经倾斜管主路的流量增多,液膜占据的筒体壁面高度沿轴向逐渐降低,且液膜集中在倾斜管主路入口附近并形成对分离性能有利的旋环流流型;模拟结果显示,在前述过程中,旋流场涡核中心逐渐稳定,有利于抑制LCO的发生。调节入口阀门开度以调控液膜流型是改善GLCC分离性能的可行手段。

中图分类号:

周宇航, 陈建义, 王亚安, 张丁于, 马红莹, 叶松. 基于液膜流型的双入口管柱式气液分离器性能研究[J]. 化工学报, 2022, 73(3): 1221-1231.

Yuhang ZHOU, Jianyi CHEN, Ya’an WANG, Dingyu ZHANG, Hongying MA, Song YE. Research on performance of dual-inlet gas-liquid cylindrical cyclone based on liquid film flow pattern[J]. CIESC Journal, 2022, 73(3): 1221-1231.

| 流体 | 密度ρ/(kg·m-3) | 动力黏度μ/(Pa·s) | 液相体积流量Ql /(m3·h-1) | 气相体积流量Qg/(m3·h-1) |

|---|---|---|---|---|

| 自来水 | 998.6 | 1.0×10-3 | 0.6~3.0 间隔为0.3 | 80~220 间隔为20 |

| 空气 | 1.185 | 1.83×10-5 |

表1 流体物性及实验工况(25℃)

Table 1 Parameters of fluid properties and experimental conditions (25℃)

| 流体 | 密度ρ/(kg·m-3) | 动力黏度μ/(Pa·s) | 液相体积流量Ql /(m3·h-1) | 气相体积流量Qg/(m3·h-1) |

|---|---|---|---|---|

| 自来水 | 998.6 | 1.0×10-3 | 0.6~3.0 间隔为0.3 | 80~220 间隔为20 |

| 空气 | 1.185 | 1.83×10-5 |

| 阀体转动角度θ/ (°) | 流通面积Aθ /mm2 | 流通面积比S/% |

|---|---|---|

| 0 | 1847 | 100 |

| 22.5 | 1277 | 70 |

| 45.0 | 734 | 40 |

| 67.5 | 261 | 15 |

| 90.0 | 0 | 0 |

表2 阀体转动角度与流通面积的转换

Table 2 Conversion of valve body rotation angle and flow area

| 阀体转动角度θ/ (°) | 流通面积Aθ /mm2 | 流通面积比S/% |

|---|---|---|

| 0 | 1847 | 100 |

| 22.5 | 1277 | 70 |

| 45.0 | 734 | 40 |

| 67.5 | 261 | 15 |

| 90.0 | 0 | 0 |

| 网格数量/个 | 壁面Y+值 | 模拟压降值 | 压降误差(Pexp=2851 Pa) | |

|---|---|---|---|---|

| 705432 | 70~75 | 3523 | 23.57% | |

| 836543 | 60~65 | 3430 | 20.31% | |

| 943451 | 55~60 | 3147 | 10.38% | |

| 998965 | 40~45 | 2992 | 4.94% | |

| 1084654 | 10~15 | 2956 | 3.68% | |

表3 不同网格数目下壁面Y+值和气相压降值对比

Table 3 Wall Y+ of upper cylinder and errors of gas pressure drop under different grid sizes

| 网格数量/个 | 壁面Y+值 | 模拟压降值 | 压降误差(Pexp=2851 Pa) | |

|---|---|---|---|---|

| 705432 | 70~75 | 3523 | 23.57% | |

| 836543 | 60~65 | 3430 | 20.31% | |

| 943451 | 55~60 | 3147 | 10.38% | |

| 998965 | 40~45 | 2992 | 4.94% | |

| 1084654 | 10~15 | 2956 | 3.68% | |

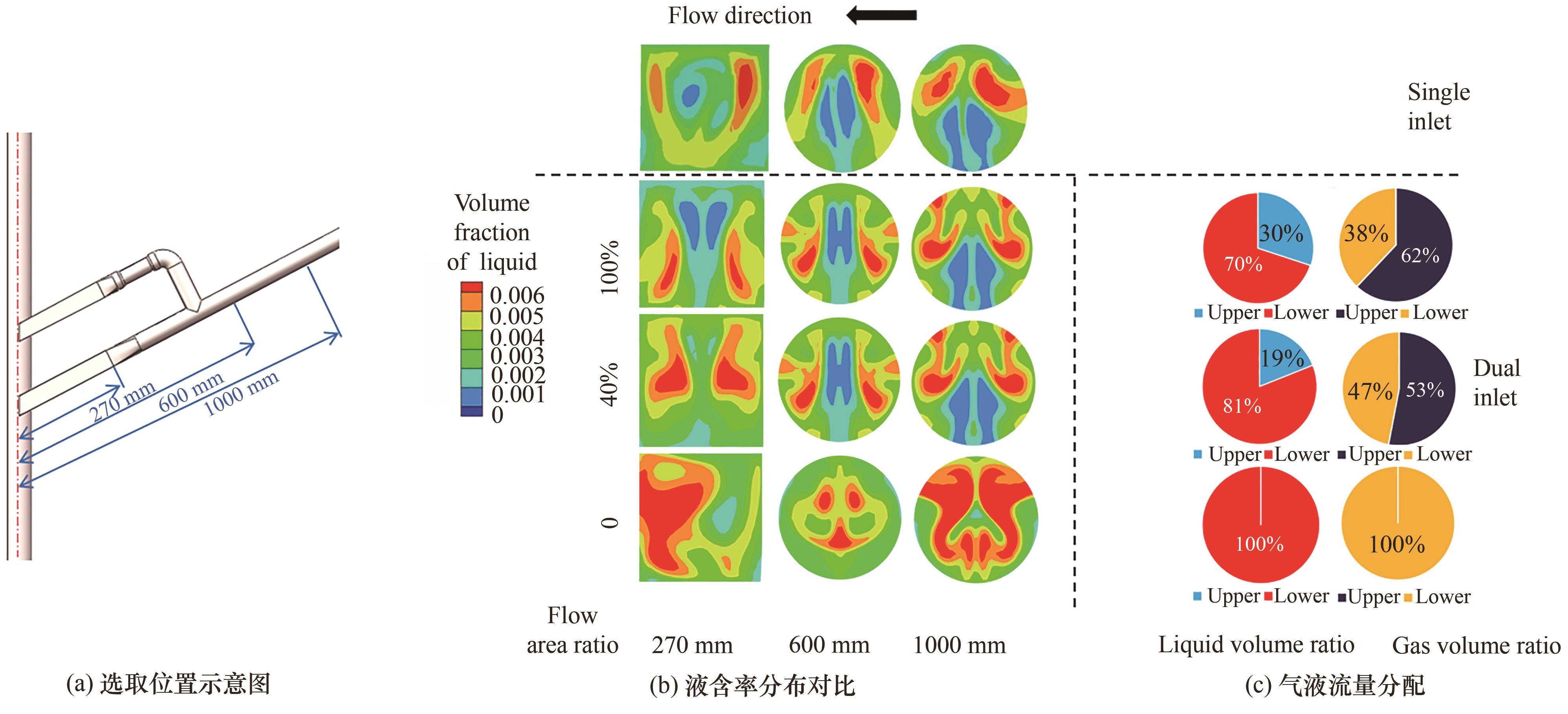

图8 液含率分布对比及气液流量分配关系(Ql 1.5 m3·h-1, Qg 180 m3·h-1)

Fig.8 Comparison of the liquid volume fraction and gas-liquid flowrate distribution(Ql 1.5 m3·h-1Qg 180 m3·h-1)

图9 GLCC上部筒体内切向速度对比(Ql 1.5 m3·h-1, Qg 180 m3·h-1)

Fig.9 Comparison of tangential velocity distribution in the upper cylinder of GLCC(Ql 1.5 m3·h-1, Qg 180 m3·h-1)

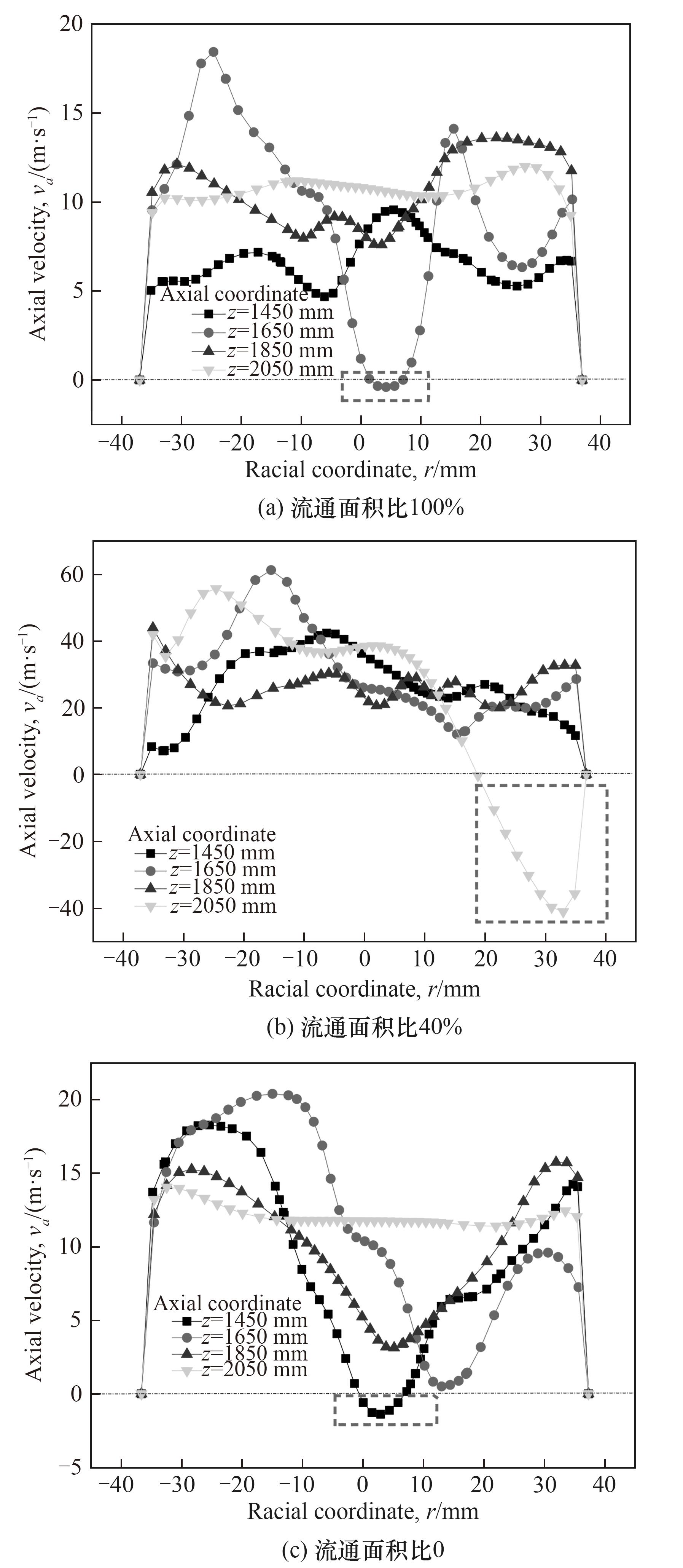

图10 GLCC上部筒体内轴向速度对比(Ql 1.5 m3·h-1, Qg 180 m3·h-1)

Fig.10 Comparison of axial velocity distribution in the upper cylinder of GLCC(Ql 1.5 m3·h-1, Qg 180 m3·h-1)

| 1 | 王懿, 陈建义, 段梦兰, 等. 水下生产系统及工程[M]. 北京: 中国石油大学出版社, 2017: 65-66. |

| Wang Y, Chen J Y, Duan M L, et al. Underwater Production System and Engineering[M]. Beijing: China University of Petroleum Press, 2017: 65-66. | |

| 2 | 陈家庆. 海洋油气开发中的水下生产系统(一)[J]. 石油机械, 2007, 35(5): 54-58. |

| Chen J Q. Underwater production system in offshore oil and gas development(1)[J]. China Petroleum Machinery, 2007, 35(5): 54-58. | |

| 3 | Arpandi I A. A mechanistic model for two-phase flow in gas-liquid cylindrical cyclone separators[D]. Tulsa: The University of Tulsa, 1995. |

| 4 | Gomez L, Mohan R, Shoham O. Swirling gas-liquid two-phase flow—experiment and modeling part (Ⅰ): Swirling flow field[J]. Journal of Fluids Engineering, 2004, 126(6): 935-942. |

| 5 | Gomez L, Mohan R, Shoham O. Swirling gas-liquid two-phase flow—experiment and modeling part (Ⅱ): Turbulent quantities and core stability[J]. Journal of Fluids Engineering, 2004, 126(6): 943-959. |

| 6 | Movafaghian S, Jaua-Marturet J A, Mohan R S, et al. The effects of geometry, fluid properties and pressure on the hydrodynamics of gas-liquid cylindrical cyclone separators[J]. International Journal of Multiphase Flow, 2000, 26(6): 999-1018. |

| 7 | Mele´ndez-Rami´rez A J, Reyes-Gutie´rrez M A, Rojas-Solo´rzano L R, et al. Experimental study of a gas-liquid cylindrical cyclone separator performance[C]//Proceedings of ASME 2004 International Mechanical Engineering Congress and Exposition, November 13-19, 2004, Anaheim, California, USA. 2008: 755-761. |

| 8 | Molina R, Wang S B, Gomez L E, et al. Wet gas separation in gas-liquid cylindrical cyclone separator[J]. Journal of Energy Resources Technology, 2008, 130(4): 130-134. |

| 9 | 蒋明虎, 李洪臻, 张红军, 等. 柱状气液分离器入口结构数值模拟及试验研究[J]. 石油机械, 2013, 41(2): 79-83. |

| Jiang M H, Li H Z, Zhang H J, et al. Numerical simulation and experimental study of the inlet structure of cylindrical gas liquid cyclone[J]. China Petroleum Machinery, 2013, 41(2): 79-83. | |

| 10 | Hreiz R, Lainé R, Wu J, et al. On the effect of the nozzle design on the performances of gas-liquid cylindrical cyclone separators[J]. International Journal of Multiphase Flow, 2014, 58: 15-26. |

| 11 | 路远. 深海GLCC分离器入口喷嘴结构改进实验研究[D]. 北京: 中国石油大学(北京), 2016: 47-76. |

| Lu Y. Experimental study on the improvement of inlet nozzle geometrys on gas-liquid cylindrical cyclone in subsea production system[D]. Beijing: China University of Petroleum (Beijing), 2016: 47-76. | |

| 12 | 许承炜. 管柱式气液分离器分离性能实验研究[D]. 北京: 中国石油大学(北京), 2017: 31-51. |

| Xu C W. Experimental study on separation performance of gas-liquid cylindrical cyclone (GLCC)[D]. Beijing: China University of Petroleum (Beijing), 2017: 31-51. | |

| 13 | 许承炜, 陈建义, 董腾, 等. 深海管柱式气液分离器液相分离效率测量与分析[J]. 中国海洋平台, 2018, 33(4): 59-65. |

| Xu C W, Chen J Y, Dong T, et al. Measurement and analysis of liquid phase separation efficiency of deep sea gas-liquid cylindrical cyclones[J]. China Offshore Platform, 2018, 33(4): 59-65. | |

| 14 | 贾中会. 管柱式气液旋流分离器气相分离性能实验研究[D]. 北京: 中国石油大学(北京), 2019: 42-69. |

| Jia Z H. Experimental study on gas phase separation performance of gas-liquid cylindrical cyclone[D]. Beijing: China University of Petroleum (Beijing), 2019: 42-69. | |

| 15 | 王亚安, 陈建义, 叶松, 等. 管柱式气液旋流分离器液膜厚度的空间分布特性[J]. 化工学报, 2020, 71(11): 5216-5225. |

| Wang Y A, Chen J Y, Ye S, et al. Spatial distribution characteristics of liquid film thickness in gas-liquid cylindrical cyclone[J]. CIESC Journal, 2020, 71(11): 5216-5225. | |

| 16 | Wang Y A, Chen J Y, Yue T, et al. Measurement of thickness and analysis on flow characteristics of upper swirling liquid film in gas-liquid cylindrical cyclone[J]. Experimental Thermal and Fluid Science, 2021, 123: 110331. |

| 17 | Wang J R, Zhang C M, Qiu C, et al. Field application of GLCC (Gas Liquid Cylindrical Cyclone) based multiphase metering system[C]//Advances in Multiphase Flows vol.2: Multiphase, Non-Newtonian and Reacting Flows. Veritas Tech (Ningbo) Co. Ltd., Ningbo, China, 2004. |

| 18 | 曹仁子. 柱状气液分离器数值模拟及结构优选[D]. 大庆: 大庆石油学院, 2009. |

| Cao R Z. Numerical simulation and structure optimal of columnar gas and liquid separator[D]. Daqing: Daqing Petroleum Institute, 2009. | |

| 19 | Reyes-Gutie´rrez M A, Rojas-Solo´rzano L R, Colmenares J, et al. Eulerian-eulerian modeling of disperse two-phase flow in a gas-liquid cylindrical cyclone[J]. Journal of Fluids Engineering, 2005, 128(4): 832-837. |

| 20 | 谢骏遥. 深水管柱式气液旋流分离器数值分析与优化设计[D]. 北京: 中国石油大学(北京), 2017. |

| Xie J Y. Numerical analysis and optimization design of gas-liquid cylindrical cyclone separator in deepwater[D]. Beijing: China University of Petroleum (Beijing), 2017. | |

| 21 | 许如敏. 深海管柱式气液分离器流动特性的数值模拟研究[D]. 北京: 中国石油大学(北京), 2018. |

| Xu R M. Numerical study on hydrodynamics properties of gas-liquid cylindrical cyclone in subsea production system[D]. Beijing: China University of Petroleum (Beijing), 2018. | |

| 22 | Yue T, Chen J Y, Song J F, et al. Experimental and numerical study of Upper Swirling Liquid Film (USLF) among Gas-Liquid Cylindrical Cyclones (GLCC)[J]. Chemical Engineering Journal, 2019, 358: 806-820. |

| 23 | 岳题. 管柱式气液分离器(GLCC)上部筒体气液流动行为及分离机理研究[D]. 北京: 中国石油大学(北京), 2019. |

| Yue T. Gas-liquid flow behavior and separation mechanism for the upper cylinder in gas-liquid cylindrical cyclone(GLCC)[D]. Beijing: China University of Petroleum (Beijing), 2019. | |

| 24 | 杨洋. 双入口GLCC气液两相流动数值模拟和结构改进研究[D].北京: 中国石油大学(北京), 2020. |

| Yang Y. Numerical simulation of gas-liquid two-phase flow and structure improvement in dual inlet GLCC[D]. Beijing: China University of Petroleum (Beijing), 2020. | |

| 25 | Erdal F M, Shirazi S A, Shoham O, et al. CFD simulation of single-phase and two-phase flow in gas-liquid cylindrical cyclone separators[J]. SPE Journal, 1997, 2(4): 436-446. |

| 26 | Erdal F M, Mantilla I, Shirazi S A, et al. Simulation of free interface shape and complex two-phase flow behavior in a gas-liquid cylindrical cyclone separator[JB/OL]. . |

| 27 | Wang Y A, Chen J Y, Yang Y, et al. Experimental and numerical performance study of a downward dual-inlet gas-liquid cylindrical cyclone (GLCC)[J]. Chemical Engineering Science, 2021, 238: 116595. |

| 28 | Han Q, Zhang C, Xu B, et al. The effect of geometry and operation conditions on the performance of a gas-liquid cylindrical cyclone separator with new structure[J]. AIP Conference Proceedings, 2013, 1547(1): 350-361. |

| 29 | 阎昌琪. 气液两相流[M]. 3版. 哈尔滨: 哈尔滨工程大学出版社, 2017. |

| Yan C Q. Gas and Liquid Two-phase Flow[M]. 3ed. Harbin: Harbin Engineering University Press, 2017. | |

| 30 | 张金红. 气液两相流流型实验研究[D]. 哈尔滨: 哈尔滨工程大学, 2005. |

| Zhang J H. The experimental study of flow patterns in gas-liquid two-phase flow[D]. Harbin: Harbin Engineering University, 2005. | |

| 31 | Elsayed K, Lacor C. The effect of cyclone inlet dimensions on the flow pattern and performance[J]. Applied Mathematical Modelling, 2011, 35(4): 1952-1968. |

| 32 | 彭杰伟, 马有福, 吴恒亮, 等. 水平管内多孔板后的气液两相流型可视化实验[J]. 化工学报, 2017, 68(6): 2266-2274, 2620. |

| Peng J W, Ma Y F, Wu H L, et al. Visualization study on flow pattern of gas-liquid two-phase flowing through multi-orifice plate in horizontal pipe[J]. CIESC Journal, 2017, 68(6): 2266-2274, 2620. | |

| 33 | 杨国强, 李志鹏. 基于Fluent的球阀内部流场的仿真模拟及研究[J]. 机械科学与技术, 2014, 33(12): 1880-1883. |

| Yang G Q, Li Z P. Simulation and research on internal flow fields of ball valve based on fluent software[J]. Mechanical Science and Technology for Aerospace Engineering, 2014, 33(12): 1880-1883. | |

| 34 | 石柯. 球阀开启过程的瞬态数值模拟与实验研究[D]. 杭州: 浙江理工大学, 2014. |

| Shi K. Transient simulation and experimental study on the opening process of ball valve[D]. Hangzhou: Zhejiang Sci-Tech University, 2014. |

| [1] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [2] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [3] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [4] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [5] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [6] | 康飞, 吕伟光, 巨锋, 孙峙. 废锂离子电池放电路径与评价研究[J]. 化工学报, 2023, 74(9): 3903-3911. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [9] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [10] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [11] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [12] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [13] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [14] | 郭雨莹, 敬加强, 黄婉妮, 张平, 孙杰, 朱宇, 冯君炫, 陆洪江. 稠油管道水润滑减阻及压降预测模型修正[J]. 化工学报, 2023, 74(7): 2898-2907. |

| [15] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号